Biodegradable layered sheet

A biodegradable, laminated board technology, applied in the field of laminated boards, can solve the problems of low heat resistance and unsuitability of polylactic acid resin, and achieve the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

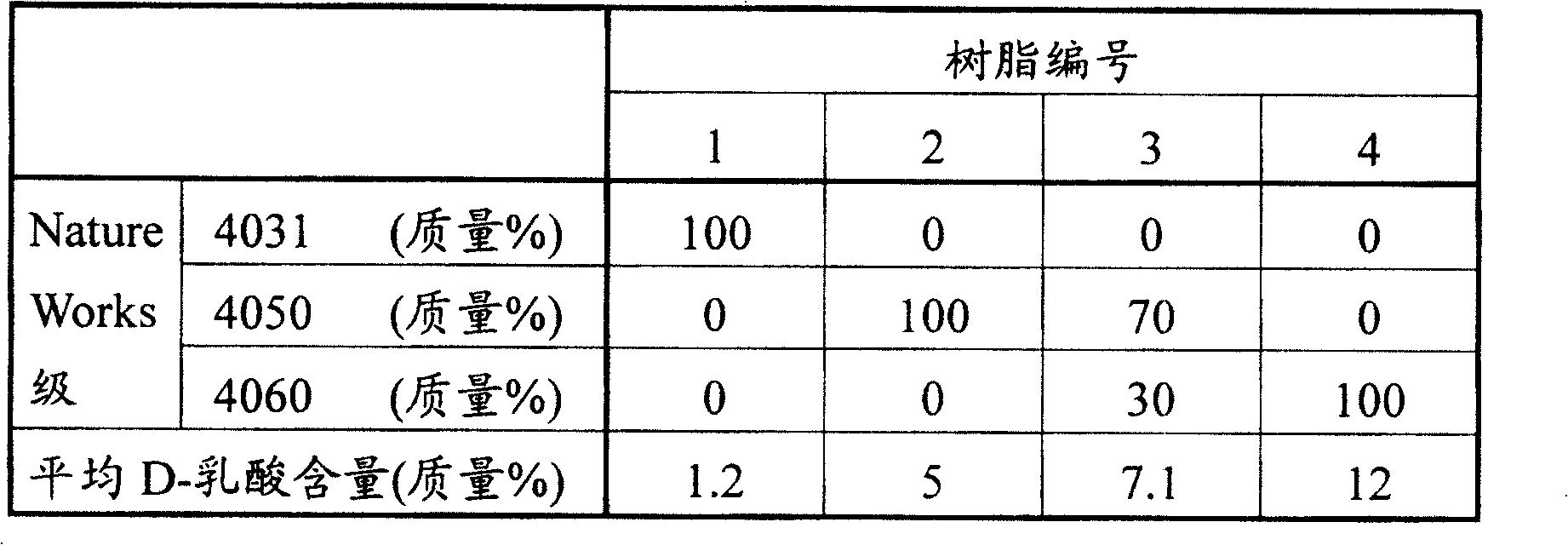

[0105] Resin 1 in Table 2 as polylactic acid was mixed with PBS (polybutylene succinate, manufactured by Showa Highpolymer Co., Ltd.: Bionolle 1001, melting point: 111° C.; glass transition temperature: -40° C.), mixed together at the ratio of polylactic acid resin / biodegradable aliphatic polyester=50 / 50 (% by mass). To 100% by mass of this mixture, 10% by mass of talc (manufactured by Nippon Talc Co., Ltd.: Micro Ace L1) was added as an inorganic filler, and the mixture was extruded at 220° C. Manifold extrusion head to extrude in the form of front and back layers.

[0106] In addition, Resin 4 in Table 2 as polylactic acid and PBS of the aforementioned model as biodegradable aliphatic polyester were mixed according to polylactic acid resin / biodegradable aliphatic polyester=50 / 50 (% by mass) proportions are mixed together. To 100% of this mixture by mass, add 10% by mass of the aforementioned type of talc as an inorganic filler, and extrude this mixture in the form of an in...

Embodiment 2

[0109] Resin 1 in Table 2 as polylactic acid and PBS of the aforementioned model as biodegradable aliphatic polyester were mixed at a ratio of polylactic acid resin / biodegradable aliphatic polyester=25 / 75 (% by mass) Mix together. To this mixture of 100% by mass, add 20% by mass of the aforementioned type of talc as an inorganic filler, and the mixture is extruded from the multi-manifold head of a parallel twin-screw extruder with a diameter of 25mm at 220°C, the previous layer and extrude in the form of the back layer.

[0110] In addition, Resin 4 in Table 2 as polylactic acid and PBS of the aforementioned model as biodegradable aliphatic polyester were calculated as polylactic acid resin / biodegradable aliphatic polyester=25 / 75 (mass%) proportions are mixed together. To 100% of this mixture by mass, add 20% by mass of the aforementioned type of talc as an inorganic filler, and extrude this mixture in the form of an intermediate layer from the multi-manifold extrusion head ...

Embodiment 3

[0113] Resin 1 in Table 2 as polylactic acid and PBS of the aforementioned model as biodegradable aliphatic polyester were used in a ratio of polylactic acid resin / biodegradable aliphatic polyester=75 / 25 (% by mass) Mix together. To this mixture of 100% by mass, add 10% by mass of the aforementioned type of talc as an inorganic filler, and the mixture is extruded from the multi-manifold head of a parallel twin-screw extruder with a diameter of 25mm at 220°C, the previous layer and extrude in the form of the back layer.

[0114] In addition, Resin 4 in Table 2 as polylactic acid and PBS of the aforementioned model as biodegradable aliphatic polyester were calculated on the basis of polylactic acid resin / biodegradable aliphatic polyester=75 / 25 (mass%) proportions are mixed together. To 100% of this mixture by mass, add 10% by mass of the aforementioned type of talc as an inorganic filler, and extrude this mixture in the form of an intermediate layer from the multi-manifold ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com