Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Over wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic scraper

ActiveCN104646665AOver wear resistanceHigh hardnessAdditive manufacturing apparatusHigh wear resistanceFerromagnetism

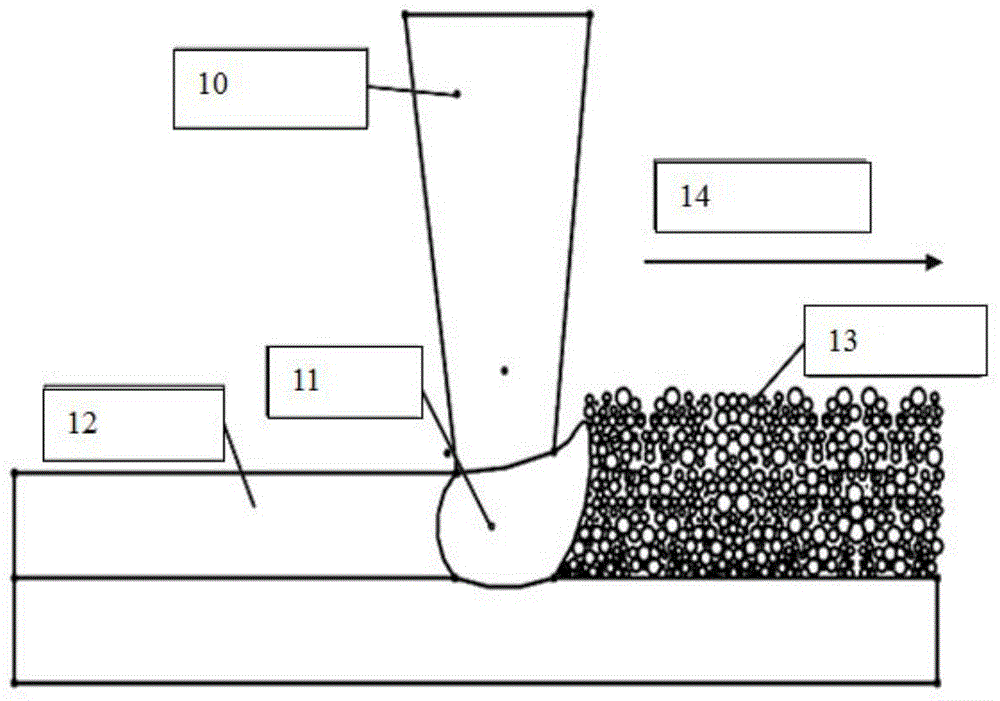

The invention relates to a ceramic scraper, which is used for powder spreading in the process of laser rapid prototyping. Both ends of an edge are provided with rounded corners, the upper part of the scraper is provided with screw holes, and thereby the ceramic scraper can be conveniently fixed on a scraper holder of a powder spreader. Since a conventional steel scraper has high ferromagnetism, in the process of powder spreading, the steel scraper can attract magnetic powder because of static electricity generated by friction, the magnetized powder can be easily agglomerated, as a result, the surface of a formed layer is uneven, the machining precision of parts is decreased, and even the interruption of a modeling process is caused. Since the ceramic scraper does not have ferromagnetism, the problems existing in the conventional scraper can be solved perfectly, the evenness of a powder layer is increased, and prototyping precision is improved. Moreover, since the rigidity of the ceramic scraper is high, the ceramic scraper has high wear resistance, furthermore, since the edge of the scraper is added with the rounded corners, friction force applied on the scraper can be further decreased, and therefore the service life of the scraper made of ceramic can be effectively prolonged. The ceramic scraper also has the advantages of simplicity in production, low machining cost, convenience in use and the like.

Owner:BEIJING UNIV OF TECH

Alumina ceramic wafer treatment process

InactiveCN105732098AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in a 30-40 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 60-70% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is soaked in 10% sulfuric acid solution and dried; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, strong surface adsorption force, which is the highest surface adsorption force of untreated ceramic sheet 10‑20, very strong and durable after being combined with rubber by glue.

Owner:杨莉

Aluminum oxide ceramic sheet processing technology

The invention relates to an aluminum oxide ceramic sheet processing technology. The aluminum oxide ceramic sheet processing technology comprises the following steps: (1) washing with distilled water: washing the ceramic sheet in 100% pure water, and drying; (2) washing with acetone: immersing the washed ceramic sheet in 50% to 60% acetone, and drying; and (3) washing with alkali: immersing the ceramic sheet washed with the acetone in 60% to 70% sodium carbonate solution, and drying. The aluminum oxide ceramic sheet processing technology has the beneficial effects that the hardness is high, the abrasion resistance is extremely good, the weight is light, the surface adsorption capacity is high and is 10 to 20 of that of the ceramic sheet which is not processed, and the aluminum oxide ceramic sheet is firm and durable after being bonded to rubber by virtue of glue.

Owner:解全义

Nanometer clay modified silide composition for filming on polished brick and its prepn process

The nanometer clay modified silide composition for filming on polished brick consists of organic / inorganic composite silide adhesive in 100 weight portions, nanometer sheet silicate clay in 1.0-20 weight portions, surfactant in 7-15 weight portions, and nanometer oxide in 1.0-20 weight portions. The said composition is superior to available antifoulant and hard wax for polished brick and has excellent brightness, high antifoulant performance, good antibiotic performance, high wear resistance, and high chemical corrosion resistance. It is used to film on the surface of polished brick.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

Aluminum oxide ceramic chip treatment technology

The invention discloses an aluminum oxide ceramic chip treatment technology. The technology comprises the following steps of 1, distilled water washing, wherein a ceramic chip is placed in 100% pure water to be cleaned and then dried; 2, acetone washing, wherein the cleaned ceramic chip is placed in 40-50% acetone to be soaked and then dried; 3, alkali washing, wherein the ceramic chip washed with the acetone is placed in a 80-90% sodium carbonate solution to be soaked and then dried. The aluminum oxide ceramic chip treatment technology has the advantages that the ceramic chip is high in hardness, excellent in wear resistance, low in weight and high in surface adsorption capacity which is 10-20 times that of an untreated ceramic chip, and is quite firm and durable after being combined with rubber through glue.

Owner:解全义

Alumina ceramic wafer treatment technique

The invention relates to an alumina ceramic wafer treatment technique which comprises the following steps: (1) distilled water washing: washing a ceramic wafer in 100% pure water, and drying; (2) ketone washing: immersing the cleaned ceramic wafer in 40-50% acetone, and drying; and (3) alkali washing: immersing the ceramic wafer subjected to ketone washing in a 90-100% sodium carbonate solution, and drying. The alumina ceramic wafer treated by the technique has the advantages of high hardness, excellent wear resistance, light weight and high surface adsorptivity (the surface adsorptivity is 10-20 times of that of the untreated ceramic wafer), and is very firm and durable after being combined with glue and rubber.

Owner:解全义

Aluminum oxide ceramic chip treatment technology

The invention discloses an aluminum oxide ceramic chip treatment technology which comprises the following steps that 1, a ceramic chip is washed with distilled water, wherein the ceramic chip is placed in 100% pure water to be cleaned and then dried; 2, acetone washing is carried out, wherein the cleaned ceramic chip is placed in 70-80% acetone to be soaked and then dried; 3, alkali washing is carried out, wherein the ceramic chip washed with the acetone is placed in a 90-100% sodium carbonate solution to be soaked and then dried. The aluminum oxide ceramic chip treatment technology has the advantages that the ceramic chip is high in hardness, excellent in wear resistance, low in weight and high in surface adsorption capacity which is 10-20 times that of an untreated ceramic chip, and is quite firm and durable after being combined with rubber through glue.

Owner:解全义

Alumina ceramic wafer treatment process

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in 20‑30 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 90-100% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is placed in 8‑12% sulfuric acid solution for soaking and drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet The strength is 10‑20, and it is very strong and durable after being combined with glue and rubber.

Owner:解伟伟

Alumina ceramic wafer treatment process

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in a 40‑50 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 90-100% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is soaked in 10% sulfuric acid solution and dried; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, strong surface adsorption force, which is the highest surface adsorption force of untreated ceramic sheet 10‑20, very strong and durable after being combined with rubber by glue.

Owner:杨莉

Treatment process for aluminum oxide ceramic chip

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 30-40% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 50-60% to be soaked and dried; the step four of acid pickling, wherein the ceramic chip dried in the step three is placed into a sulfuric acid solution with the concentration being 10% and dried. The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:杨莉

Treatment process for aluminum oxide ceramic chip

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 30-40% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 90-100% to be soaked and dried; the step four of acid pickling, wherein the ceramic chip dried in the step three is placed into a sulfuric acid solution with the concentration being 10% and dried The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:杨莉

Alumina ceramic wafer treatment process

InactiveCN105732104AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

A process for treating an alumina ceramic sheet, the steps are as follows: (1) cleaning with distilled water: placing the ceramic sheet in 100% pure water for cleaning and drying; (2) ketone washing: placing the cleaned ceramic sheet at 10-20 Soak in % acetone, and dry; (3) alkaline washing: soak the ketone-washed ceramic sheet in a 50-60% sodium carbonate solution, and dry; (4) pickling: dry in step (3) The ceramic sheet is soaked in 8-12% sulfuric acid solution and dried; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet With a force of 10‑20, it is very strong and durable after being combined with rubber by glue.

Owner:解伟伟

Treatment process for aluminum oxide ceramic chip

InactiveCN105565886AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 30-40% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 50-60% to be soaked and dried. The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:解全义

Aluminum oxide ceramic chip treatment technology

The invention discloses an aluminum oxide ceramic chip treatment technology. The technology comprises the following steps of 1, distilled water washing, wherein a ceramic chip is placed in 100% pure water to be cleaned and then dried; 2, acetone washing, wherein the cleaned ceramic chip is placed in 20-30% acetone to be soaked and then dried; 3, alkali washing, wherein the ceramic chip washed with the acetone is placed in a 40-50% sodium carbonate solution to be soaked and then dried. The aluminum oxide ceramic chip treatment technology has the advantages that the ceramic chip is high in hardness, excellent in wear resistance, low in weight and high in surface adsorption capacity which is 10-20 times that of an untreated ceramic chip, and is quite firm and durable after being combined with rubber through glue.

Owner:解全义

Treatment process for aluminum oxide ceramic chip

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 50-60% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 50-60% to be soaked and dried. The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:解全义

Aluminum oxide ceramic chip treatment technology

The invention discloses an aluminum oxide ceramic chip treatment technology which comprises the following steps that 1, a ceramic chip is washed with distilled water, wherein the ceramic chip is placed in 100% pure water to be cleaned and then dried; 2, acetone washing is carried out, wherein the cleaned ceramic chip is placed in 60-70% acetone to be soaked and then dried; 3, alkali washing is carried out, wherein the ceramic chip washed with the acetone is placed in a 90-100% sodium carbonate solution to be soaked and then dried. The aluminum oxide ceramic chip treatment technology has the advantages that the ceramic chip is high in hardness, excellent in wear resistance, low in weight and high in surface adsorption capacity which is 10-20 times that of an untreated ceramic chip, and is quite firm and durable after being combined with rubber through glue.

Owner:解全义

Aluminum oxide ceramic chip treatment technology

The invention discloses an aluminum oxide ceramic chip treatment technology which comprises the following steps that 1, a ceramic chip is washed with distilled water, wherein the ceramic chip is placed in 100% pure water to be cleaned and then dried; 2, acetone washing is carried out, wherein the cleaned ceramic chip is placed in 70-80% acetone to be soaked and then dried; 3, alkali washing is carried out, wherein the ceramic chip washed with the acetone is placed in a 8-12% sodium carbonate solution to be soaked and then dried. The aluminum oxide ceramic chip treatment technology has the advantages that the ceramic chip is high in hardness, excellent in wear resistance, low in weight and high in surface adsorption capacity which is 10-20 times that of an untreated ceramic chip, and is quite firm and durable after being combined with rubber through glue.

Owner:解伟伟

Treatment process of alumina ceramic wafers

InactiveCN105541398AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

A treatment process of alumina ceramic wafers comprises the following steps of (1) washing with distilled water: washing ceramic wafers with 100% pure water, and drying; (2) washing with acetone: soaking the washed ceramic wafers in 80-90% acetone, and drying; (3) alkali washing: soaking the ceramic wafers washed with the acetone in 10-20% sodium carbonate solution, and drying. The treatment process of the alumina ceramic wafers has the beneficial effects of being large in hardness, excellent in wear resistance, light in weight, strong in surface adhesive force (10-20 times of that of the untreated ceramic wafers), and firm and durable after being combined with rubber through glue.

Owner:孙英

Alumina ceramic wafer treatment process

InactiveCN105732113AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

The invention provides an alumina ceramic wafer treatment process. The process comprises the following steps: (1) cleaning with distilled water: putting a ceramic wafer in 100% pure water to be cleaned and drying the ceramic wafer; (2) cleaning with acetone: putting the cleaned ceramic wafer in 10-20% acetone to be soaked and drying the ceramic wafer; (3) cleaning with alkali: putting the ceramic wafer cleaned with acetone in a 70-80% sodium carbonate solution to be soaked and drying the ceramic wafer. The process has the beneficial effects that the ceramic wafer has high hardness, excellent wear resistance, light weight and strong surface adsorbability which is 10-20 times that of untreated ceramic wafers; the ceramic wafer is very firm and durable after being bonded with rubber via glue.

Owner:孙英

Alumina ceramic wafer treatment process

InactiveCN105732105AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in 80‑90 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 10-20% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is placed in 8‑12% sulfuric acid solution for soaking and drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet The strength is 10‑20, and it is very strong and durable after being combined with glue and rubber.

Owner:解伟伟

Alumina ceramic wafer treatment process

InactiveCN105732110AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in a 60‑70 % acetone soaking, drying; (3) alkali washing: the ketone washed ceramic sheet is placed in 80-90% sodium carbonate solution for soaking, drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance , light weight, strong surface adsorption, which is 10‑20 of the surface adsorption of untreated ceramic sheets, and it is very firm and durable after being combined with glue and rubber.

Owner:解全义

Alumina ceramic wafer treatment process

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in a 50‑60 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 10-20% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is placed in 8‑12% sulfuric acid solution for soaking and drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet The strength is 10‑20, and it is very strong and durable after being combined with glue and rubber.

Owner:解伟伟

Alumina ceramic wafer processing process

An alumina ceramic wafer processing process includes the following steps that firstly, distilled water is used for cleaning, wherein a ceramic wafer is placed in 100% pure water to be cleaned and then is dried; secondly, ketone washing is performed, wherein the cleaned ceramic wafer is placed in 10-20% acetone to be soaked and then is dried; thirdly, alkaline cleaning is performed, wherein the ceramic wafer washed in acetone is placed in a 80-90% sodium carbonate solution to be soaked and then is dried; fourthly, acid pickling is performed, wherein the ceramic wafer dried in the third step is placed in a 8-12% sulfuric acid solution to be soaked and then is dried. The alumina ceramic wafer processing process has the advantages that hardness is large, abrasion resistance is excellent, weight is low, surface adsorption capacity is high, the surface adsorption capacity of the processed ceramic wafer is 10-20 times that of a non-processed ceramic wafer, and the processed ceramic wafer is quite firm and durable after being combined with rubber through glue.

Owner:解伟伟

Treatment process for aluminum oxide ceramic chip

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 20-30% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 50-60% to be soaked and dried; the step four of acid pickling, wherein the ceramic chip dried in the step three is placed into a sulfuric acid solution with the concentration being 8-12% and dried. The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:解伟伟

Alumina ceramic wafer treatment technique

InactiveCN105585337AOver wear resistanceHigh hardnessCleaning using liquidsDistilled waterHigh surface

The invention relates to an alumina ceramic wafer treatment technique which comprises the following steps: (1) distilled water washing: washing a ceramic wafer in 100% pure water, and drying; (2) ketone washing: immersing the cleaned ceramic wafer in 40-50% acetone, and drying; and (3) alkali washing: immersing the ceramic wafer subjected to ketone washing in a 60-70% sodium carbonate solution, and drying. The alumina ceramic wafer treated by the technique has the advantages of high hardness, excellent wear resistance, light weight and high surface adsorptivity (the surface adsorptivity is 10-20 times of that of the untreated ceramic wafer), and is very firm and durable after being combined with glue and rubber.

Owner:解全义

Treatment process of alumina ceramic wafers

A treatment process of alumina ceramic wafers comprises the following steps of (1) washing with distilled water: washing ceramic wafers with 100% pure water, and drying; (2) washing with acetone: soaking the washed ceramic wafers in 10-20% acetone, and drying; (3) alkali washing: soaking the ceramic wafers washed with the acetone in 20-30% sodium carbonate solution, and drying. The treatment process of the alumina ceramic wafers has the beneficial effects of being large in hardness, excellent in wear resistance, light in weight, strong in surface adhesive force (10-20 times of that of the untreated ceramic wafers), and firm and durable after being combined with rubber through glue.

Owner:孙英

Treatment process for aluminum oxide ceramic chip

InactiveCN105565888AHigh hardnessGood wear resistanceCleaning using liquidsSodium carbonateAlumina ceramic

The invention provides a treatment process for an aluminum oxide ceramic chip. The treatment process comprises the following step one of distilled water washing, wherein the ceramic chip is placed into 100% pure water to be washed and dried; the step two of acetone washing, wherein the washed ceramic chip is placed into acetone with the concentration being 20-30% to be soaked and dried; the step three of alkaline washing, wherein the ceramic chip subjected to acetone washing is placed into a sodium carbonate solution with the concentration being 90-100% to be soaked and dried. The treatment process has the advantages that hardness is high, a wear-resisting property is excellent, the weight is low, surface adsorption force is large and is 10-20 times that of an untreated ceramic chip, and after being combined with rubber through glue, the ceramic chip is extremely firm and durable.

Owner:解全义

Alumina ceramic wafer treatment process

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in 20‑30 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 80-90% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is placed in 8‑12% sulfuric acid solution for soaking and drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet The strength is 10‑20, and it is very strong and durable after being combined with glue and rubber.

Owner:解伟伟

Treatment process of alumina ceramic wafers

A treatment process of alumina ceramic wafers comprises the following steps of (1) washing with distilled water: washing ceramic wafers with 100% pure water, and drying; (2) washing with acetone: soaking the washed ceramic wafers in 60-70% acetone, and drying; (3) alkali washing: soaking the ceramic wafers washed with the acetone in 10-20% sodium carbonate solution, and drying. The treatment process of the alumina ceramic wafers has the beneficial effects of being large in hardness, excellent in wear resistance, light in weight, strong in surface adhesive force (10-20 times of that of the untreated ceramic wafers), and firm and durable after being combined with rubber through glue.

Owner:孙英

Alumina ceramic wafer treatment technique

The invention relates to an alumina ceramic wafer treatment technique which comprises the following steps: (1) distilled water washing: washing a ceramic wafer in 100% pure water, and drying; (2) ketone washing: immersing the cleaned ceramic wafer in 20-30% acetone, and drying; and (3) alkali washing: immersing the ceramic wafer subjected to ketone washing in a 60-70% sodium carbonate solution, and drying. The alumina ceramic wafer treated by the technique has the advantages of high hardness, excellent wear resistance, light weight and high surface adsorptivity (the surface adsorptivity is 10-20 times of that of the untreated ceramic wafer), and is very firm and durable after being combined with glue and rubber.

Owner:解全义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com