Liquid magnetic grinding and it preparation method

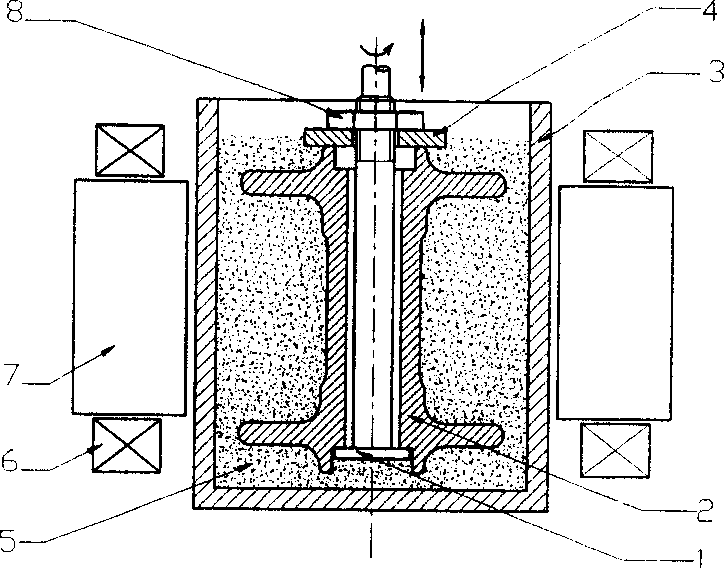

A technology of liquid magnetism and magnetic abrasive tools, which is applied in the manufacture of tools, metal processing equipment, metal processing, etc., can solve complex polishing and deburring problems, and achieve good material adaptability, low precision requirements, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] Adopt the liquid magnetic grinding tool of the present invention, to the diameter 30mm magnetic material 45 steel specimens and non-magnetic material duralumin (YL12) specimens were tested respectively, 45# steel and hard aluminum alloy YL12 two Nine pieces of each material were divided into two groups and tested in an orthogonal manner. The liquid magnetic grinding tool that experiment adopts is by water 195 grams (weight ratio 31.4%), carbonyl iron 270 grams (weight ratio 43.4%), sodium dodecylsulfonate 6.2 grams (weight ratio 1%) and 54 purpose silicon carbide abrasives 150 grams (24.2% by weight) for preparation; sodium dodecyl sulfonate was added to water, and mechanically stirred for 10 minutes to disperse it evenly in the base liquid; carbonyl iron particles were added to the base liquid and the surface In the mixed solution of the active agent, and use a stirrer to fully mix, the mixing time is 4 hours; add the silicon carbide abrasive to the mixed solution of t...

Embodiment approach 2

[0044] Adopt the liquid magnetic grinding tool of the present invention, to the diameter 30mm magnetic material 45 steel specimens and non-magnetic material duralumin (YL12) specimens were tested respectively, 45# steel and hard aluminum alloy YL12 two Nine pieces of each material were divided into two groups and tested in an orthogonal manner. The liquid magnetic abrasive tool that experiment adopts is made of water 200 grams (weight ratio 29.96%), carbonyl iron 280 grams (weight ratio 41.95%), sodium dodecylsulfonate 7.5 grams (weight ratio 1.12%) and 80 mesh silicon carbide abrasives 180 grams (weight ratio 26.97%) preparation. Add sodium dodecylsulfonate into water, and use mechanical stirring method to stir for 30 minutes to disperse it evenly in the base liquid; add carbonyl iron particles to the mixed solution of base liquid and surfactant, and use stirring The mixing time is 6 hours; the silicon carbide abrasive is added to the mixture of base liquid, surfactant and p...

Embodiment approach 3

[0049] Adopt the liquid magnetic grinding tool of the present invention, to the diameter 30mm magnetic material 45 steel specimens and non-magnetic material duralumin (YL12) specimens were tested respectively, 45# steel and hard aluminum alloy YL12 two Nine pieces of each material were divided into two groups and tested in an orthogonal manner. The liquid magnetic grinding tool that experiment adopts is made of water 200 grams (weight ratio 29.96%), carbonyl iron 280 grams (weight ratio 41.95%), sodium dodecylsulfonate 7.5 grams (weight ratio 1.12%) and 80 mesh Al 2 o 3 Abrasive 180 grams (weight ratio 26.97%) is prepared. Add sodium dodecylsulfonate into water, and use mechanical stirring method to stir for 20 minutes to disperse it evenly in the base liquid; add carbonyl iron particles to the mixed solution of base liquid and surfactant, and use colloid Grinding is fully mixed, and the mixing time is 5 hours; the non-magnetic abrasive AL 2 o 3 Add the mixed liquid of bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com