Flow guiding electrode for temperature difference generator and its preparing method

A technology for thermoelectric generators and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, materials for lead-out wires of thermoelectric devices, etc., and can solve the problems of low conversion efficiency of thermoelectric generators, fast attenuation of thermoelectric generators, and low welding strength, etc. , to achieve the effect of improving compactness, increasing area and improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

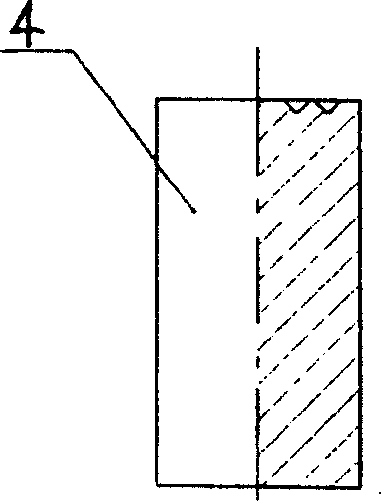

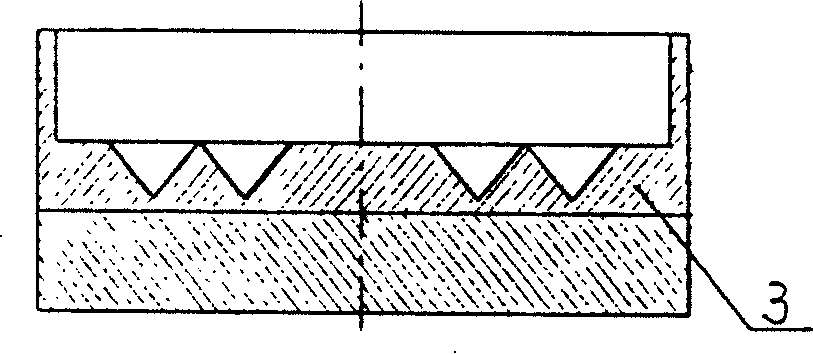

[0026] Embodiment 1: with reference to attached Figure 1-3 , in the pressing process, firstly clean the indenter 1, the female mold 2, the inner core 4 and the mold frame 5. The diameter of the inner core 4 is consistent with the diameter of the thermoelectric material used, and its shape is a cylinder, and there are several specially processed circular grooves on one end surface, forming an angle of 90 degrees at the bottom of the circular groove. 5 tight fit. After the inner core 4 is put into the mold frame 5, its top will be higher than the mold frame 5. It depends on the height of the hat brim required by the flow-guiding electrode. The general height of the hat brim is 1mm, and the brim is image 3 The shown shape is a semi-hollow cylinder with thin walls around and a hat brim shape with grooves at the bottom, and is put into the female mold 2 together. After the female mold 2 is put into the horizontal position, firstly mix the uniform transition that is weighed acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com