Preparation for organic/inorganic composite corrosion-resisting protective film coating layer for concrete and application thereof

An inorganic composite and corrosion-resistant film technology, which is applied in the preparation of neutral organic/inorganic composite concrete corrosion-resistant film coatings, and in the field of anti-corrosion of reinforced concrete structures, can solve the problems of large gaps in depth, shortened service life, and complicated preparation processes problems, achieve the effects of low cost, enhanced hardness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

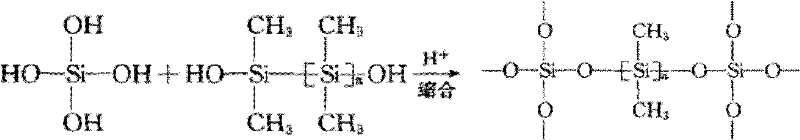

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of neutral composite sol: at room temperature, mix TEOS with deionized water and ethanol in a molar ratio of 1:3:3, stir evenly with a magnetic stirrer, add 1% wt of dibutyltin dilaurate, and magnetically Stir for 1.5 h, then add 15% wt of PDMS-OH and magnetically stir for 2 h to form a transparent and stable sol with a viscosity of 4-6 mpa·s.

[0031] 2. The coating is applied by brushing. The C35 concrete used is first placed in the standard room for 28 days of curing. Before brushing, remove dust, oil and other harmful substances and pollutants on the surface of the test piece that are not conducive to the coating film, and rinse. Afterwards, let it dry naturally, so that the surface of the concrete is surface-dry. Each surface of the concrete is brushed three times, and the coating amount is 300g / m2 2 , each time interval is at least 6h. Then send the concrete specimen to the curing room for standard curing for 7 days, the curing temperature is (20±...

Embodiment 2

[0033] 1. Preparation of neutral composite sol: at room temperature, mix TEOS with deionized water and ethanol in a molar ratio of 1:3:3, stir evenly with a magnetic stirrer, add 1% wt of dibutyltin dilaurate, and magnetically Stir for 1.5 h, then add 15% wt of PDMS-OH and magnetically stir for 2 h to form a transparent and stable sol with a viscosity of 4-6 mpa·s.

[0034]2. The coating is applied by brushing. The C35 concrete used is first placed in the standard room for 28 days of curing. Before brushing, remove dust, oil and other harmful substances and pollutants on the surface of the test piece that are not conducive to the coating film, and rinse. Afterwards, let it dry naturally, so that the surface of the concrete is surface-dry. Each surface of the concrete is brushed three times, and the coating amount is 450g / m2 2 , each time interval is at least 6h. Then send the concrete specimen to the curing room for standard curing for 7 days, the curing temperature is (20±3...

Embodiment 3

[0036] 1. Preparation of neutral composite sol: at room temperature, mix TEOS with deionized water and ethanol in a molar ratio of 1:3:3, stir evenly with a magnetic stirrer, add 1% wt of dibutyltin dilaurate, and magnetically Stir for 1.5 h, then add 15% wt of PDMS-OH and magnetically stir for 2 h to form a transparent and stable sol with a viscosity of 4-6 mpa·s.

[0037] 2. The coating is applied by brushing. The C35 concrete used is first placed in the standard room for 28 days of curing. Before brushing, remove dust, oil and other harmful substances and pollutants on the surface of the test piece that are not conducive to the coating film, and rinse. Afterwards, let it dry naturally, so that the surface of the concrete is surface-dry. Each surface of the concrete is brushed three times, and the coating amount is 600g / m2 2 , each time interval is at least 6h. Then send the concrete specimen to the curing room for standard curing for 7 days, the curing temperature is (20±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com