Method for purifying flue gas by application of active coke

A technology for activated coke and flue gas, applied in the field of flue gas purification, can solve the problems of slow reaction speed, low denitration efficiency, and large moving bed device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, flue gas purification desulfurization, denitrification, demercury

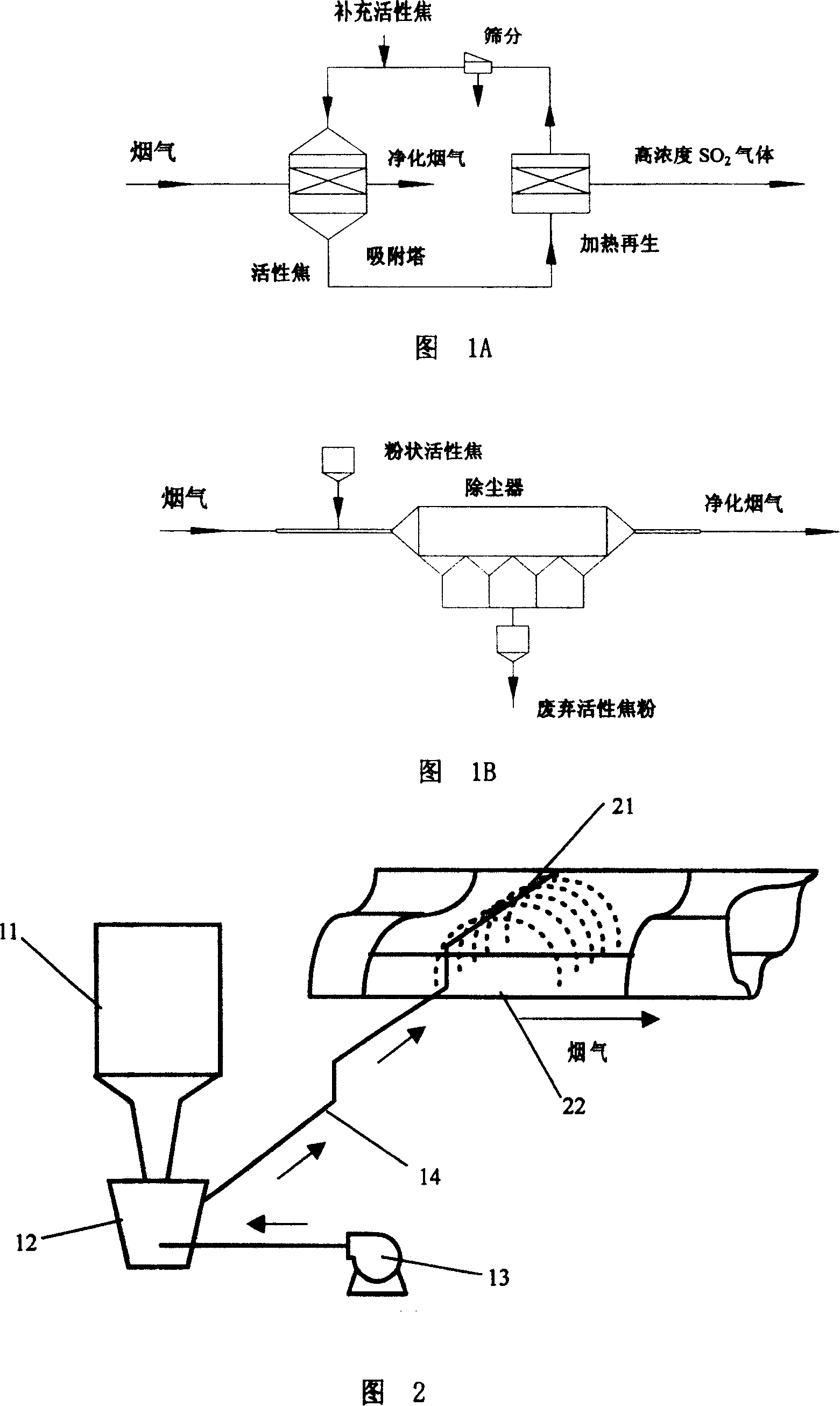

[0016] 1. The flue gas is purified by active coke moving bed reactor

[0017] Sulfur and nitrate in flue gas were removed by using two-stage moving bed reactor produced by Nanjing Electric Power Automation Equipment General Factory. SO in flue gas 2 The concentration is 5000mg / m 3 , NO X The concentration is 500mg / m 3 , Hg content is 20ug / m 3 , the temperature is 120°C, and the space velocity of the moving bed reactor is 1000h -1 . deSO x / off NO X The first section of the reactor is added with 150 kg of active coke; the added NH 3 The concentration of reducing agent mixed with CO is 500 mg / m 3 (NH 3 / CO molar ratio is 20), the temperature is 10-100°C, and the intake flow rate is 500m 3 / h. The activated coke after the second desulfurization reaction is recovered and sent to the regeneration tower, heated at 200-600u℃ for 3-30h for regeneration, and the CO gas generated durin...

Embodiment 2

[0023] Embodiment 2, flue gas purification desulfurization, denitrification, demercury

[0024] 1. The flue gas is purified by pipe spraying active coke

[0025] flue gas SO 2 The content is 3000mg / m 3 , NO X The concentration is 300mg / m 3 , Hg content is 10ug / m 3 , the temperature of the flue gas is 120°C, and the flue gas is passed into the pipeline jet cleaner as in Example 1, with 380mg active coke powder / m 3 The injection volume of flue gas injects active coke into the duct. Among them, the initial active coke powder used can be new active coke, and the subsequent process can use broken active coke generated in the moving bed.

[0026] 2. The flue gas is purified by active coke moving bed reactor

[0027] Gained flue gas of last step is passed in the moving bed reactor as embodiment 1, and wherein, moving bed space velocity is 800h -1 , adding the NH 3 The concentration of the reducing agent mixed with CO is 300PPm (NH 3 / CO mol ratio is 5), all the other proces...

Embodiment 3

[0029] Embodiment 3, flue gas purification desulfurization, denitrification, demercury

[0030] flue gas SO 2 The content is 7500 mg / m 3 , NO X The concentration is 600 mg / m 3 , Hg content is 25ug / m 3 , the flue gas temperature is 180°C, and the flue gas purification is carried out continuously according to step 1 and step 2 of Example 1, wherein the space velocity of the moving bed is 900h -1 , adding H 2 The concentration of reducing agent mixed with CO is 600mg / m 3 (H 2 / CO molar ratio is 0.5), the injection volume of active coke pipeline is 50mg / m 3 . The whole process SO 2 The removal rate is 90%, NO X The removal rate is 75%, and the Hg removal rate is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com