Polyethylene yarn, method for manufacturing same, and cool-feeling fabric comprising same

A polyethylene yarn, skin cooling technology, applied in the field of polyethylene yarn, can solve the problems of reduced fabric cutability and sewability, high cost of organic solvents, environmental problems and recycling, etc., and achieves excellent cutability and sewability. performance, increased productivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

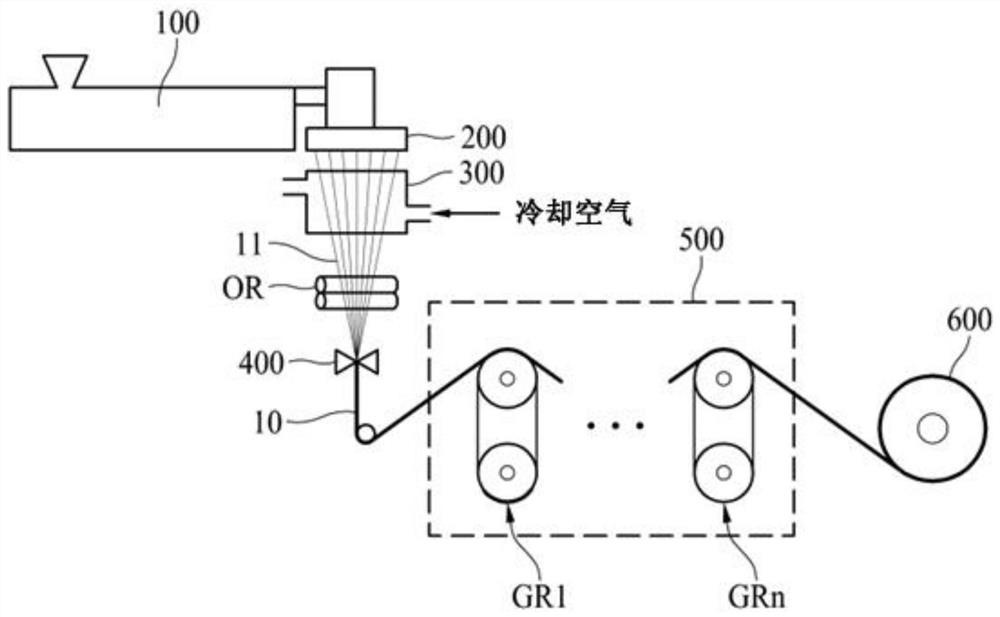

[0113] use figure 1 The apparatus shown produces polyethylene yarn comprising 200 filaments and having a total fineness of 400 denier. In detail, will have 0.961g / cm 3 A polyethylene sheet with a density of 87660 g / mol weight average molecular weight (Mw), a polydispersity index (PDI) of 6.4, and a melt index (MI at 190° C.) of 11.9 g / 10 min was injected into the extruder 100 and to melt. The molten polyethylene was extruded through a spinneret 200 having 200 holes. The ratio L / D of the hole length (L) to the hole diameter (D) of the spinneret 200 was 6. The temperature of the spinneret was 265°C.

[0114] The filaments 11 formed while being ejected from the spinneret 200 are finally cooled to 30° C. in the quenching zone 300 by cooling air having a wind speed of 0.45 m / s, and converged into multifilaments 10 by the bunching section 400, and Move to the multi-stage stretching section 500 .

[0115] The multi-stage drawing section 500 is composed of a total of five stages...

Embodiment 2

[0118] In addition to using a 0.958g / cm 3 density, weight average molecular weight (Mw) of 98290g / mol, polydispersity index (PDI) of 8.4, and melt index (MI at 190°C) of polyethylene sheets of 6.1g / 10min, and the temperature of the spinneret Except that the temperature was 275° C., polyethylene yarns were obtained in the same manner as in Example 1.

Embodiment 3

[0120] In addition to using a 0.948g / cm 3 density, weight average molecular weight (Mw) of 78620g / mol, polydispersity index (PDI) of 8.2, and melt index (MI at 190°C) of polyethylene sheets of 15.5g / 10min, and the temperature of the spinneret Polyethylene yarns were obtained in the same manner as in Example 1, except that the temperature was 255°C and the total draw ratio was 6.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tenacity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com