Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Meet the requirements of complex pick and place operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional translation and one-dimensional rotation parallel mechanism capable of realizing high-speed movement

InactiveCN101863024AReduce complexityCompact structureProgramme-controlled manipulatorJointsFixed frameEngineering

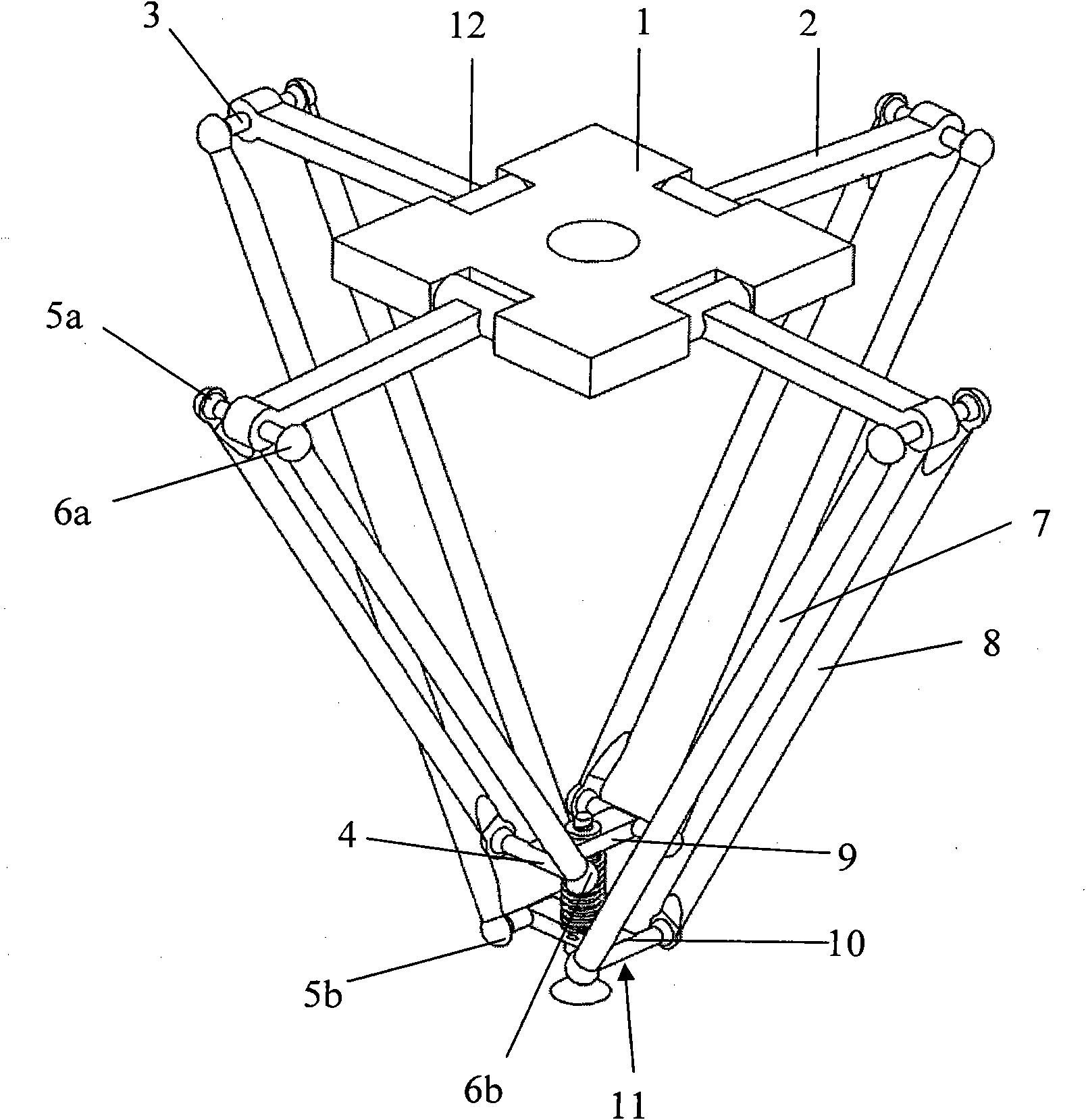

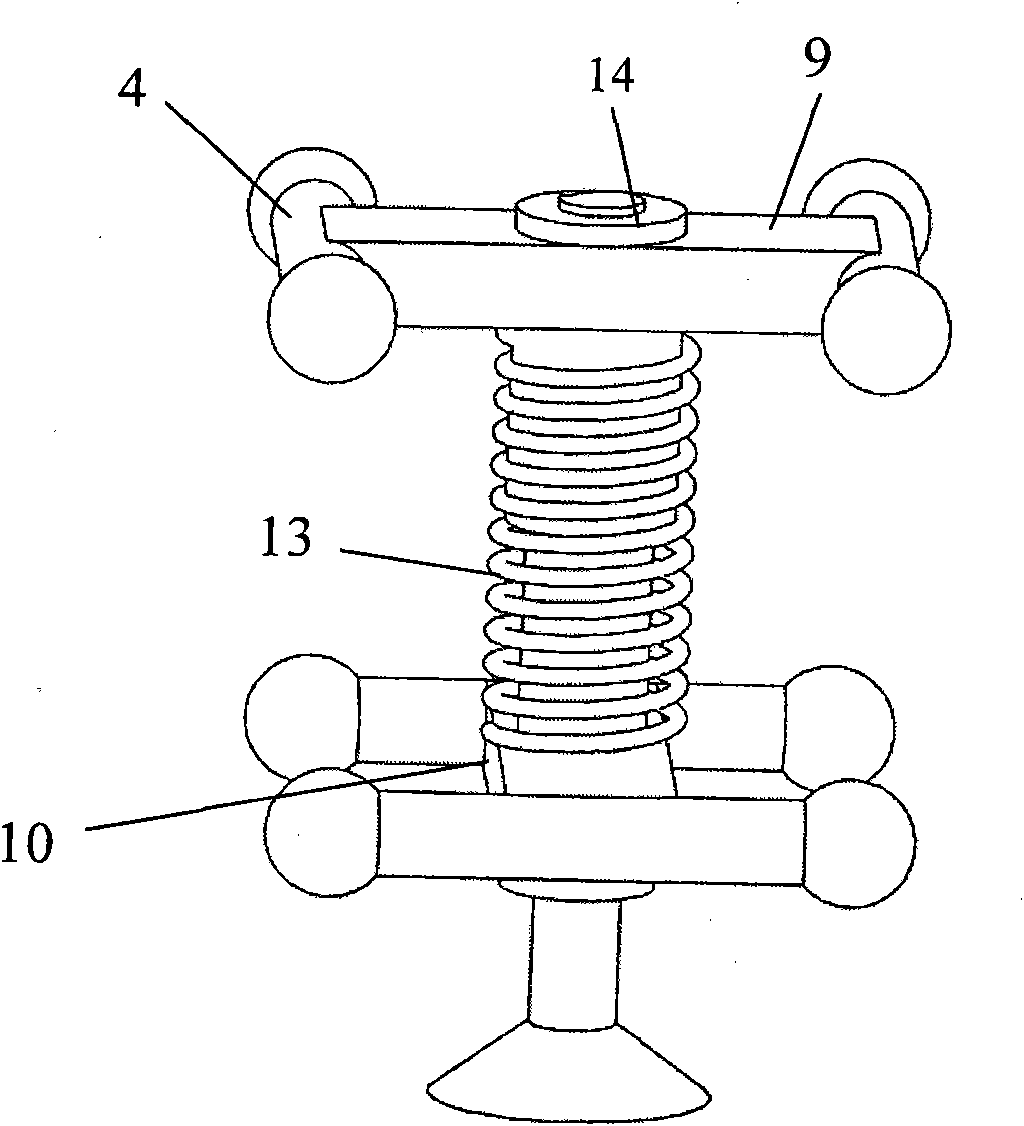

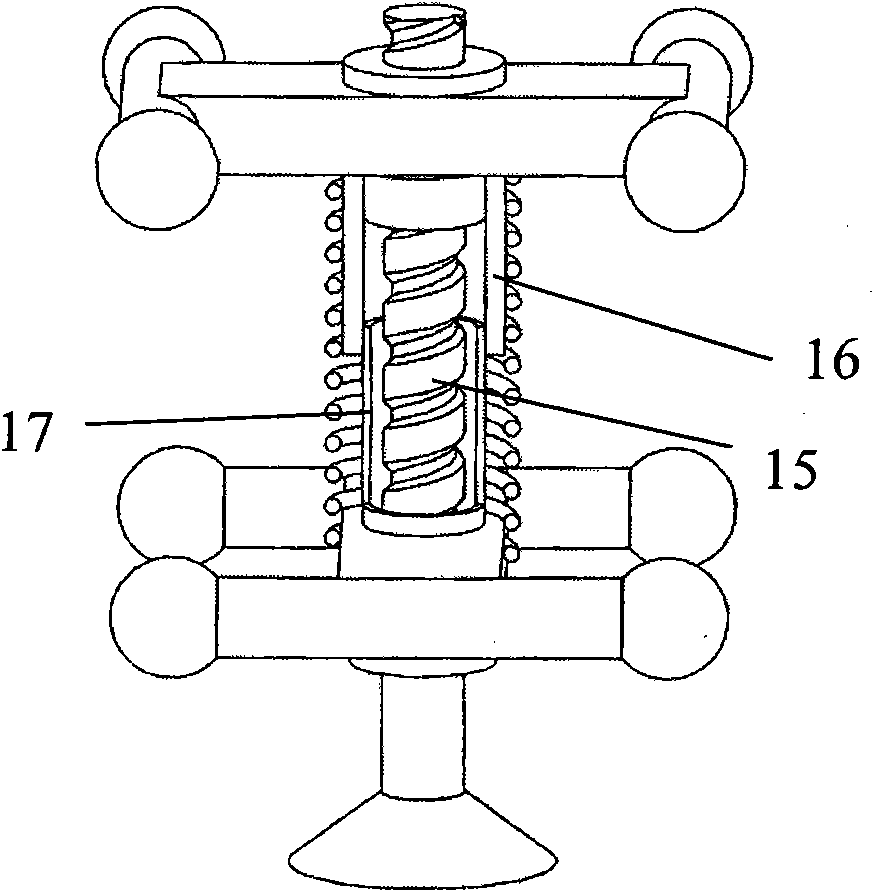

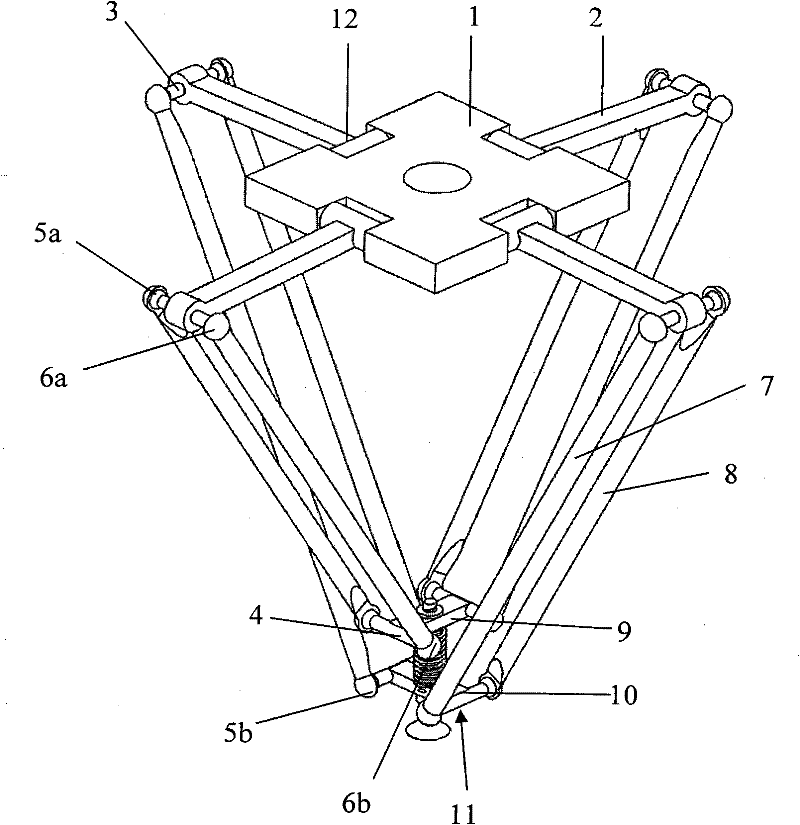

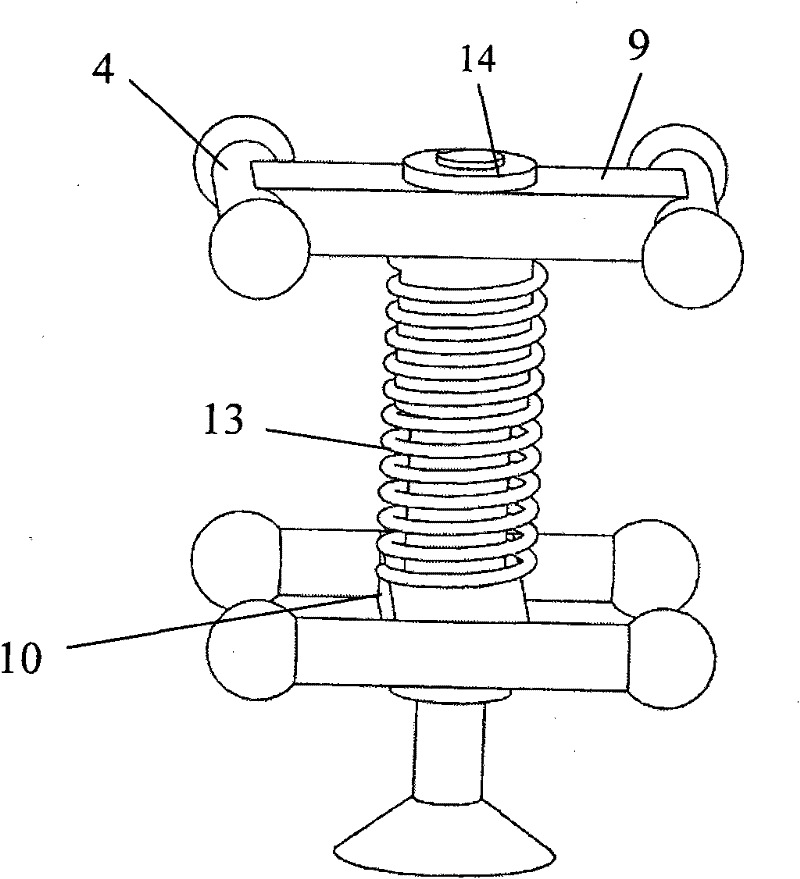

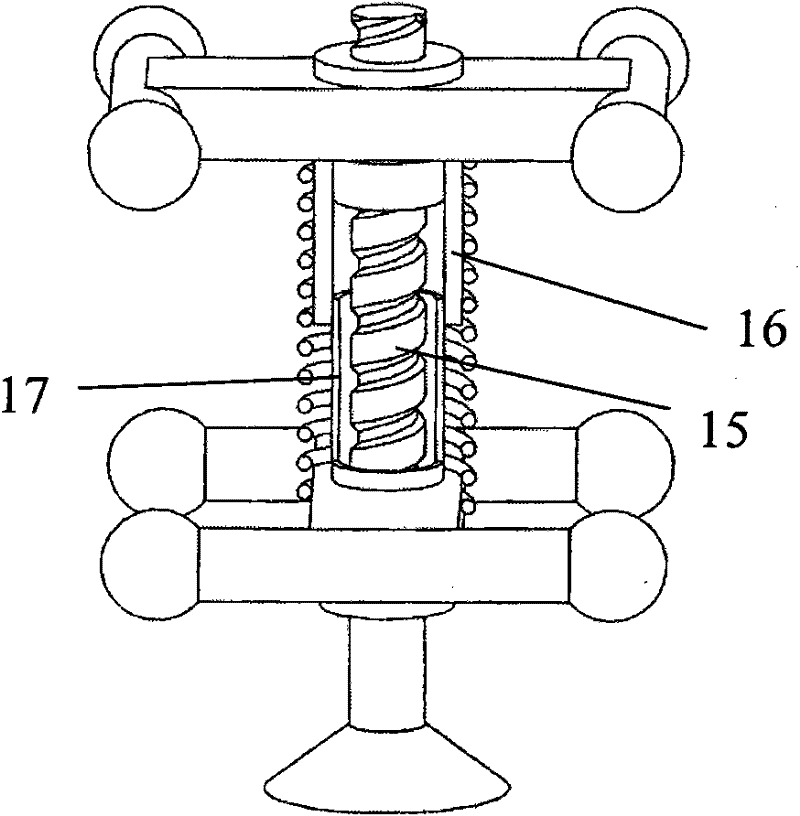

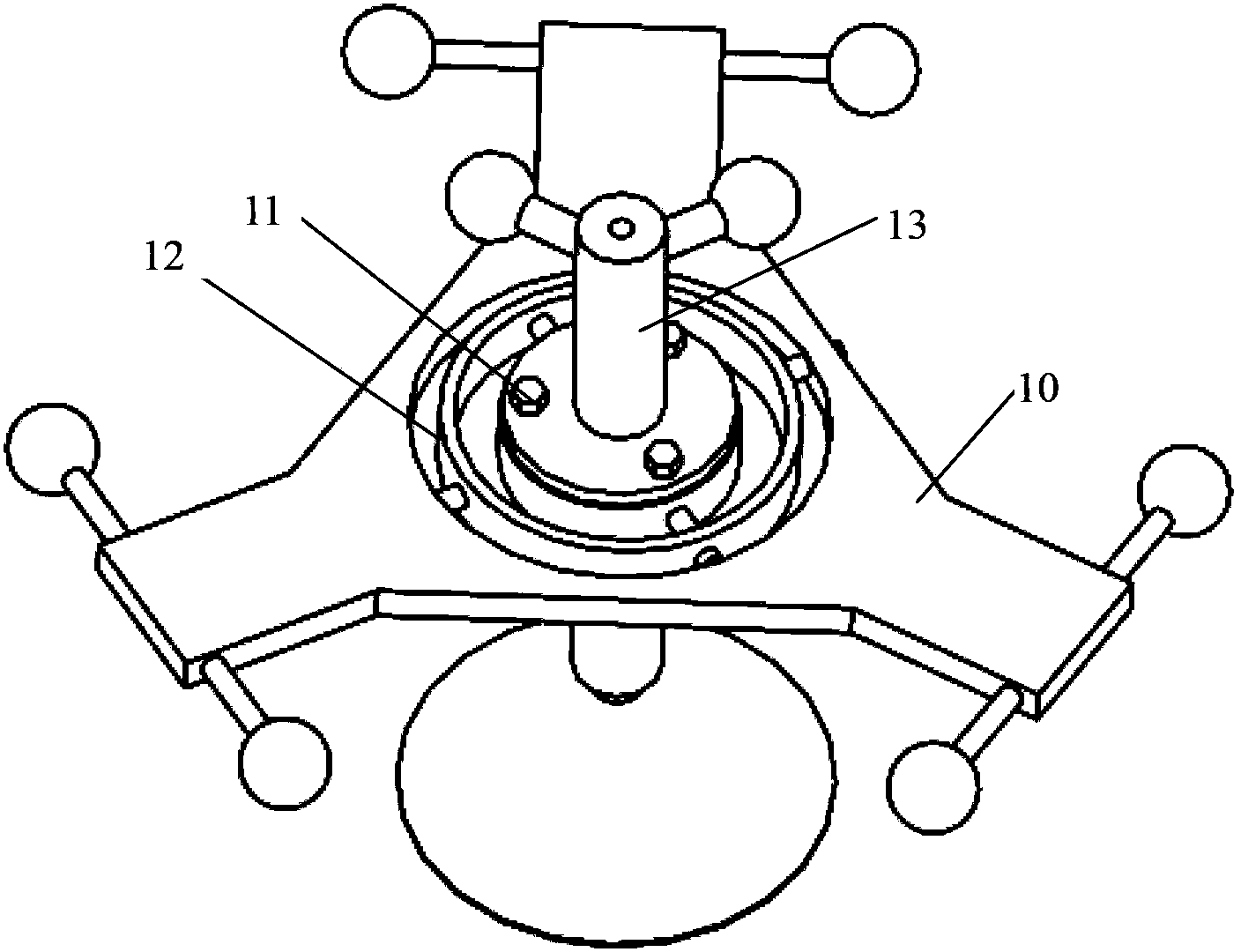

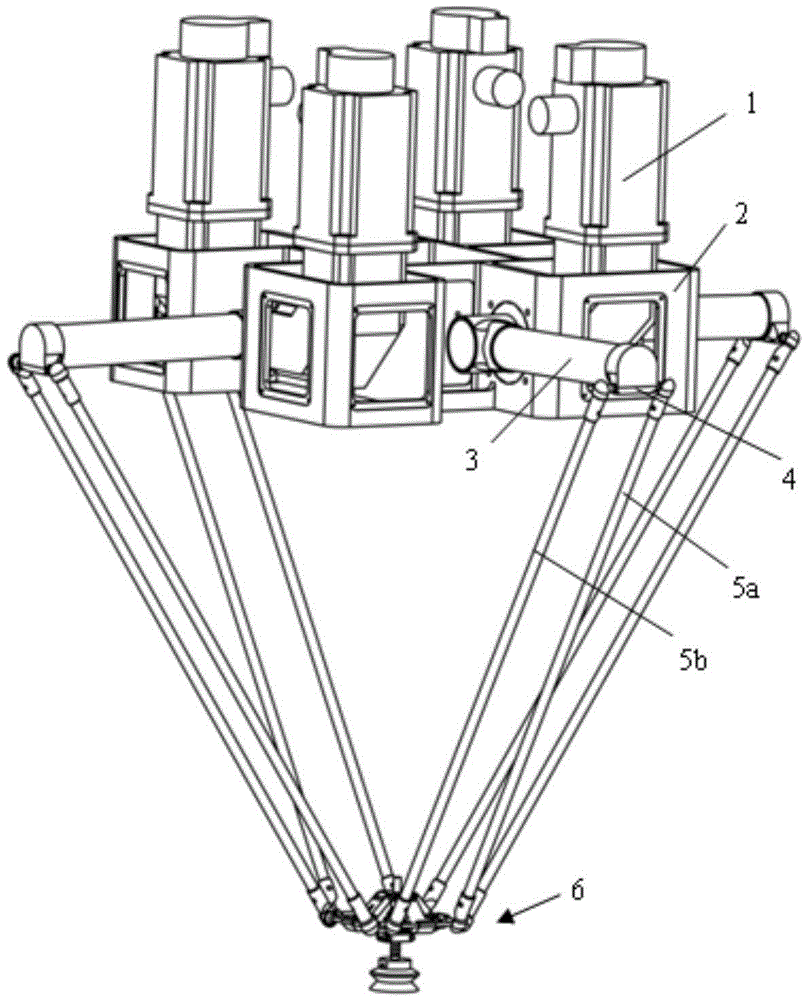

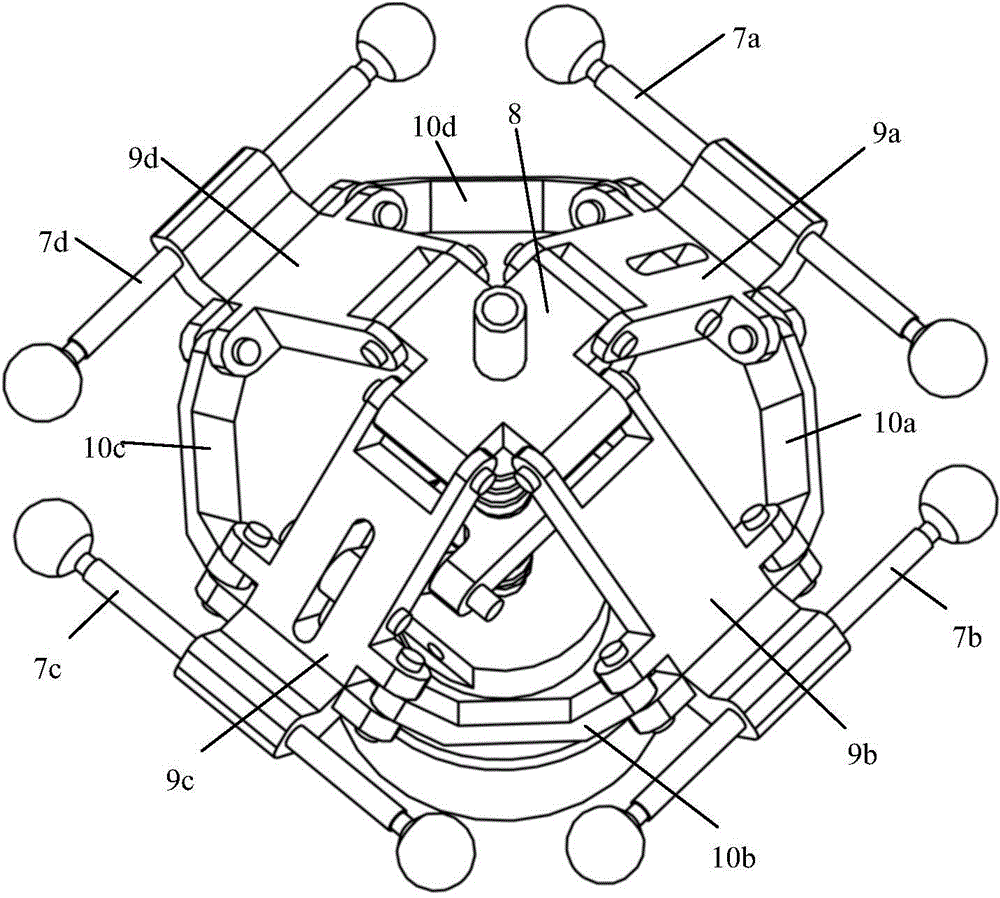

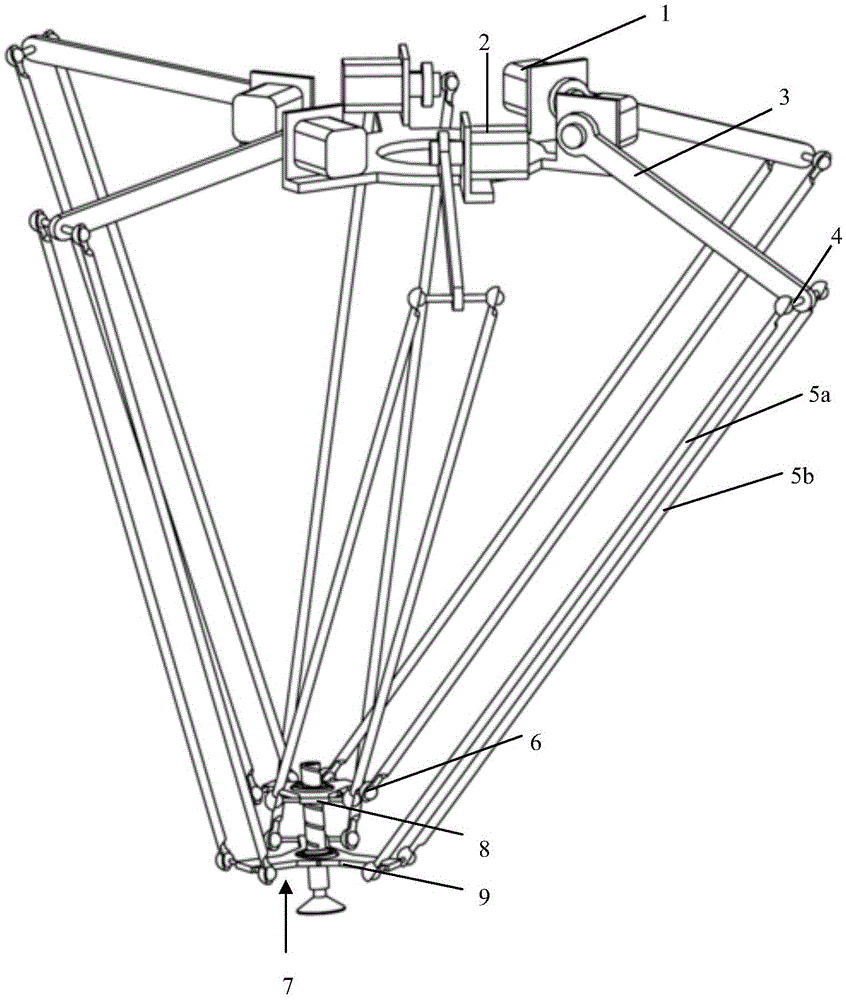

The invention provides a three-dimensional translation and one-dimensional rotation parallel mechanism capable of realizing high-speed movement, comprising a fixed frame, a movable platform and four branched chains which are symmetrically arranged between the fixing frame and the movable platform and have same structures. The movable platform comprises an upper platform and a lower platform, which are horizontally arranged and are connected through a rotating mechanism. The rotating mechanism comprises a lead screw nut fixed on the upper platform and a lead screw connected with the lead screw nut, and the lead screw is supported by a bearing installed on the lower platform. In the three-dimensional translation and one-dimensional rotation parallel mechanism, the movement of the upper platform and the lower platform is converted into rotation round the axis of the lead screw through the rotating mechanism, and the upper platform and the lower platform are respectively and fixedly connected with a pair of opposite lower connecting shafts. In the invention, the upper platform and the lower platform which are horizontally arranged are adopted for the movable platform, and the upper platform and the lower platform are connected through the rotating mechanism, thereby the three-dimensional translation and one-dimensional rotation parallel mechanism has compact structure, avoids using a steering mechanism and an amplifying mechanism, reduces the mechanism complexity and the movement quality, is easy to realize high-speed capture, and meets the requirement of complex catching and releasing operation.

Owner:TIANJIN UNIV

Parallel mechanism capable of realizing four-degree-of-freedom movement

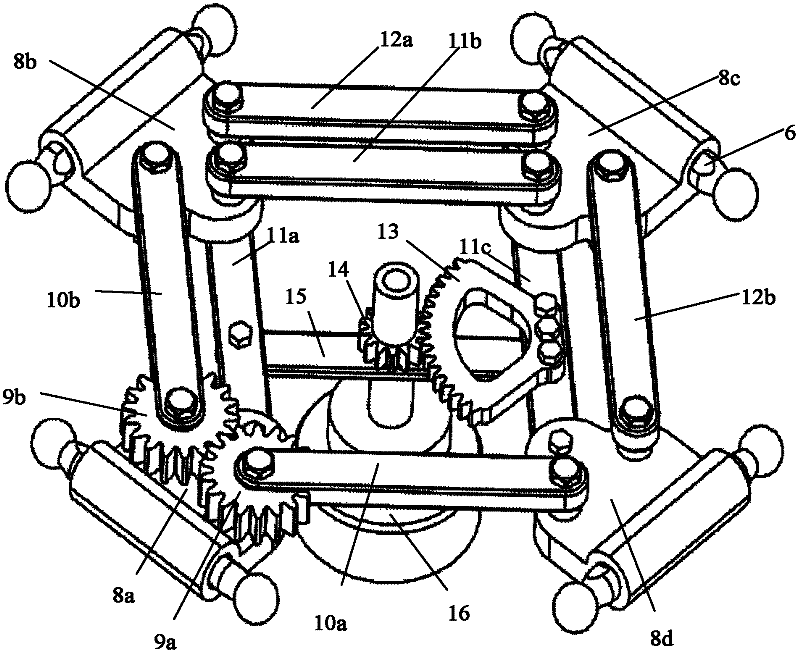

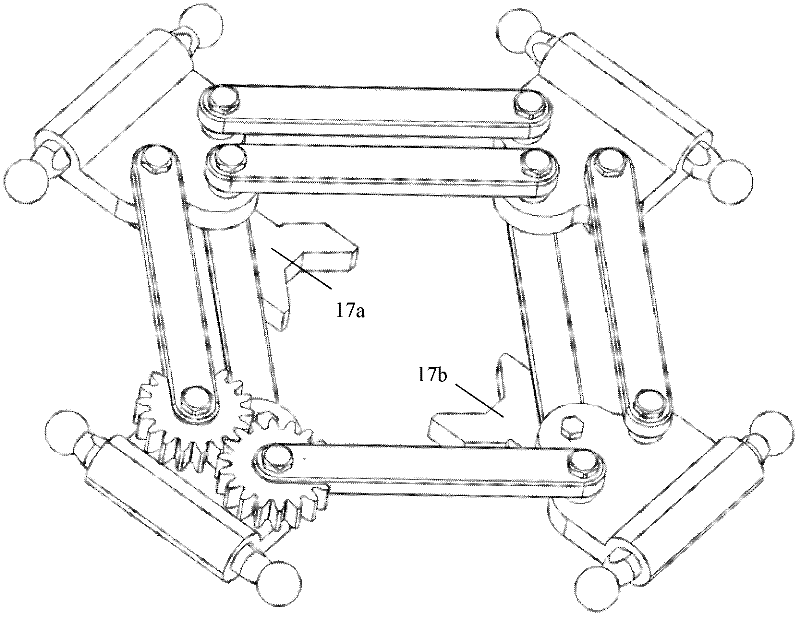

ActiveCN102229141AFlexible structureFlexible movementProgramme-controlled manipulatorDiagonalMagnification

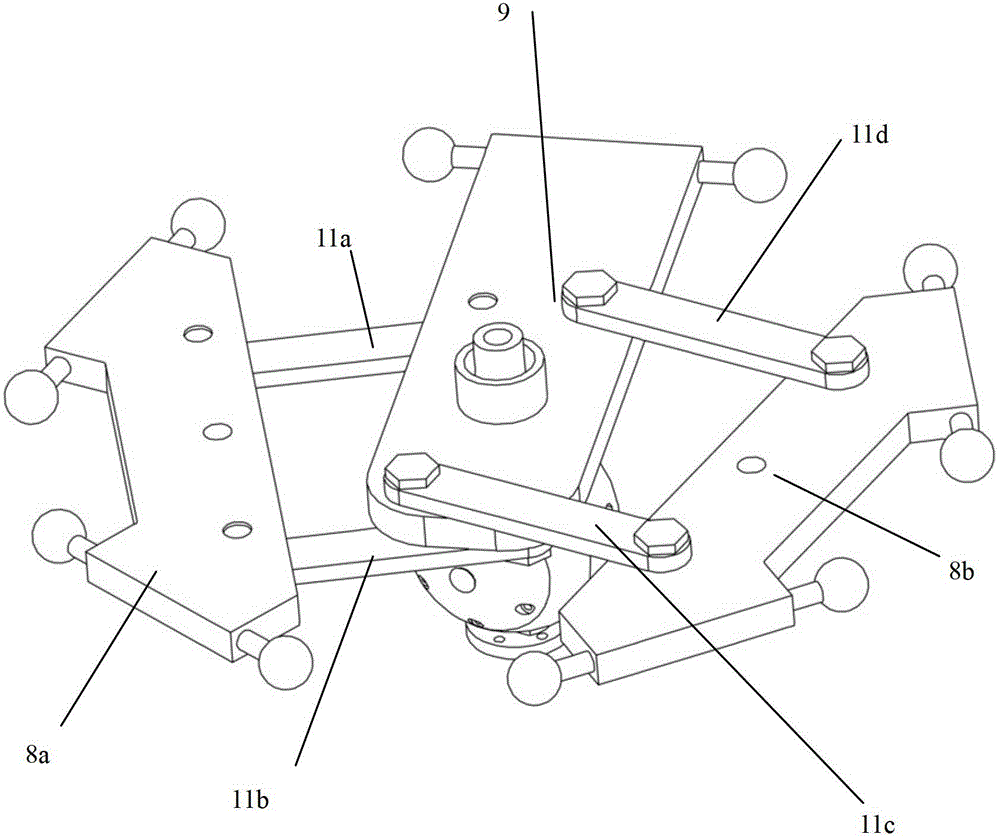

The invention discloses a parallel mechanism capable of realizing four-degree-of-freedom movement. The mechanism is characterized in that a subangle mechanism or the combination of the subangle mechanism and a parallelogram structure is adopted for a moving platform, thus the moving platform is of a rhombus structure, the relative positions of virtual central points of the structure are not changed, and only the deformation movement of relative extension and compression along the diagonal direction can be performed. The mechanism provided by the invention has the advantages of flexible movement, uniform stress, high movement accuracy; the relative movement is converted into rotation movement of an actuator through an angular magnification mechanism, moving pairs are not used in the mechanism, the defects such as nonuniform stress, great friction, short service life and the like are avoided, the integral structure has good rigidity and stability, high-speed movement can be realized easily, and requirements of complex grabbing operations are satisfied; and the mechanism has high reorganization, multiple configurations can be realized, and the clamping and rotation operations can be implemented, thus multiple choices are provided for practical applications.

Owner:WUHU IROBSYS ROBOT CO LTD

Up-and-down telescopic three-platform one-rotation parallel mechanism

ActiveCN102161201ASmall overall sizeCompact structureProgramme-controlled manipulatorMarine engineeringVertical axis

The invention discloses an up-and-down telescopic three-platform one-rotation parallel mechanism, comprising a fixed frame, a moving platform and four groups of branch chains, wherein the branch chains are same in structure and are symmetrically arranged between the fixed frame and the moving platform; the moving platform comprises an upper platform and a lower platform which are mutually parallel; the vertical axes of the upper platform and the lower platform are coincident; a connecting rod group guiding mechanism is connected between the upper platform and the lower platform, and consists of at least three dual-connecting-rod structures which are same in structure and are distributed along the circumference of the vertical axis of the moving platform; each dual-connecting-rod structure comprises an upper connecting rod hinged with the upper platform and a lower connecting rod hinged with the lower platform; and the upper connecting rod is hinged with the lower connecting rod. In the up-and-down telescopic three-platform one-rotation parallel mechanism, relative movement of the upper platform and the lower platform along the direction of the common vertical axis is converted into the rotation of a lead screw around the axis of the lead screw through a rotating mechanism and the connecting rod group guiding mechanism, the vertical relative movement of the upper platform and the lower platform is guaranteed by utilizing the constrained characteristic of the connecting rod group guiding mechanism, and the rigidity and the stability are good.

Owner:WUHU IROBSYS ROBOT CO LTD

Parallel mechanism with three-dimensional translation and one-dimensional rotation

InactiveCN102069497AIncrease stiffnessImprove stabilityProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a parallel mechanism with three-dimensional translation and one-dimensional rotation, which comprises a fixed mount, a moving platform and four branched chains which are symmetrically arranged between the fixed mount and the moving platform and have same structures, wherein the moving platform comprises a main platform and a secondary platform which are horizontally arranged on the same centre line; the main platform is a closed structure; the secondary platform is embedded into the main platform; the main platform and the secondary platform are connected through a rotating mechanism; the rotating mechanism comprises a nut which is fixedly connected with the secondary platform and a screw which is rotatablely connected with the main platform through a bearing; the nut and the screw form a screw pair; the centre line of the screw is coincident with the vertical axis of the moving platform; the main platform is fixedly connected with a guide rod; and the secondary platform is glidingly connected with the guide rod. The parallel mechanism has a compact structure and high rigidity and stability; a guide mechanism and the rotating mechanism are designed light, thereby, the motion quality is reduced, high-speed capture is easy to realize and the requirements of the complicated capture and release operations are met.

Owner:TIANJIN UNIV

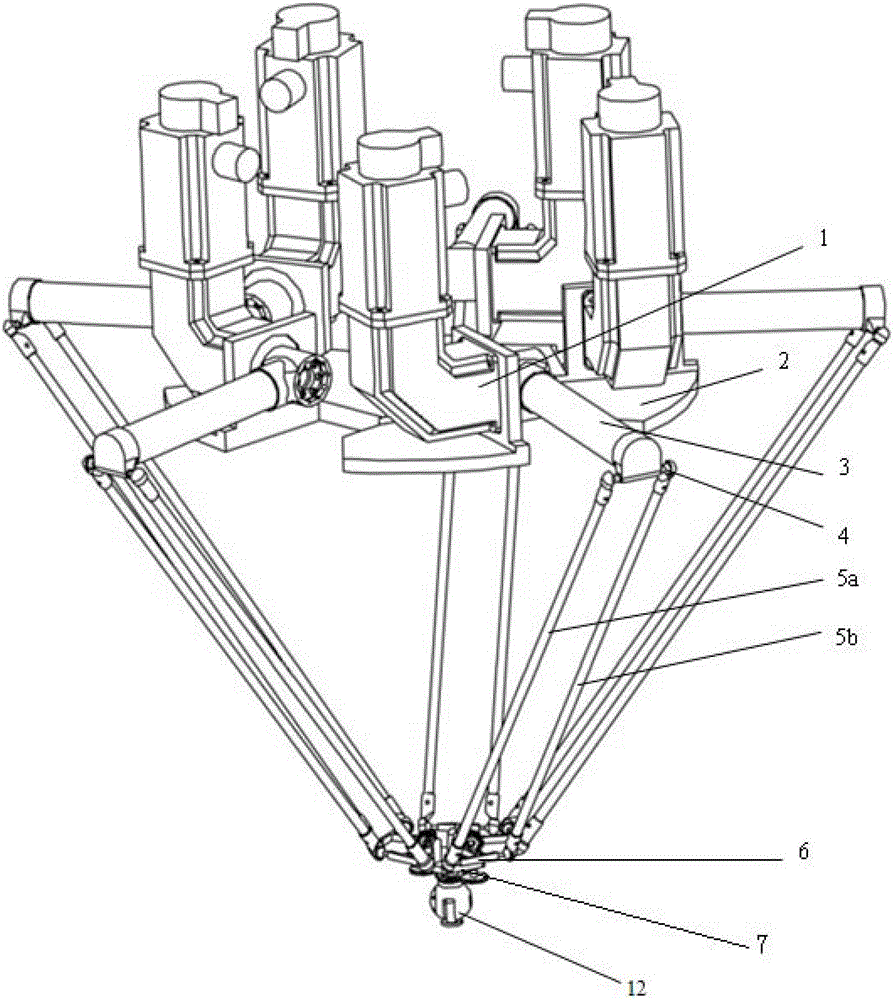

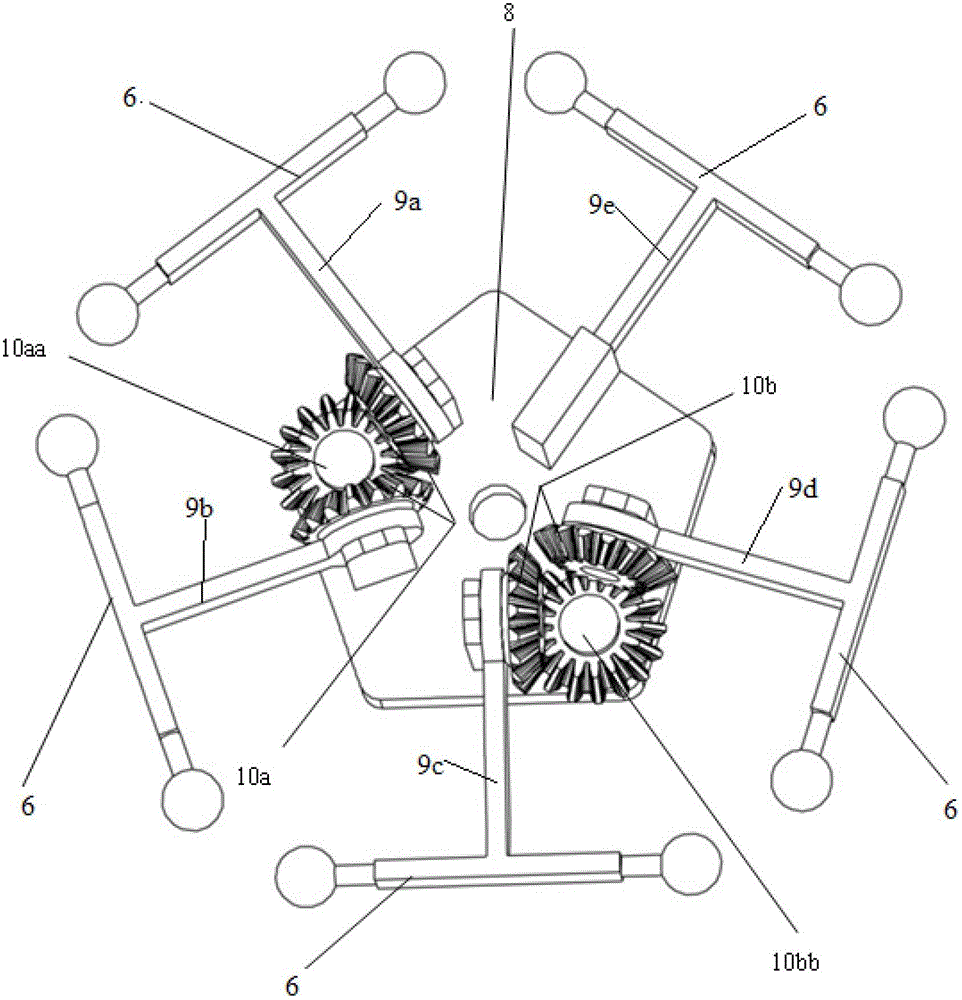

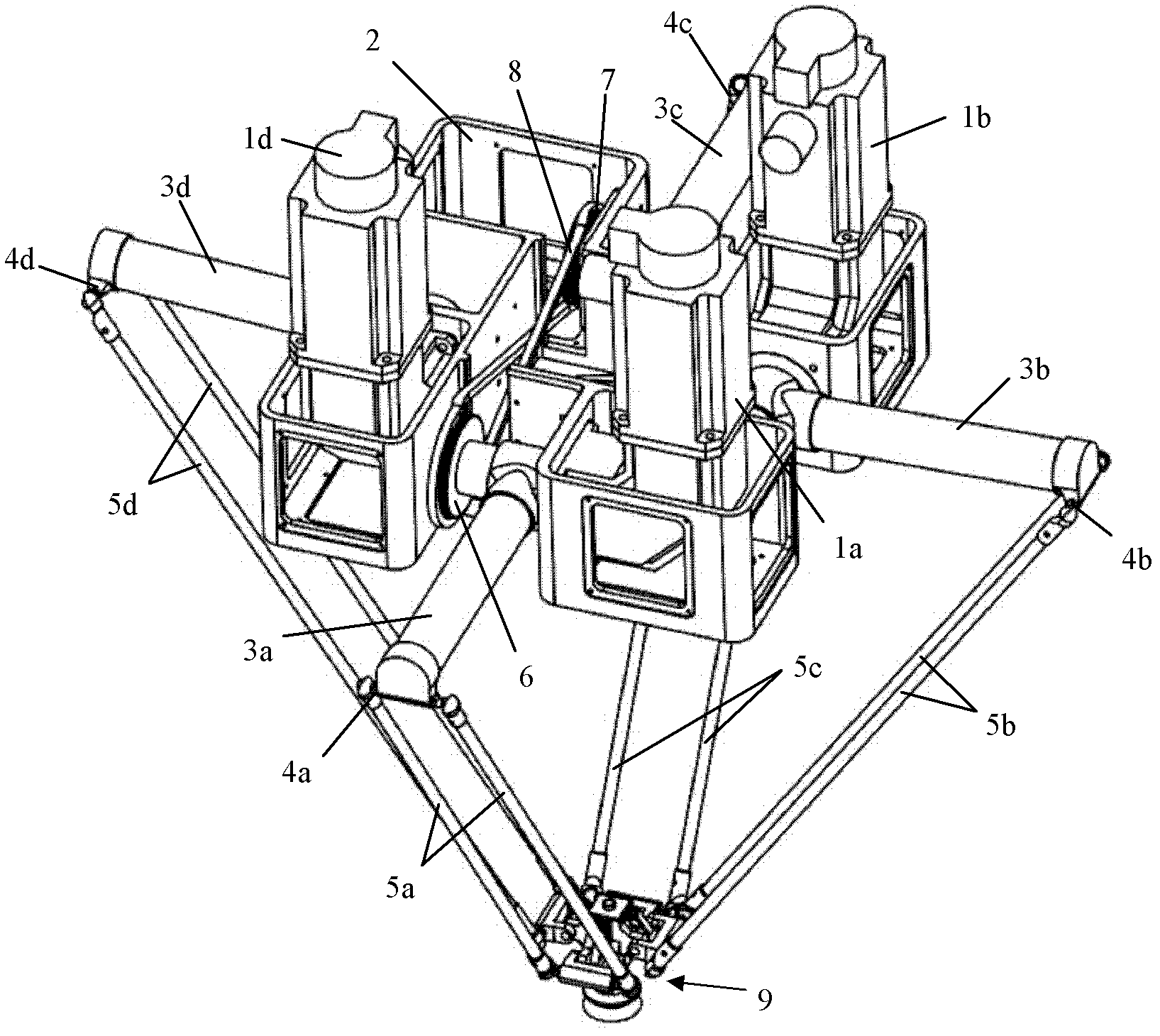

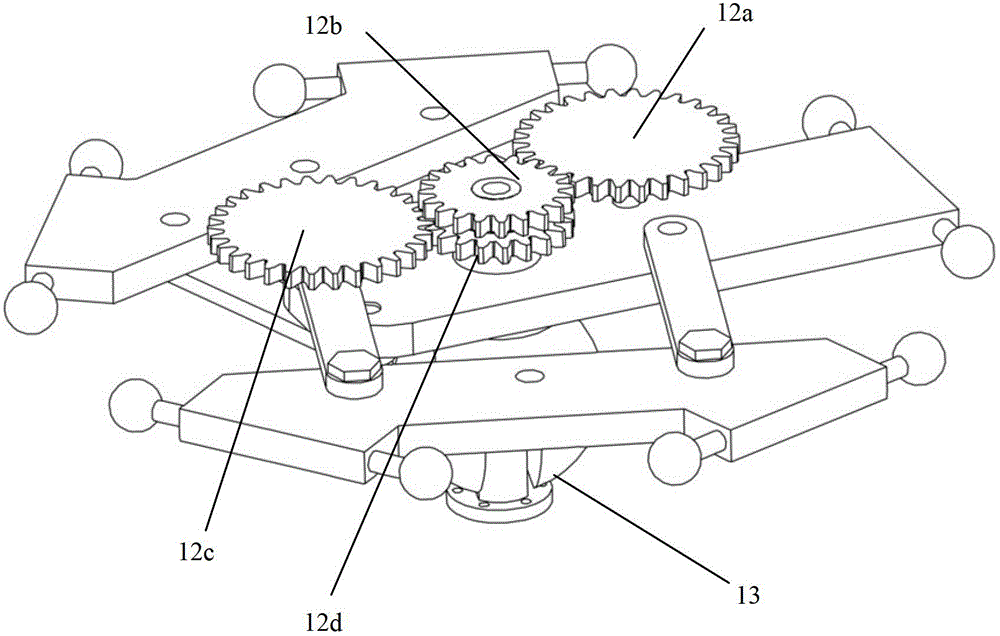

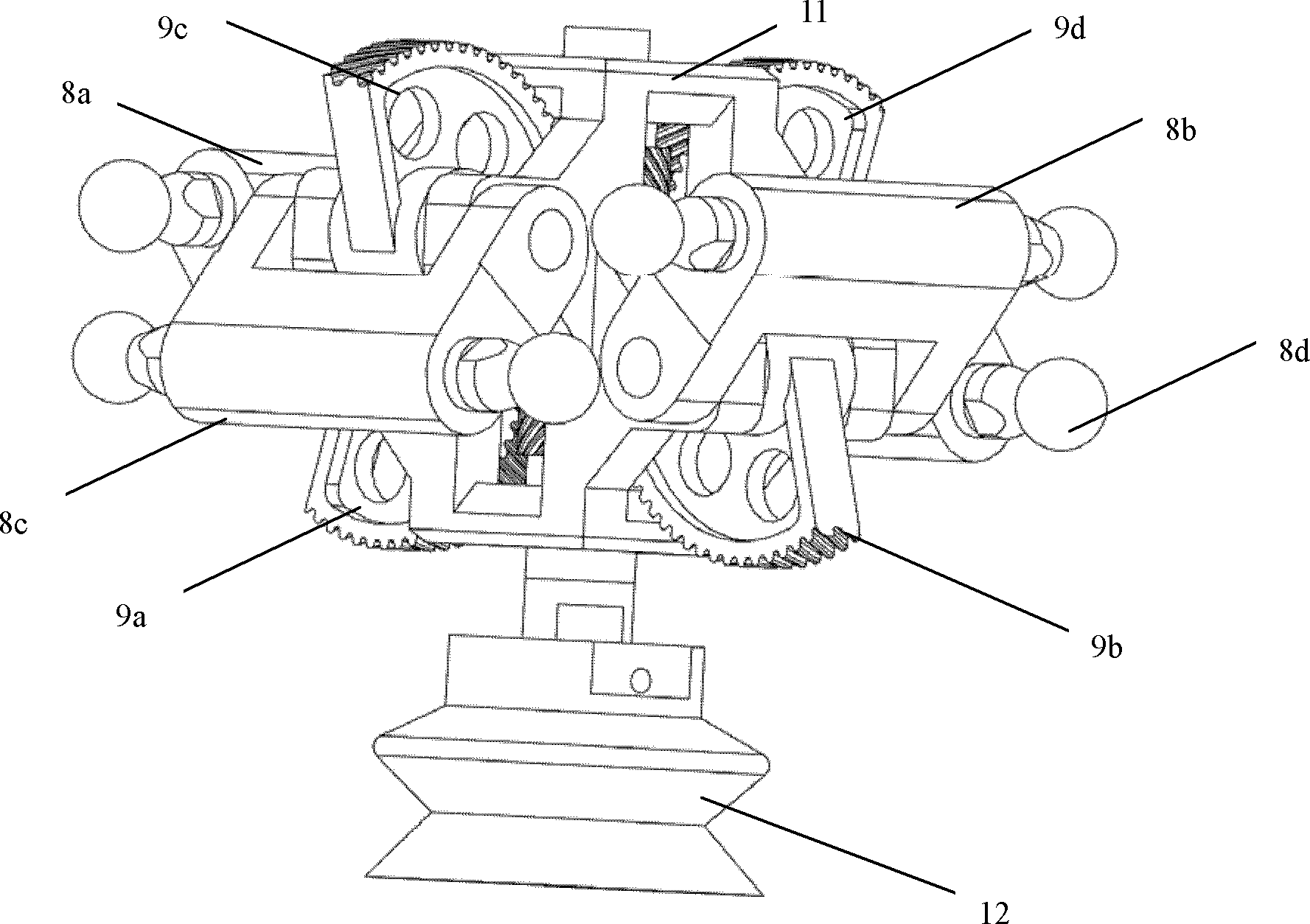

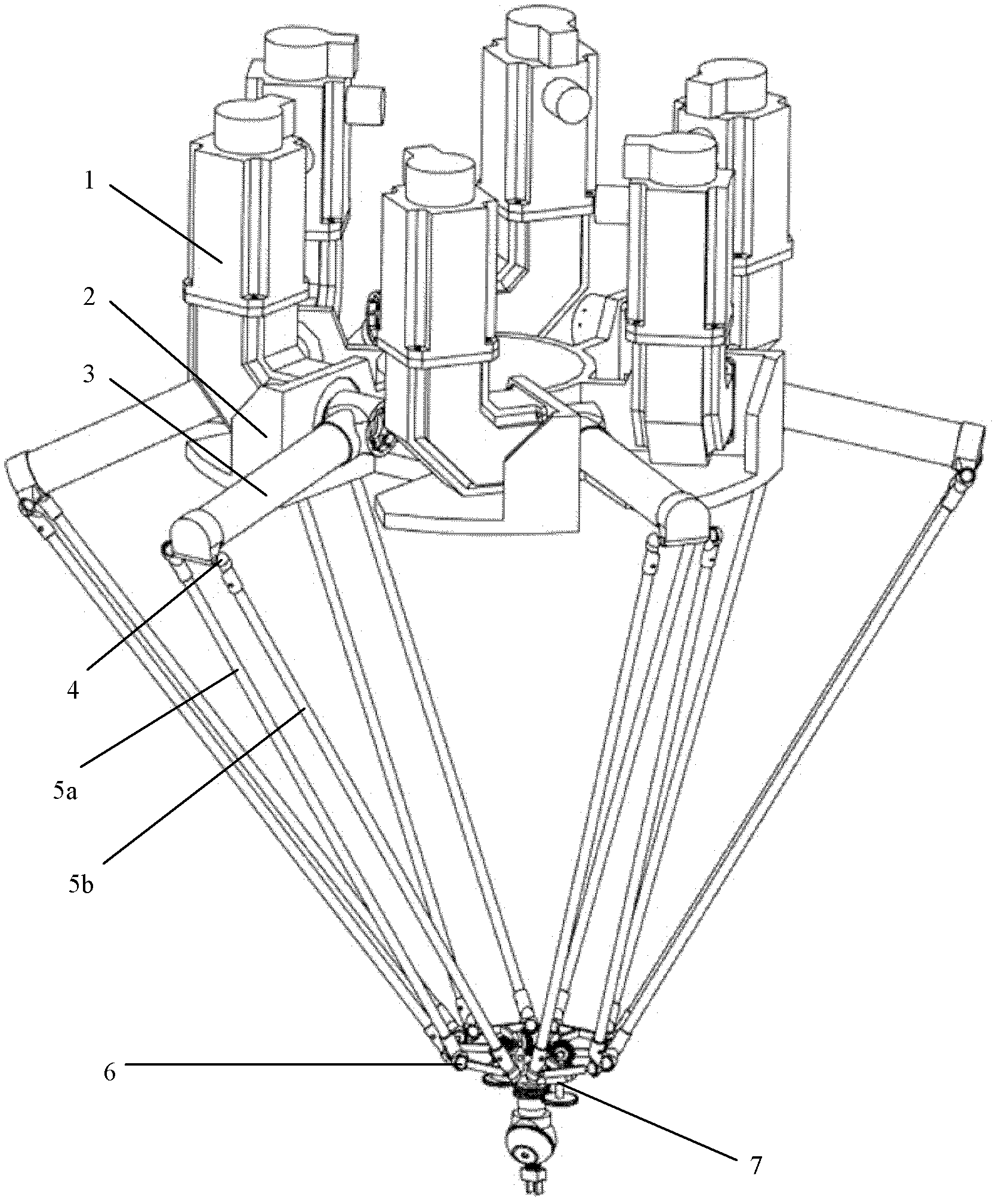

High-speed five-degree of freedom parallel manipulator

InactiveCN102975203AStructural symmetryEven by forceProgramme-controlled manipulatorEngineeringDegrees of freedom

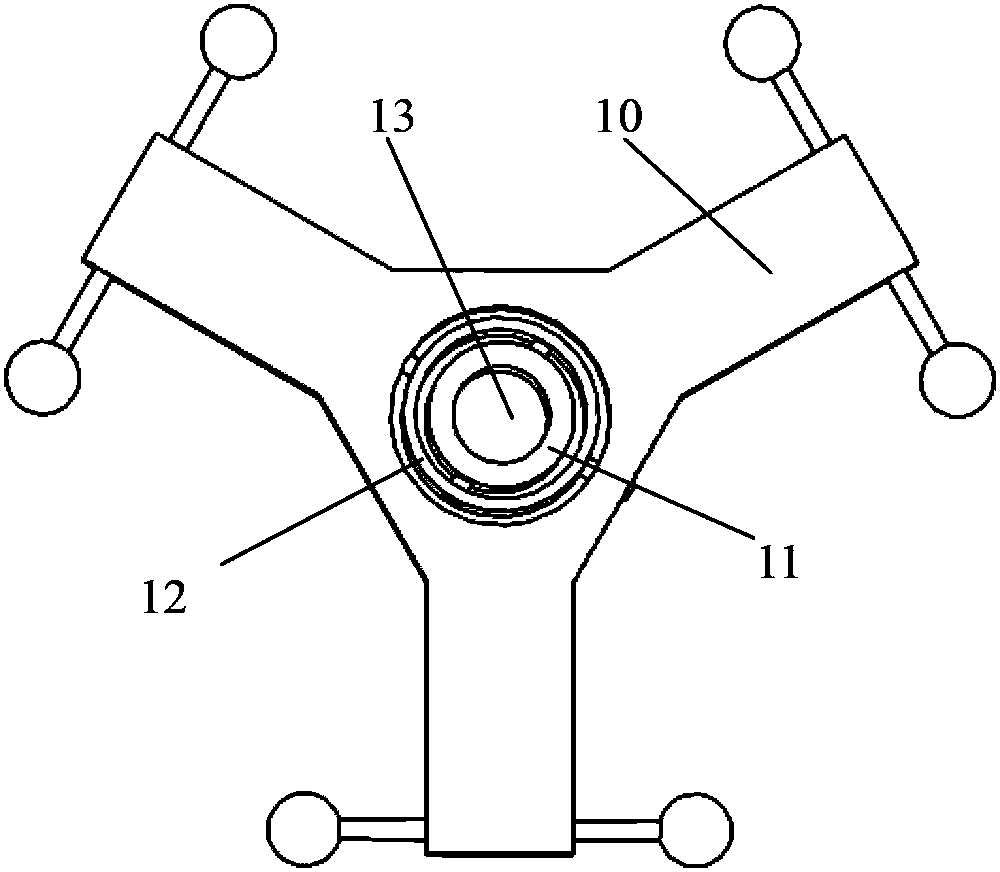

The invention discloses a high-speed six-degree of freedom parallel manipulator. The parallel manipulator comprises a fixed frame, a movable platform, a two-degree of freedom wrist and five branched chains which are arranged between the fixed frame and the movable platform and have the same structure, wherein the five branched chains with the same structure drive the movable platform to carry out three-dimensional translational motion; the movable platform comprises a center plate, two groups of subangle gear sets, four connecting rods and a fixed connecting rod; the fixed connecting rod and the four connecting rods are radially and uniformly distributed on the center plate; one end of the fixed connecting rod is fixedly connected with the center plate; one ends of the four connecting rods are respectively fixedly connected rotating shafts of subangle bevel gears in the two groups of subangle gear sets; and through the meshing function between the two groups of subangle gear sets and center bevel gears, the motion is transmitted to the two-degree of freedom wrist so as to generate two-degree of freedom controllable rotation. The parallel manipulator is symmetrical in structure, even in stress, little in mass of movement parts, and excellent in dynamic performance; and through the parallel manipulator, high-speed motion can be realized, and complex grabbing operation requirements are satisfied.

Owner:TIANJIN UNIV

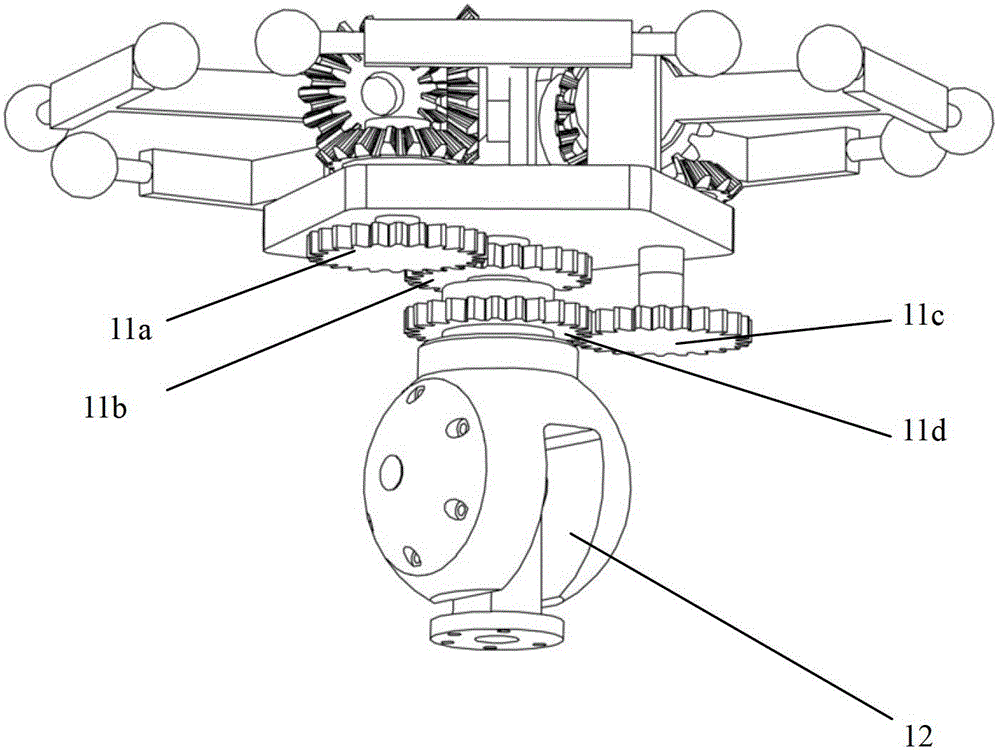

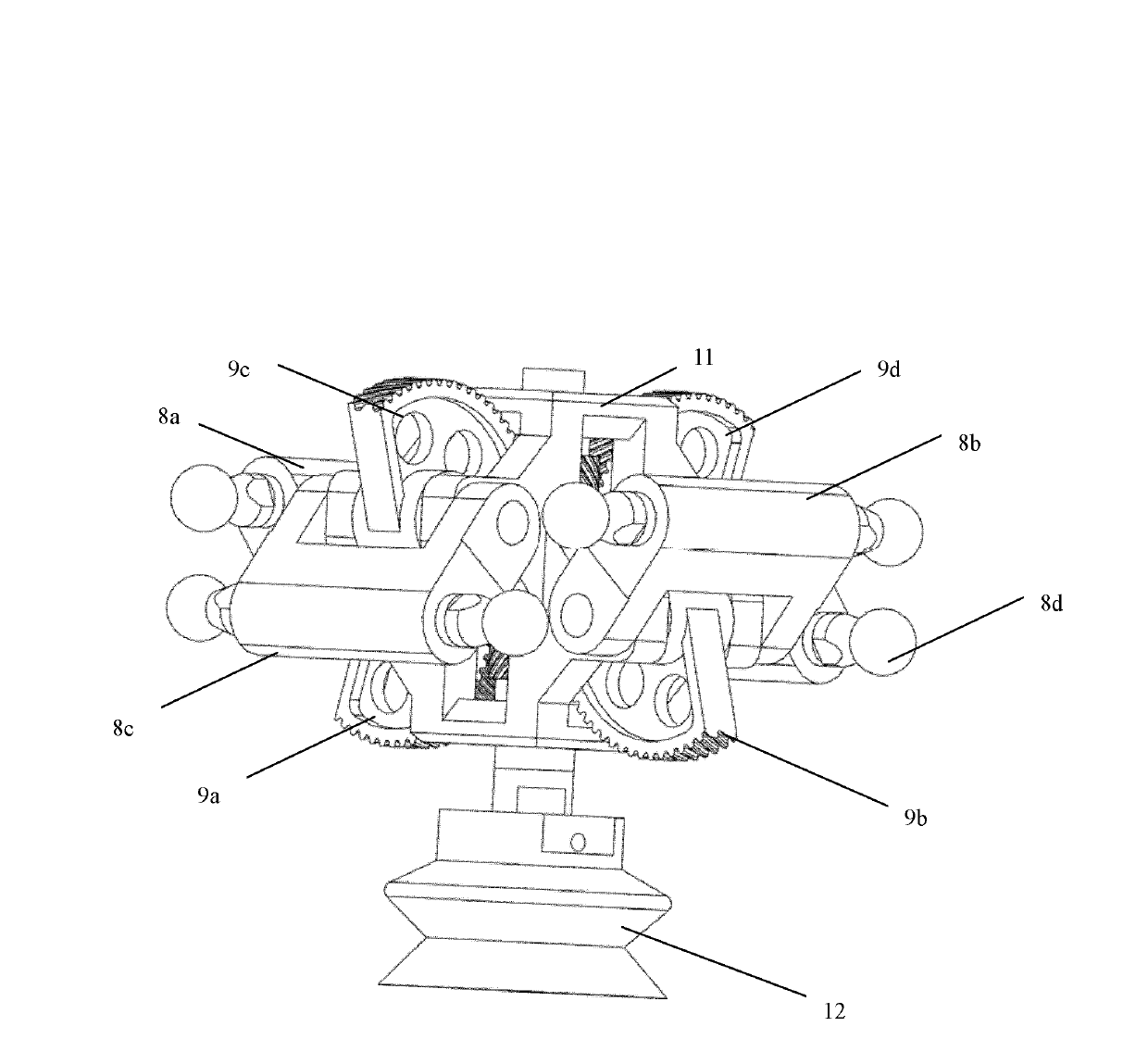

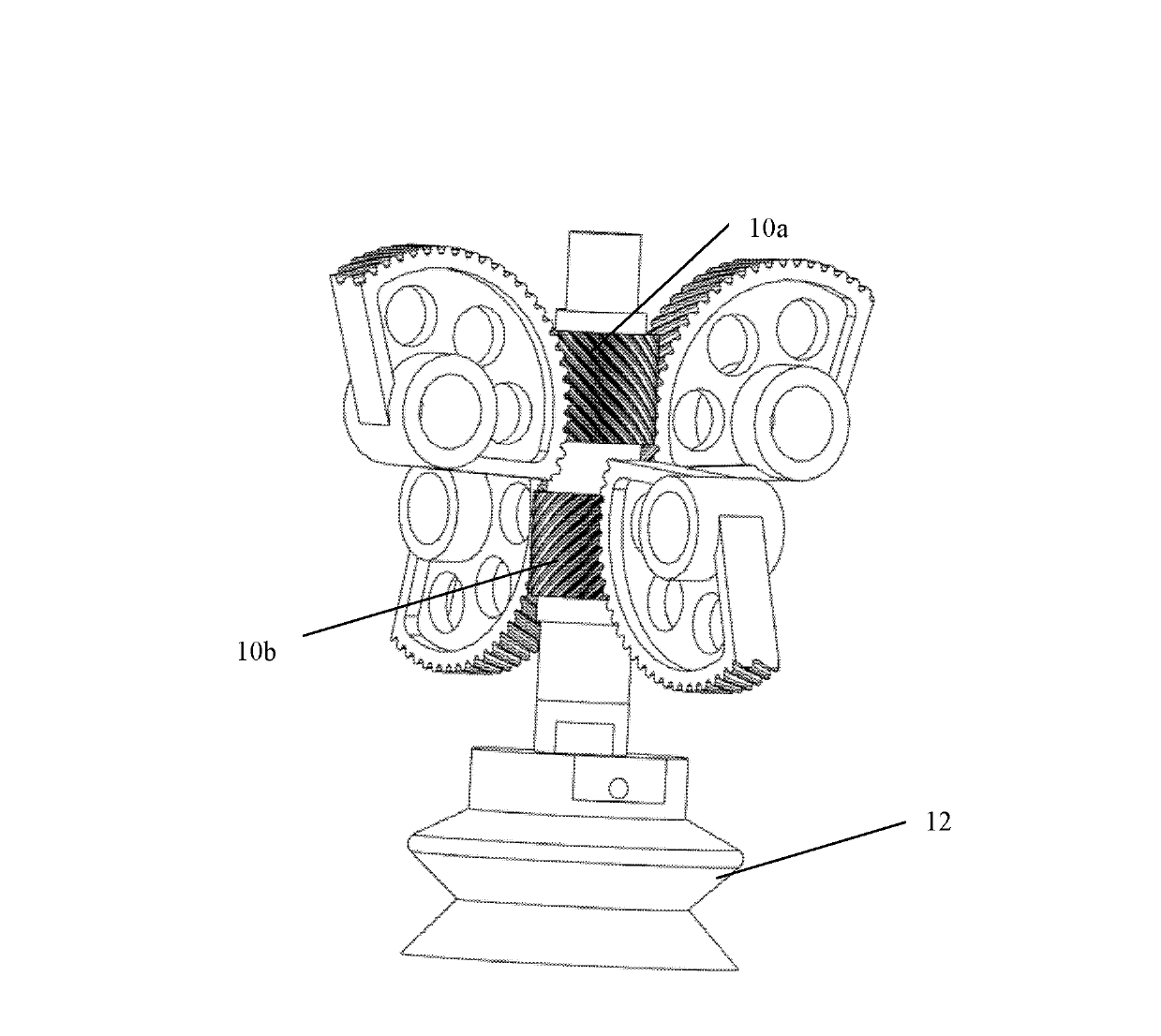

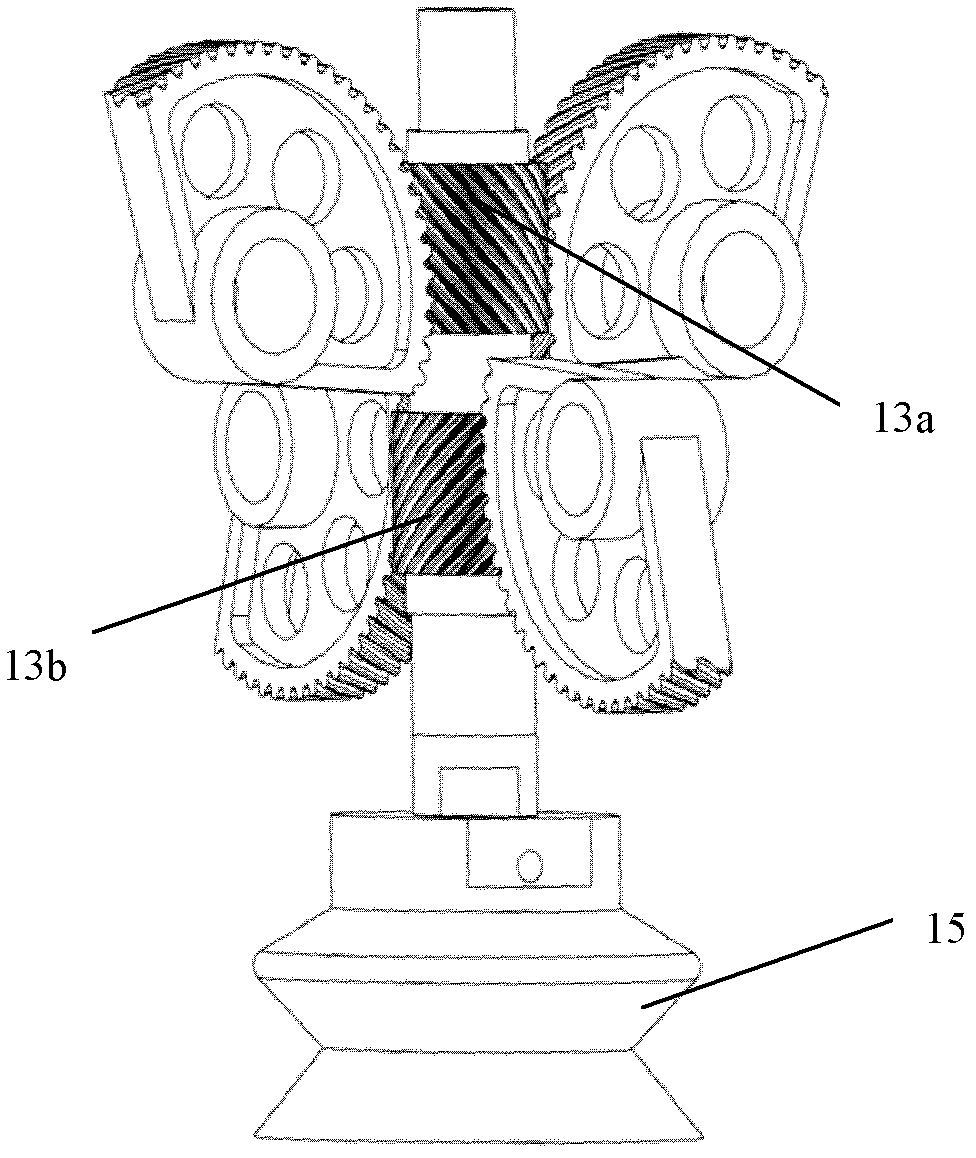

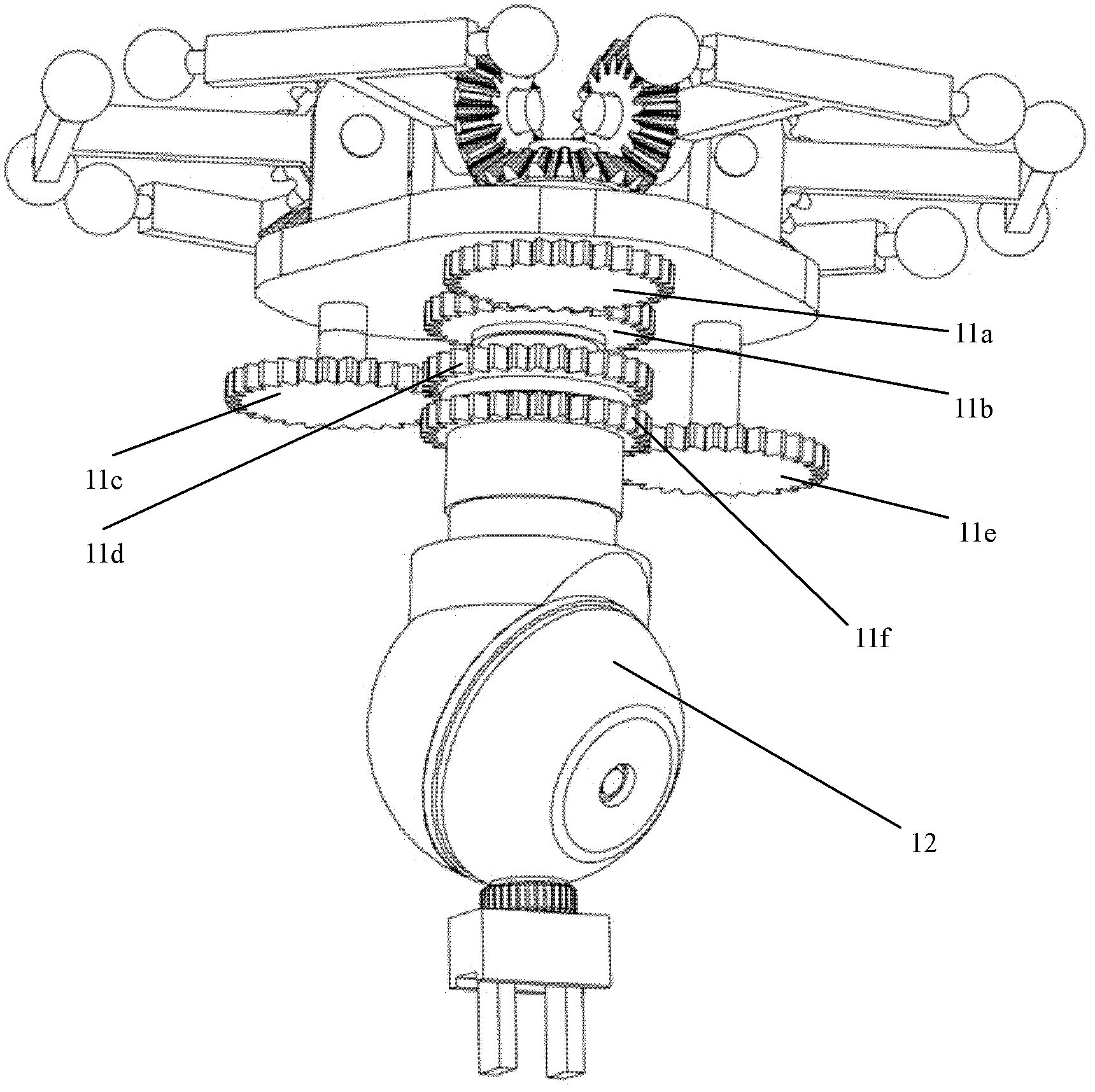

High-speed six-degree of freedom parallel manipulator

InactiveCN102632502AStructural symmetryEven by forceProgramme-controlled manipulatorFixed frameThree degrees of freedom

The invention discloses a high-speed six-degree of freedom parallel manipulator which comprises a fixed frame, a movable platform, a three-degree of freedom wrist and six moving branched chains that are arranged between the fixed frame and the movable platform and have the same structure; the fixed frame is fixedly connected with six driving devices; the movable platform comprises a centre plate, three subangle gear sets and six connecting rods, wherein each subangle gear set comprises a center bevel gear and two subangle bevel gears; the center bevel gears are rotatablely connected with the centre plate; the subangle bevel gears are rotatablely connected with the centre plates; every two subangle bevel gears are arranged at the two sides of each center bevel gear and are meshed and connected with the center bevel gear; one ends of the connecting rods are fixedly connected with a lower connecting shaft, and the other ends of the connecting rods are fixedly connected with one subangle bevel gear in the subangle gear sets; the three-degree of freedom wrist is fixedly connected on the center plate; three groups of gear transmission mechanisms are arranged around the three-degree of freedom wrist; and the three center bevel gears are respectively used for providing three power input for the three groups of gear transmission mechanisms, so that the three-degree of freedom wrist is driven to realize three-dimensional controllable rotation.

Owner:TIANJIN UNIV

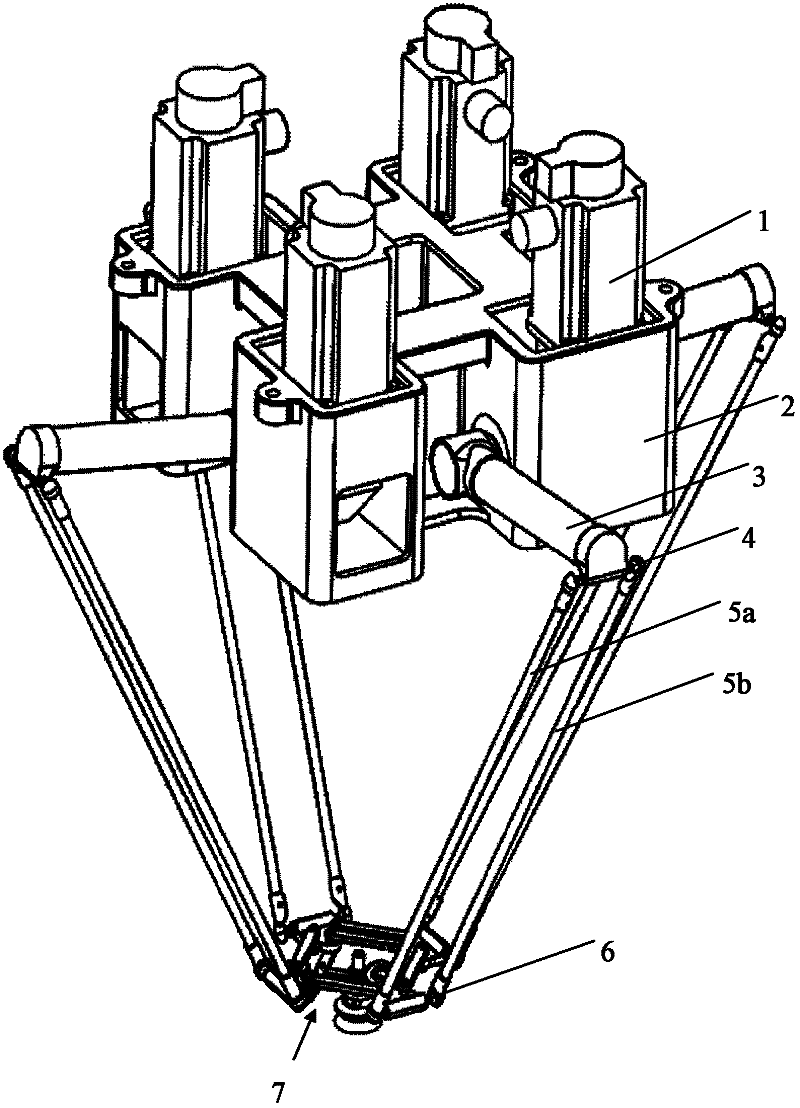

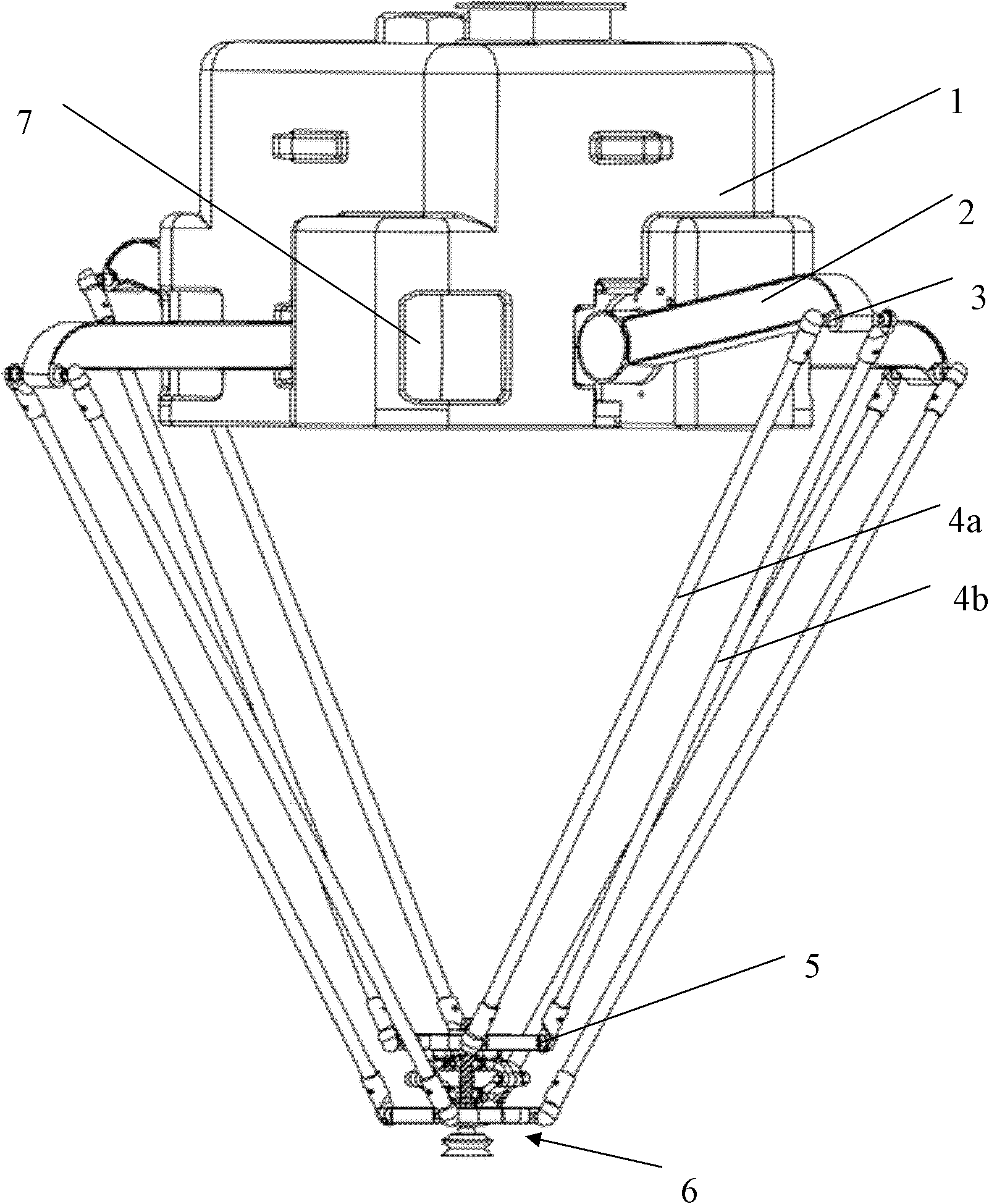

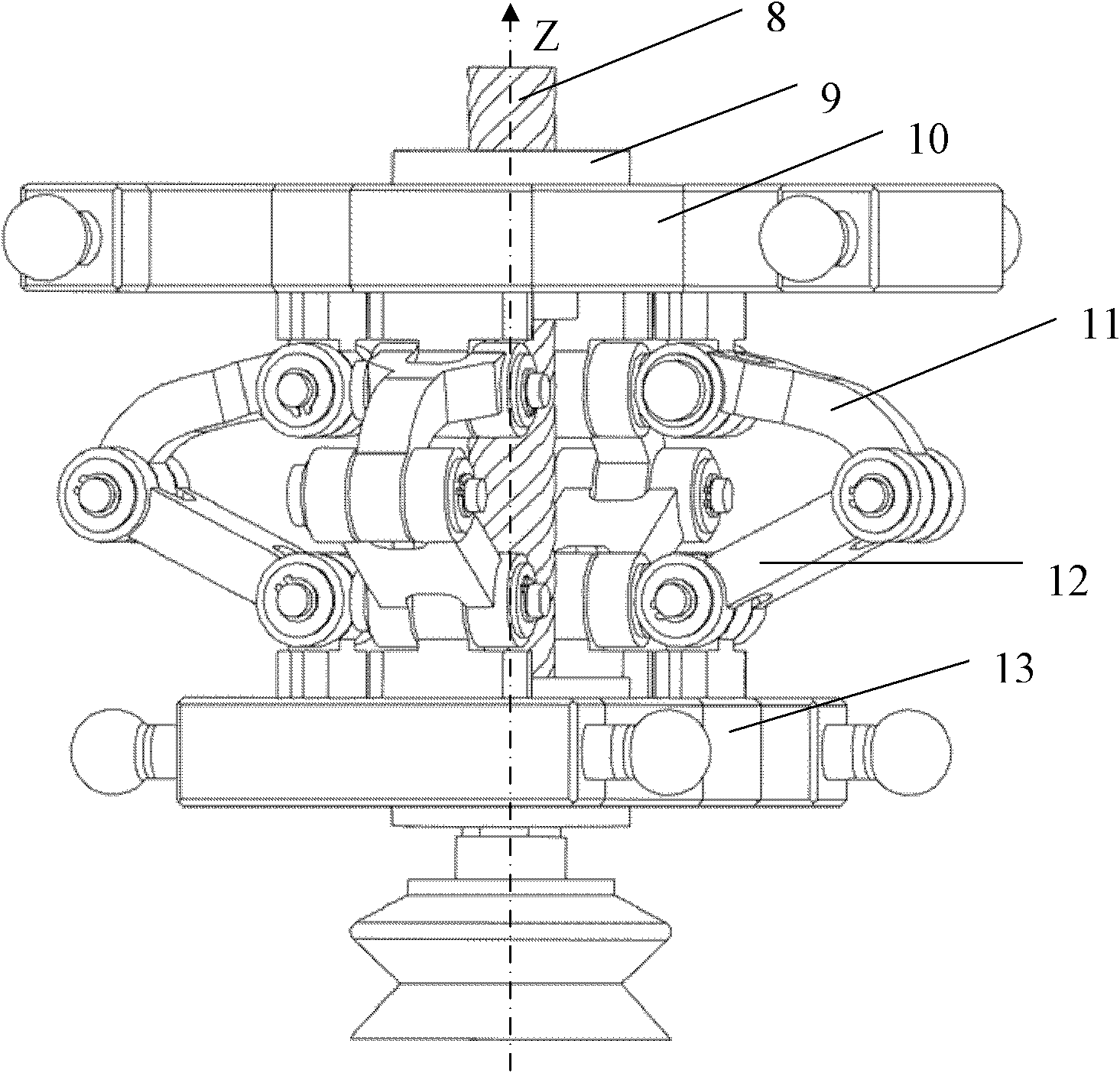

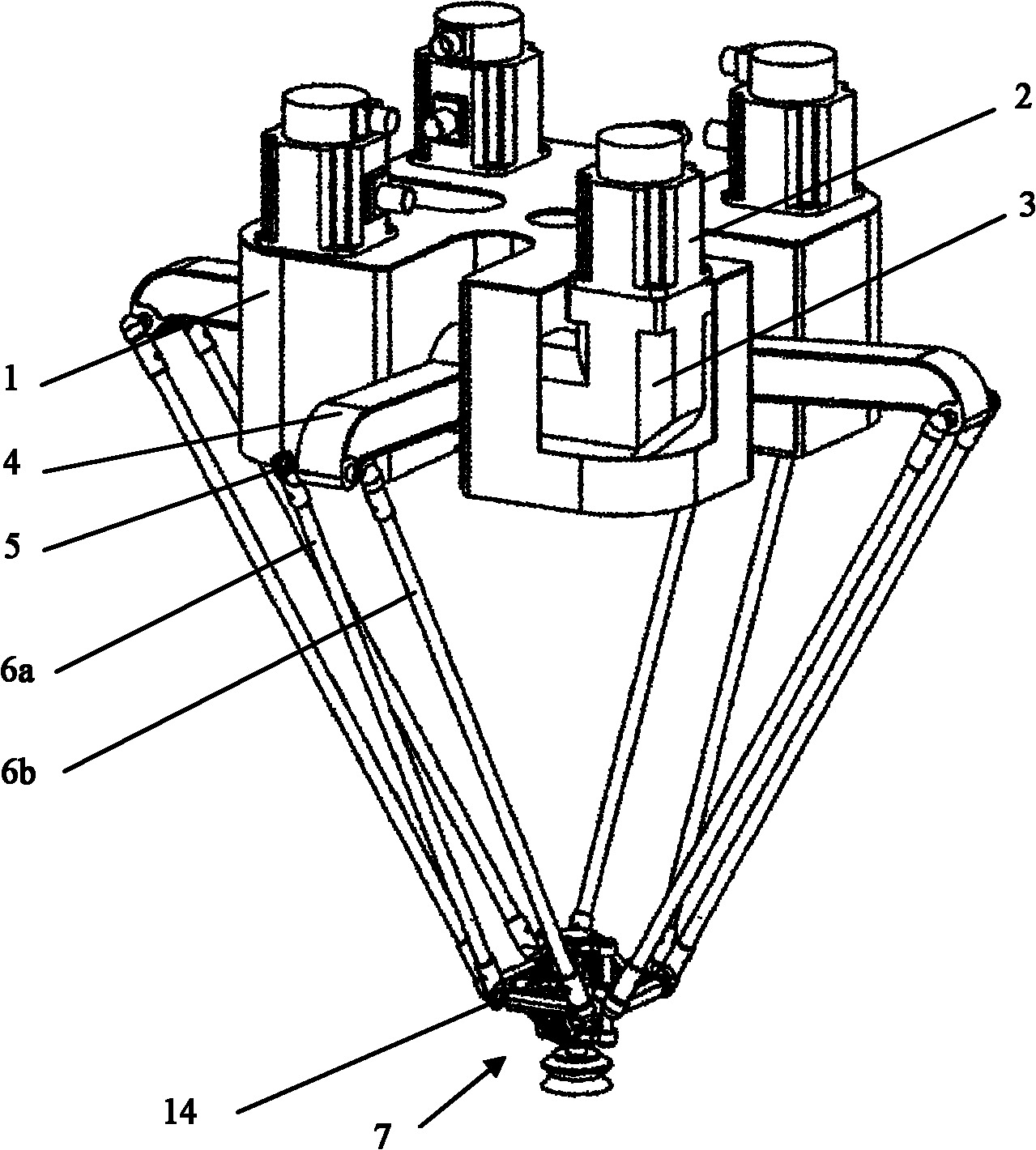

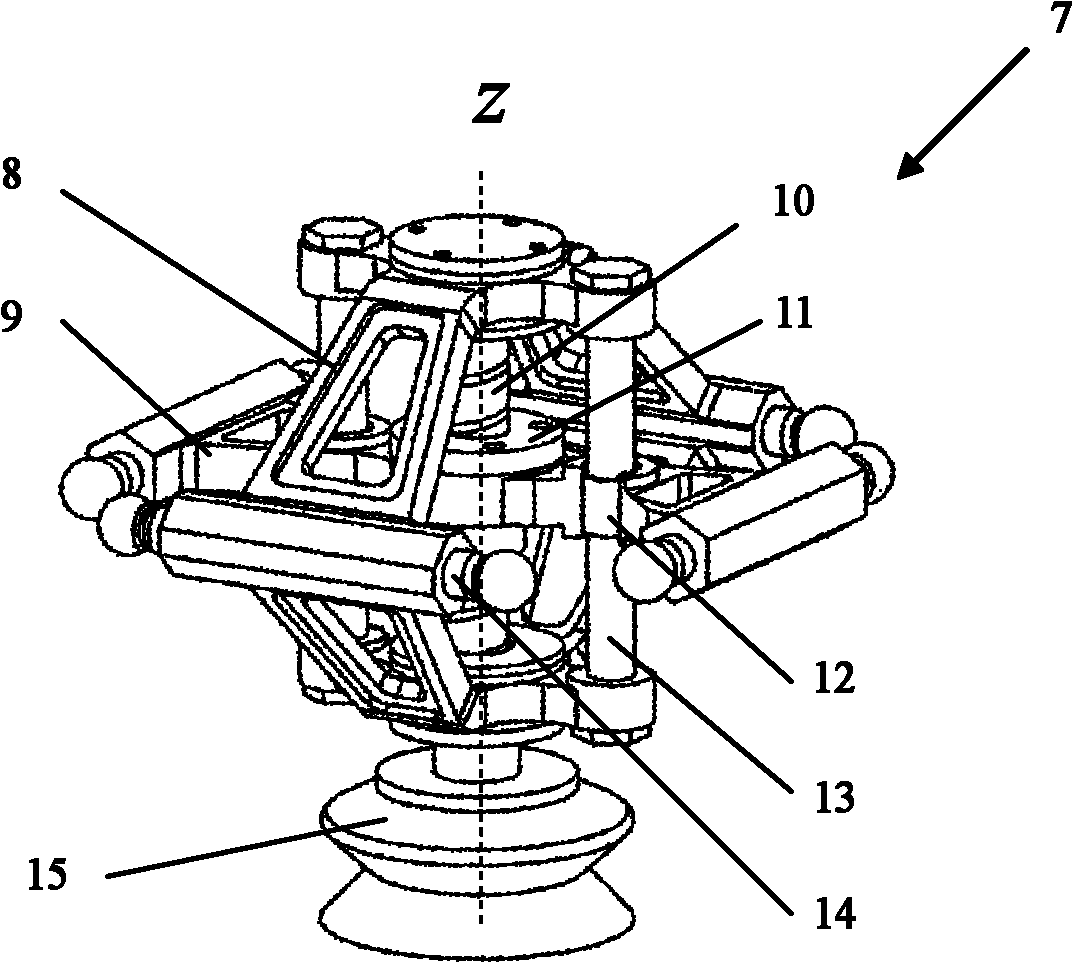

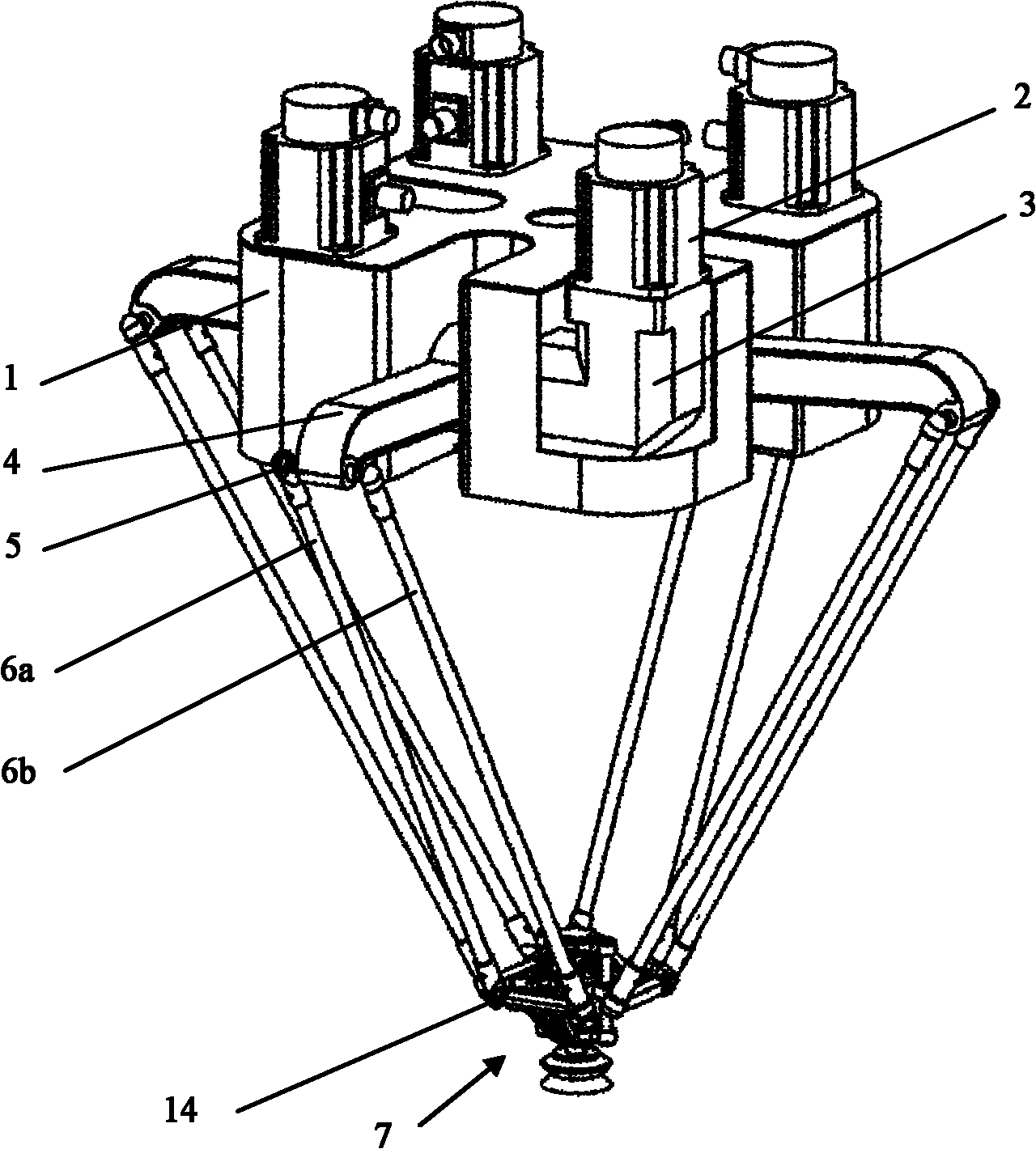

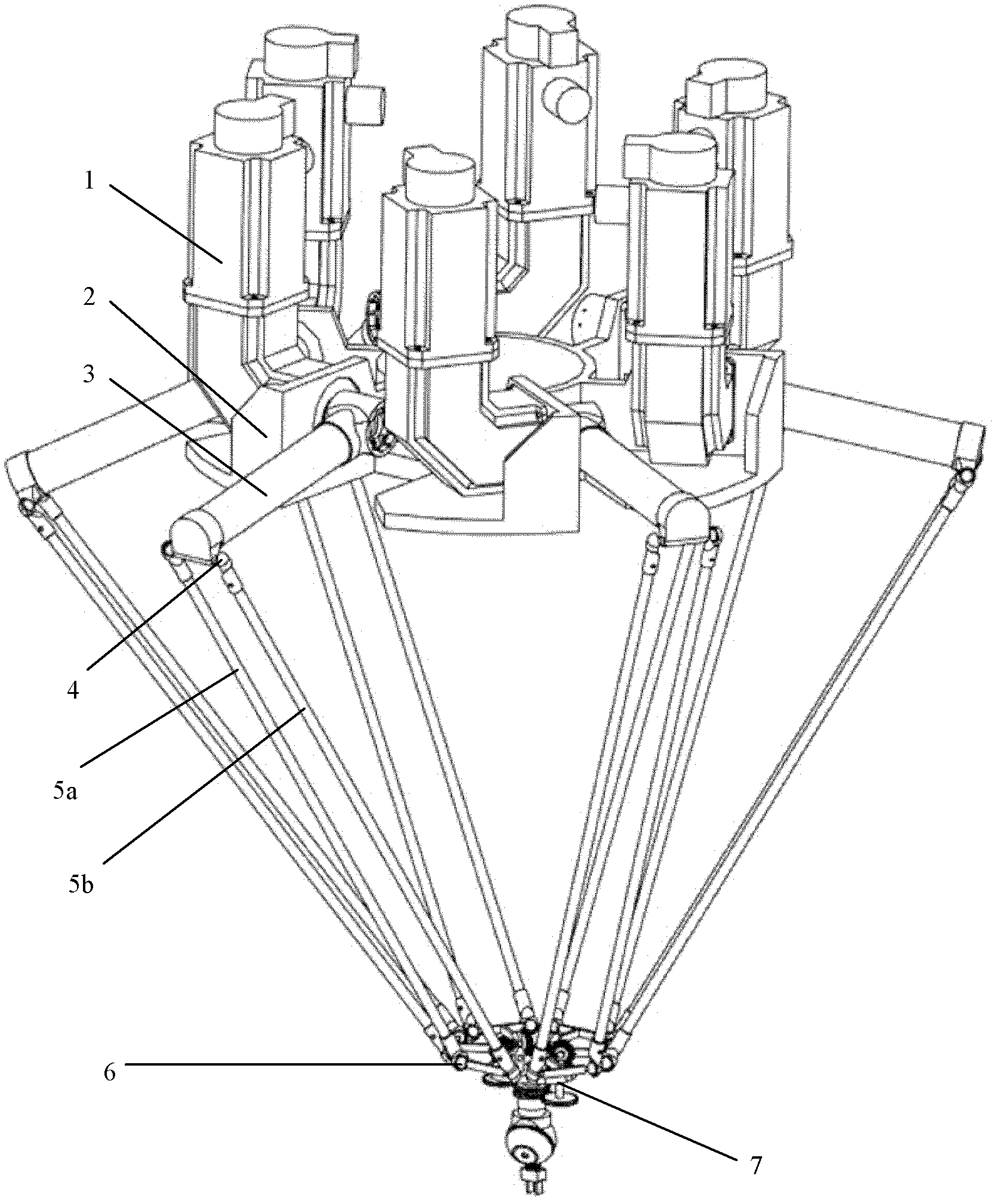

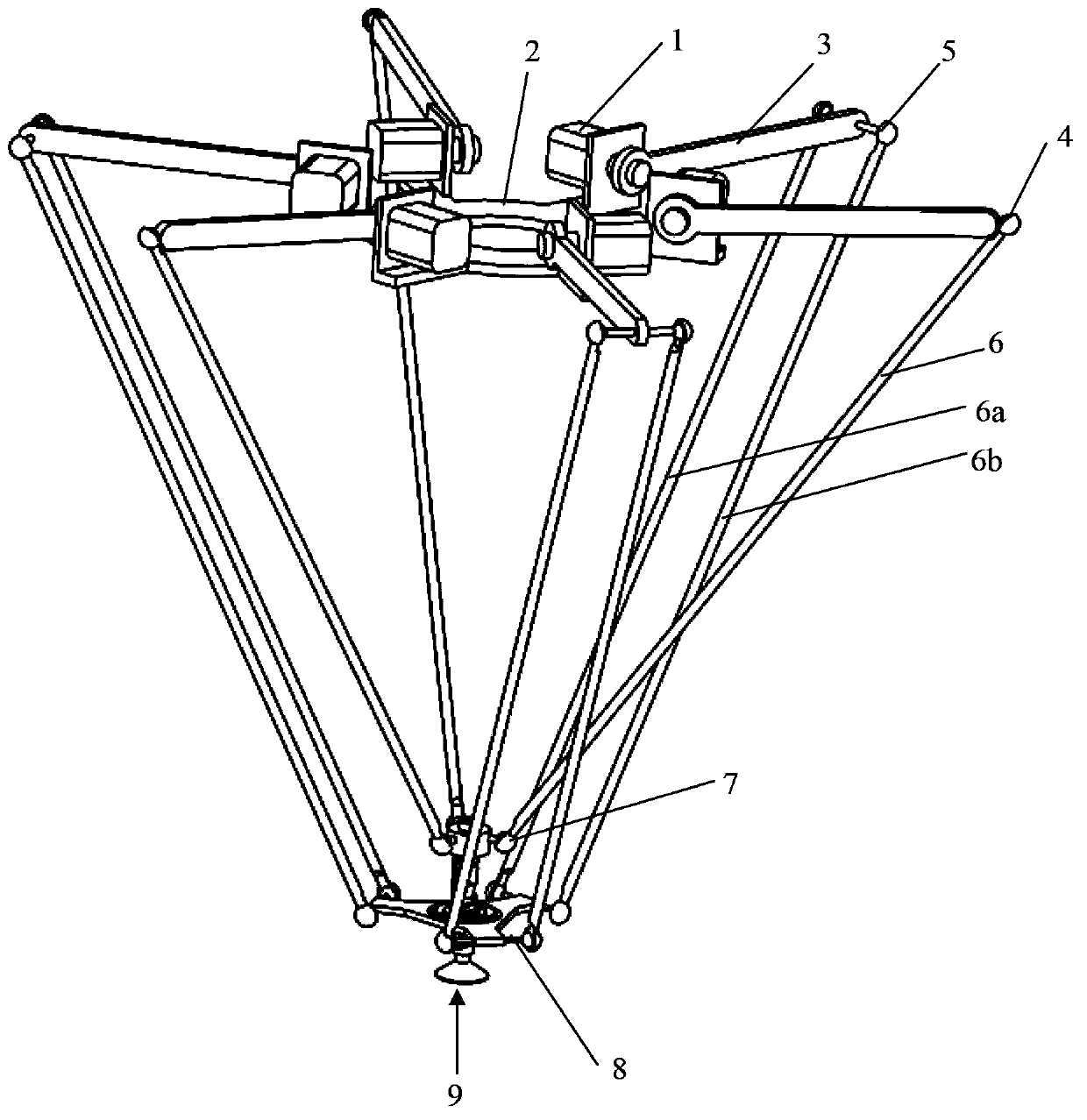

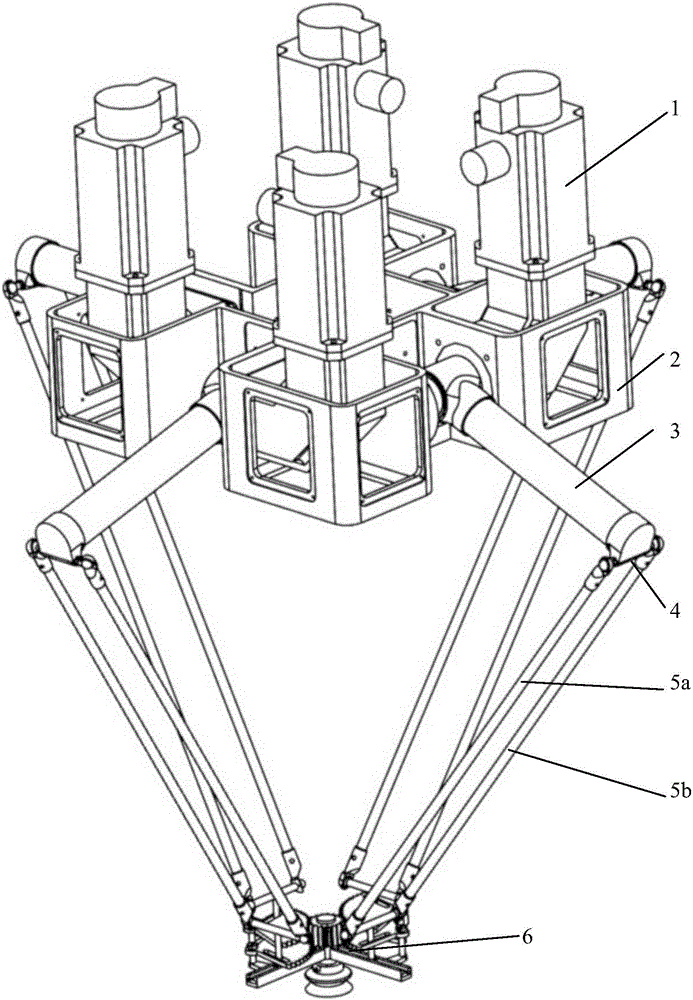

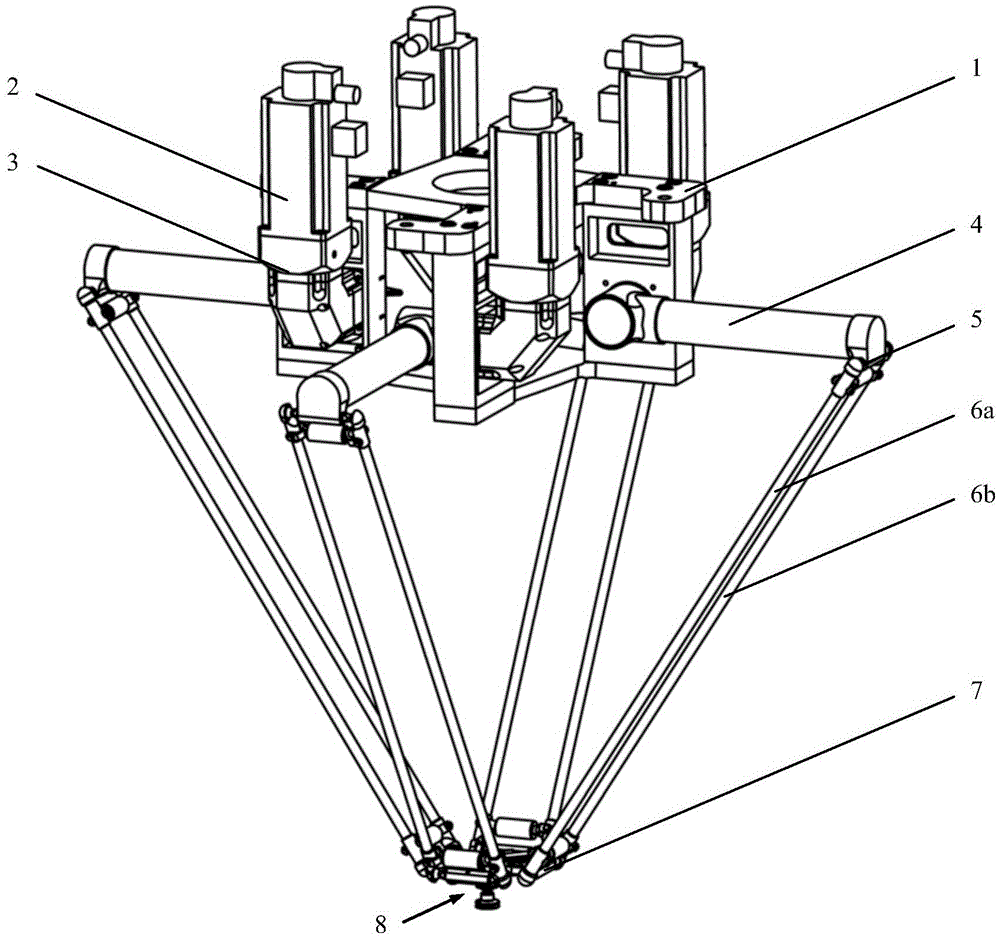

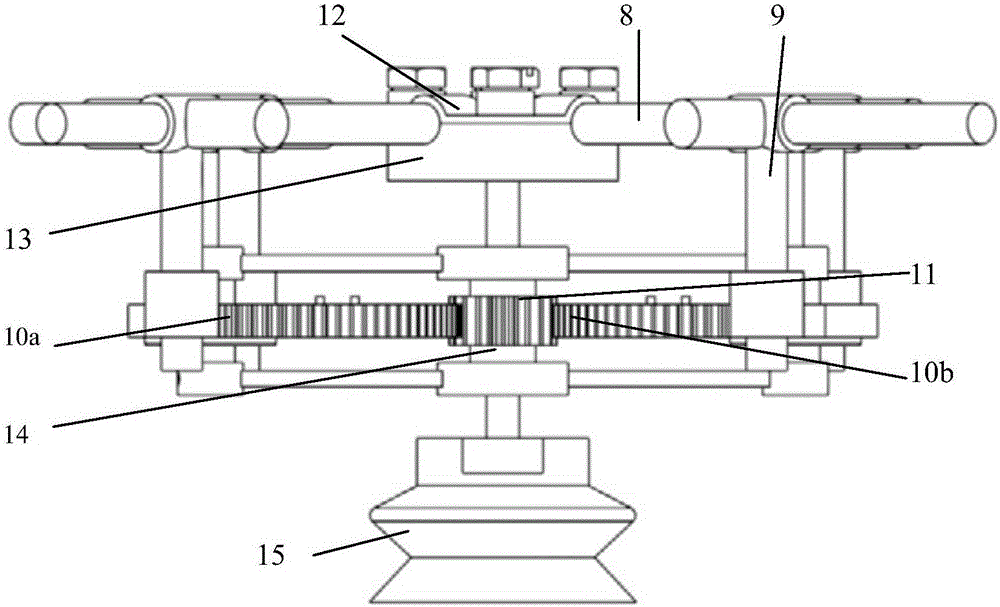

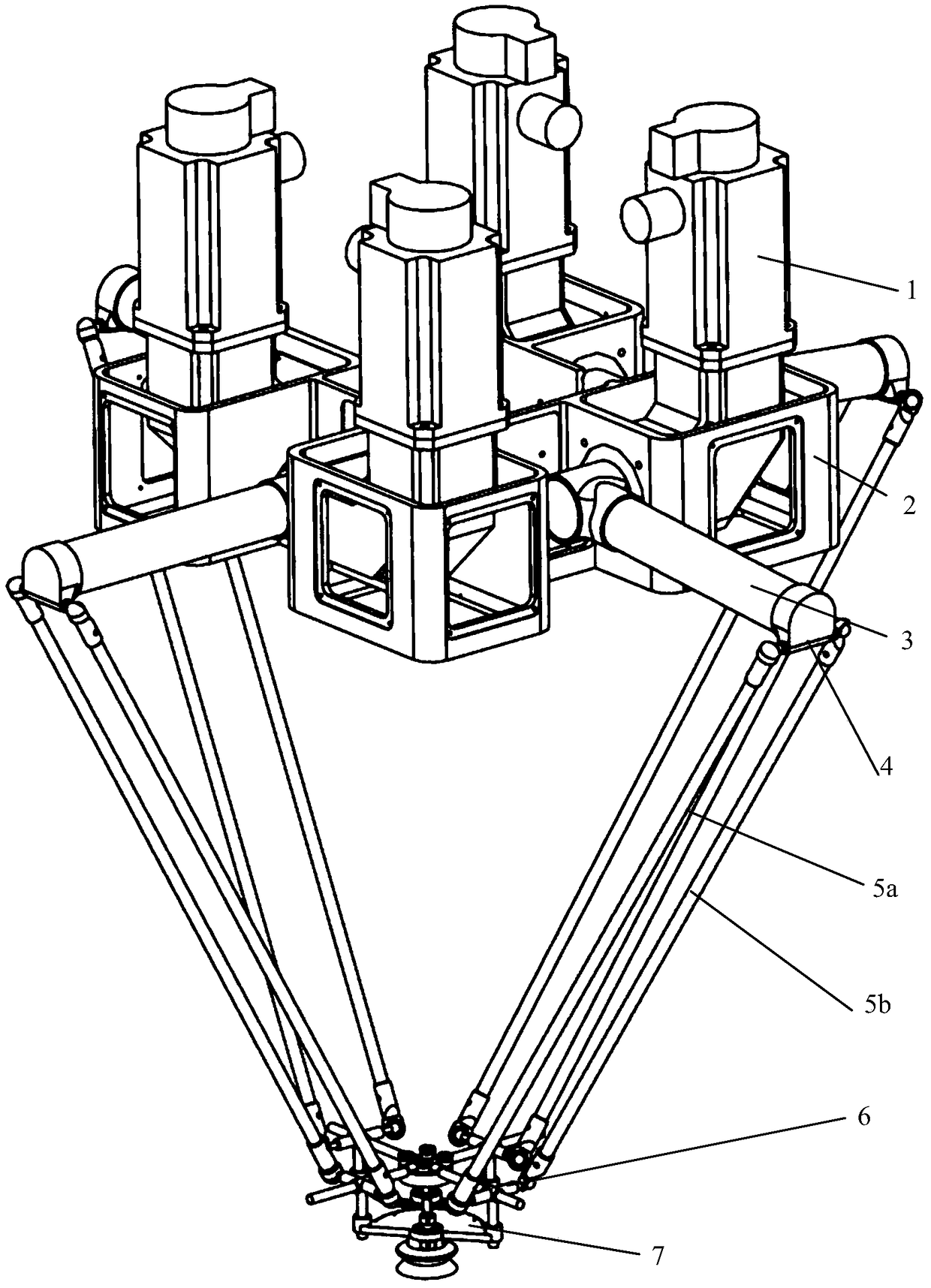

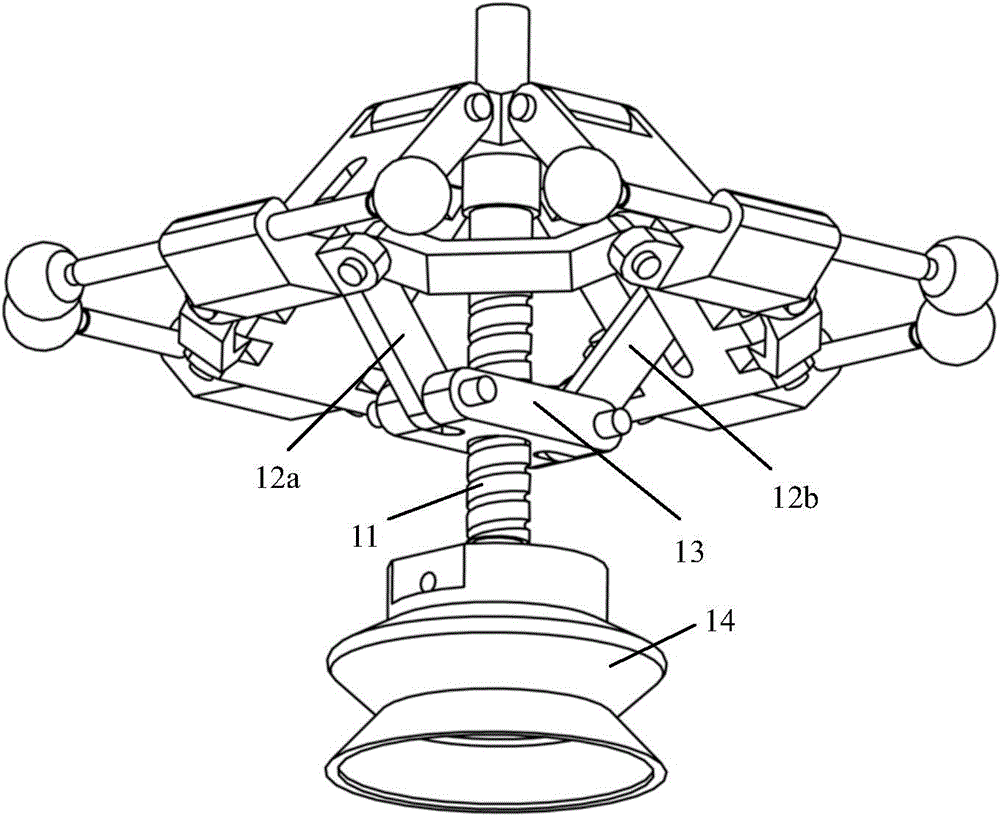

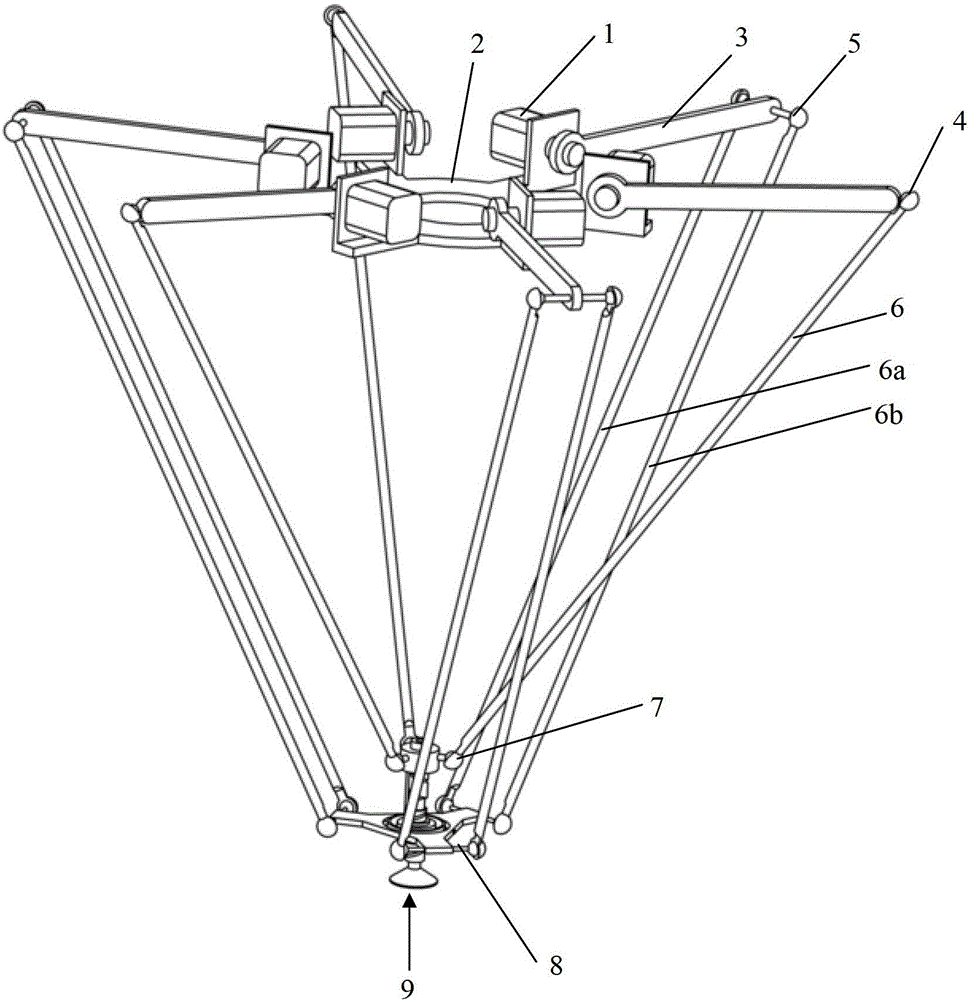

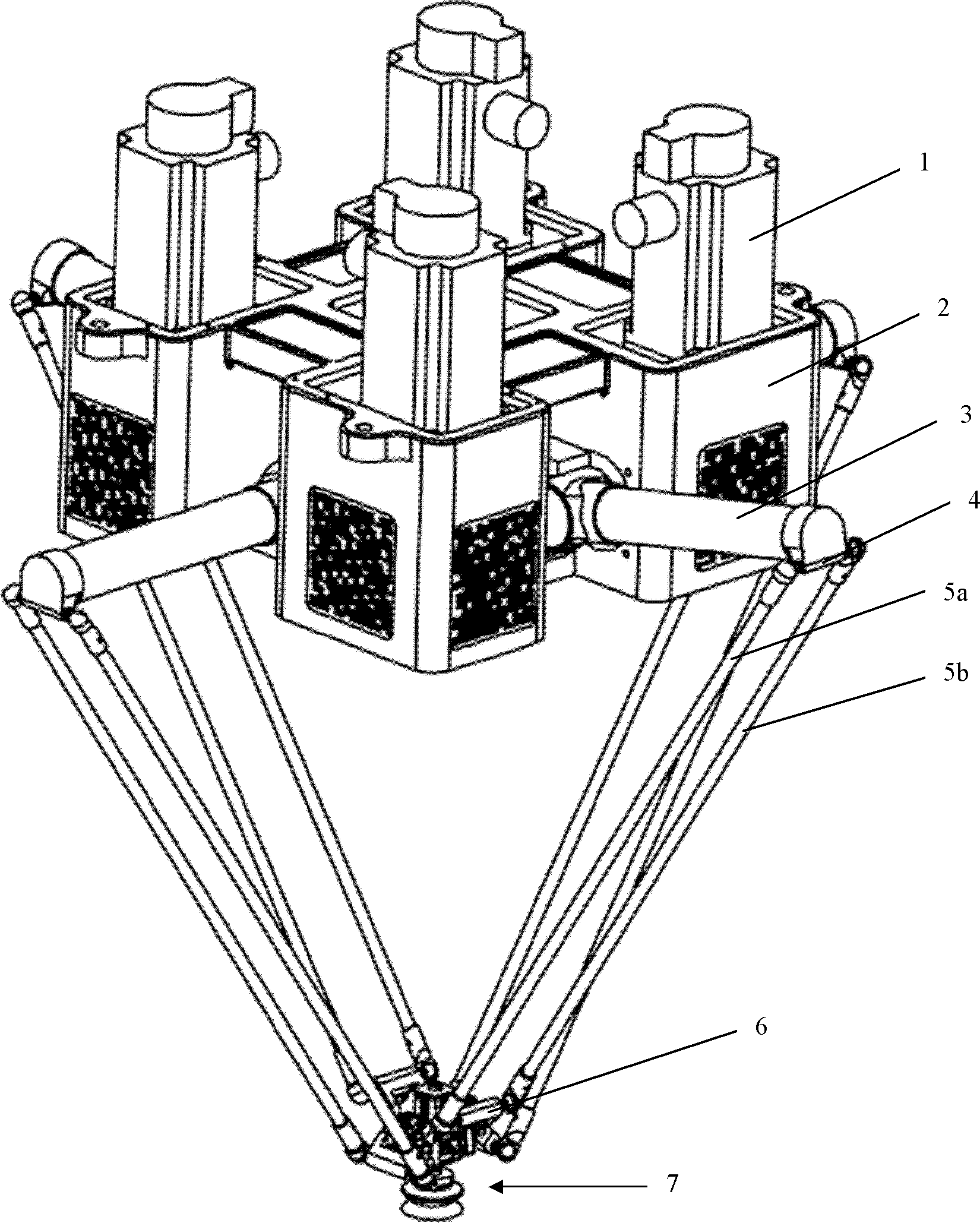

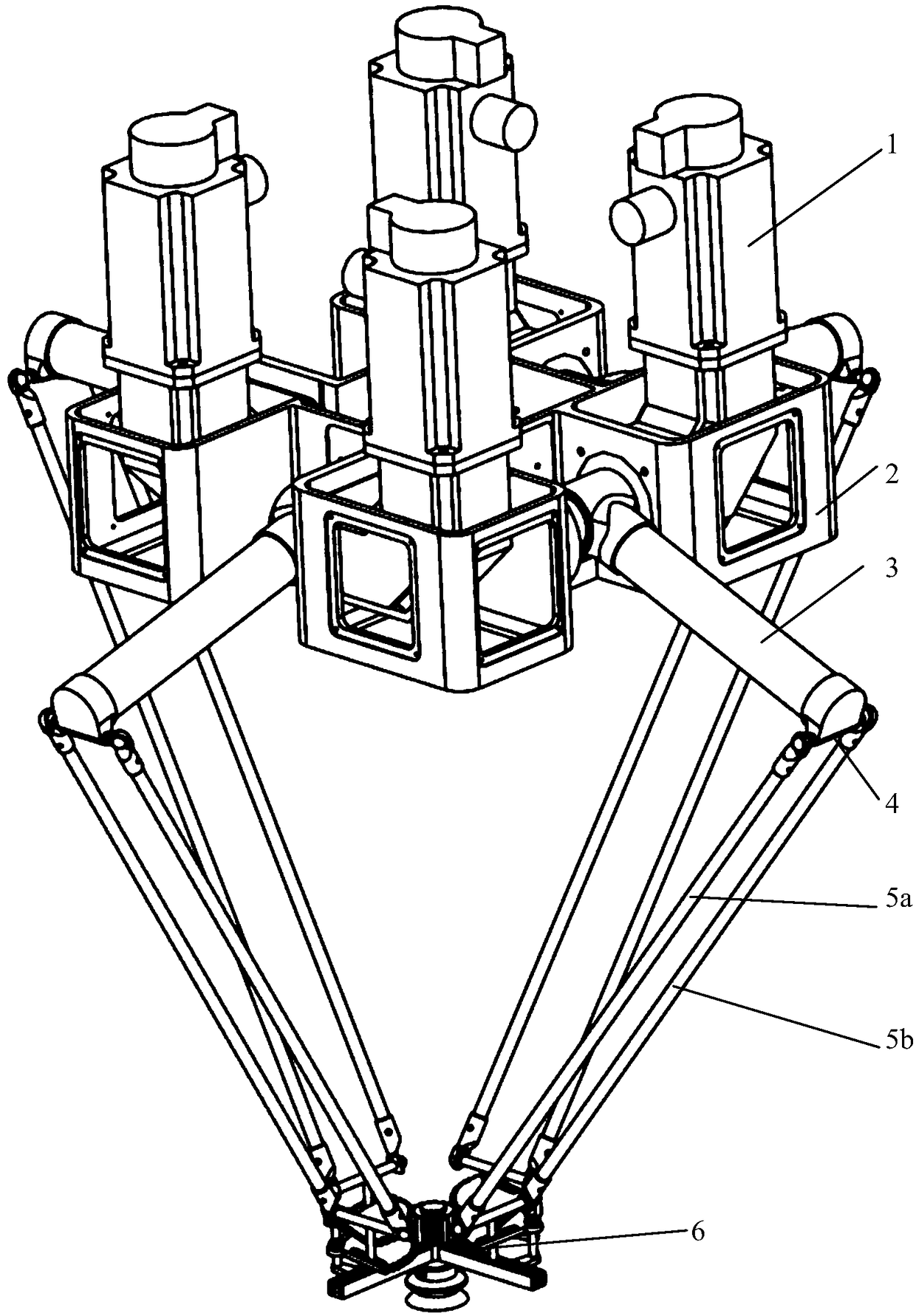

High-speed parallel manipulator with six degrees of freedom

ActiveCN103846911AAvoid magnificationReduce complexityProgramme-controlled manipulatorDegrees of freedomEngineering

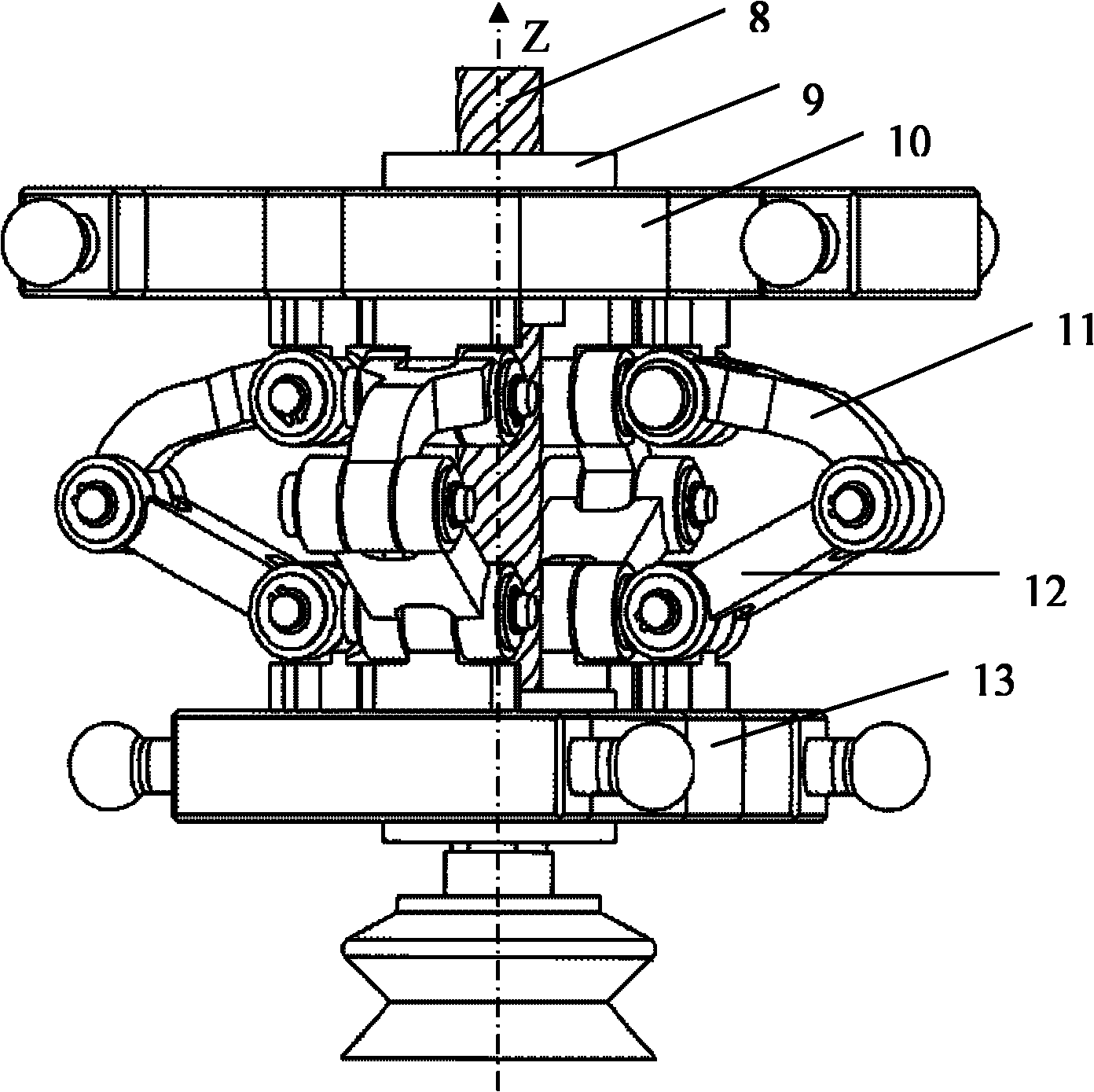

The invention discloses a high-speed parallel manipulator with six degrees of freedom. The high-speed parallel manipulator comprises a fixed rack, a movable platform and six branch chains with the same structures, wherein the fixed rack is provided with six driving devices; each branch chain consists of a near rack rod, an upper connecting shaft, two mutually-parallel far rack rods with equal length and a lower connecting shaft; the output ends of all the driving devices in the branch chains are respectively and fixedly connected with one end of one near rack rod and used for providing one degree of freedom for the corresponding near rack rod; the movable platform comprises an upper platform and a lower platform which are horizontally arranged and are mutually parallel; the upper platform and the lower platform are connected by virtue of a rotating mechanism with a screw rod; the six branch chains are classified into two groups of branch chains at sequential intervals, and the two groups of branch chains are used for respectively driving the upper platform and the lower platform; upper three-dimensional relative movement and lower three-dimensional relative movement are converted into three rotation movements of the screw rod by virtue of the rotating mechanism. The high-speed parallel manipulator is compact in structure, can be used for omitting an amplification mechanism, reducing the complexity of the mechanism, meanwhile reducing the quality of moving parts and improving the movement precision, and is easy for realization of complex picking and placing operations.

Owner:TIANJIN UNIV

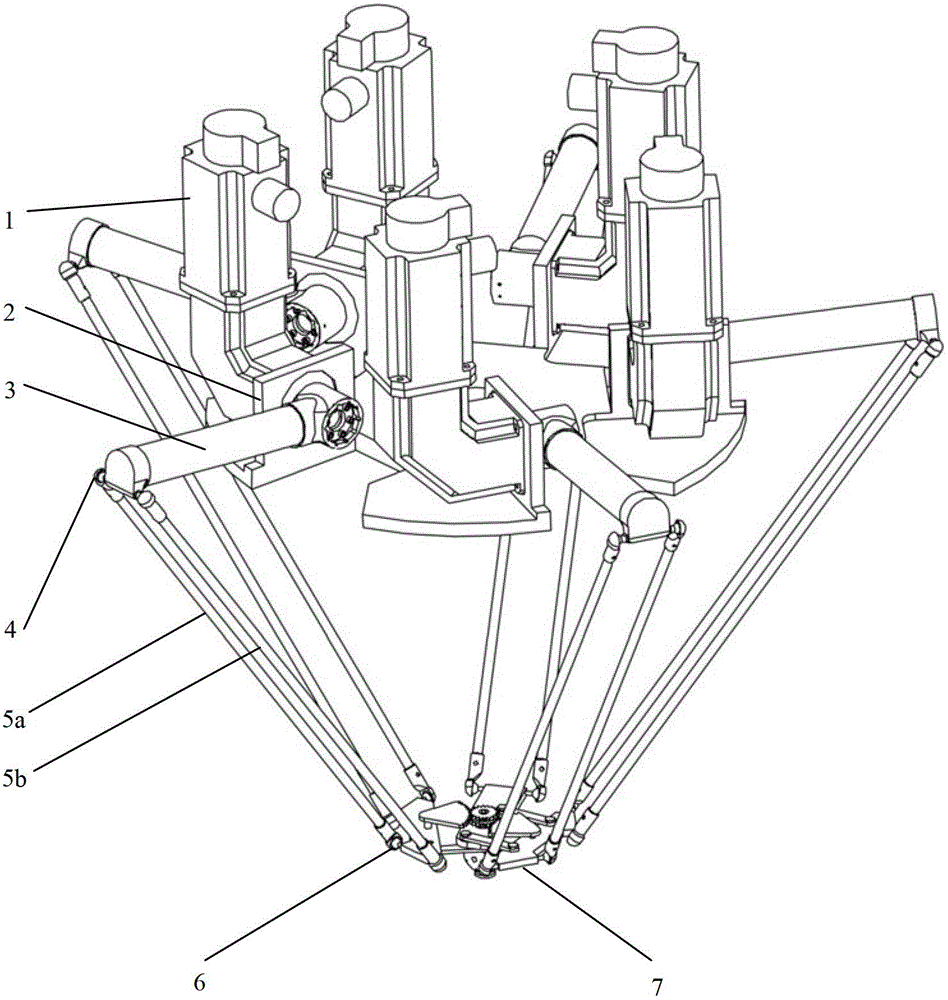

High-speed moving parallel mechanical arm with six degrees of freedom

InactiveCN102848383AThe overall structure is symmetricalEven by forceProgramme-controlled manipulatorJointsSix degrees of freedomManipulator

The invention discloses a high-speed moving parallel mechanical arm with six degrees of freedom. The mechanical arm comprises a fixed mount, a movable platform, a three-degree-of-freedom wrist, and six moving branch chains which are arranged between the fixed mount and the movable platform and are of a same structure, wherein the movable platform comprises a central plate, three ball arm seats and three groups of connecting rods; each connecting rod group is composed of two parallel connecting rods with the same length; the ball arm seats are rotationally connected with the central plate through one group of connecting rods to form a group of parallelogram structures; the movable platform is provided with three groups of parallelogram structures; the three-degree-of-freedom wrist is fixedly connected with the central plate; three input axes of the three-degree-of-freedom wrist are arranged coaxially or in parallel and are parallel to a rotating axis on the central plate; three groups of gear mechanisms are arranged in the three groups of parallelogram structures; and the rotation of the connecting rods in each group of parallelogram structures relative to the central plate or the parallel movement of the ball arm seats relative to the central plate is converted into the controllable movement of the three-degree-of-freedom wrist.

Owner:天津大学中原先进技术研究院(开封)有限公司

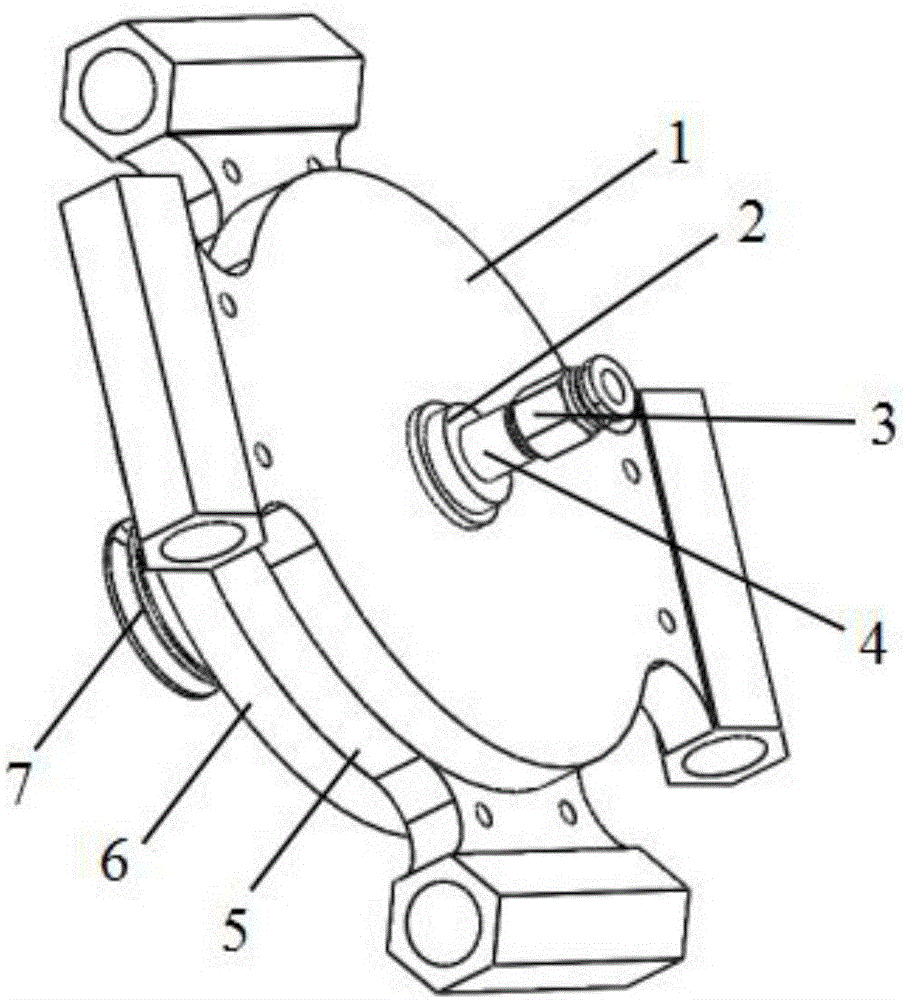

High-speed parallel manipulator with three-dimensional translation and one-dimensional rotation

InactiveCN102848382AThe overall structure is simpleSmall sizeProgramme-controlled manipulatorEngineeringParallel manipulator

The invention discloses a high-speed parallel manipulator with three-dimensional translation and one-dimensional rotation. The manipulator comprises a fixing frame, a moving platform and four branch chains which have the same structure and are arranged between the fixing frame and the moving platform symmetrically, wherein four drive devices are fixedly connected with the fixing frame, the moving platform comprises four gear handles, four bevel sectors, two bevel gears, a base and an end effector, the end effector is hinged with the base in a rotary mode, two bevel gears have opposite spin directions, the bevel gears and the end effector are fixed coaxially, the four gear handles are arranged at an angle of 90 degrees and are respectively connected with the base through rotary shafts in a rotary mode, each of the bevel sectors is fixedly connected with the rotary shaft of one of the gear handles respectively, and the two pairs of bevel sectors which are arranged opposite and the two bevel gears mesh respectively. By the aid of the meshing constraint action between the bevel sectors and the bevel gears of which the spin directions are opposite, the three-dimensional translation of the base and the end effector rotation relative to the base can be achieved when the drive devices drive corresponding branch chains to move.

Owner:TIANJIN UNIV

Parallel mechanism capable of realizing three-dimensional translation and three-dimensional rotation

InactiveCN103386681AAvoid magnificationReduce complexityProgramme-controlled manipulatorDegrees of freedomEngineering

The invention discloses a parallel mechanism capable of realizing three-dimensional translation and three-dimensional rotation. The parallel mechanism comprises a fixed frame and a movable platform, wherein the fixed frame is fixedly connected with six driving devices, the movable platform comprises a central plate and a rocking rod, the central plate and the rocking rod are rotatably connected by utilizing a hooke joint, and the upper part and the lower part of the rocking rod are respectively a first lead screw and a second lead screw with different rotation directions; three first branch chains are connected between the fixed frame and the central plate, and three second branch chains are connected with the fixed frame and three bulb rods; the rocking rod is driven by the three first branch chains to realize the three-dimensional translation, and the rocking rod is driven by the three second branch chains to realize two-dimensional rotation relative to the central plate by the hooke joint; the rocking rod realizes autorotation by the relative movement of a nut and a hooke inner ring; and therefore, the rocking rod has three translation degrees of freedom and also has three rotation degrees of freedom. The parallel mechanism capable of realizing the three-dimensional translation and the three-dimensional rotation, which is disclosed by the invention, has the advantages that the structure is simple and compact, six degrees of freedom by utilizing the hooke joint and a screw pair are smartly realized, the mechanism complexity is reduced and the high-speed, high-precision complex grabbing is easily realized.

Owner:TIANJIN UNIV

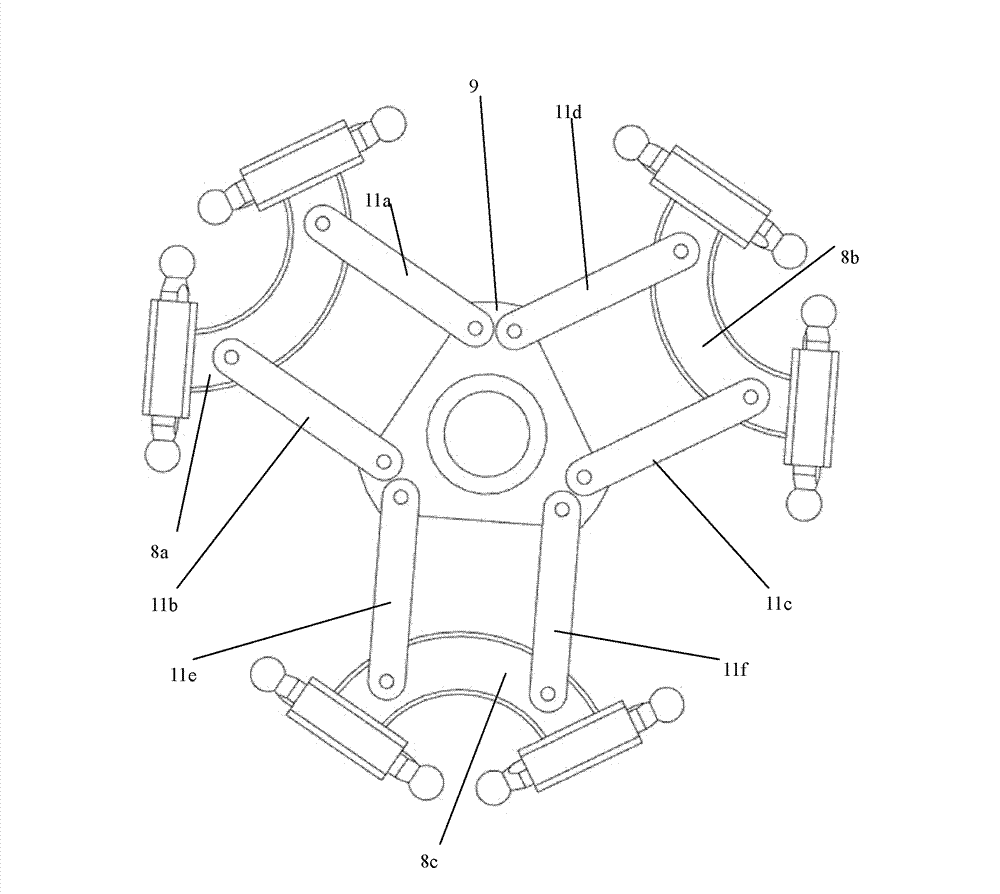

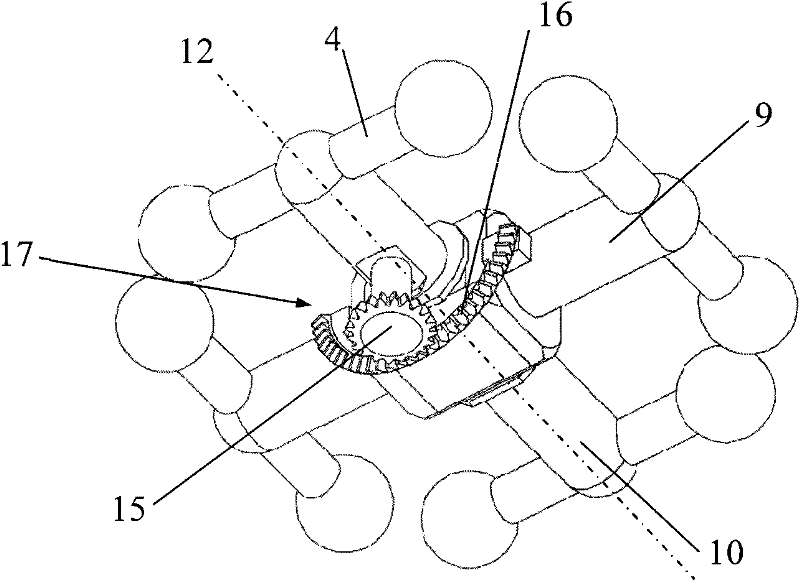

Rocker dislocation-type four-branch-chain three-translation one-rotation high-speed parallel manipulator

InactiveCN106426115ACompact structureSimple structureProgramme-controlled manipulatorEngineeringParallel manipulator

The invention discloses a rocker dislocation-type four-branch-chain three-translation one-rotation high-speed parallel manipulator. The rocker dislocation-type four-branch-chain three-translation one-rotation high-speed parallel manipulator comprises a fixed rack, a movable platform and four moving branch chains with the same structure, wherein spatial three-dimensional translation of the movable platform is ensured through the four moving branch chains with the same structure; the movable platform comprises a central gear, a platform and an end effector; four guide rails which are of centrally-radial arrangement are arranged on the platform; a sliding block is arranged in each guide rail; the central gear is meshed with four identical arc gears; a guiding groove is formed in the disc surface of each arc gear; the four sliding blocks separately drive the arc gears to move through the guiding grooves; and a rotary shaft is driven to rotate through the gears, so that the end effector has three degrees of translation freedom and one degree of rotation freedom. The movable platform is compact in structure and is symmetrically arranged; movement is flexible; stress is uniform; movement precision is high; the integral structure is good in stability; the structure is simple; manufacture and repair are convenient; and requirement of complex grabbing and releasing operation is met.

Owner:TIANJIN UNIV

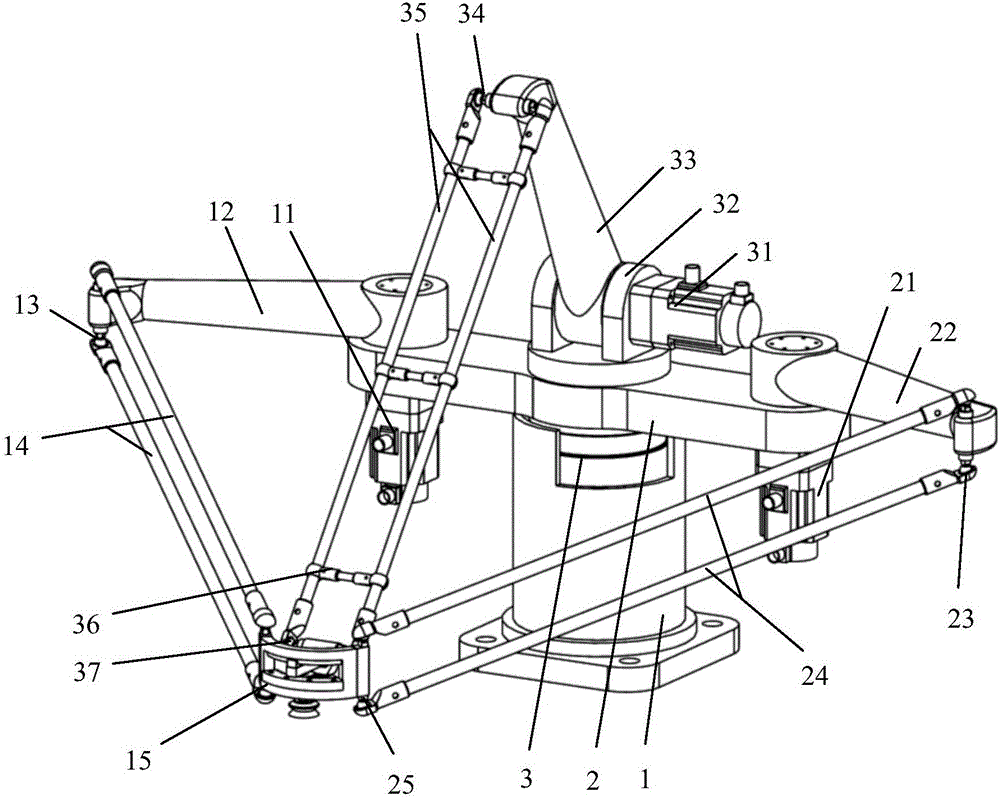

Four-degree-of-freedom robot mechanism capable of realizing whole-circle rotation

ActiveCN106272362AMeet the requirements of complex pick and place operationsLarge rack volume ratioProgramme-controlled manipulatorFixed frameHinge angle

The invention discloses a four-degree-of-freedom robot mechanism capable of realizing whole-circle rotation. The four-degree-of-freedom robot mechanism comprises a fixed frame, a movable platform, a rotary table rotationally connected to the fixed frame, a first branched chain, a second branched chain and a third branched chain, wherein the first, second and third branched chains are arranged between the rotary table and the movable platform; each branched chain comprises a near-frame bar and two far-frame bars; the far-frame bars are parallel to and as long as each other; the third branched chain further comprises a conversion fork fixedly connected with the fixed frame; one end of each near-frame bar is connected with the rotary table or the conversion fork; the other end of each near-frame bar is connected with the corresponding far-frame bars via spherical hinges; the far-frame bars are connected with the movable platform via spherical hinges; the movable platform comprises a main platform and an accessory platform which can rotate relatively. The four-degree-of-freedom robot mechanism can realize whole-circle rotation, and has the advantage of large working space-rack size ratio.

Owner:NANJING UNIV OF SCI & TECH

Parallel mechanism with three-dimensional translation and one-dimensional rotation

InactiveCN101708611BIncrease stiffnessSimple structureProgramme-controlled manipulatorMechanical apparatusFixed frameRotational degrees of freedom

Owner:TIANJIN UNIV

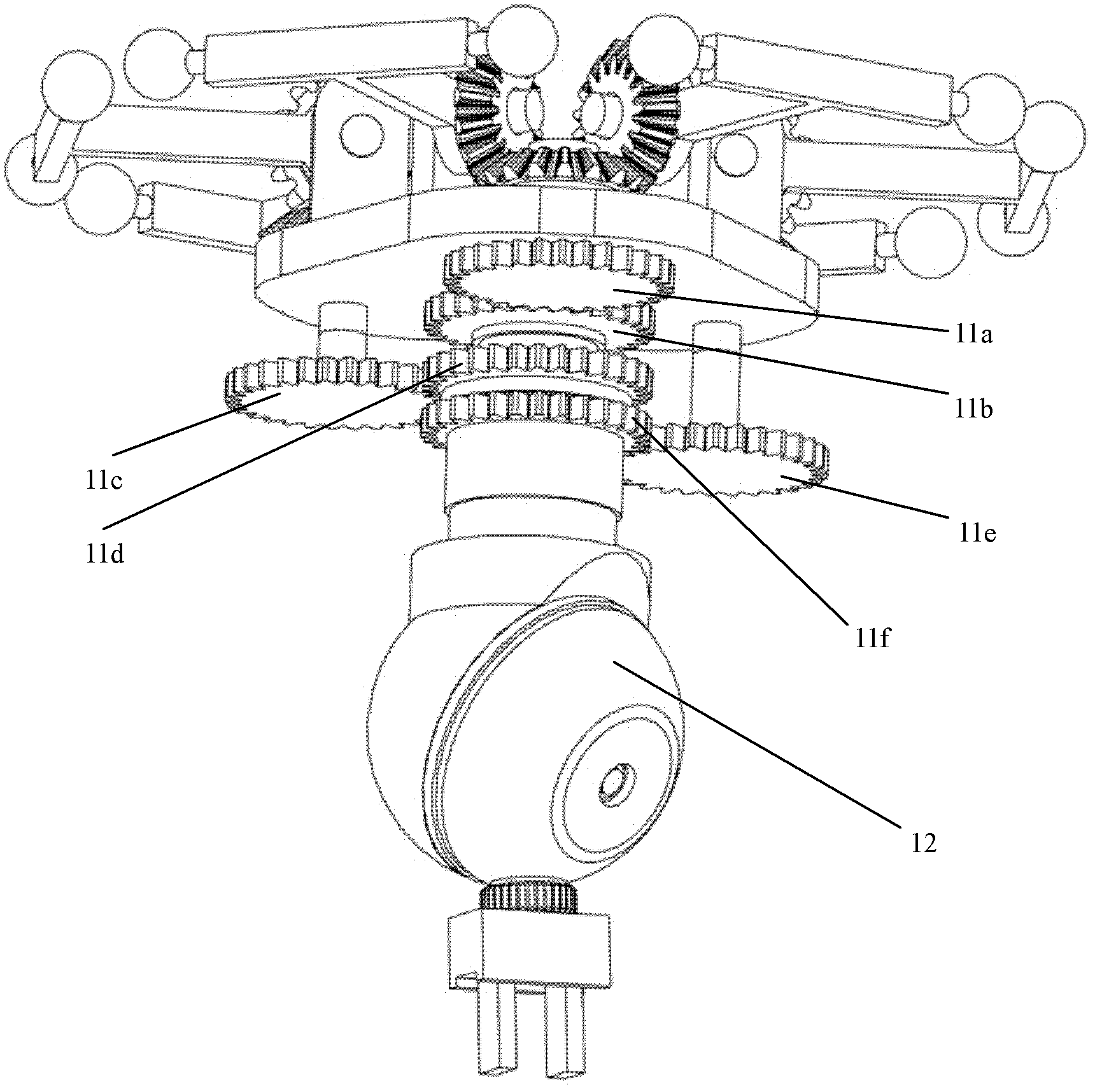

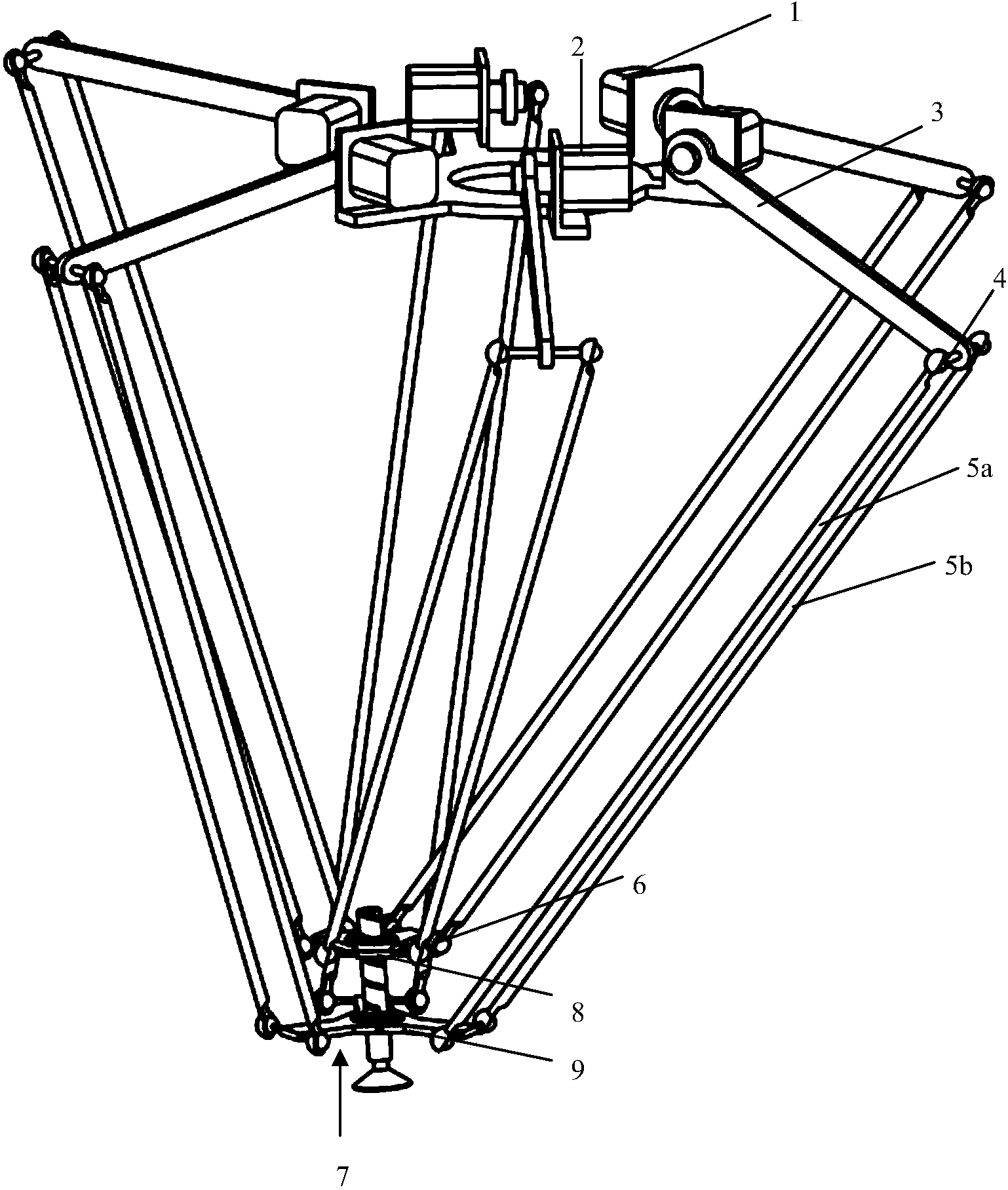

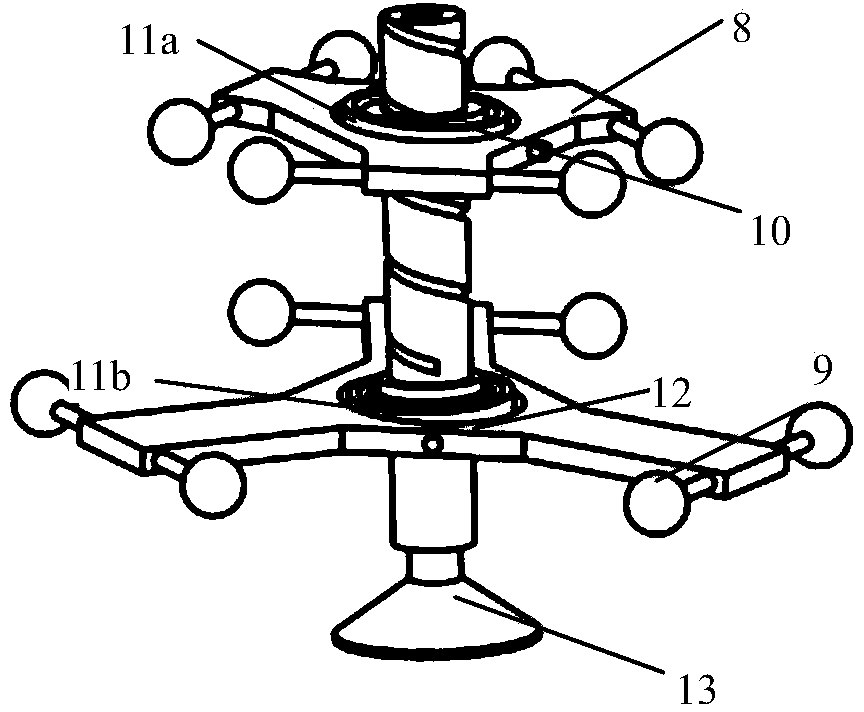

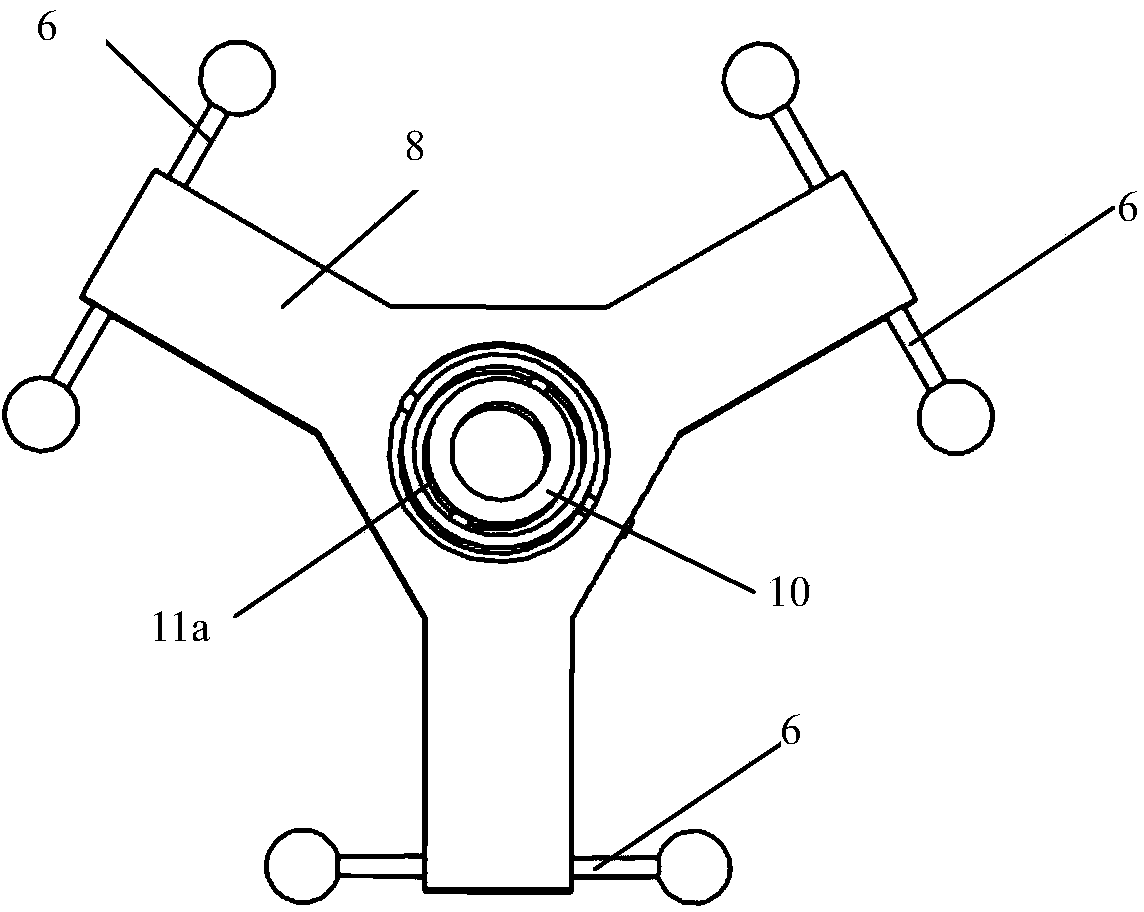

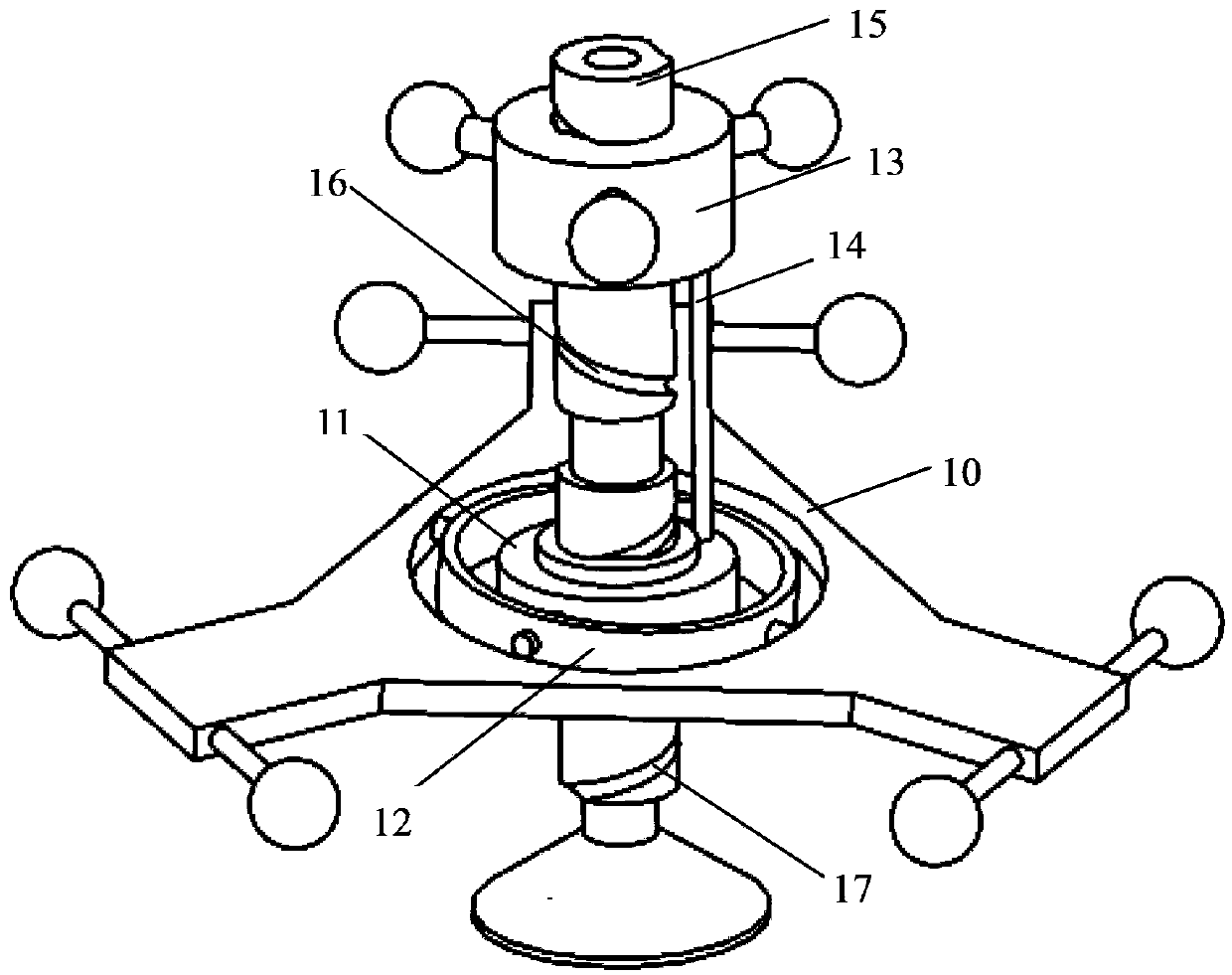

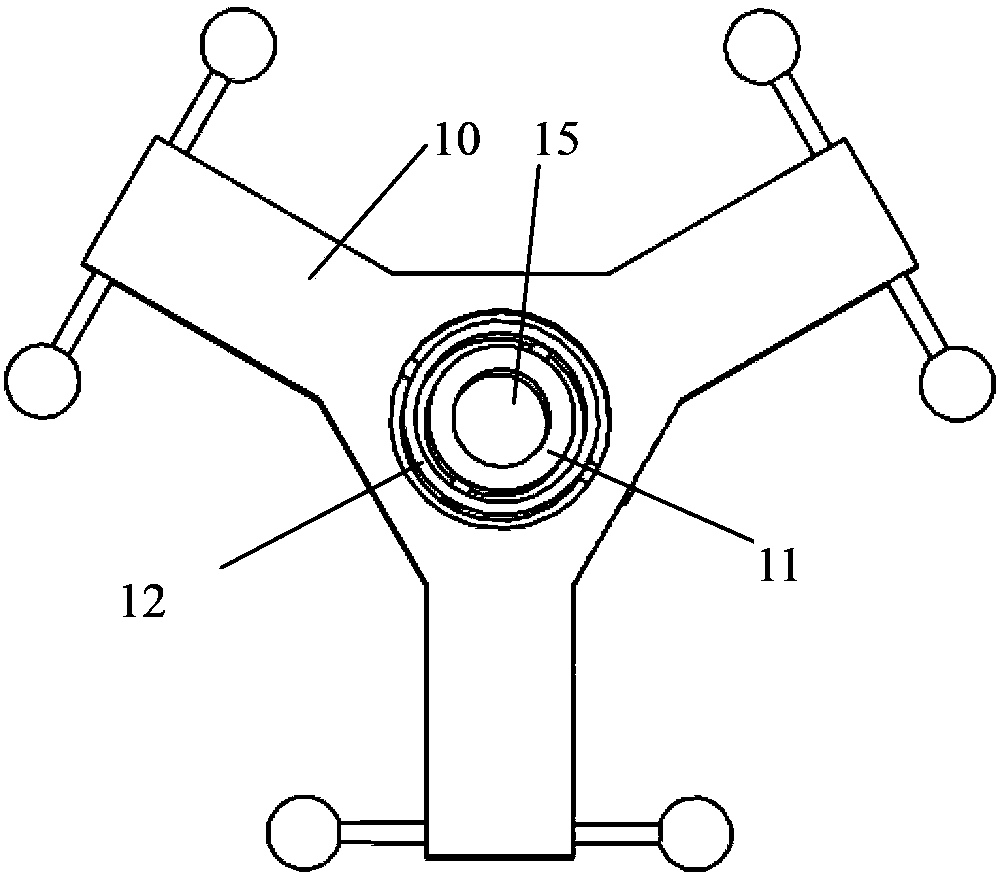

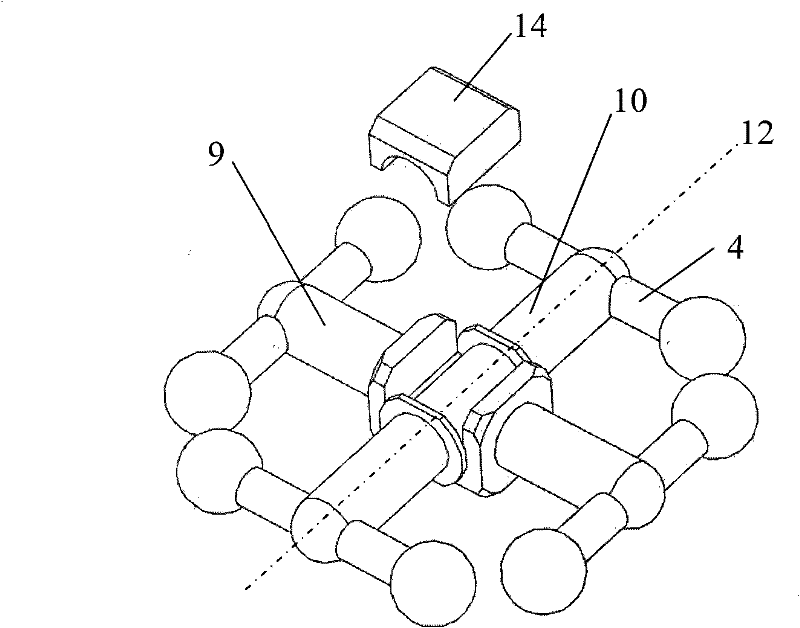

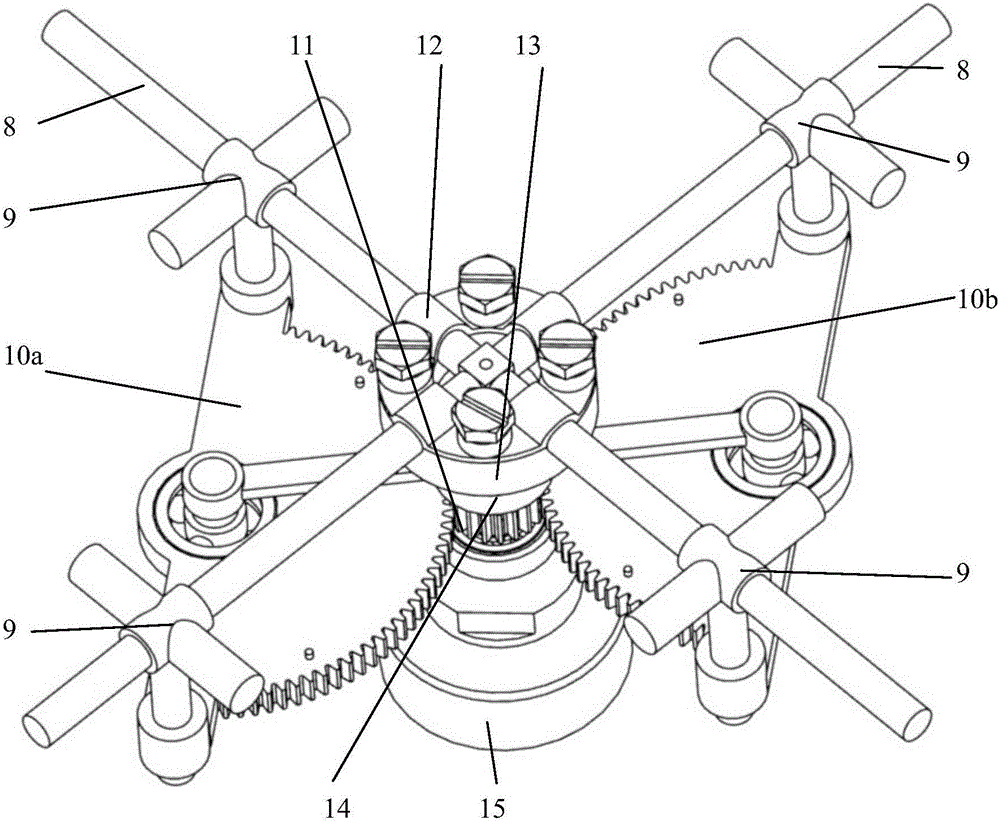

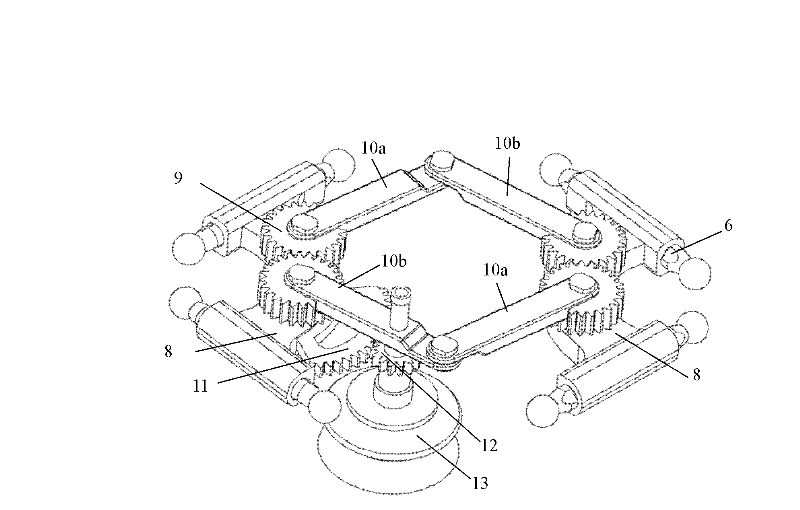

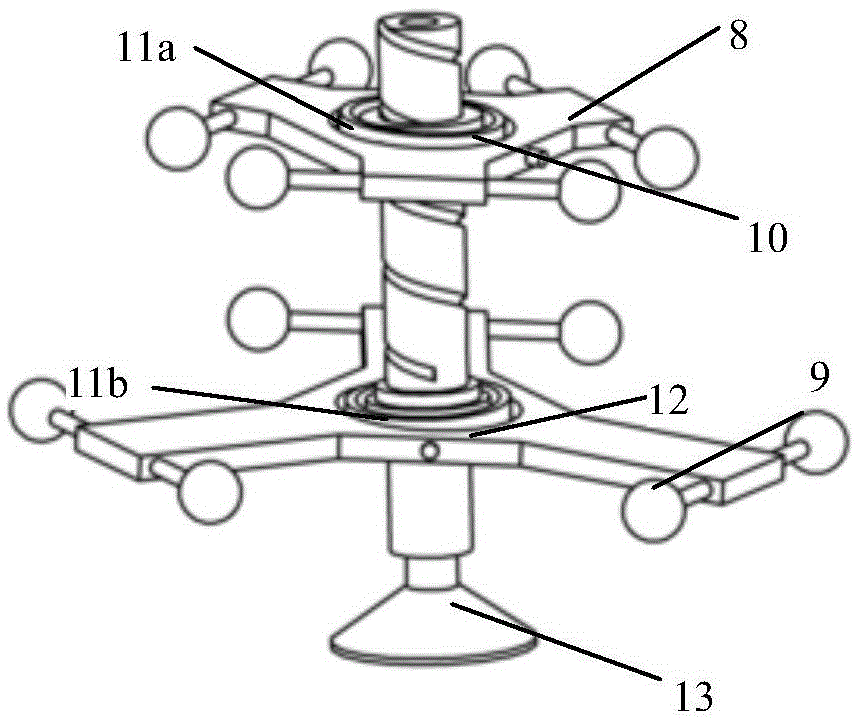

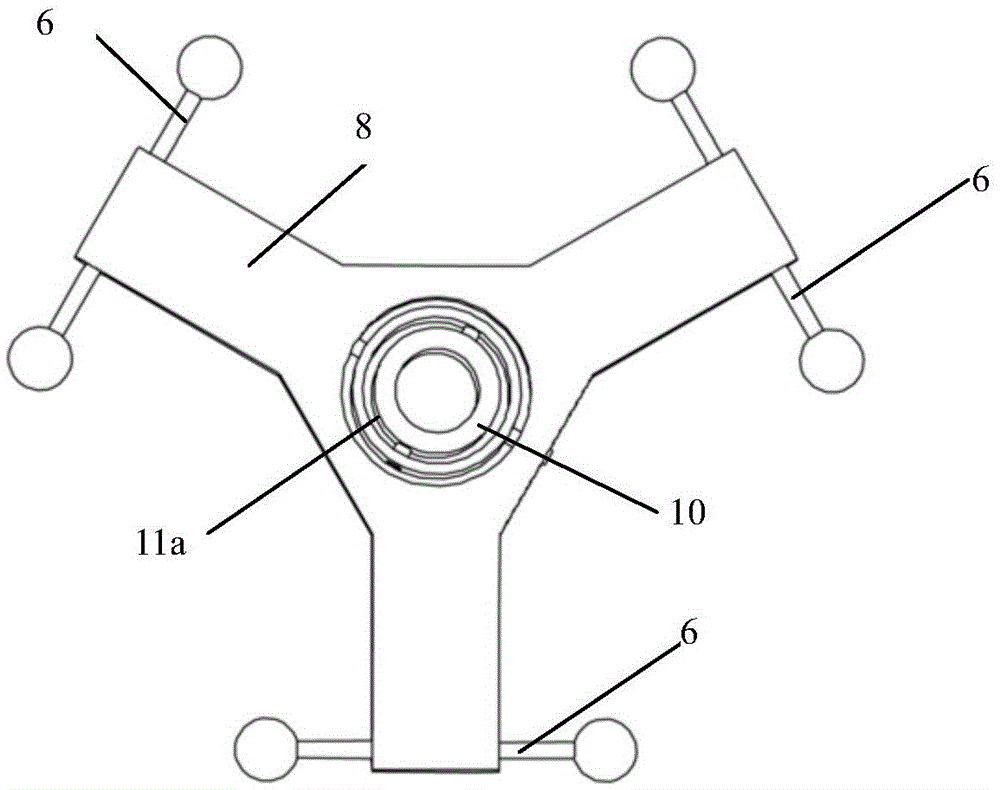

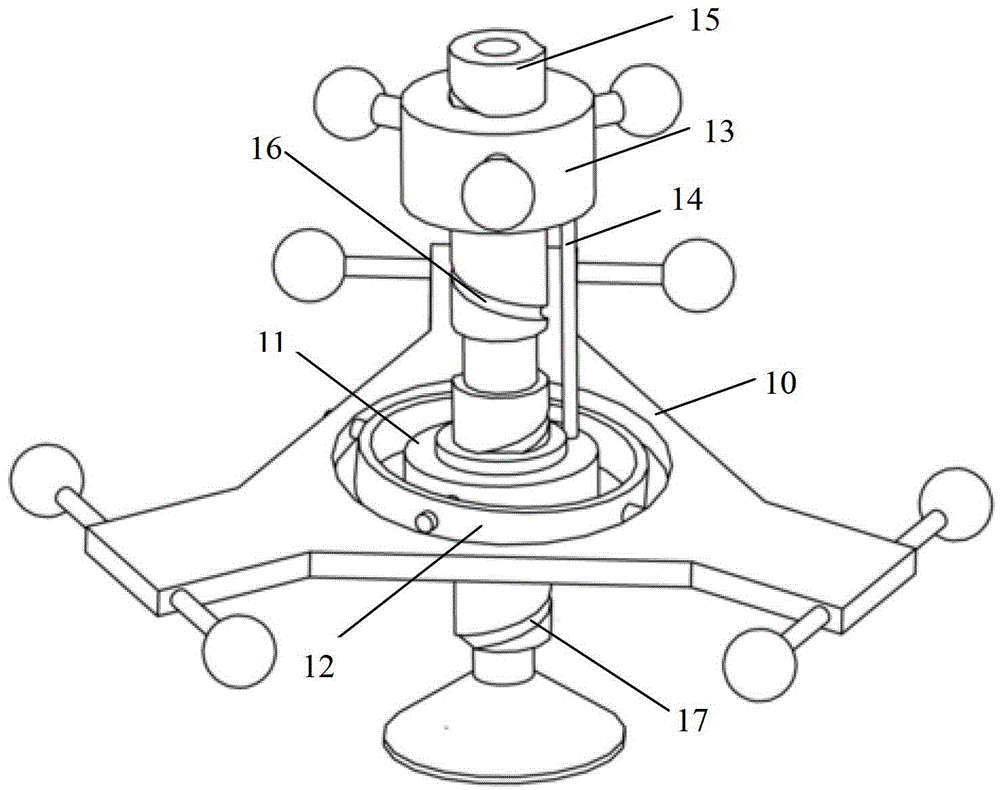

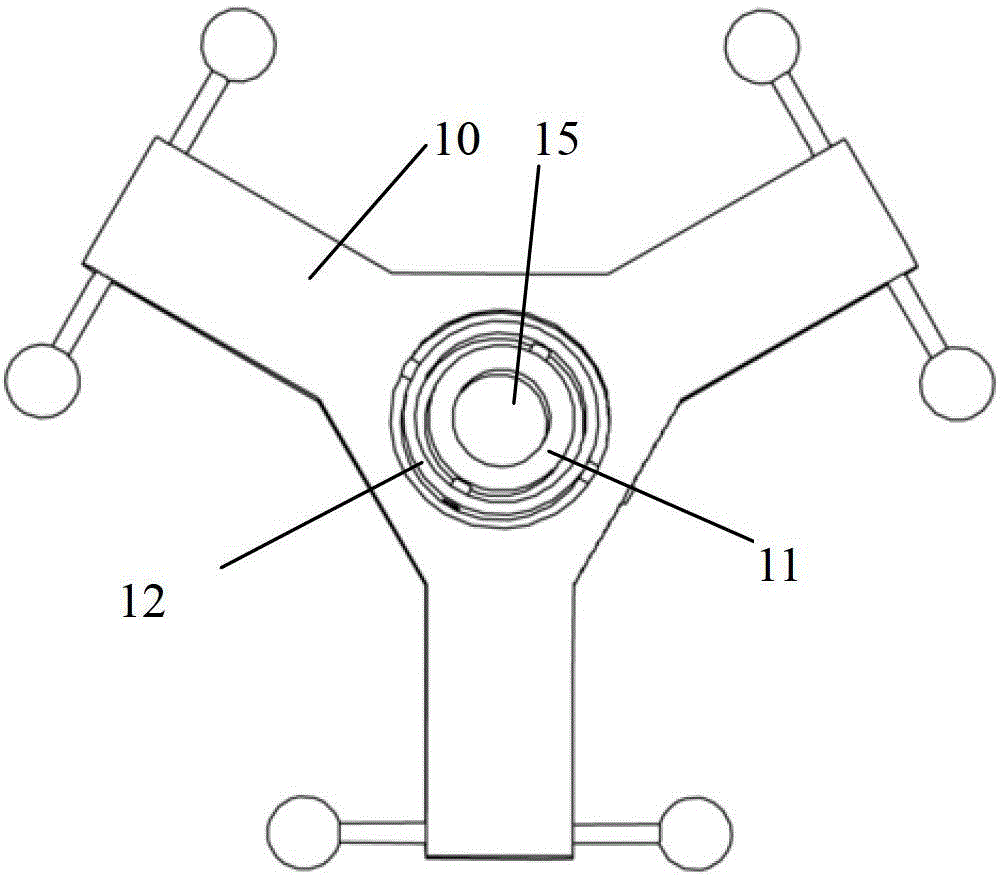

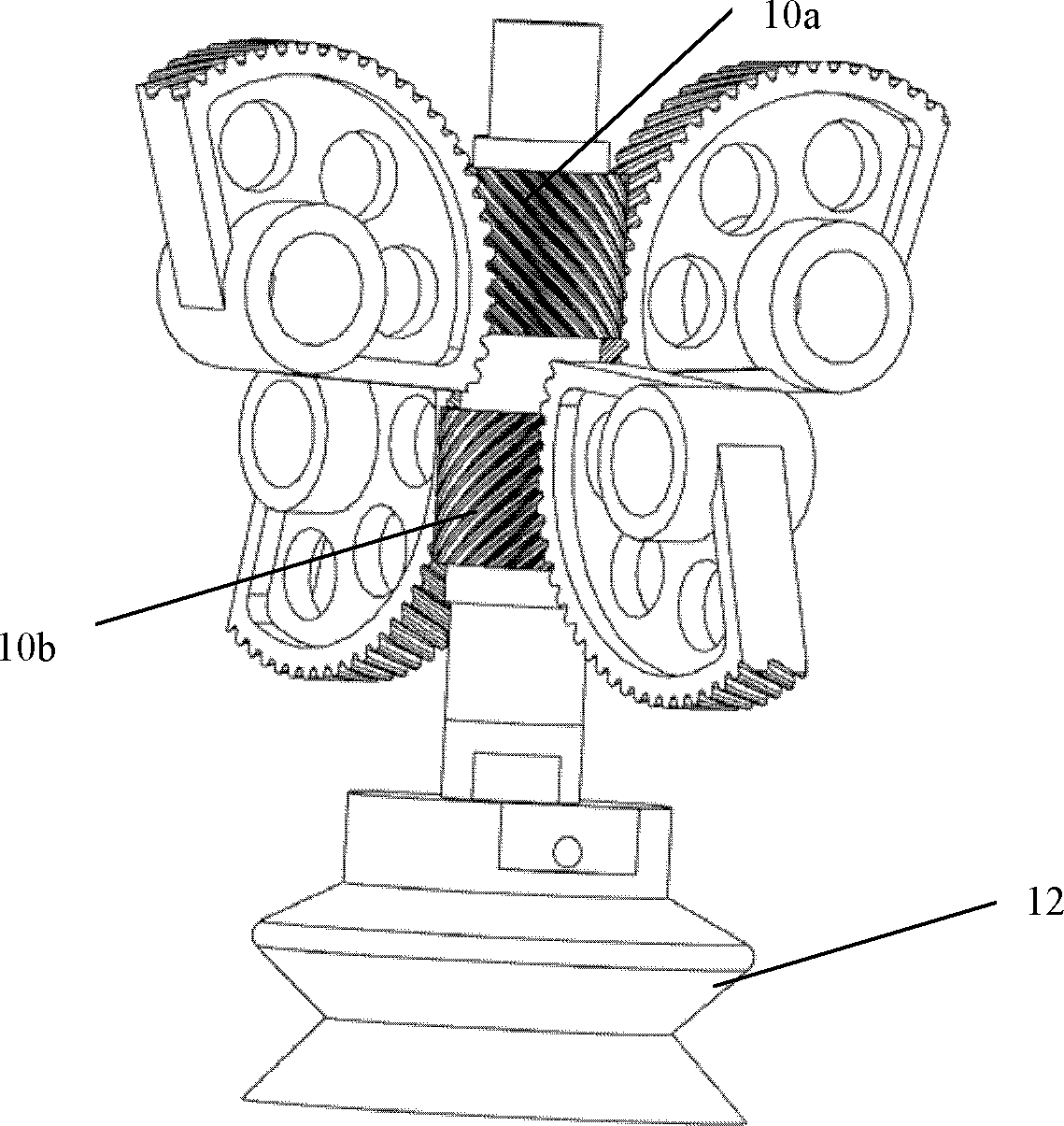

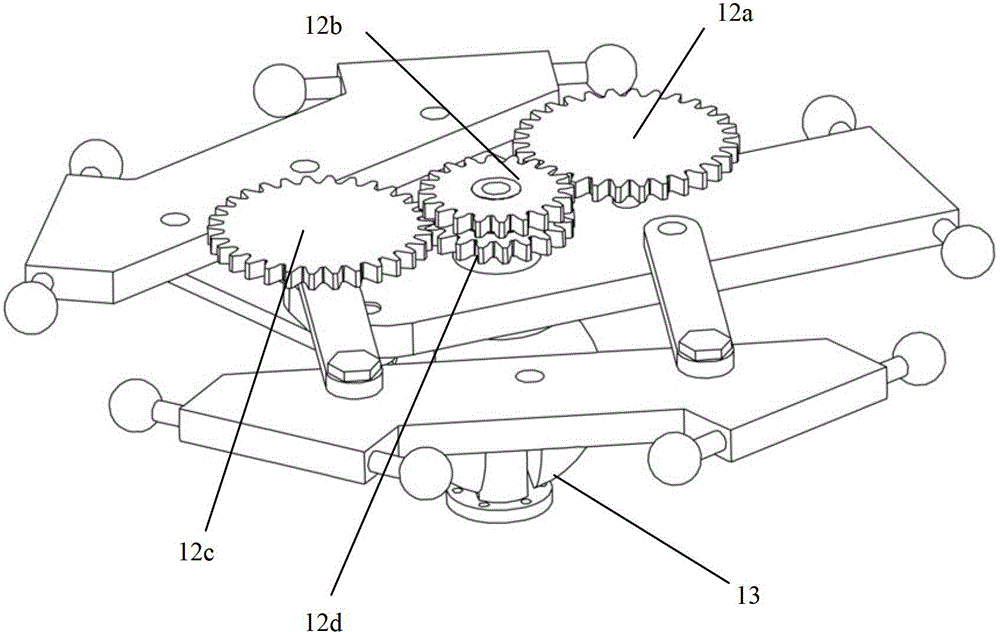

Wheel train type movable platform for four-axis parallel robot

InactiveCN106217356ACompact structureFlexible designProgramme-controlled manipulatorCarrying capacityWheel train

The invention relates to a wheel train type movable platform for a four-axis parallel robot. The wheel train type movable platform comprises a main shaft, a subplatform I, a subplatform II and a four-axis parallel mechanism, wherein the subplatform I and the subplatform II are crossed with each other; two groups of relative branched chains are mounted on the four-axis parallel mechanism; each of the relative branched chains is provided with a lower connecting shaft; and the subplatform I and the subplatform II are fixedly connected with corresponding lower connecting shafts. The wheel train type movable platform is compact in structure, light and handy in design, large in transmission range and excellent in carrying capacity, meets the requirements of high-speed grab-put operation, adopts wheel train transmission, is reliable in transmission, can realize transmission of the main shaft, improves the transmission accuracy, is low in operating noise and high in efficiency, and meets the requirements of complicated grab-put operation.

Owner:WUHU IROBSYS ROBOT CO LTD

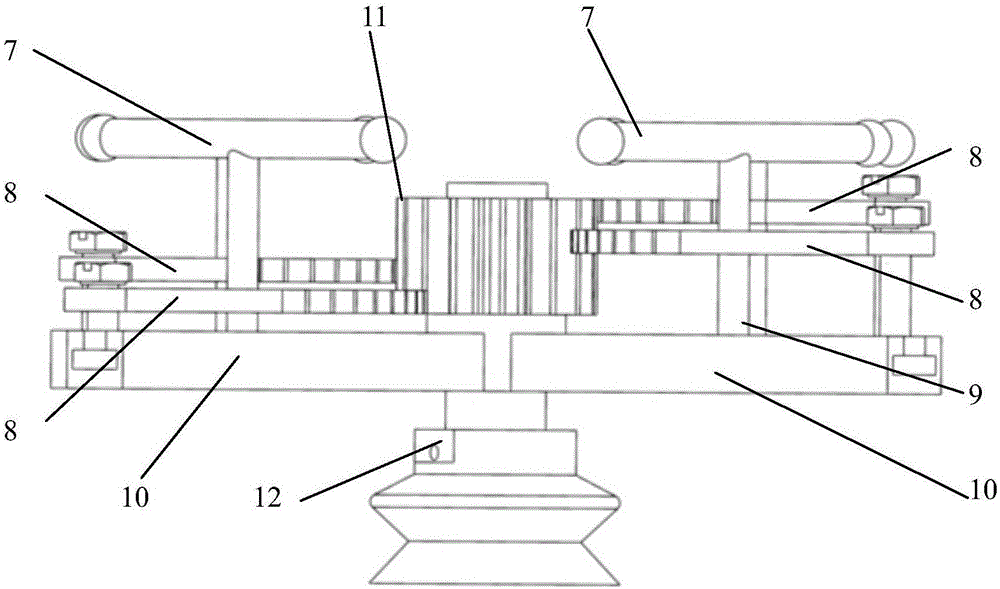

Three-dimensional translation and one-dimensional rotation parallel mechanism capable of realizing high-speed movement

InactiveCN101863024BReduce complexityCompact structureProgramme-controlled manipulatorJointsEngineeringMovement quality

The invention provides a three-dimensional translation and one-dimensional rotation parallel mechanism capable of realizing high-speed movement, comprising a fixed frame, a movable platform and four branched chains which are symmetrically arranged between the fixing frame and the movable platform and have same structures. The movable platform comprises an upper platform and a lower platform, which are horizontally arranged and are connected through a rotating mechanism. The rotating mechanism comprises a lead screw nut fixed on the upper platform and a lead screw connected with the lead screwnut, and the lead screw is supported by a bearing installed on the lower platform. In the three-dimensional translation and one-dimensional rotation parallel mechanism, the movement of the upper platform and the lower platform is converted into rotation round the axis of the lead screw through the rotating mechanism, and the upper platform and the lower platform are respectively and fixedly connected with a pair of opposite lower connecting shafts. In the invention, the upper platform and the lower platform which are horizontally arranged are adopted for the movable platform, and the upper platform and the lower platform are connected through the rotating mechanism, thereby the three-dimensional translation and one-dimensional rotation parallel mechanism has compact structure, avoids using a steering mechanism and an amplifying mechanism, reduces the mechanism complexity and the movement quality, is easy to realize high-speed capture, and meets the requirement of complex catching and releasing operation.

Owner:TIANJIN UNIV

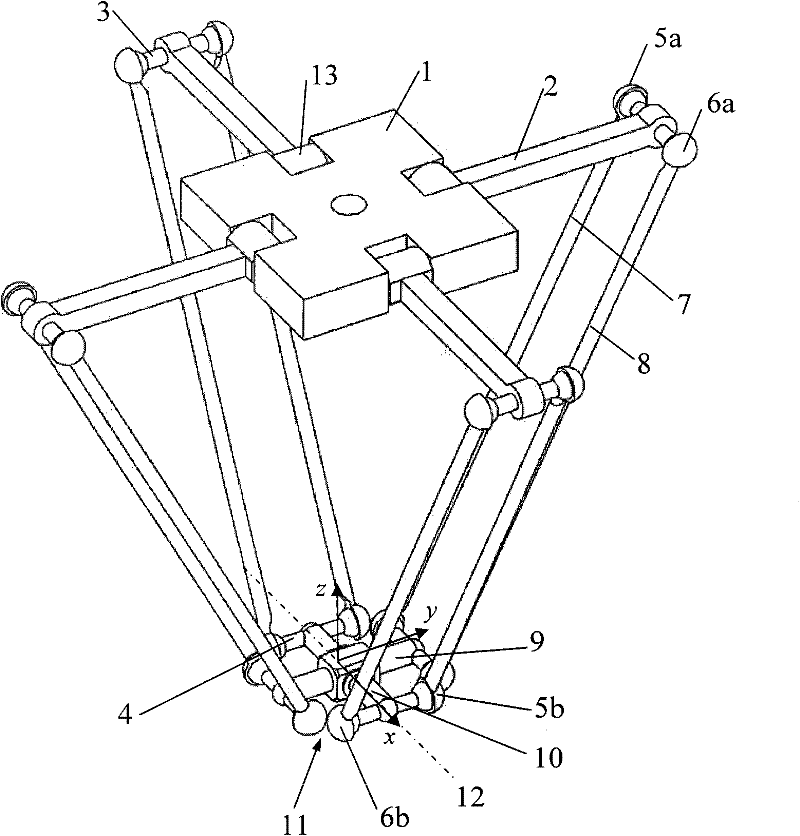

Parallel mechanism capable of realizing three-dimensional translational motion and two-dimensional rotation

InactiveCN103350417BLight in massCompact structureProgramme-controlled manipulatorFixed frameDegrees of freedom

The invention discloses a parallel mechanism capable of realizing three-dimensional translational motion and two-dimensional rotation. The parallel mechanism comprises a fixing frame and a movable platform. Five drive devices are fixedly connected to the fixing frame. The movable platform comprises a central plate and a rocker vertically penetrating through the center of the central plate. The central plate is connected with the rocker through a hooke hinge in a rotating mode. Two ball head rods are fixed at the upper end of the rocker. Three first branch chains are connected between the fixing frame and the central plate. Two second branch chains are connected between the fixing frame and the two ball head rods. The central plate is driven by the three first branch chains to be in three-dimensional translational motion. The rocker is driven by the two second branch chains to be in two-dimensional rotation relative to the central plate through the hooke hinge. Consequently, the rocker is enabled to have not only three translational motion freedom degrees but also two rotation freedom degrees. The parallel mechanism is simple and compact in structure, exquisitely realizes five freedom degrees through the hooke hinge, reduces mechanism complexity, and can realize high-speed high-precision complex grab easily.

Owner:TIANJIN UNIV

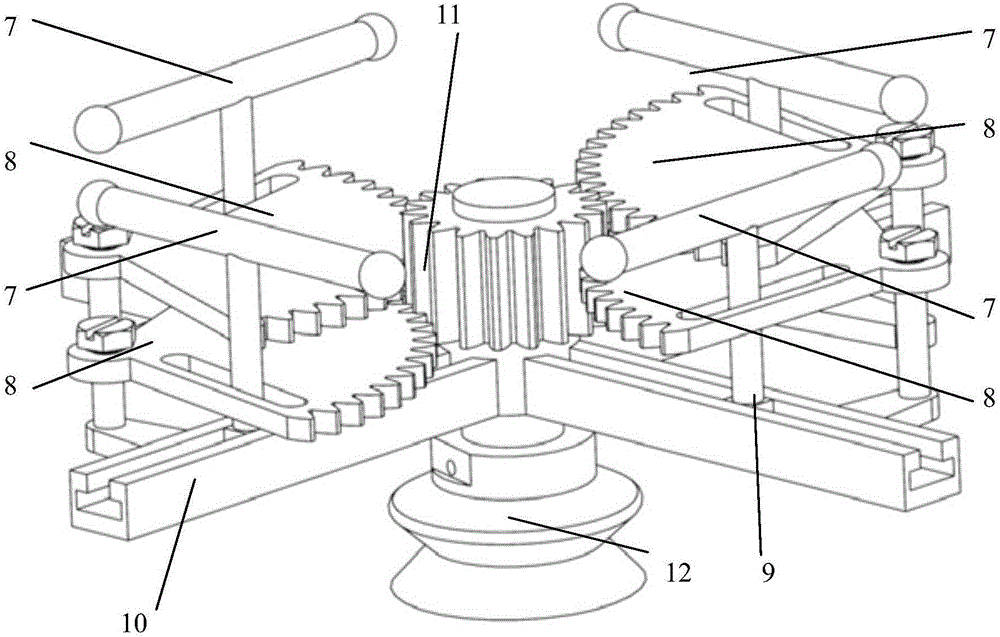

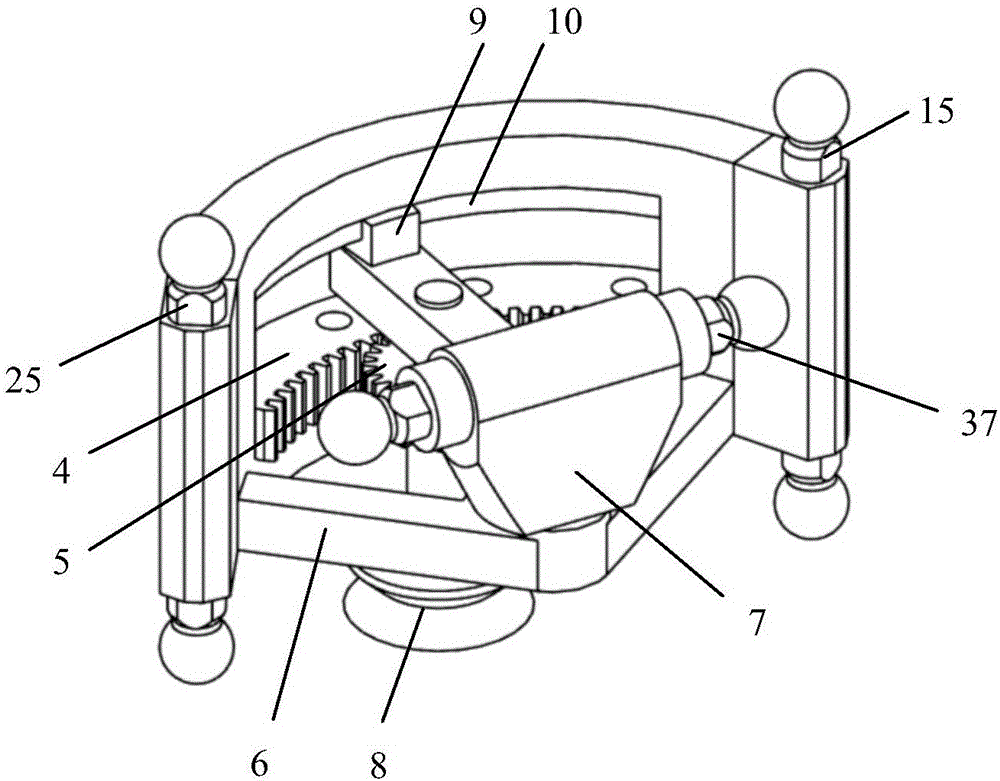

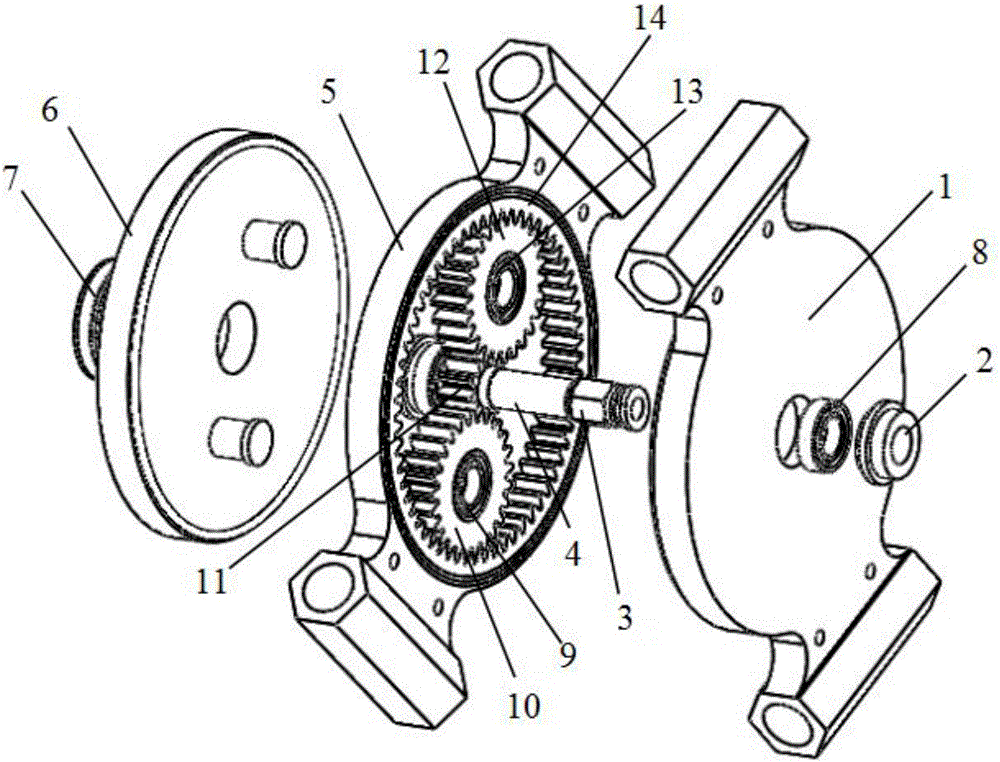

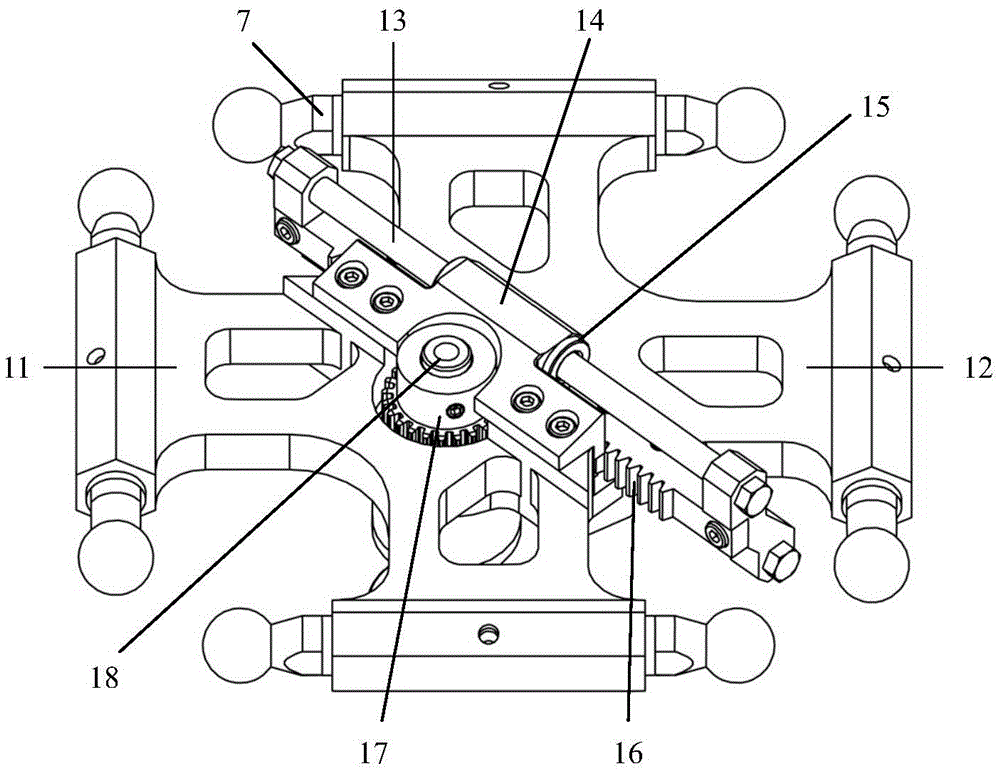

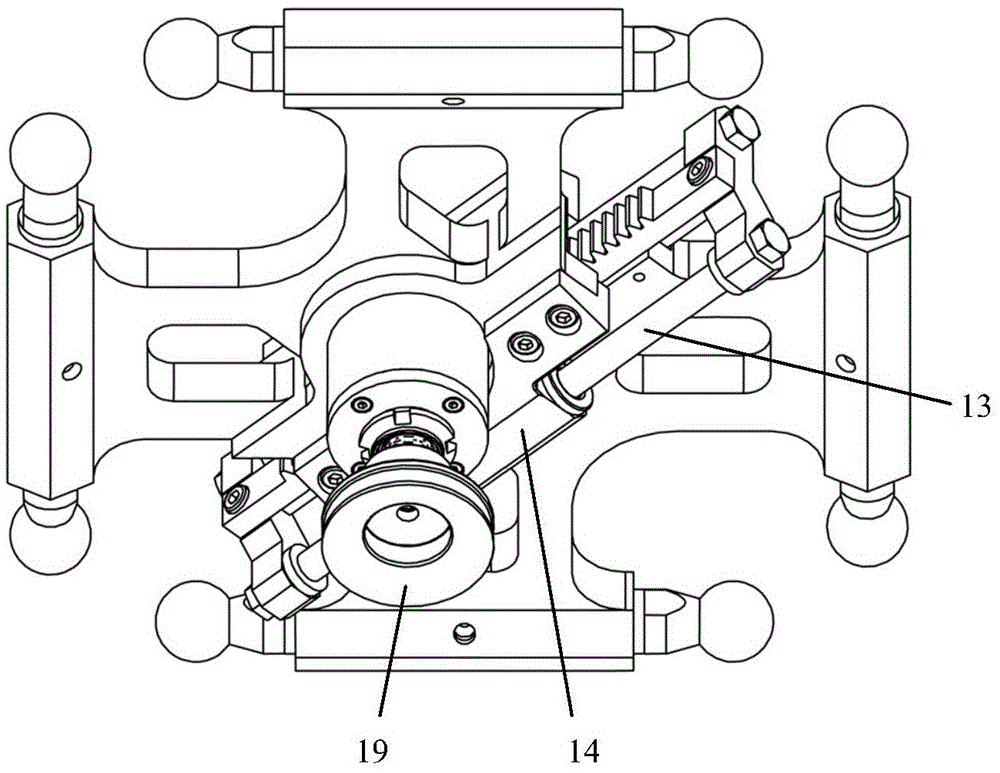

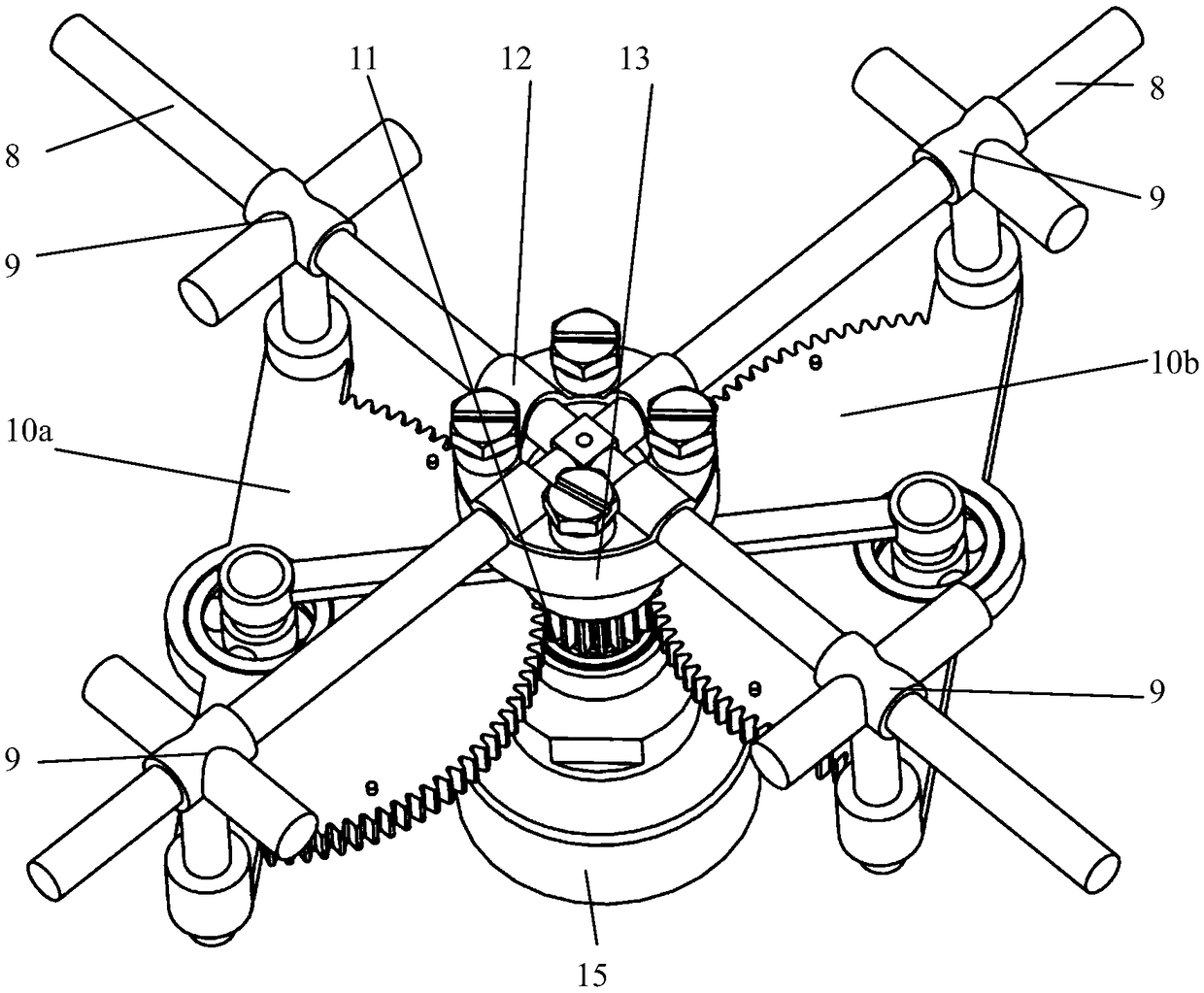

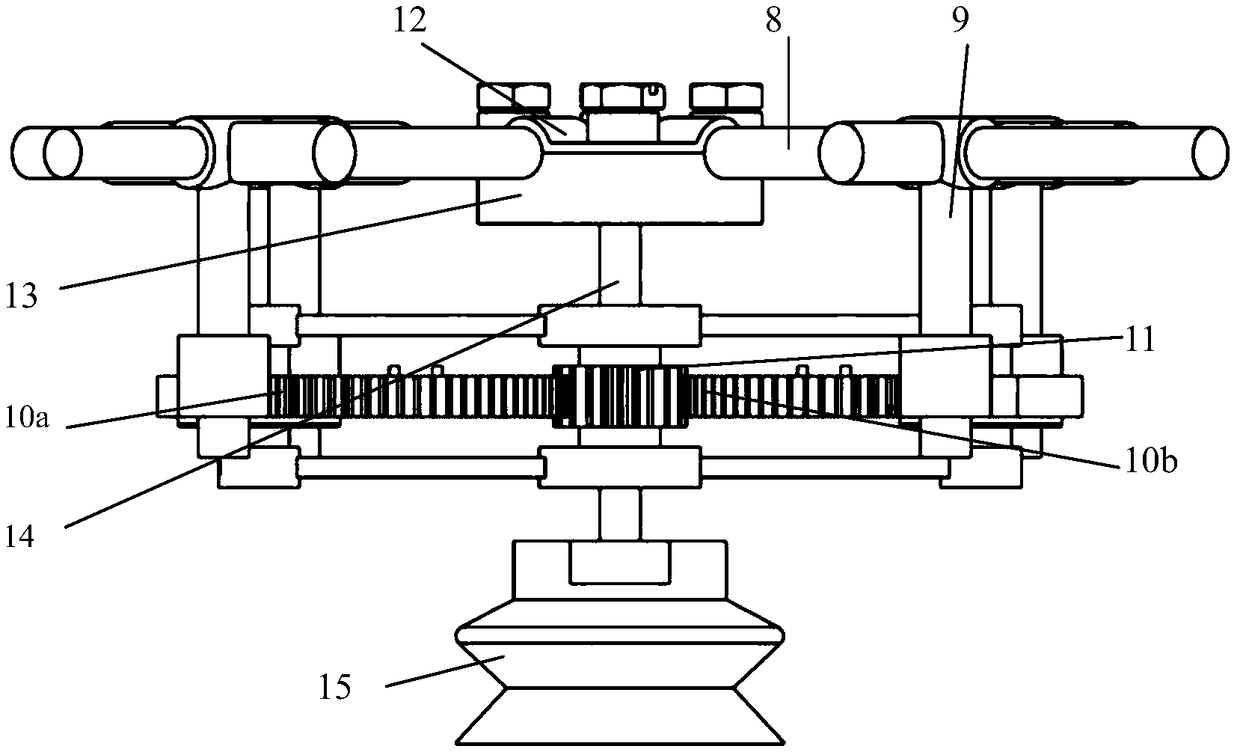

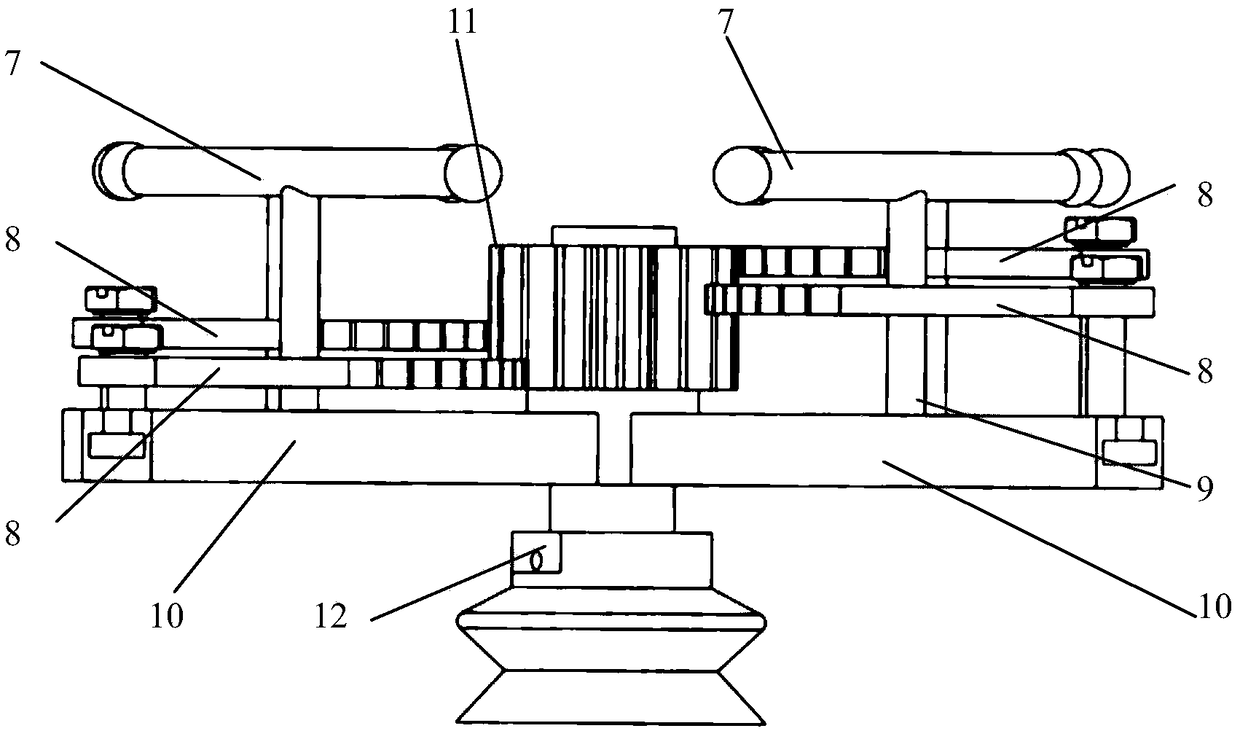

A rack-and-pinion four-degree-of-freedom high-speed parallel robot

ActiveCN103753521BEliminate error amplificationLight in massProgramme-controlled manipulatorAngular degreesDegrees of freedom

The invention discloses a pinion-and-rack type four-freedom-degree high-speed parallel robot comprising a fixed platform, a moving platform and four groups of branched chains with same structures. The moving platform comprises a sub platform I and a sub platform II which are opposite to each other. The two sub platforms are connected with lower connecting rods of two groups of adjacent branched chains respectively. A guide mechanism and an angle switching mechanism are arranged between the sub platforms. The guide mechanism comprises two guide frames and two guide shafts. The guide shafts in parallel are fixed on the upper side and the lower side of the sub platform II respectively. The guide frames are fixed on the upper side and the lower side of the sub platform I respectively. Each guide frame is in sliding connection with the corresponding guide shaft. The angle switching mechanism comprises a rack and a pinion. The rack is fixed on the sub platform II, the pinion is mounted on a pinion shaft, and the pinion is meshed with the rack. An actuator is fixedly connected to the tail end of the pinion shaft. The pinion shaft is rotationally connected with the sub platform I. The pinion-and-rack type four-freedom-degree high-speed parallel robot is compact in structure of the moving platform, light and handy in design of the moving platform, high in transmission accuracy, good in force transmission effect and capable of meeting requirements on high-speed grabbing and releasing operations.

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

Cross slide block type four-branched-chain three-translation and one-rotation high-speed parallel manipulator

InactiveCN106426114ACompact structureFlexible movementProgramme-controlled manipulatorThree degrees of freedomDegrees of freedom

The invention discloses a cross slide block type four-branched-chain three-translation and one-rotation high-speed parallel manipulator. The manipulator comprises a fixed frame, a movable platform, and four motion branched chains with the same structures; the movable platform includes four guide rods, four slide sleeves, two semicircular gears, two horizontal connecting rods, a platform, a rotating shaft and a terminal actuator; a center gear engaged with the two semicircular gears is arranged on a shaft section between the platform and the terminal actuator; the two same semicircular gears are rotationally connected with the two adjacent slide sleeves; and under driving of driving devices, power is transferred to the four motion branched chains by output ends of the four driving devices, and is transferred to the slide sleeves by the motion branched chains to drive the two same semicircular gears to rotate, and the rotating shaft is driven to rotate through gear transmission, so that the terminal actuator has three-degree-of-freedom of translation and one-degree-of-freedom of rotation.

Owner:TIANJIN UNIV

Parallel mechanism with two-dimensional translation and two-dimensional rotation

The invention discloses a parallel mechanism with two-dimensional translation and two-dimensional rotation. The parallel mechanism comprises a fixed frame, a moving platform and four branched chains which are symmetrically arranged between the fixed frame and the moving platform and provided with a drive device respectively, wherein the four branched chains have two types of structures; the branched chain with one type of structure comprises a straight line guide rail, a drive block arranged in the straight line guide rail and a fixed-length connecting rod of which both ends are provided withrotary hinges; the branched chain with the other type of structure comprises a straight line guide rail, a drive block arranged in the straight line guide rail and a fixed-length connecting rod of which both ends are provided with spherical hinges; the four branched chains with the two types of structures are in crossed arrangement; one end of the fixed-length connecting rod is connected with themoving platform, and the other end of the fixed-length connecting rod is connected with the drive block; and the moving platform is connected with a main platform and a fork-shaped shaft, of which the axial lines are vertical to each other, by a rotary pair, and the main platform can rotate around the axial line of the fork-shaped shaft. The parallel mechanism has the advantages that: the structure is simple; the mode of motion is definite; the requirements on complicated holding-releasing operations are met; and because the connecting rod is the fixed length rod which helps to reduce the inertia load, the parallel mechanism has higher rigidity in different operational ranges, and the high-speed movement is easily realized.

Owner:TIANJIN UNIV

Four-branch-chain two-dimensional translation and one-dimensional rotation freedom parallel mechanical arm

InactiveCN102626922AHigh positioning accuracyIncrease lateral stiffnessProgramme-controlled manipulatorFixed frameEngineering

The invention discloses a four-branch-chain two-dimensional translation and one-dimensional rotation freedom parallel mechanical arm. The mechanical arm comprises a fixing frame, a motion platform and four motion branch chains, wherein the four motion branch chains are symmetrically arranged between the fixing frame and the motion platform and have the same structure; a pair of synchronous belt wheels which are crossly connected through a cog belt are fixedly connected to two opposite near frame rods; the motion platform comprises four gear handles, four helical sectors, two helical gears, a base and an end effecter; the end effecter is rotatably hinged with the base; the rotation directions of the two helical gears are opposite, and the two helical gears are coaxially fixed with the end effecter; the four gear handles mutually form 90 degrees and rotatably connected with the base respectively through a rotation shaft; and when the branch chains are driven to move by corresponding driving devices, the two-dimensional translation in a plane and the one-dimensional rotation relative to the base of the end effecter can be achieved.

Owner:TIANJIN UNIV

Bar-wheel combined type three-translation one-rotation parallel mechanism

The invention discloses a bar-wheel combined type three-translation one-rotation parallel mechanism which comprises a movable platform; the movable platform consists of two angle dividing mechanisms which are distributed horizontal and symmetrically; each angle dividing mechanism comprises a supporting plate, two angle dividing connecting bars, and two angle dividing gears; the angle dividing connecting bars are fixedly connected with the angle dividing gears; the angle dividing gears are hinged with the supporting plate; the angle dividing gears on the two angle dividing connecting bars are mutually engaged and are symmetrically arranged relative to the central line of the supporting plate; two adjacent lower connecting shafts are arranged on the supporting plate; the angle dividing connecting bars of the two angle dividing mechanisms are correspondingly connected one by one through a rotating pair; the four angle dividing connecting bars of the two angle dividing mechanisms form a structure similar to a diamond; an angle enlarging mechanism is fixedly connected with the supporting plate of any angle dividing mechanism; and a tail end actuator is fixedly connected with each angleenlarging mechanism. The bar-wheel combined type three-translation one-rotation parallel mechanism has the advantages of skillful and unique design, and good structural rigidity and good stability; moreover, the bar-wheel combined type three-translation one-rotation parallel mechanism can easily realize high speed motions, and can satisfy the requirements of complex grabbing and loosening operations.

Owner:江苏金邦电气工程有限公司

Cross-slider type four-chain three-level one-rotation high-speed parallel manipulator

InactiveCN106426114BCompact structureFlexible movementProgramme-controlled manipulatorThree degrees of freedomDegrees of freedom

The invention discloses a cross slide block type four-branched-chain three-translation and one-rotation high-speed parallel manipulator. The manipulator comprises a fixed frame, a movable platform, and four motion branched chains with the same structures; the movable platform includes four guide rods, four slide sleeves, two semicircular gears, two horizontal connecting rods, a platform, a rotating shaft and a terminal actuator; a center gear engaged with the two semicircular gears is arranged on a shaft section between the platform and the terminal actuator; the two same semicircular gears are rotationally connected with the two adjacent slide sleeves; and under driving of driving devices, power is transferred to the four motion branched chains by output ends of the four driving devices, and is transferred to the slide sleeves by the motion branched chains to drive the two same semicircular gears to rotate, and the rotating shaft is driven to rotate through gear transmission, so that the terminal actuator has three-degree-of-freedom of translation and one-degree-of-freedom of rotation.

Owner:TIANJIN UNIV

Four-branch three-level one-rotation high-speed parallel manipulator

InactiveCN103846908BCompact structureFlexible movementProgramme-controlled manipulatorActuatorParallel manipulator

The invention discloses a four-branch-chain three-platform one-rotor high-speed parallel connection mechanical hand, which comprises a fixing frame, a movable platform and four moving branch chains, wherein the four moving branch chains are arranged between the fixing frame and the movable platform, are in central symmetry arrangement and have the same structures, the movable platform comprises an upper platform, a lower platform, a tail end executer, four swinging rods, a spiral shaft and two support rods, the four swinging rods are arranged around the movable platform in a radial shape, and the two adjacent swinging rods are in rotational connection or hooke hinging or ball hinging to a connecting element, so the adjacent swinging rods realize the movement in opposite directions, one end of a spiral rod is rotationally connected with the upper platform, the middle of the spiral rod is spirally connected with the lower platform, the other end of the spiral rod is fixedly connected with the tail end executer, under the driving effect of a driving device, the lower platform moves in the spiral shaft direction, and the tail end executer fixedly connected with the spiral shaft realizes the rotation around the self axial line through screw thread connection effects. The four-branch-chain three-platform one-rotor high-speed parallel connection mechanical hand has the advantages that the force transmission effect of the movable platform is good, the movement of the mechanism is smooth, and the service life is long.

Owner:TIANJIN UNIV

Five-degree-of-freedom parallel manipulator capable of realizing high-velocity motion

ActiveCN102975202AEven by forceLight in massProgramme-controlled manipulatorEngineeringDegrees of freedom

The invention discloses a five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion. The five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion comprises a fixed mount, a movable platform and five branched chains with the same structure, wherein the branched chains are symmetrically arranged between the fixed mount and the movable platform; the fixed mount is fixedly connected with five driving devices; the movable platform comprises two ball arm seats, two mutually-parallel connecting rods with the equal length and a central plate; two groups of plane-surface parallelogram structures are respectively formed; a transmission mechanism is meshed by two groups of gears; the translational motion of the the two ball arm seats relative to the central plate or the rotation of the two groups of parallel connecting rods relative to the central plate is converted into two power inputs of a two-degree-of-freedom wrist; and under the action of the driving device, the three-dimensional translational motion of the movable platform and the two-dimensional rotation of the two-degree-of-freedom wrist are realized. The five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion, which is disclosed by the invention, has the advantages of symmetrical integral structure, even stressing of the movable platform, light motion part quality and big possibility of realizing high-velocity motion, and the complex fetching and releasing requirements can be satisfied.

Owner:天津大学中原先进技术研究院(开封)有限公司

A high-speed six-degree-of-freedom parallel manipulator

ActiveCN103846911BAvoid magnificationReduce complexityProgramme-controlled manipulatorDegrees of freedomParallel manipulator

The invention discloses a high-speed parallel manipulator with six degrees of freedom. The high-speed parallel manipulator comprises a fixed rack, a movable platform and six branch chains with the same structures, wherein the fixed rack is provided with six driving devices; each branch chain consists of a near rack rod, an upper connecting shaft, two mutually-parallel far rack rods with equal length and a lower connecting shaft; the output ends of all the driving devices in the branch chains are respectively and fixedly connected with one end of one near rack rod and used for providing one degree of freedom for the corresponding near rack rod; the movable platform comprises an upper platform and a lower platform which are horizontally arranged and are mutually parallel; the upper platform and the lower platform are connected by virtue of a rotating mechanism with a screw rod; the six branch chains are classified into two groups of branch chains at sequential intervals, and the two groups of branch chains are used for respectively driving the upper platform and the lower platform; upper three-dimensional relative movement and lower three-dimensional relative movement are converted into three rotation movements of the screw rod by virtue of the rotating mechanism. The high-speed parallel manipulator is compact in structure, can be used for omitting an amplification mechanism, reducing the complexity of the mechanism, meanwhile reducing the quality of moving parts and improving the movement precision, and is easy for realization of complex picking and placing operations.

Owner:TIANJIN UNIV

Parallel mechanism capable of realizing three-dimensional translation and three-dimensional rotation

InactiveCN103386681BAvoid magnificationReduce complexityProgramme-controlled manipulatorFixed frameDegrees of freedom

The invention discloses a parallel mechanism capable of realizing three-dimensional translation and three-dimensional rotation. The parallel mechanism comprises a fixed frame and a movable platform, wherein the fixed frame is fixedly connected with six driving devices, the movable platform comprises a central plate and a rocking rod, the central plate and the rocking rod are rotatably connected by utilizing a hooke joint, and the upper part and the lower part of the rocking rod are respectively a first lead screw and a second lead screw with different rotation directions; three first branch chains are connected between the fixed frame and the central plate, and three second branch chains are connected with the fixed frame and three bulb rods; the rocking rod is driven by the three first branch chains to realize the three-dimensional translation, and the rocking rod is driven by the three second branch chains to realize two-dimensional rotation relative to the central plate by the hooke joint; the rocking rod realizes autorotation by the relative movement of a nut and a hooke inner ring; and therefore, the rocking rod has three translation degrees of freedom and also has three rotation degrees of freedom. The parallel mechanism capable of realizing the three-dimensional translation and the three-dimensional rotation, which is disclosed by the invention, has the advantages that the structure is simple and compact, six degrees of freedom by utilizing the hooke joint and a screw pair are smartly realized, the mechanism complexity is reduced and the high-speed, high-precision complex grabbing is easily realized.

Owner:TIANJIN UNIV

High-speed parallel manipulator with three-dimensional translation and one-dimensional rotation

InactiveCN102848382BSimple structureCompact structureProgramme-controlled manipulatorGear wheelFixed frame

Owner:TIANJIN UNIV

Rocker staggered four-chain three-level one-rotation high-speed parallel manipulator

InactiveCN106426115BCompact structureSimple structureProgramme-controlled manipulatorGear driveParallel manipulator

The invention discloses a rocker dislocation-type four-branch-chain three-translation one-rotation high-speed parallel manipulator. The rocker dislocation-type four-branch-chain three-translation one-rotation high-speed parallel manipulator comprises a fixed rack, a movable platform and four moving branch chains with the same structure, wherein spatial three-dimensional translation of the movable platform is ensured through the four moving branch chains with the same structure; the movable platform comprises a central gear, a platform and an end effector; four guide rails which are of centrally-radial arrangement are arranged on the platform; a sliding block is arranged in each guide rail; the central gear is meshed with four identical arc gears; a guiding groove is formed in the disc surface of each arc gear; the four sliding blocks separately drive the arc gears to move through the guiding grooves; and a rotary shaft is driven to rotate through the gears, so that the end effector has three degrees of translation freedom and one degree of rotation freedom. The movable platform is compact in structure and is symmetrically arranged; movement is flexible; stress is uniform; movement precision is high; the integral structure is good in stability; the structure is simple; manufacture and repair are convenient; and requirement of complex grabbing and releasing operation is met.

Owner:TIANJIN UNIV

Five-degree-of-freedom parallel manipulator capable of realizing high-velocity motion

ActiveCN102975202BEven by forceLight in massProgramme-controlled manipulatorEngineeringDegrees of freedom

The invention discloses a five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion. The five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion comprises a fixed mount, a movable platform and five branched chains with the same structure, wherein the branched chains are symmetrically arranged between the fixed mount and the movable platform; the fixed mount is fixedly connected with five driving devices; the movable platform comprises two ball arm seats, two mutually-parallel connecting rods with the equal length and a central plate; two groups of plane-surface parallelogram structures are respectively formed; a transmission mechanism is meshed by two groups of gears; the translational motion of the the two ball arm seats relative to the central plate or the rotation of the two groups of parallel connecting rods relative to the central plate is converted into two power inputs of a two-degree-of-freedom wrist; and under the action of the driving device, the three-dimensional translational motion of the movable platform and the two-dimensional rotation of the two-degree-of-freedom wrist are realized. The five-degree-of-freedom parallel manipulator capable of realizing the high-velocity motion, which is disclosed by the invention, has the advantages of symmetrical integral structure, even stressing of the movable platform, light motion part quality and big possibility of realizing high-velocity motion, and the complex fetching and releasing requirements can be satisfied.

Owner:天津大学中原先进技术研究院(开封)有限公司

High-speed six-degree of freedom parallel manipulator

InactiveCN102632502BStructural symmetryEven by forceProgramme-controlled manipulatorFixed frameThree degrees of freedom

The invention discloses a high-speed six-degree of freedom parallel manipulator which comprises a fixed frame, a movable platform, a three-degree of freedom wrist and six moving branched chains that are arranged between the fixed frame and the movable platform and have the same structure; the fixed frame is fixedly connected with six driving devices; the movable platform comprises a centre plate, three subangle gear sets and six connecting rods, wherein each subangle gear set comprises a center bevel gear and two subangle bevel gears; the center bevel gears are rotatablely connected with the centre plate; the subangle bevel gears are rotatablely connected with the centre plates; every two subangle bevel gears are arranged at the two sides of each center bevel gear and are meshed and connected with the center bevel gear; one ends of the connecting rods are fixedly connected with a lower connecting shaft, and the other ends of the connecting rods are fixedly connected with one subangle bevel gear in the subangle gear sets; the three-degree of freedom wrist is fixedly connected on the center plate; three groups of gear transmission mechanisms are arranged around the three-degree of freedom wrist; and the three center bevel gears are respectively used for providing three power input for the three groups of gear transmission mechanisms, so that the three-degree of freedom wrist is driven to realize three-dimensional controllable rotation.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com