Biological active material for realizing percutaneous device biological sealing and method for making same

A technology of bioactive and biomedical materials, which is applied in the field of bioactive materials and its preparation for the realization of transdermal device biosealing, which can solve the problems of skin biosealing, inability to combine organically, and implant failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

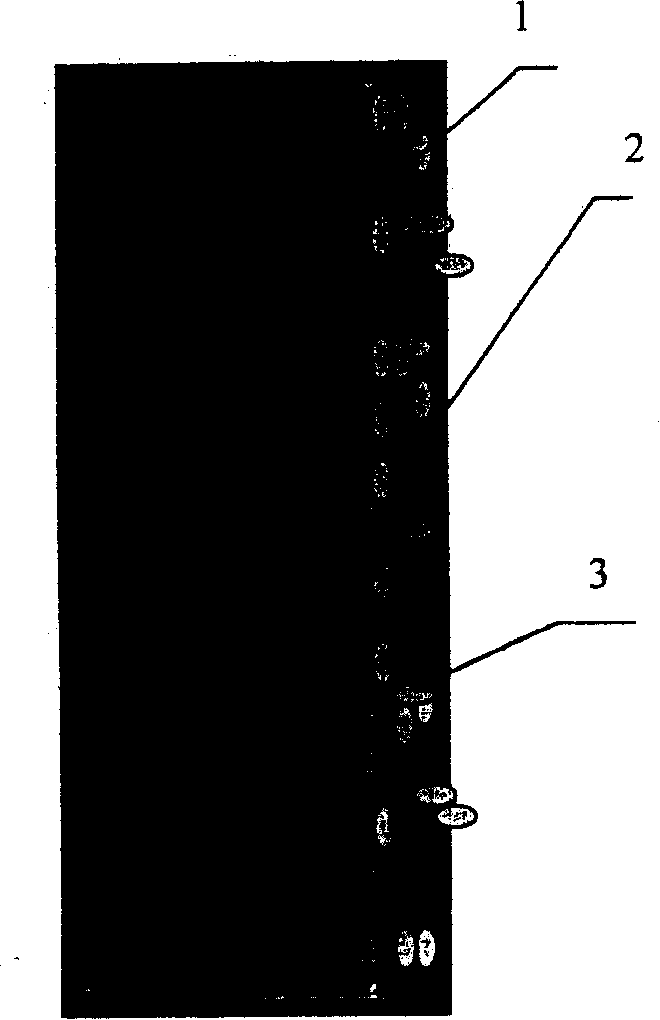

[0037] Electrochemical surface modification biomedical material titanium metal of the present invention:

[0038] Using biomedical titanium metal material 1 as anode and cathode, in 1 mol / liter of H 2 SO 4 In the solution, after being treated for 60 seconds under the conditions of 155V DC voltage and ambient temperature of 28°C, and then washed with clean water such as deionized water, normal saline, or distilled water, an oxide containing hydroxyl group 3 was generated on the surface of titanium metal material 1. Titanium 2, a titanium metal material covered with titanium oxide or directly used as a percutaneous implant; Soaked at 37.4°C for 240 hours, a calcium-phosphorus coating is formed on the surface of the material. The calcium-phosphorus coating has good biocompatibility with the skin, so the surface-modified titanium material is used as a percutaneous implant for physical fitness and skin Forms a bioseal.

Embodiment 2

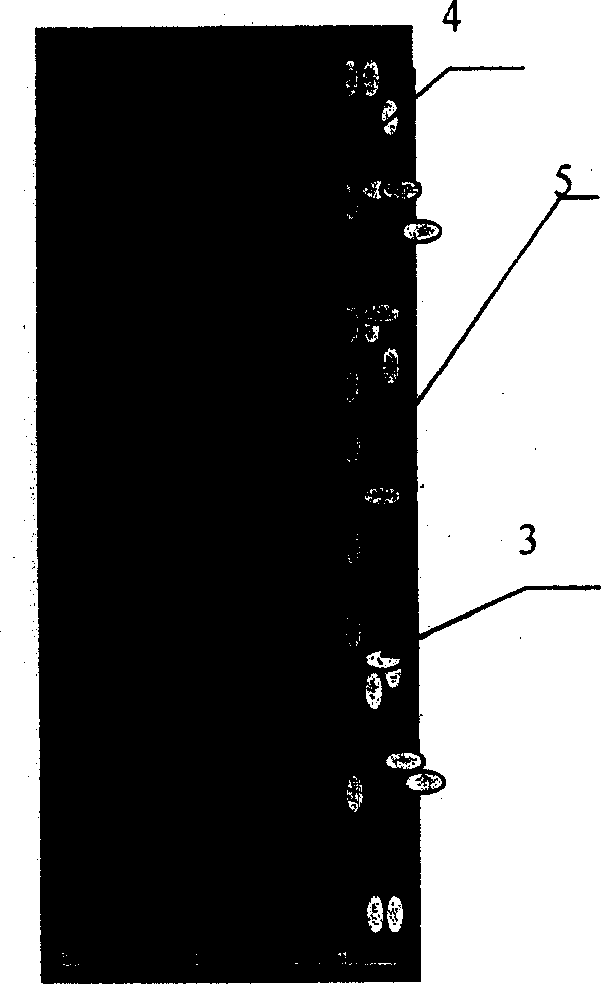

[0040] The coating surface modified biomedical material alumina ceramics of the present invention:

[0041] Biomedical alumina ceramics 10 are used as the base material, the surface roughness is Ra5 microns, calcium-phosphorus powder 11 is used as the raw material, nitrogen is used as the calcium-phosphorus plasma generation gas, and ionization is generated by heating under the condition of 400A strong current to generate plasma The surface of the calcium-phosphorus powder is melted under the action of the plasma, and the gas is sprayed onto the surface of the alumina ceramic substrate material at high speed to form a calcium-phosphorus coating. The alumina ceramic material covered with the calcium-phosphorus coating or directly Used as a percutaneous implant, the percutaneous implant absorbs calcium and phosphorus in the physiological environment at the implantation site, and produces a new calcium-phosphorus coating on the surface of the material, so that the material and the...

Embodiment 3

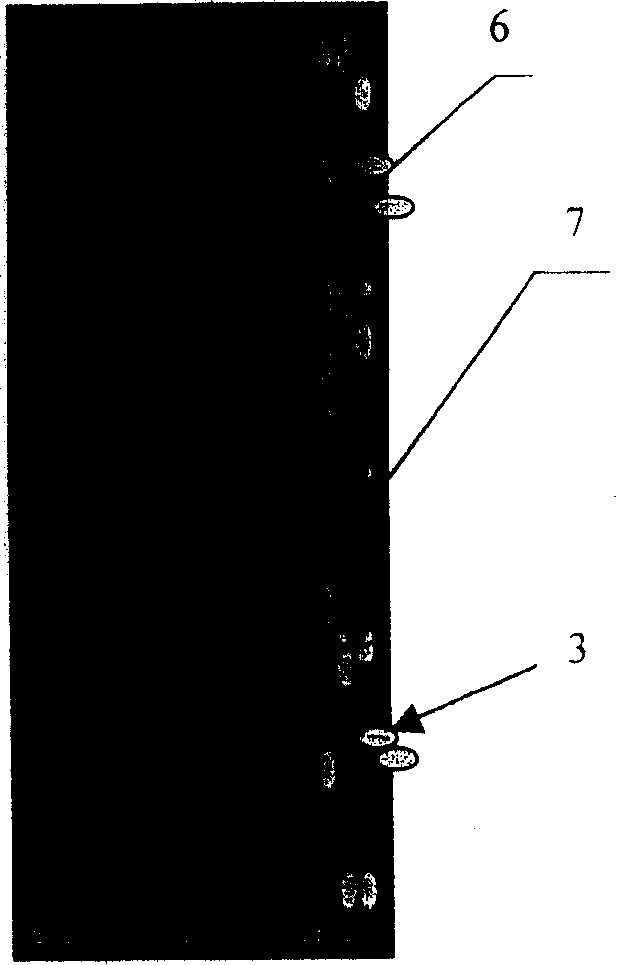

[0043] The chemical surface modification biomedical material titanium alloy of the present invention:

[0044] Biomedical titanium alloy 12 is used as the base material, soaked in 10 mol / L NaOH solution at a temperature of 60°C for 24 hours, and then heat-treated at 600°C for 24 hours, thereby producing titanium gel on the surface of the titanium alloy 13 , titanium alloy covered with titanium gel or directly used as a percutaneous implant, the percutaneous implant absorbs calcium and phosphorus in the physiological environment at the implantation site, and produces a calcium-phosphorus coating on the surface of the titanium alloy material, so that the material Form a bio-seal with the skin; or soak in a solution containing calcium and phosphorus in vitro, such as simulated body fluid, accelerated calcification solution, calcium and phosphorus solution containing protein, at 37.4°C for 240 hours, and generate calcium and phosphorus on the surface of the titanium alloy material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com