Crude oil deemulsifying agent and its preparing method

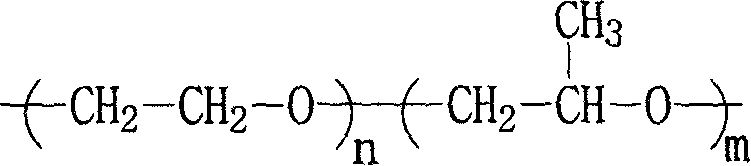

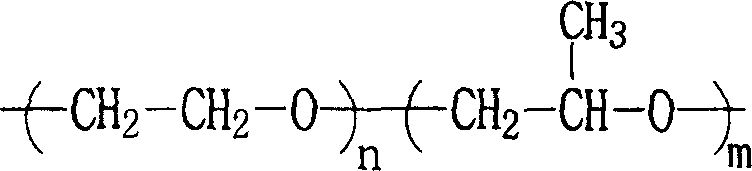

A technology of demulsifier and chain extender, applied in the field of crude oil demulsifier and its preparation, can solve problems such as unpublished research on crude oil demulsifier, and achieve the effects of low cost, high molecular weight and reasonable branching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

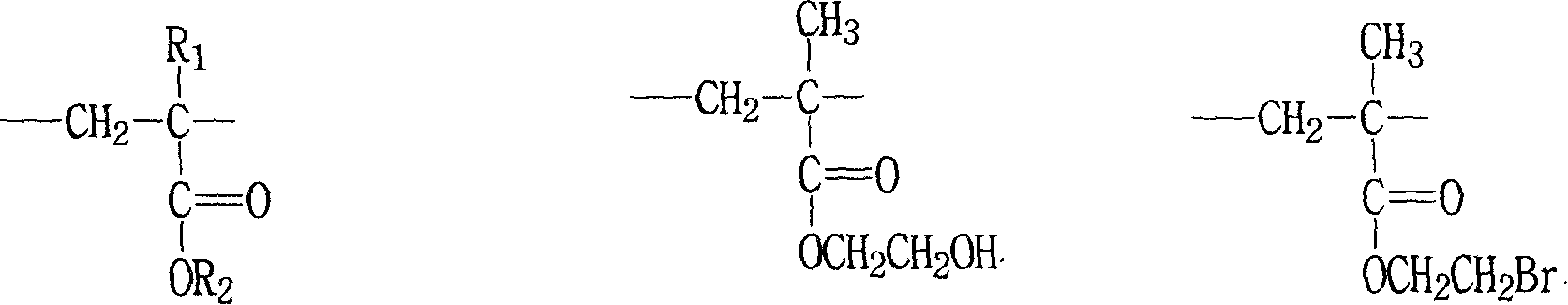

[0027] Example 1. Preparation of a chain extender with a weight average molecular weight of 710.

[0028] Using xylene as a solvent, methyl methacrylate and hydroxyethyl methacrylate were put into a three-necked flask at a molar ratio of 1:0.08, mechanically stirred, and 1 / 2 of the total mass of methyl methacrylate and hydroxyethyl methacrylate was added. 0.5% of the initiator dibenzoyl peroxide and 2% of the chain transfer agent mercaptoethanol of the total mass of methyl methacrylate and hydroxyethyl methacrylate, reacted at 100 ° C for 2 hours to obtain methyl acrylate and formazan A copolymer of hydroxyethyl methacrylate; add phosphorus tribromide which is one-third of the mole number of hydroxyethyl methacrylate to the copolymer, stir mechanically, react at 105°C for 4 hours, and distill under reduced pressure at 90°C for 2 hours , That is, a random copolymer chain extender. Wherein: the molar ratio of the structural units of methyl methacrylate, hydroxyethyl methacrylat...

Embodiment 2

[0029] Example 2. Preparation of a chain extender with a weight average molecular weight of 2580.

[0030] Using xylene as a solvent, butyl acrylate and hydroxyethyl methacrylate were put into a three-necked flask at a molar ratio of 1:0.04, mechanically stirred, and an initiator of 0.07% of the total mass of butyl acrylate and hydroxyethyl methacrylate was added. Dibenzoyl peroxide, 9% chain transfer agent isopropanol based on the total mass of butyl acrylate and hydroxyethyl methacrylate, and react at 80°C for 6 hours to obtain butyl acrylate and hydroxyethyl methacrylate A copolymer; add phosphorus tribromide which is one-third of the mole number of hydroxyethyl methacrylate to the copolymer, stir mechanically, react at 95°C for 5 hours, and distill under reduced pressure at 90°C for 2 hours to obtain random Copolymer chain extender. Wherein: the molar ratio of the structural units of butyl acrylate, hydroxyethyl methacrylate and bromoethyl methacrylate is 0.82:0.014:0.02,...

Embodiment 3

[0031] Example 3. Preparation of a chain extender with a weight average molecular weight of 1090.

[0032]Using toluene as a solvent, methyl methacrylate and hydroxyethyl methacrylate were put into a three-necked flask at a molar ratio of 1:0.12, mechanically stirred, and 0.42% of the total mass of methyl methacrylate and hydroxyethyl methacrylate was added. % initiator dibenzoyl peroxide and methyl methacrylate and 4% chain transfer agent mercaptoethanol of the total mass of hydroxyethyl methacrylate, reacted for 3 hours at 95°C to obtain methyl methacrylate and A copolymer of hydroxyethyl methacrylate; add phosphorus tribromide which is one-third of the molar number of hydroxyethyl methacrylate to the copolymer, stir mechanically, react at 90°C for 8 hours, and distill under reduced pressure at 90°C for 2 hours, the random copolymer chain extender is obtained. Wherein: the molar ratio of structural units of methyl methacrylate, hydroxyethyl methacrylate and bromoethyl metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com