Process for low-temperature catalytically burning chlorinated aliphatics

A chlorinated aliphatic hydrocarbon, low-temperature catalysis technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of easy loss of catalyst active components, low catalytic combustion activity, and short catalyst life, etc. The route is convenient and practical, the preparation process is simple, and the catalyst life is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

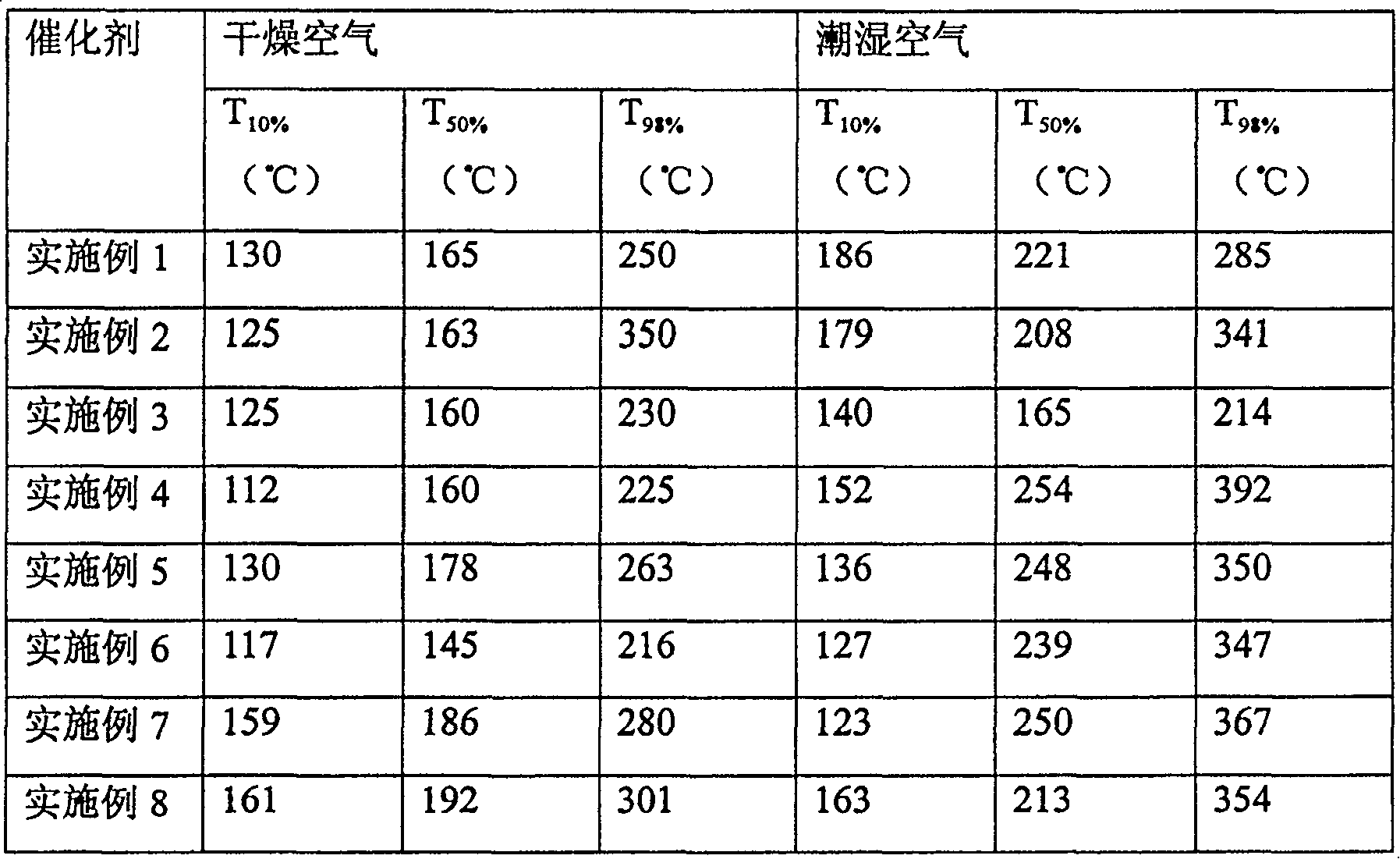

Embodiment 1

[0033] Put 100g of commercially available cerium nitrate in a heating furnace, program temperature rise in air atmosphere, 1 ℃ per minute, rise to 180 ℃, keep warm for 2 hours; then program temperature rise, 10 ℃ per minute, raise the temperature to 550 ℃, After 4 hours of heat preservation, CeO can be prepared 2 catalyst.

Embodiment 2

[0035] Put 100g of commercially available lanthanum nitrate in a heating furnace, program temperature rise in air atmosphere, 1 °C per minute, rise to 180 °C, keep warm for 2 hours; then program temperature increase, 10 °C per minute, raise the temperature to 550 °C, After 4 hours of heat preservation, La 2 o 3 catalyst.

Embodiment 3

[0037] Commercially available 50g cerium nitrate (Ce(NO 3 ) 3 )·6H 2 O and 6g copper nitrate Cu(NO 3 ) 2 )·3H 2O was dissolved in 500ml of ionized water, and the solution was placed in a constant temperature water bath at 50°C and stirred for 0.5h; then 200ml of 0.5N oxalic acid aqueous solution was added dropwise at a flow rate of 1ml per minute, stirring continuously during the process, and after the oxalate precipitated completely, Continue to stir at 50°C for 2-4h, stand still, filter with suction, wash twice with 500ml of hot deionized water, add 500ml of absolute ethanol to wash once, filter with suction, then dry in an oven at 100°C for 24h, and move to In the roasting furnace, the temperature is programmed in the air atmosphere, 1 ° C per minute, raised to 180 ° C, and kept for 2 hours; the temperature is programmed again, 10 ° C per minute, the temperature is raised to 550 ° C, and when kept for 4 hours, 10CuO-90CeO can be obtained 2 (by weight CuO:CeO 2 1:9) ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com