Process for improved yields of high molecular weight olefins form lower molecular weight olefines

A technology of molecular weight and olefins, which is applied in the production of liquid hydrocarbon mixtures, organic chemical methods, and metathesis reactions to produce hydrocarbons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

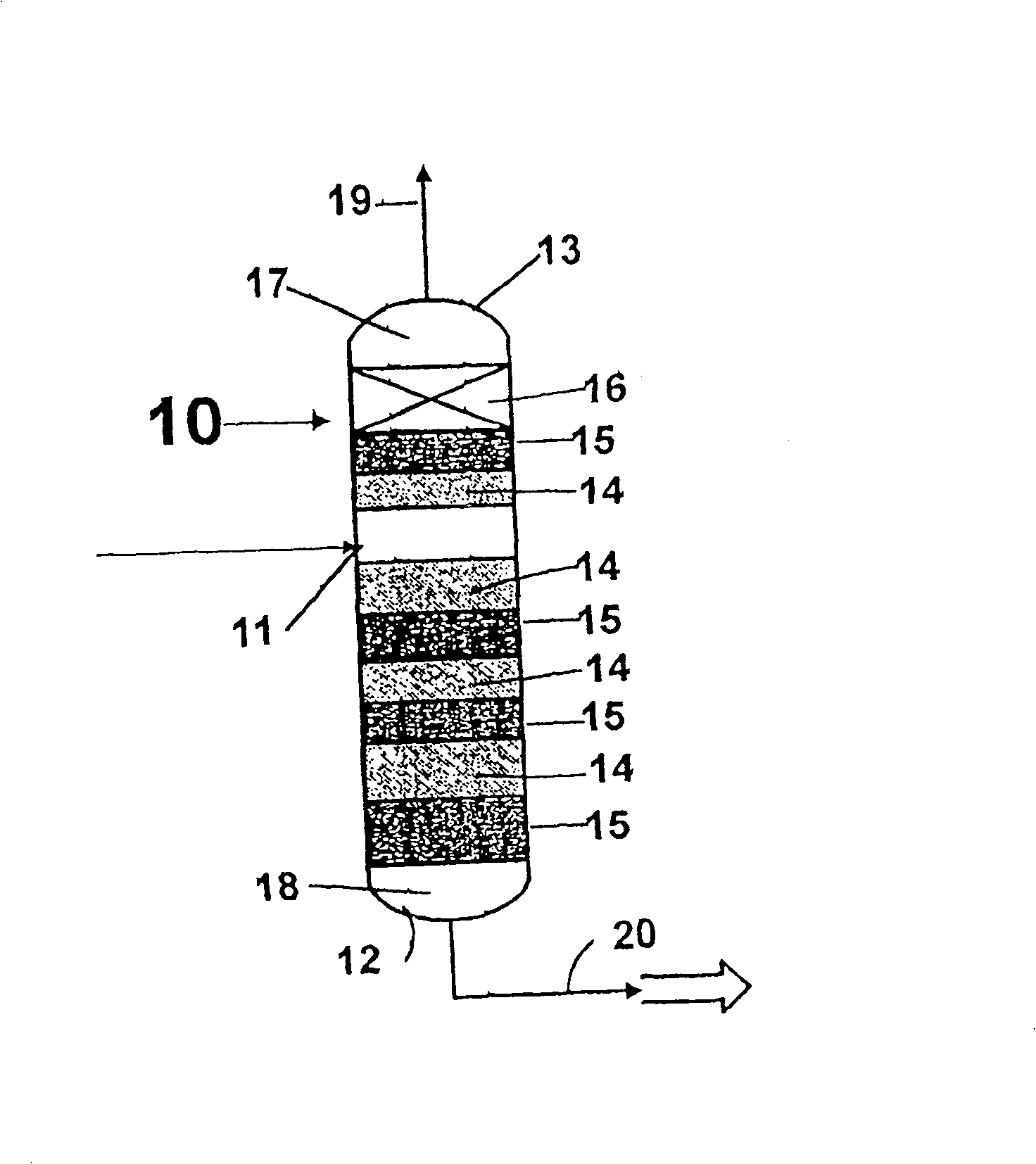

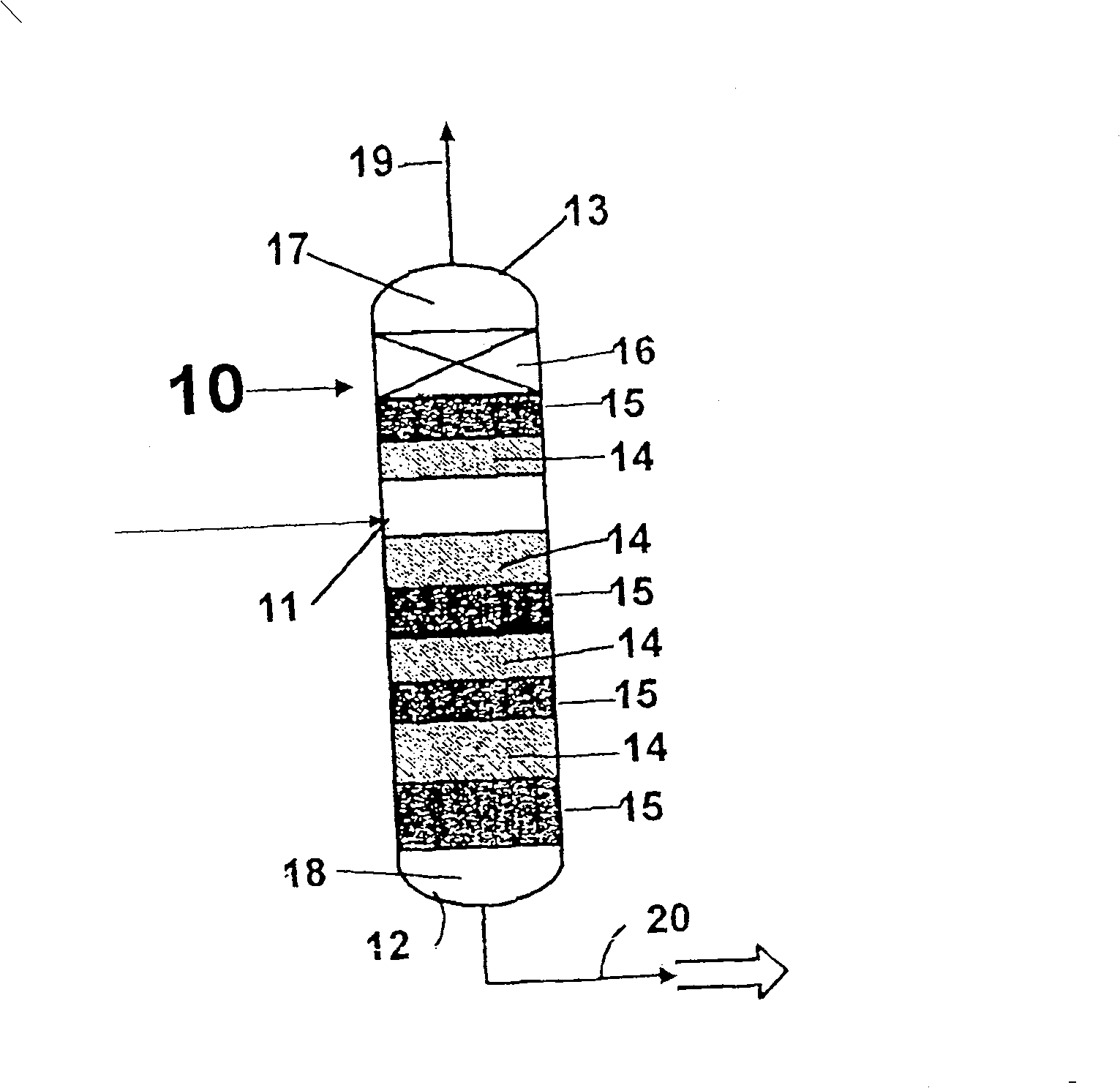

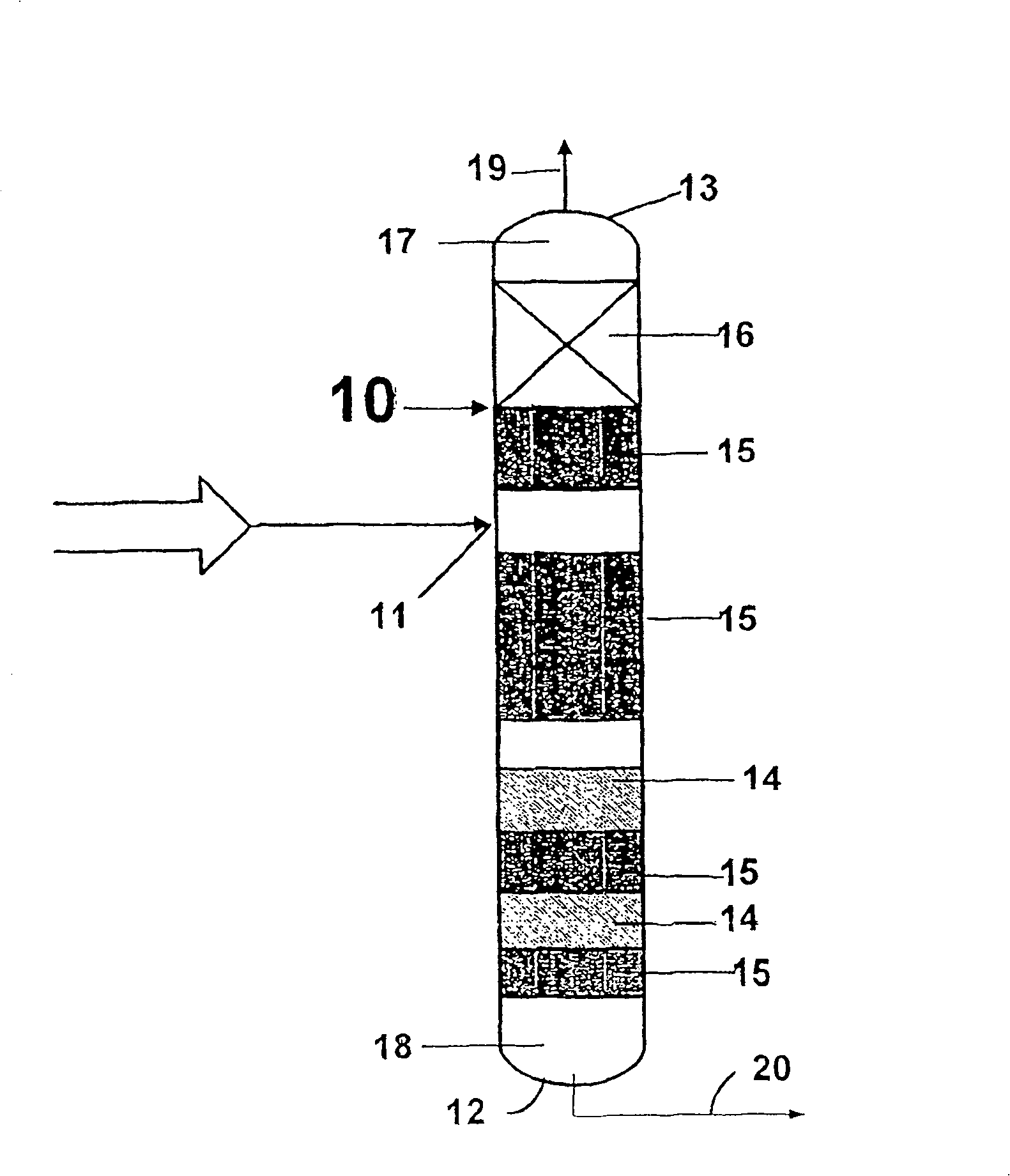

[0026] The present invention relates to a process for increasing the production of heavier olefins by using a hydrocarbon feedstock containing a substantially narrow range of lighter olefins, which feedstock is fed to a reactive distillation column at parameter 10. in such as figure 1 In at least one embodiment shown, the process of the present invention initially converts C to a predetermined point 11 in the reactive distillation column 10 6A hydrocarbon feedstock containing a substantially narrow range of lighter olefins and higher carbon numbers is fed to reactive distillation column 10 . Adjacent to the intended feed point 11 is an isomerization catalyst 14 which isomerizes the olefin-containing hydrocarbon feedstock as it enters the reactive distillation column 10 . like figure 1 As shown, the isomerization catalyst 14 should be located both adjacent to, directly above or below the predetermined feed point 11 to first isomerize the olefin-containing hydrocarbon feedstoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com