Fractionation of phytosterol esters in oil

A technology of phytosterol esters and phytostanol esters, applied in the field of fractionation of phytosterol esters in oil, can solve the problems of not teaching or implying product enrichment steps, not providing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

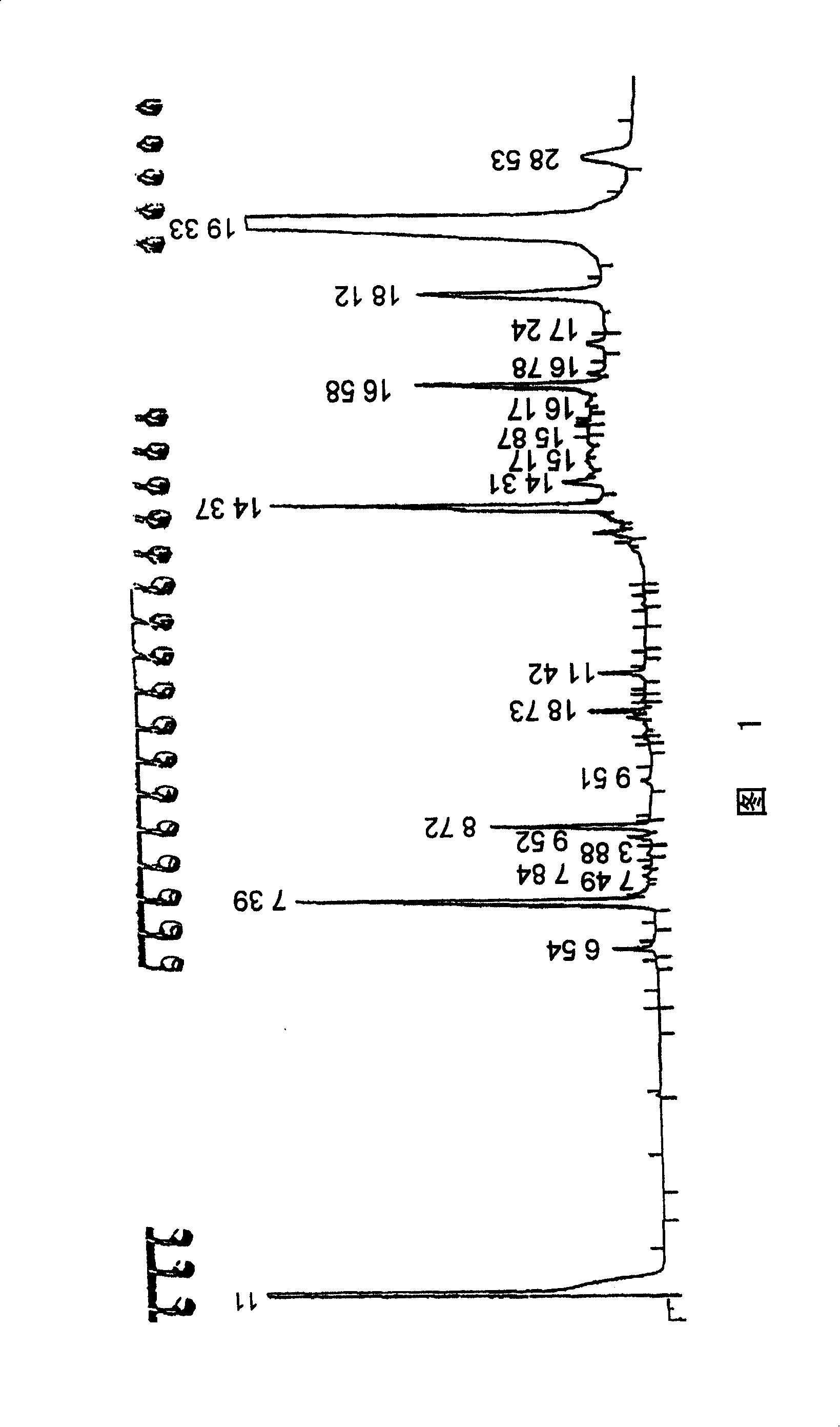

Image

Examples

Embodiment 1

[0138] Example 1 : Lipase-catalyzed alcoholysis of stigmasterol in canola oil

[0139] 1.1 Enzymatic reaction

[0140] The lipase-catalyzed conversion of stigmasterol to stigmasteryl esters in canola oil was carried out under the following reaction conditions:

[0141] 9 g of the lipase preparation obtained according to WO 01 / 75083 were added to 50 ml of canola oil enriched with 4 gr stigmasterol. Then, the reaction mixture was heated to 60°C for 14 hours. Thereafter, samples were removed, diluted with n-hexane (30 μl reaction mixture / 600 μl n-hexane), and then injected into the gas chromatography system as described above. The concentration of unreacted stigmasterol was determined by GC and the conversion rate was calculated to give a value of 94%.

[0142] 1.2 Separation of reaction products

[0143] At the end of the reaction, the enzyme was filtered off, and the mixture was cooled to 25°C and then left to stand for 12 hours.

[0144] The resulting mixture (refer...

Embodiment 2

[0149] Example 2 : Lipase-catalyzed alcoholysis of phytosterols from soybean in olive oil

[0150] 2.1 Enzymatic reaction

[0151] In a 1 liter glass stirred reactor, 100 g of a lipase preparation obtained according to WO 01 / 75083 and 120 g of soybean-derived phytosterols (containing 0.3-4% brassicasterol, 20-30% campesterol, 11-20% stigmasterol,> 40% β sitosterol) add 450g of the best light pressed high-quality olive oil. The reaction mixture was then heated to 50°C and stirred for 24 hours. The conversion of the reaction was 93%. The catalyst was isolated by filtration at 50°C. The filtered catalyst was added to a fresh mixture of 450g of the finest light pressed premium olive oil and 120g of unreacted phytosterols. The second batch also reached 93% conversion after 24 hours. Filtration of the catalyst was repeated and 566 g of product (Mixture A) were allowed to stand at room temperature for 20 hours.

[0152] Mixture A was centrifuged at 7500xg at 25°C for 15 min...

Embodiment 3

[0159] Example 3 : Further enrichment of phytosterol esters and diglycerides by molecular distillation.

[0160] A reaction mixture obtained from canola oil source, which contains: 13wt% phytosterol esters, 20wt% diglycerides by weight, 0.1-1wt% free phytosterols and 5wt% free fatty acids, the The reaction mixture was added to a molecular still (made of glass, 2 inches in diameter, laboratory equipment). The primary distillation is carried out under the conditions of 180-200° C. and 0.01-0.001 mbar, so as to remove free phytosterols and free fatty acids. The residue from the primary distillation was added again under different conditions to obtain various distillation compositions as shown in Tables 7 and 8. PSE refers to phytosterol esters.

[0161] Table 7

[0162]Distillate quality and phytosterol ester yield in the distillate (0.001-0.005mbar and at different temperatures)

[0163] temperature(℃)

Distillate quality / feedstock quality

PSE mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com