A rack-and-pinion four-degree-of-freedom high-speed parallel robot

A technology of rack and pinion and degrees of freedom, applied in the field of robotics, can solve the problems of increasing the size and weight of the moving platform, unfavorable high-speed motion, unreliable transmission, etc., and achieves the effect of reducing quality, good guidance, and improving transmission accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

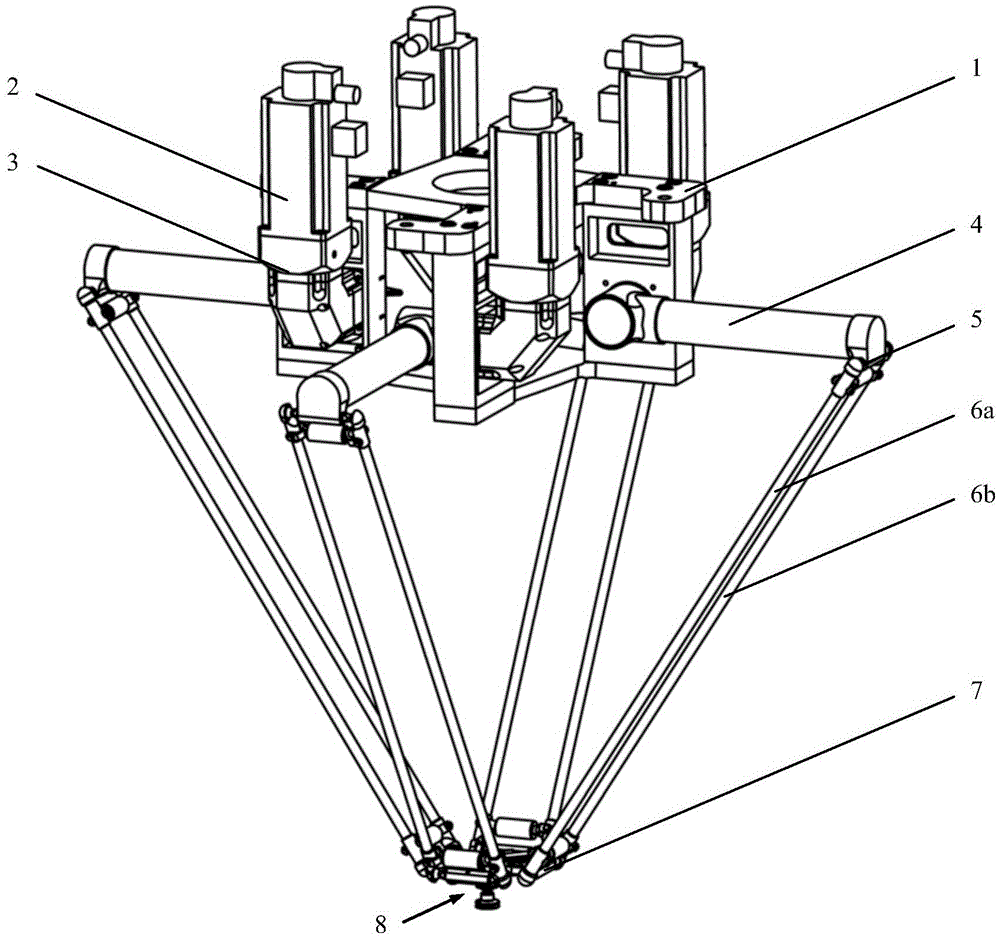

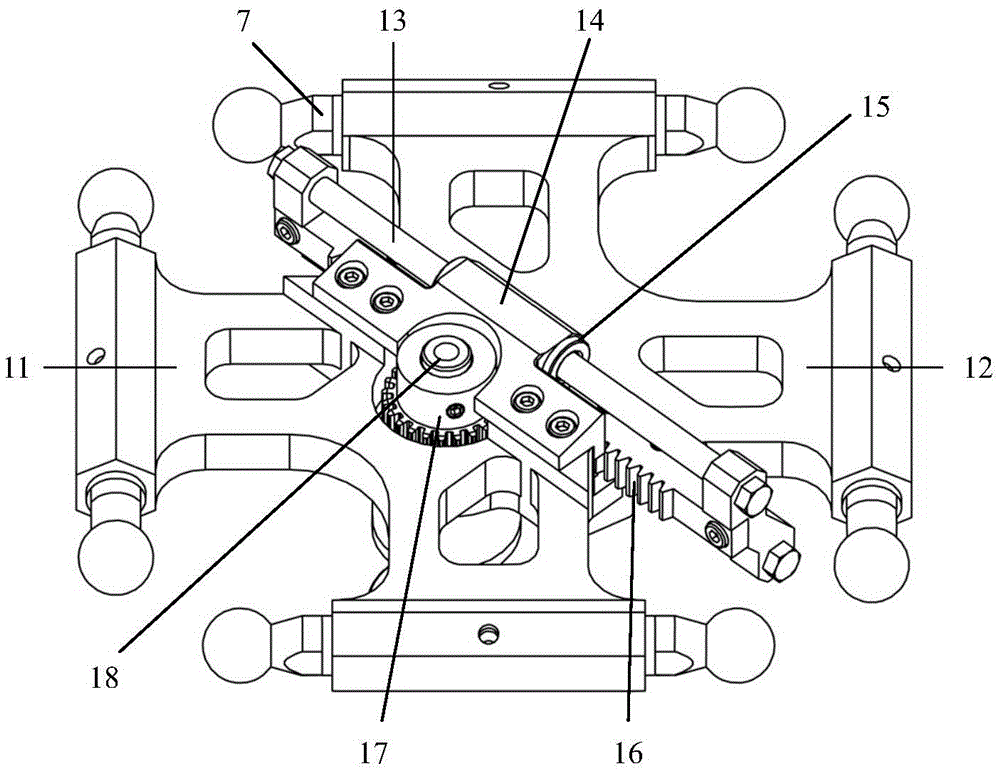

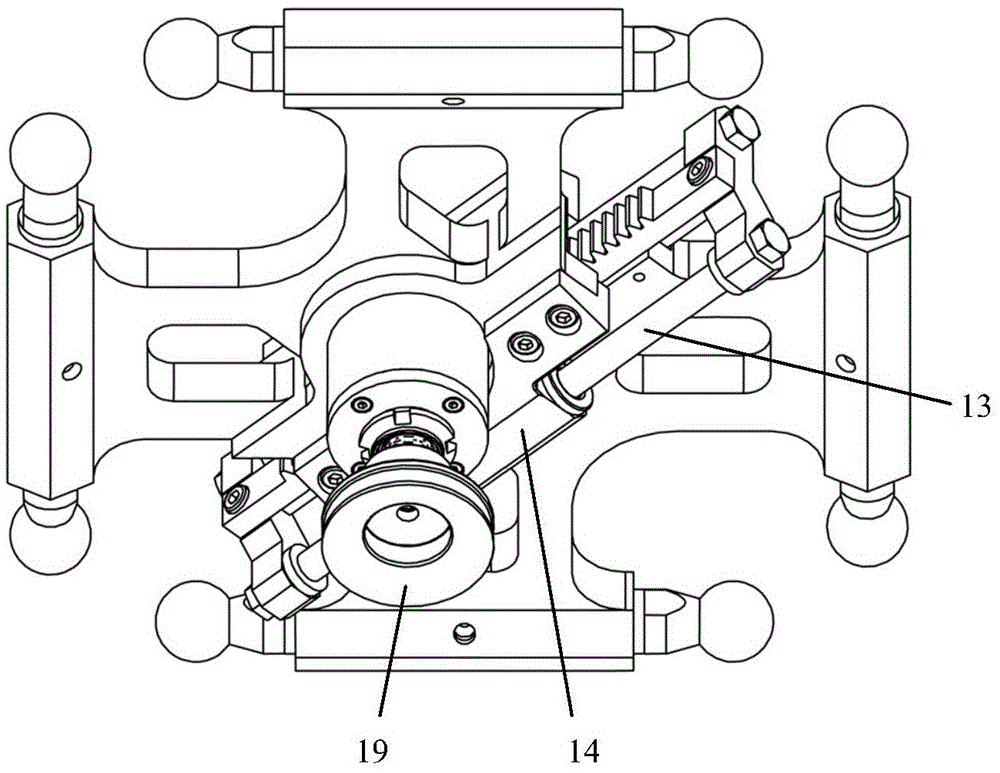

[0015] see figure 1 , a rack-and-pinion four-degree-of-freedom high-speed parallel robot, including a static platform 1, a servo motor 2, a reducer 3, a moving platform 8, and four sets of axes orthogonally arranged between the static platform 1 and the moving platform 8 Branch chains with the same structure; each group of branch chains is composed of active arm 4, upper connecting shaft 5, parallel and equal-length driven rods 6a, 6b and lower link shaft 7; the inner end of the active arm 4 is fixed on the static The output end of the reducer 3 on the platform 1 is affixed, the input end of the reducer 3 is affixed to the output end of the servo motor 2, and the outer end of the active arm 4 is affixed to the upper connecting shaft 5; the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com