Ceramic scraper

A scraper and ceramic technology, which is applied in the field of rapid prototyping, can solve the problems of uneven surface of the forming layer, uneven thickness of the melting layer, and reduced processing accuracy, and achieve the effect of firm bonding, light weight, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

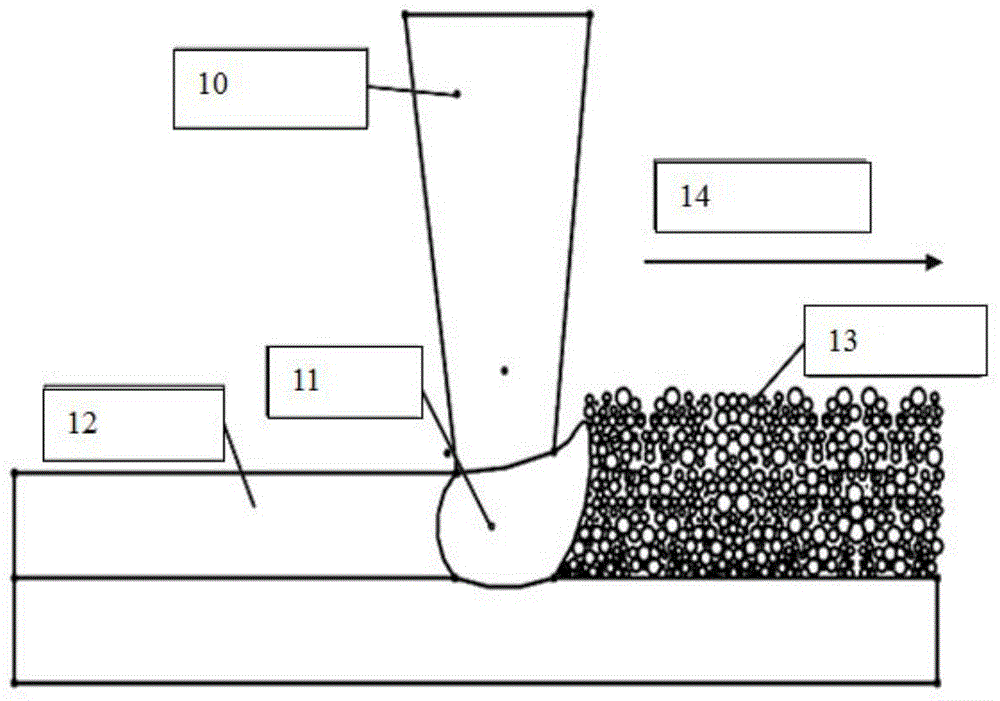

[0047] The present embodiment is that the ceramic scraper is placed on the semiconductor laser microchannel heat sink ( Figure 11 ) application in the manufacturing process.

[0048] In this embodiment, the inner channel of the semiconductor laser microchannel heat sink is an open circulation channel, and the wall thickness between adjacent channels is only 0.2mm. The material used to process the semiconductor laser microchannel heat sink is nickel alloy powder. Since the nickel alloy powder is magnetic, it is difficult to spread the powder when using a traditional steel scraper for processing ( Figure 10 ). Mainly because the traditional steel scraper has ferromagnetism, it will magnetize the nickel alloy powder. It is light and easy to adsorb on the surface of the scraper. During the movement of the scraper, the powder adsorbed on the surface of the scraper will fall off, making the powder layer that has been scraped flat become uneven. In the subsequent laser melting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com