Antibacterial glass reinforced plastic door and window materials and production method thereof

A technology of door and window profiles and glass fiber reinforced plastics, applied in windows/doors, building components, buildings, etc., can solve the problems of affecting the antibacterial effect of antibacterial agents, large corrosion of crucibles, and deposition of metal silver beads, etc., to achieve low production costs and long antibacterial life , good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] 1.1 Preparation of hydroxyapatite antibacterial agent

[0022] In the present invention using Ca(OH) 2 and H 3 PO 4 As raw material, hydroxyapatite was synthesized by chemical co-precipitation, 0.5g of hydroxyapatite prepared by the above method was dissolved in 5ml of 0.1M silver nitrate solution, and then the hydroxyapatite with adsorbed silver ions was heated at 1150°C Calcined at lower temperature for 1 hour to obtain the silver-containing hydroxyapatite antibacterial agent.

[0023] 1.2 Preparation of antibacterial unsaturated polyester resin

[0024] Fully mix 100 parts of unsaturated polyester resin with 0.1 part of hydroxyapatite antibacterial agent to obtain antibacterial unsaturated polyester resin.

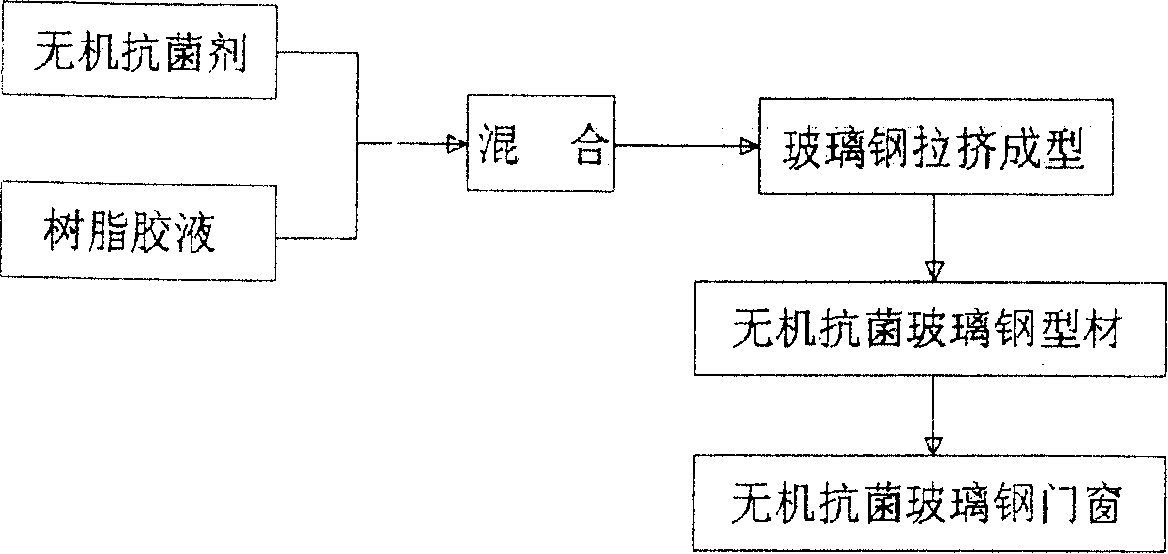

[0025] 1.3 Preparation of antibacterial FRP profiles

[0026] The antibacterial resin, glass fiber products and auxiliary materials are subjected to a pultrusion process to prepare antibacterial glass fiber reinforced plastic door and window profiles.

example 2

[0028] 2.1 Preparation of hydroxyapatite antibacterial agent

[0029] In the present invention using Ca(OH) 2 and H 3 PO 4 As raw material, hydroxyapatite is synthesized by chemical co-precipitation, 0.5 g of hydroxyapatite prepared by the above method is dissolved in 5 ml of 0.1M silver nitrate solution and 0.2M zinc nitrate mixed solution, and the adsorbed silver and zinc ions The final hydroxyapatite was calcined at 1150° C. for 1 hour to obtain a hydroxyapatite antibacterial agent containing silver and zinc.

[0030] 2.2 Preparation of antibacterial unsaturated polyester resin

[0031] Fully mix 100 parts of unsaturated polyester resin with 0.8 part of the above-mentioned hydroxyapatite antibacterial agent to obtain antibacterial unsaturated polyester resin.

[0032] 2.3 Preparation of antibacterial FRP profiles

[0033] The above-mentioned antibacterial resin, glass fiber products and auxiliary materials are subjected to a pultrusion process to prepare antibacterial ...

example 3

[0035] 3.1 Preparation of hydroxyapatite antibacterial agent

[0036] In the present invention using Ca(OH) 2 and H 3 PO 4 As raw material, hydroxyapatite is synthesized by chemical co-precipitation, 0.5g of hydroxyapatite prepared by the above method is dissolved in 5ml of 0.5M zinc nitrate solution, and the hydroxyapatite after adsorbing zinc ions is heated at 1150°C Calcined for 1 hour to obtain zinc-containing hydroxyapatite antibacterial agent.

[0037] 3.2 Preparation of antibacterial unsaturated polyester resin

[0038] Fully mix 100 parts of unsaturated polyester resin with 1.0 part of the above-mentioned hydroxyapatite antibacterial agent to obtain antibacterial unsaturated polyester resin.

[0039] 3.3 Preparation of antibacterial FRP profiles

[0040] The above-mentioned antibacterial resin, glass fiber products and auxiliary materials are subjected to a pultrusion process to prepare antibacterial glass fiber reinforced plastic door and window profiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com