Bronze coloring process of pack alloy

A cast aluminum alloy, bronze-colored technology, applied in electrolytic coatings, surface reaction electrolytic coatings, anodic oxidation, etc., can solve the problems of containing many alloy elements, difficult to color treatment, difficult to form a film layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment includes pretreatment, anodic oxidation, coloring process and subsequent sealing process. The pretreatment process includes a passivation process.

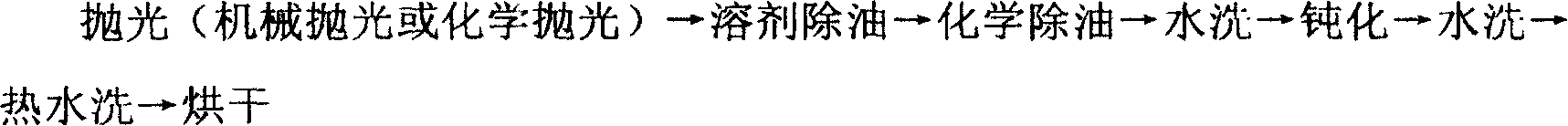

[0016] The passivation process refers to the mechanically polished or chemically polished die-casting aluminum alloys that are degreased and cleaned directly in concentrated HNO at room temperature. 3 Soak in the middle for 5-10 minutes to get the natural color and form a dense passivation film on the surface to improve its corrosion resistance. For the general process, see figure 1 .

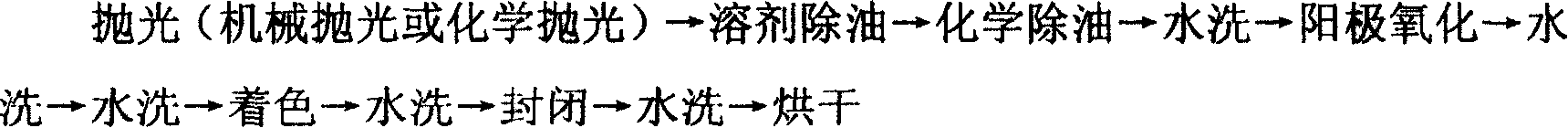

[0017] After the passivated die-casting aluminum alloy is degreased and cleaned, it is anodized, colored and sealed to obtain the required bright color with good corrosion resistance. For the general process, see figure 2 .

[0018] Anodizing solution formula: H 2 SO 4 180-220g / L, the rest is water.

[0019] Anodizing process conditions: temperature: 5-20°C, voltage: 8-18V, current density: 0.8-1.5A / dm 2 , Time: de...

Embodiment 2

[0028] This example is basically the same as Example 1, except that the formula of the coloring solution is: Alizarin yellow R: 0.6g / L, acid blue: 5g / L, glacial acetic acid: 0.4g / L, and the balance is water.

Embodiment 3

[0029] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that the coloring solution formula is: Alizarin yellow R 0.9g / L, acid Yuanqing 10g / L, glacial acetic acid 0.8g / L, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com