Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Excellent glass stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

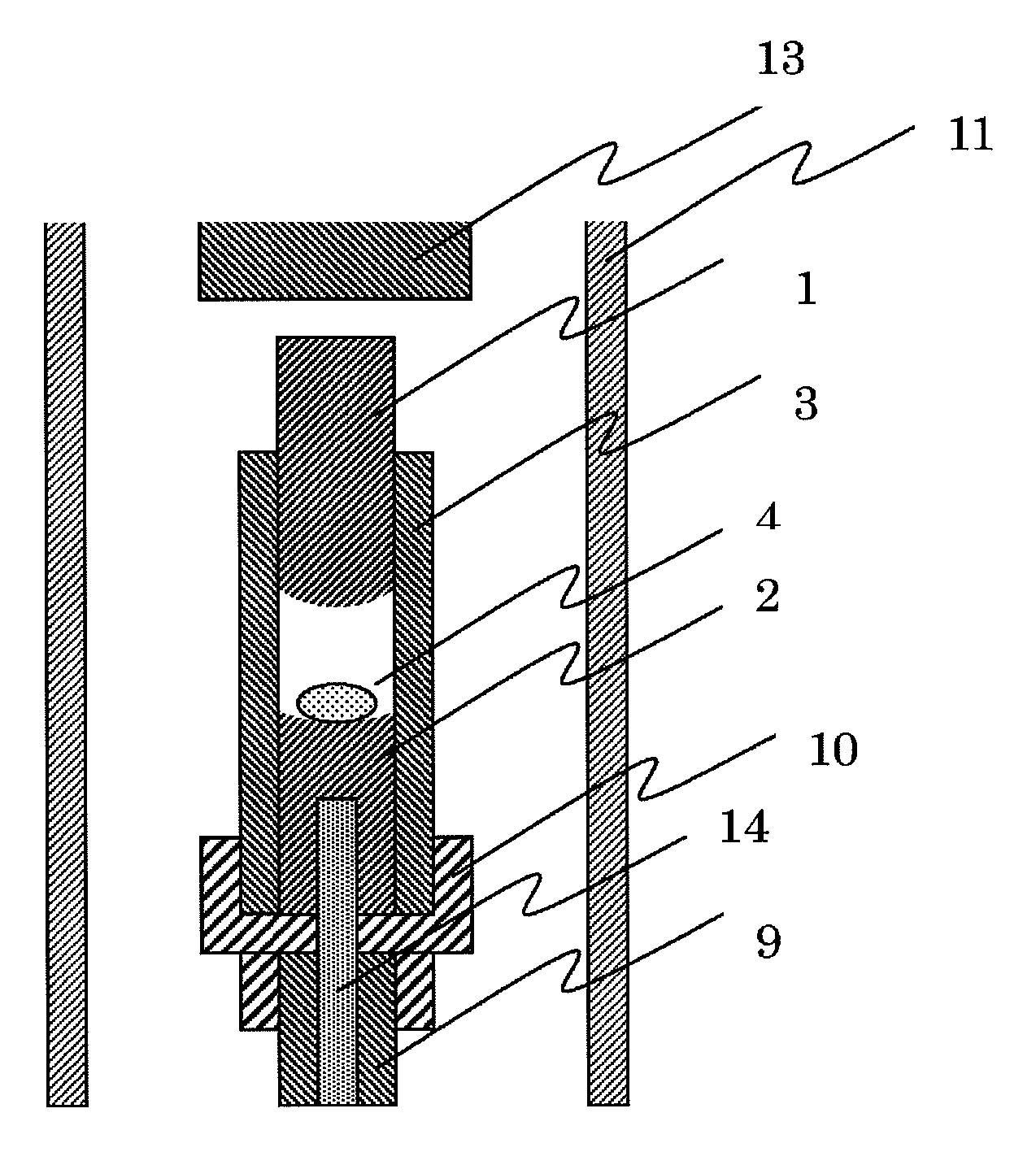

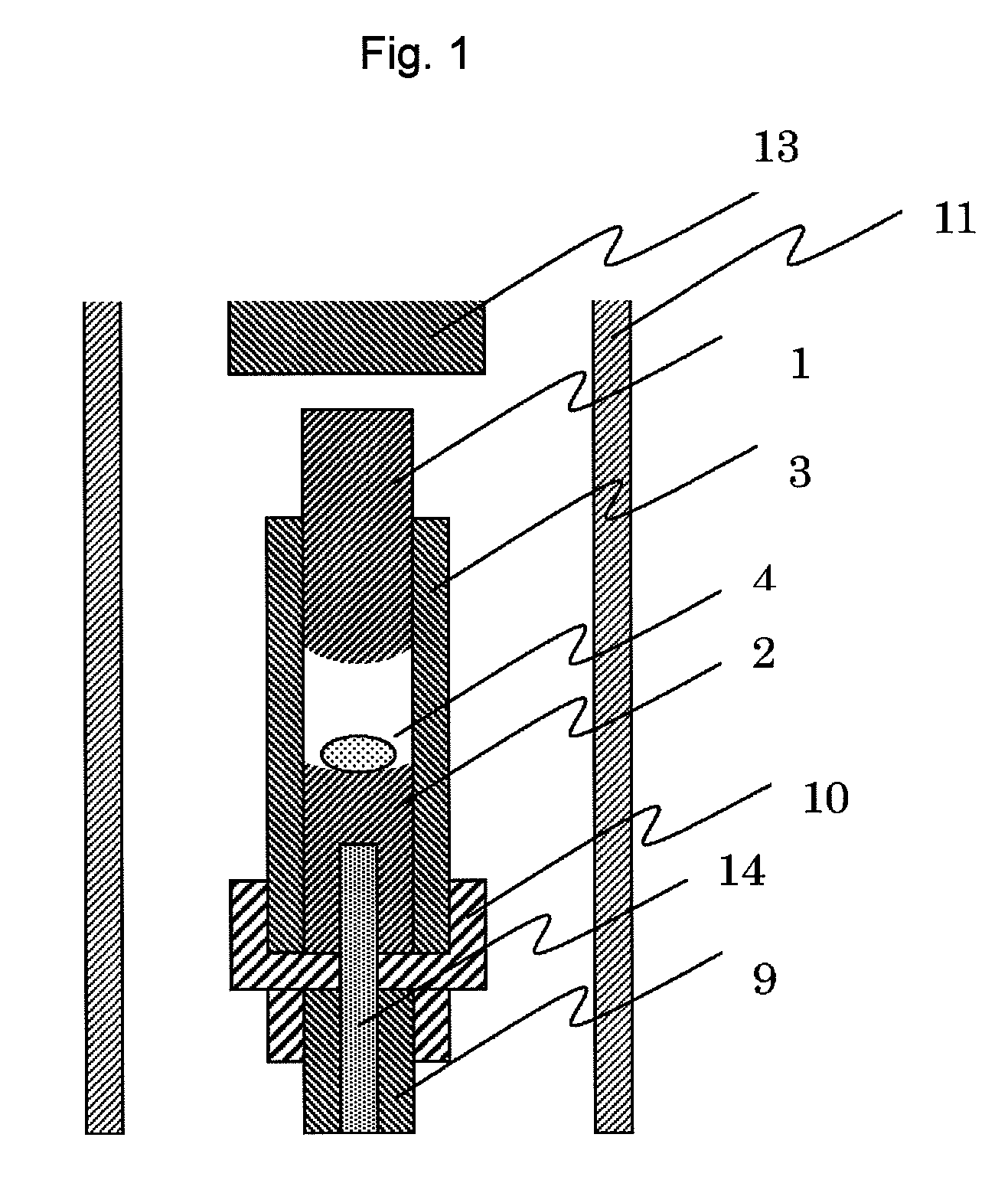

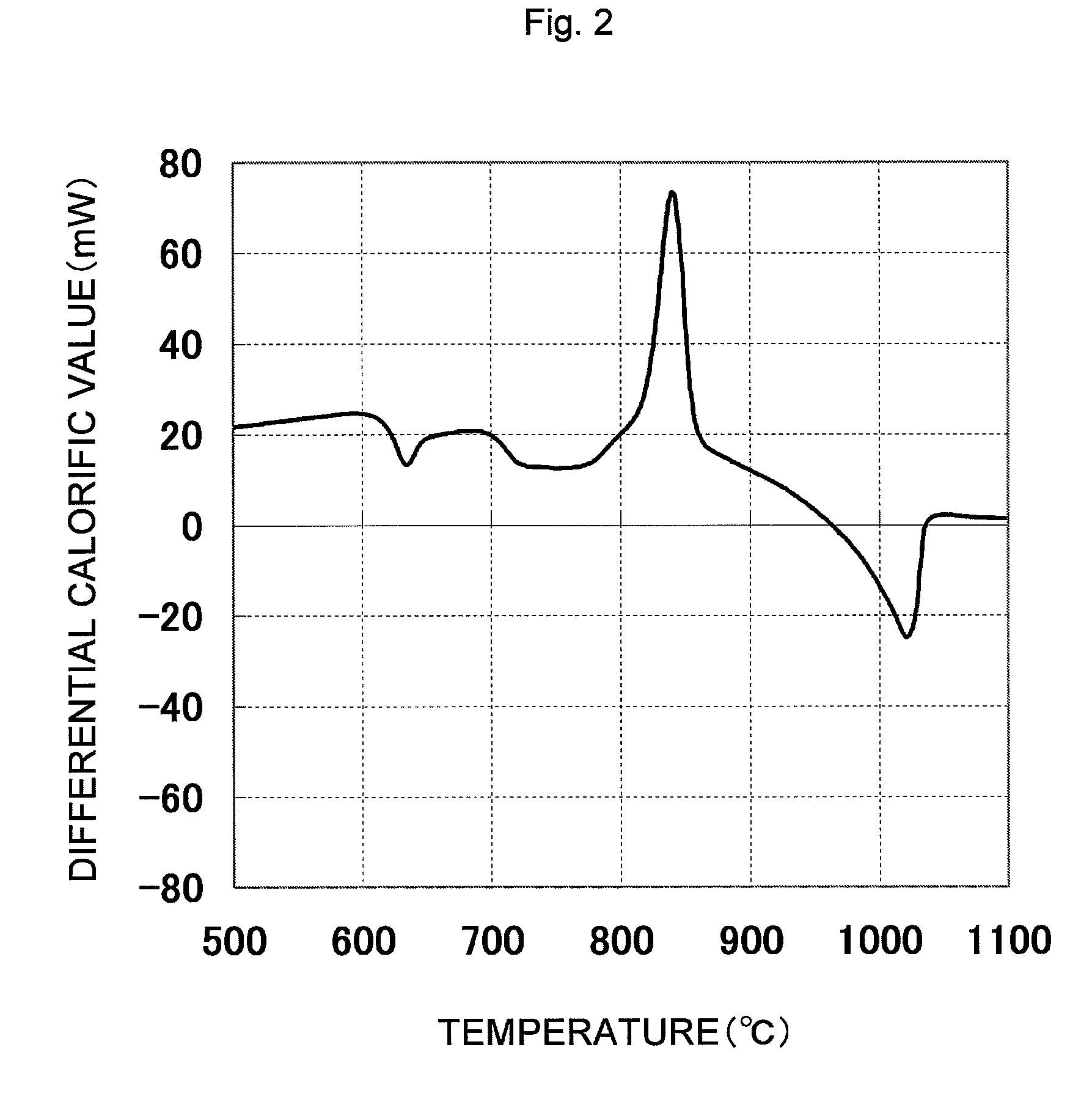

Optical glass

ActiveCN101613184AHigh refractive indexExcellent glass stabilityOptical surface grinding machinesOptical elementsRefractive indexOptical glass

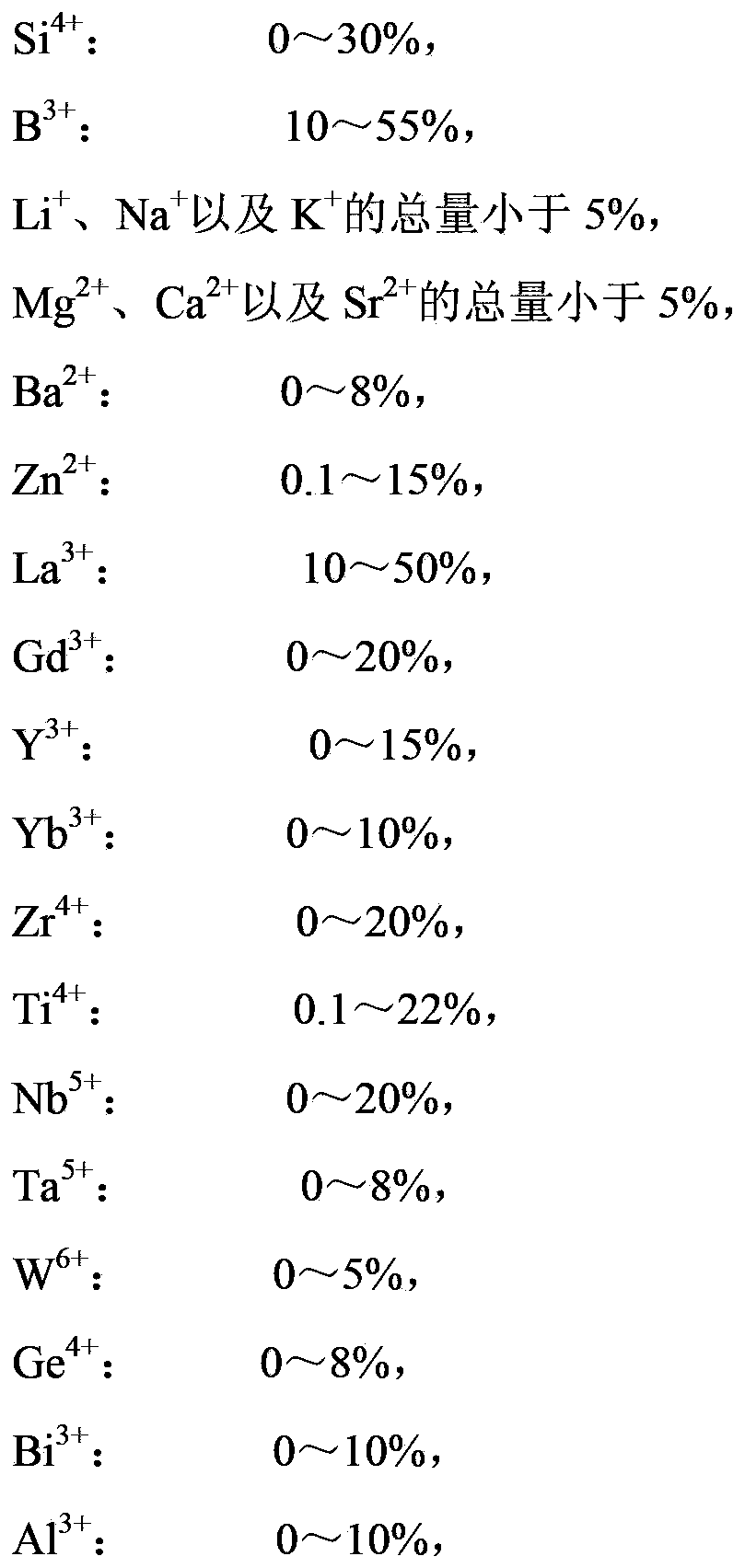

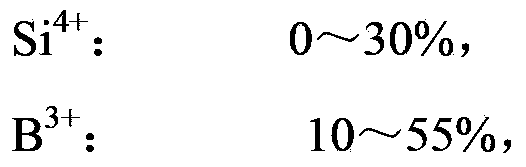

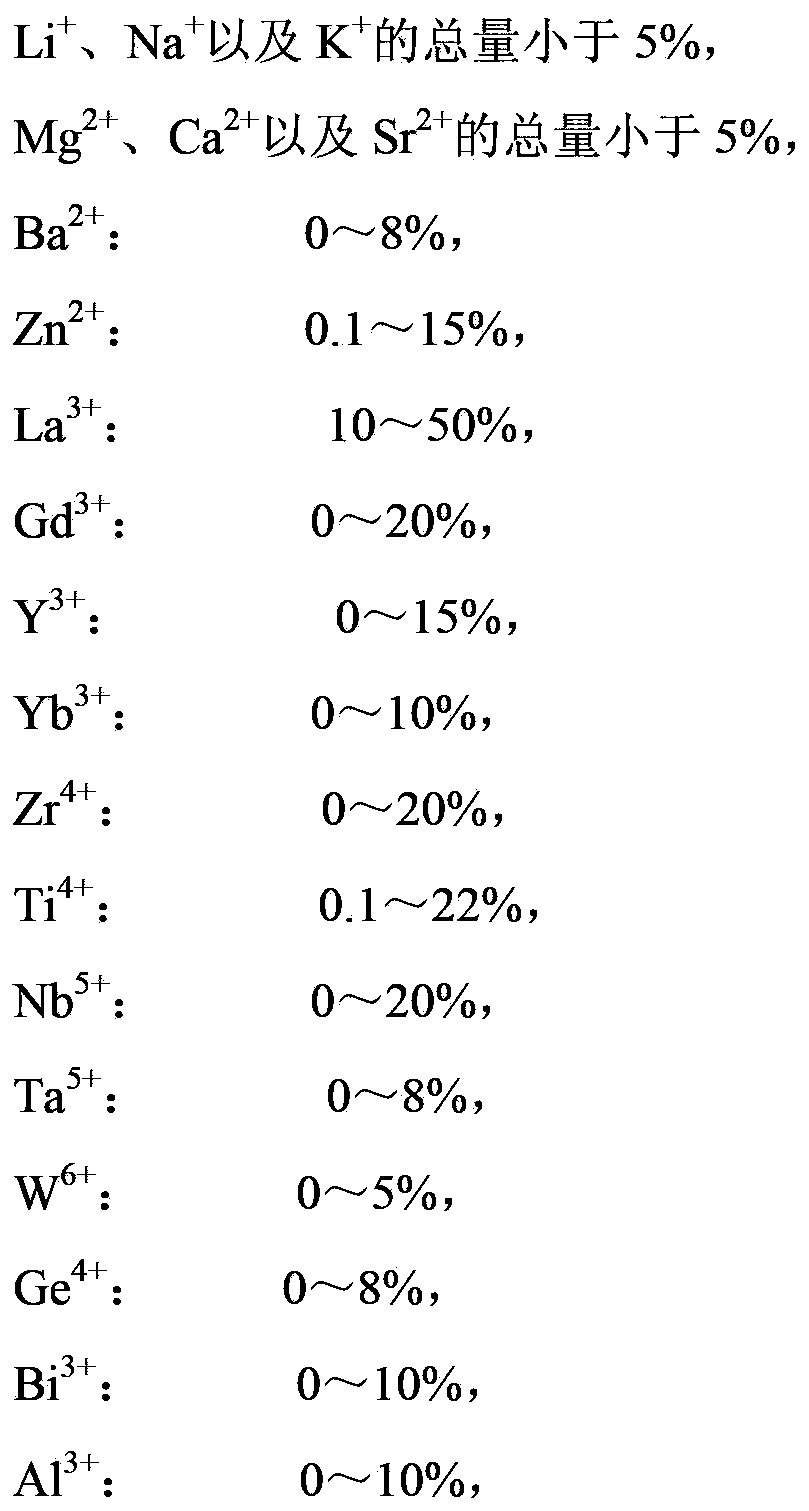

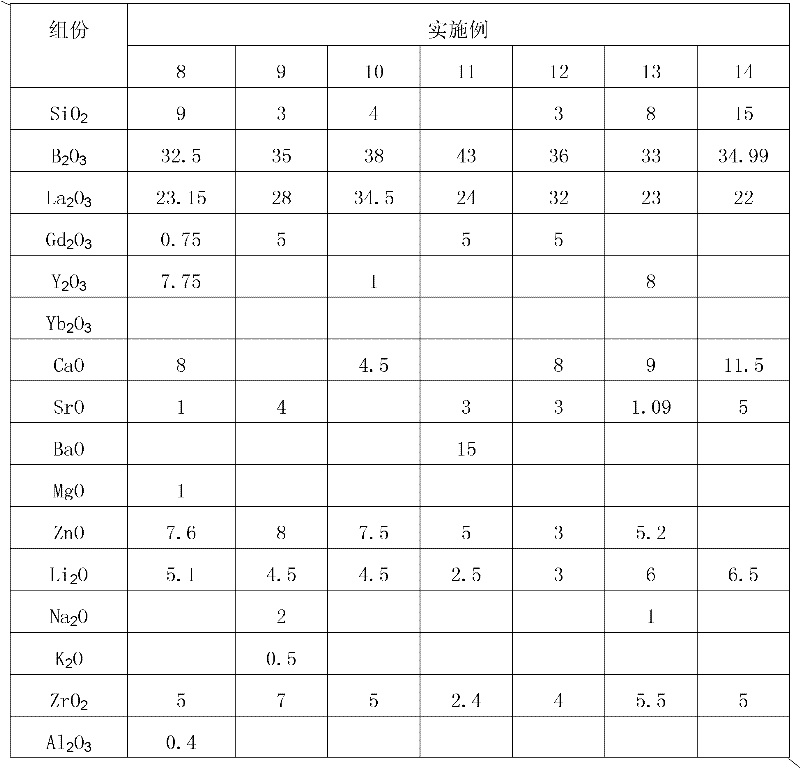

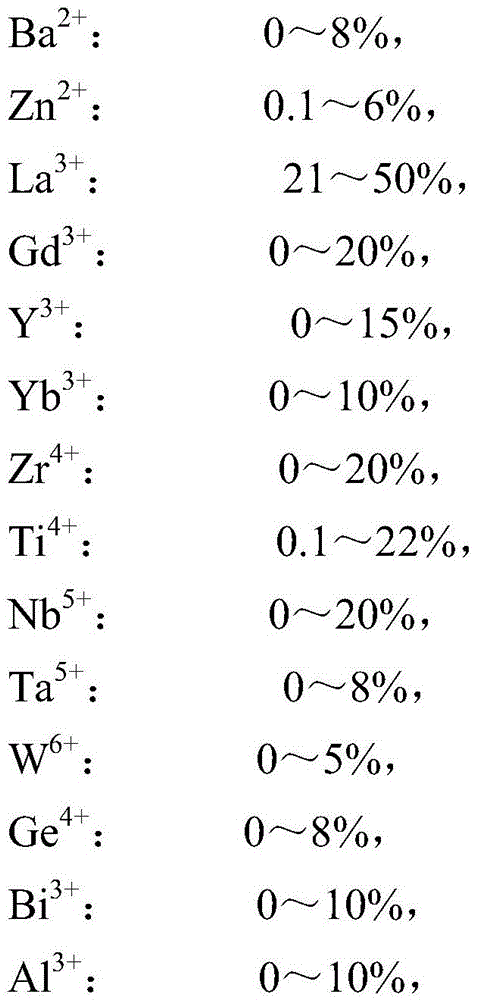

The invention provides an optical glass having a very high refractive index in spite of its low-dispersion property, having excellent glass stability and having less susceptibility to coloring. An optical glass is an oxide glass and is characterized in that the optical glass comprises, by cationic %, 0 to 30% of Si<4>, 10 to 55% of B<3>, less than 5% of total of Li<>, Na<> and K<>, less than 5% of total of Mg<2>, Ca<2> and Sr<2>, 0 to 8% of Ba<2>, 0.1 to 15% of Zn<2>, 10 to 50% of La<3>, 0 to 20% of Gd<3>, 0 to 15% of Y<3>, 0 to 10% of Yb<3>, 0 to 20% of Zr<4>, 0.1 to 22% of Ti<4>, 0 to 20% of Nb<5>, 0 to 8% of Ta<5>, 0 to 5% of W<6>, 0 to 8% of Ge<4>, 0 to 10% of Bi<3>, and 0 to 10% of Ai<3>, the cationic ratio of the content of Si<4> to the content of B<3>, Si<4> / B<3>, being less than 1.0, the total content of Nb2O5 and Ta2O5 as oxides being less than 14 mass %, the optical glass having a refractive index nd of 1.92 to 2.2 and an Abbe's number nud of 25 to 45.

Owner:HOYA CORP

Optical glass, preform for precision press-molding, optical element, and methods for manufacturing the same

InactiveUS20080293556A1Excellent glass stabilityLow melting pointGlass reforming apparatusGlass severing apparatusMetallurgyRefractive index

Provided is an optical glass comprising, denoted as molar percentages:10 to 20 percent SiO2,5 to 40 percent B2O3,SiO2+B2O3=15 to 50 percent,0 to 10 percent Li2O,12 to 36 percent ZnO,where 3×Li2O+ZnO≧18 percent,5 to 30 percent La2O3,0 to 20 percent Gd2O3,0 to 10 percent Y2O3,La2O3+Gd2O3=10 to 30 percent,La2O3 / SIGMA(Σ)RE2O3=0.67 to 0.95(where SIGMA(Σ)RE2O3=La2O3+Gd2O3+Y2O3+Yb2O3+Sc2O3+Lu2O3),0.5 to 10 percent ZrO2,1 to 15 percent Ta2O5,1 to 20 percent WO3,Ta2O5 / WO3≦2.5 (molar ratio),0 to 8 percent Nb2O5,0 to 8 percent TiO2; andhaving a refractive index nd of not less than 1.87 andan Abbé number nu(v)d of not less than 35 but less then 40.A method for manufacturing a preform for precision press molding by separating a glass melt gob from a glass melt obtained by mixing, heating, and melting glass starting materials, and forming a preform in a glass melt gob cooling step, said mixing, heating, and melting of glass starting materials is conducted so as to obtain the above optical glass.

Owner:HOYA CORP

Optical glass, preform for precision press molding, optical element and method of manufacturing thereof

ActiveUS20070232477A1Excellent glass stabilityLow propertyGlass furnace apparatusGlass forming apparatusRefractive indexMaterials science

The optical glass of the present invention has a refractive index nd of 1.70 or greater and an Abbé number of 50 or greater. Given as mole percentages, it comprises: B2O320 to 80 percent,SiO20 to 30 percent,Li2O1 to 25 percent;ZnO0 to 20 percent,La2O34 to 30 percent,Gd2O31 to 25 percent,Y2O30 to 20 percent,ZrO20 to 5 percent,MgO0 to 25 percent,CaO0 to 15 percent,SrO0 to 10 percent,with the combined quantity of the above components being 97 percent or greater. The molar ratio of {ZnO / (La2O3+Gd2O3+Y203)} is 0.8 or less and the molar ratio of {+SrO+BaO) / (La2O3+Gd2O3+Y203)} is 0.8 or less. Ta2O5 may be incorporated as an optional component, with the molar ratio {(ZrO2+Ta2O5) / (La2O3+Gd2O3+Y2O3)}being 0.4 or less. The present invention further relates to a preform for precision press molding comprised of this glass, an optical element comprised of this glass, and methods of manufacturing the same.

Owner:HOYA CORP

Optical glass

ActiveUS20110028300A1Excellent glass stabilityStably supplyGlass furnace apparatusGlass drawing apparatusChemistryRefractive index

An optical glass comprising, by mol %,0.1 to 40% of SiO2,10 to 50% of B2O3,0 to 10% of total of Li2O, Na2O and K2O,0 to 10% of total of MgO, CaO, SrO and BaO,0.5 to 22% of ZnO,5 to 50% of La2O3,0.1 to 25% of Gd2O3,0.1 to 20% of Y2O3,0 to 20% of Yb2O3,0 to 25% of ZrO2,0 to 25% of TiO2,0 to 20% of Nb2O5,0 to 10% of Ta2O5,over 0.1% but not more than 20% of WO3,0 to less than 3% of GeO2,0 to 10% of Bi2O3, and0 to 10% of Al2O3,the mass ratio of the content of SiO2 to the content of B2O3, SiO2 / B2O3, being 1 or less,the optical glass having a refractive index nd of 1.86 to 1.95 and an Abbe's number νd of (2.36−nd) / 0.014 or more but less than 38.

Owner:HOYA CORP

Optical glass, preform for precision press-molding, process for the production of the preform, optical element, and process for the production of the element

InactiveUS20060079390A1High refractive indexExcellent glass stabilityGlass pressing apparatusGlass reforming apparatusRefractive indexOptical glass

An optical glass which has an Abbe's number (νd) of 50 to 59, has the property of not easily reacting with a press mold, a low-temperature softening property, excellent glass stability and high refractivity, and is suitable for precision press-molding. The optical glass comprising B2O3 and SiO2 as essential components and having a B2O3 and SiO2 total content (B2O3+SiO2) of 45 to 70 by mol % and an SiO2 content / B2O3 content molar ratio (SiO2 / B2O3) of from 0.1 to 0.5, the optical glass further comprising, by mol %, 5 to 15% of La2O3, 0.1 to 8% of Gd2O3, provided that the total content of La2O3 and Gd2O3 is 8% or more, 0 to 10% of Y2O3, 3 to 18% of Li2O, provided that the molar ratio of the content of Li2O to the total content of B2O3 and SiO2 [Li2O / (B2O3+SiO2)] is over 0 but not more than 0.2, 0.1 to 15% of ZnO, 2 to 20% of CaO, 0 to 5% of BaO, provided that the content of BaO is smaller than the content of ZnO, 0 to 5% of SrO, 0 to 5% of MgO, provided that the molar ratio of the total content of MgO, CaO, SrO and BaO to the total content of B2O3 and SiO2 [(MgO+CaO+SrO+BaO) / (B2O3+SiO2) is from 0.1 to 0.4, and 0 to 5% of ZrO2, and having a refractive index (nd) and an Abbe's number (νd) which satisfy the equation (1), νd≧308.5−150×nd (in which 50≦νd≦59) (1)

Owner:HOYA CORP

Optical glass, prefabricated part for precise compression molding and optical element

ActiveCN101439929ANot easy to crystallizeExcellent glass stabilityGlass pressing apparatusCompression moldingMetallurgy

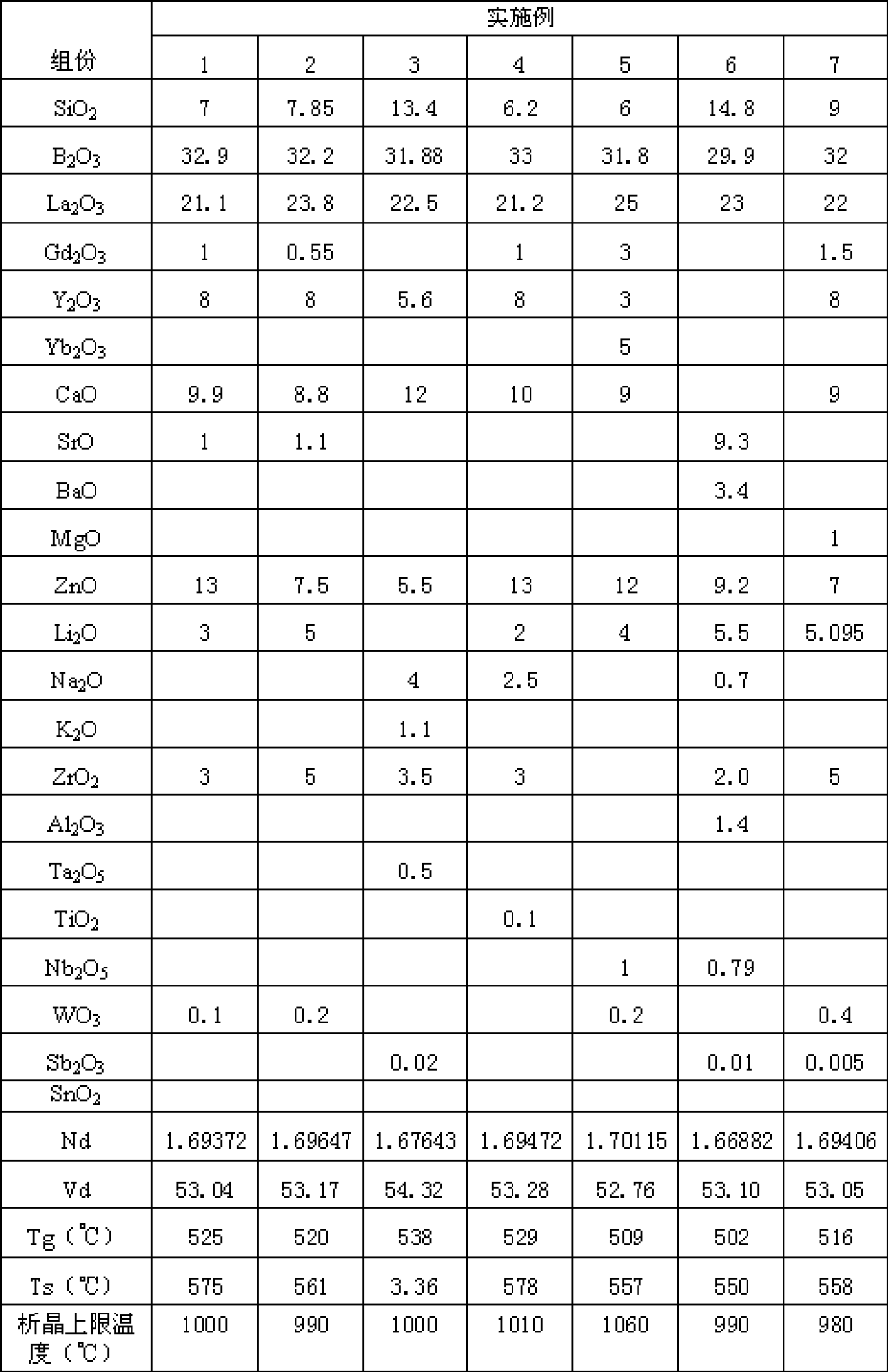

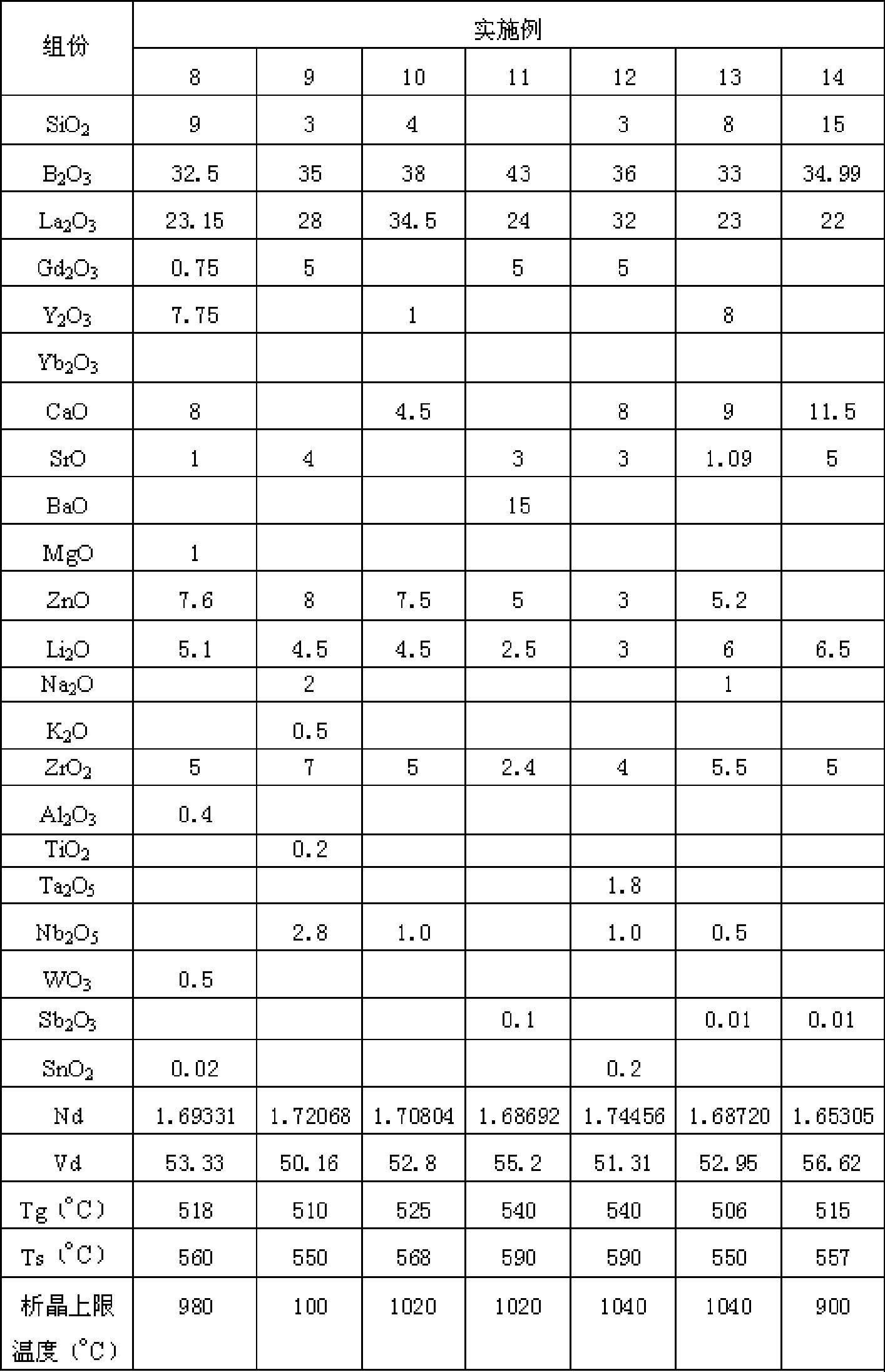

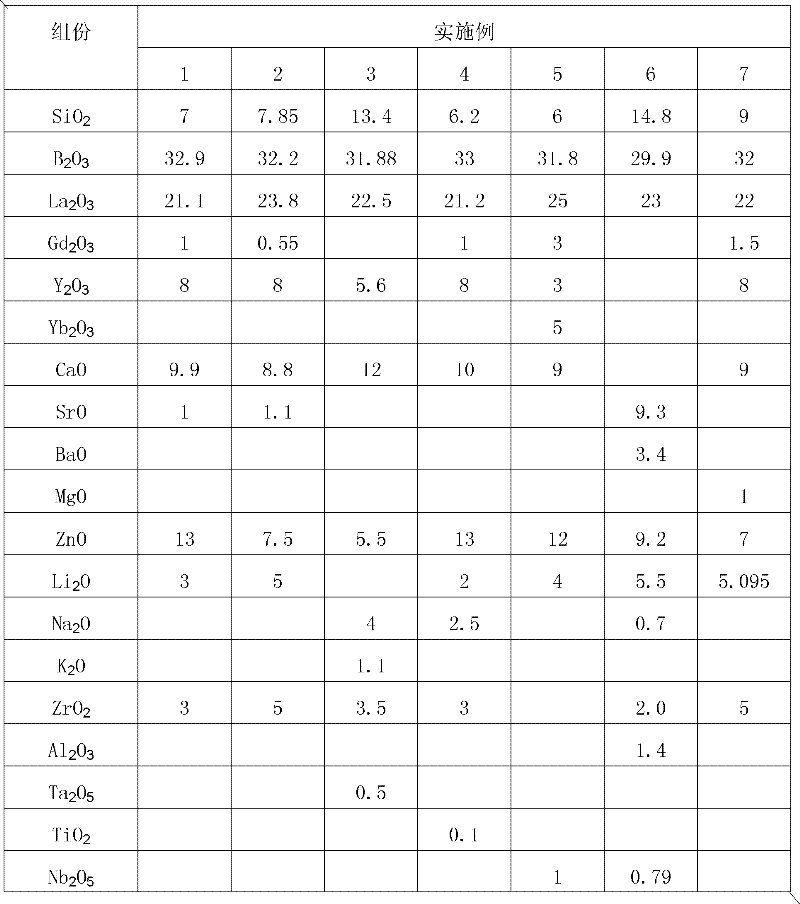

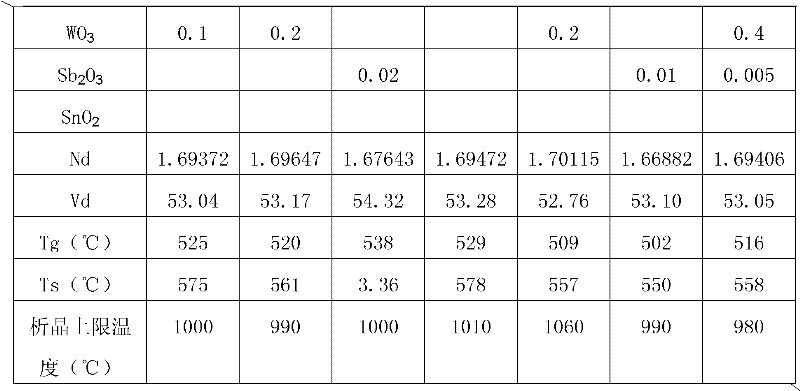

The invention provides optical glass for precision compression, a preformed unit for precision compression and an optical element, wherein the nd is between 1.65 and 1.75, vd is between 50 and 60 and the transformation temperature Tg is less than 540 DEG C. The optical glass comprises the following compositions by weight percentage: 0 to 15 percent of SiO2, 28 to 43 percent of B2O3, 21 to 35 percent of La2O3, 0 to 15 percent of Gd2O3, Y2O3 and Yb2O3, 3 to 13 percent of ZnO, 1 to 8 percent of Li2O, Na2O and K2O, 1 to 20 percent of MgO, CaO, SrO and BaO, 0 to 8 percent of ZrO2, 0 to 0.1 percent of Sb2O3, 0 to 0.5 percent of SnO2, and 0 to 3 percent of Ta2O5, WO3, Nb2O5 and TiO2. The optical glass prolongs the service life of a mould, realizes high-efficiency production, and simultaneously can also reduce the production cost of the optical element.

Owner:CDGM OPTICAL GLASS

Optical glass and use thereof

ActiveUS9302930B2Excellent glass stabilityLittle colorationGlass furnace apparatusGlass forming apparatusRefractive indexOptical glass

An aspect of the present invention relates to optical glass, which is oxide glass, having a refractive index nd ranging from 1.95 to 2.50 and an Abbé number νd ranging from 18 to 40, including essential components in the form of Si4+, B3+, La3+, Ti4+, Nb5+, and at least one from among Gd3+, Y3+, and Yb3+, including, denoted as cation %, 1 to 30% of Si4+, 1 to 50% of B3+, wherein a total of Si4+ and B3+ ranges from 5 to 55%, a total of 11 to 70% of La3+, Gd3+, Y3+, and Yb3+, with 10 to 50% of La3+, a total of 23 to 70% of Ti4+, Nb5+, Ta5+, and W6+, with equal to or greater than 1% of Nb5+ and greater than 22% of Ti4+.

Owner:HOYA CORP

Optical glass, preform for precision press molding, method for manufacturing preform for precision press molding, optical element, and method for manufacturing optical element

ActiveUS20090099002A1Low propertyExcellent glass stabilityGlass pressing apparatusGlass rolling apparatusPhysical chemistryRefractive index

The present invention relates to an optical glass having optical constants in the form of a refractive index nd of 1.70 or higher and an Abbé number nud of 50 or higher, a preform for precision press molding comprised of this glass, an optical element comprised of this glass, and methods for manufacturing the preform and the optical element.

Owner:HOYA CORP

Optical glass

InactiveUS7563738B2Excellent chemical durabilityImprove the immunityWeather resistanceRefractive index

An optical glass has a low glass transition temperature (Tg) and optical constants in which a refractive index (nd) is in the range of from 1.70 to less than 1.74 and an Abbe number (νd) is between 40 and 45 (excluding 40 and 45), has a content of SiO2 is 17% by mass or less, a glass transition temperature (Tg) is 540° C. or less, and a weathering resistance (surface-method) in Class 1 or 2, and has excellent chemical durability, particularly weathering resistance (surface-method) and is appropriate for precision mold press forming.

Owner:OHARA

Optical glass

InactiveUS20060100085A1Excellent chemical durabilityImprove the immunityWeather resistanceRefractive index

An optical glass has a low glass transition temperature (Tg) and optical constants in which a refractive index (nd) is in the range of from 1.70 to less than 1.74 and an Abbe number (νd) is between 40 and 45 (excluding 40 and 45), has a content of SiO2 is 17% by mass or less, a glass transition temperature (Tg) is 540° C. or less, and a weathering resistance (surface-method) in Class 1 or 2, and has excellent chemical durability, particularly weathering resistance (surface-method) and is appropriate for precision mold press forming.

Owner:OHARA

Optical glass

ActiveUS8424344B2Excellent glass stabilityStable supplyGlass furnace apparatusGlass drawing apparatusRefractive indexSilicon dioxide

Owner:HOYA CORP

Optical glass and optical element

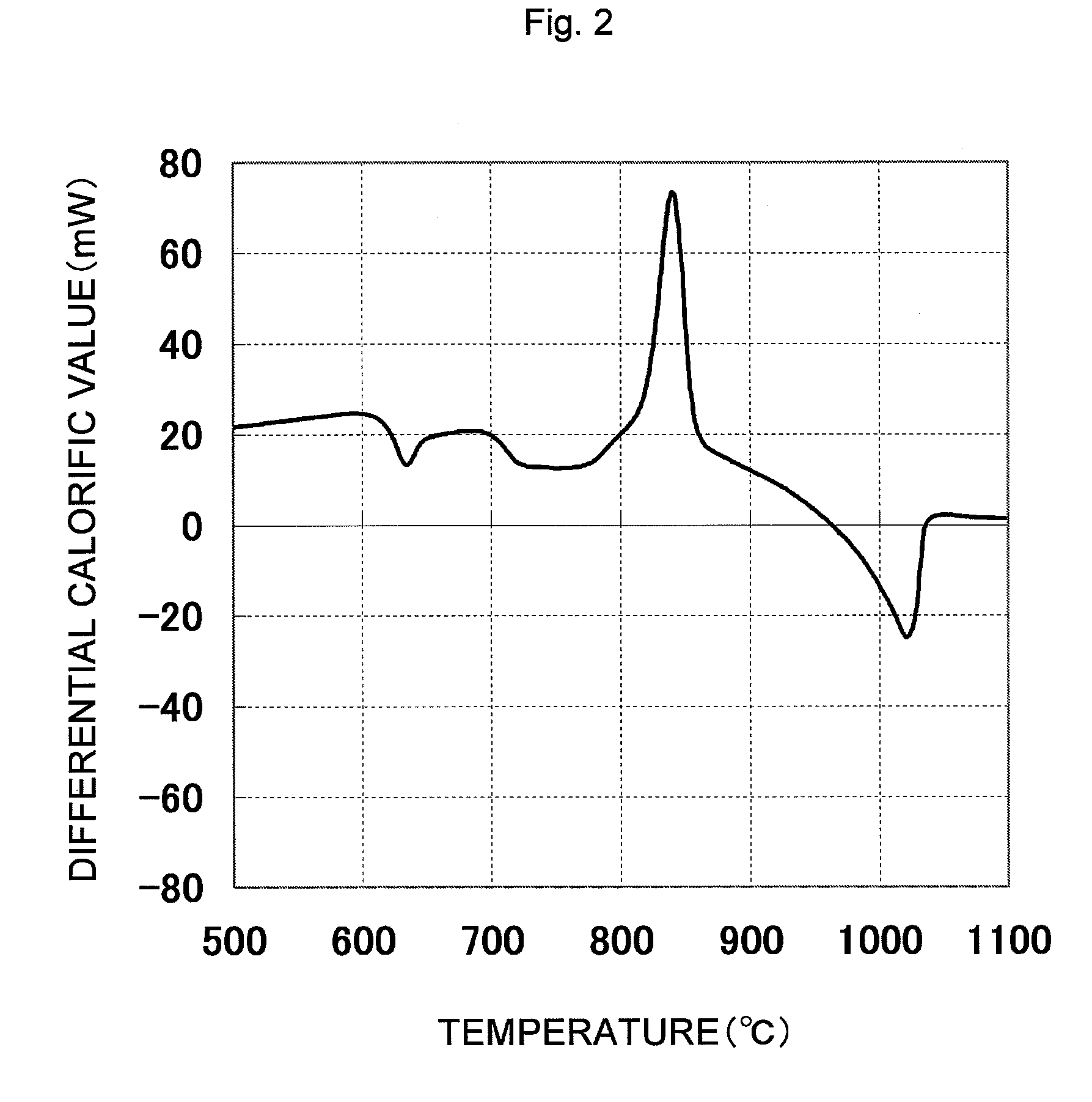

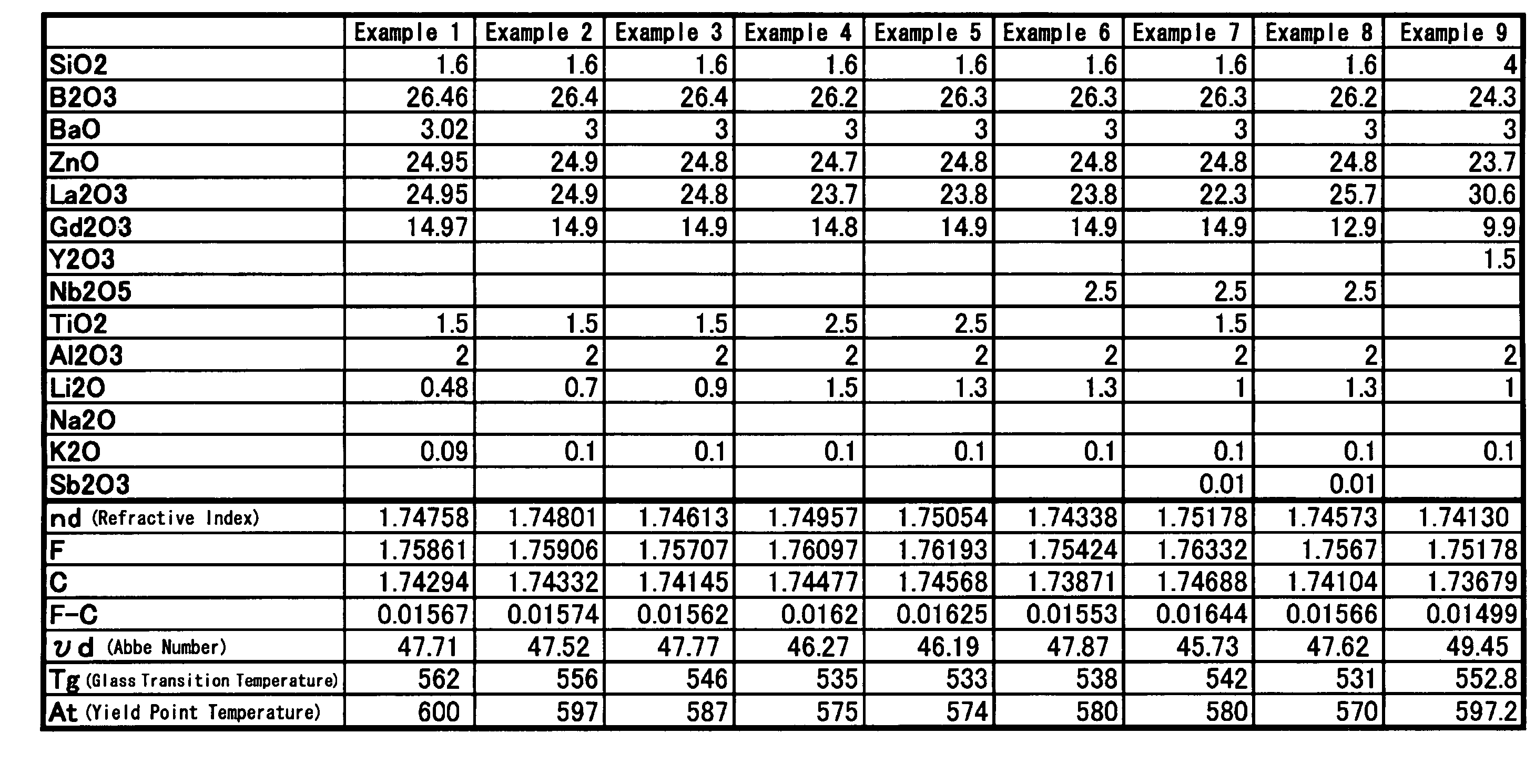

InactiveUS20090011918A1Low melting pointDesired optical characteristics and glass stabilityOptical elementsRefractive indexGlass transition point

An optical glass of the present invention has optical constants with a refractive index (nd) of 1.74 to 1.76 and an Abbe number (υd) of 45 to 49.5, contains SiO2, B2O3, BaO, ZnO, La2O3, Gd2O3, TiO2, Al2O3, and Li2O as essential components, does not contain Ta2O5, GeO2, or ZrO2 which usually affects the stabilization of glass, does not contain lead, arsenic, or fluorine having adverse effects on the environment, and has a glass transition point Tg of 530 to 590° C.According to the present invention, a stable glass for precision press-molding can be provided which has a low glass transition temperature (Tg), has a high refractive index and a low dispersion property, and does not contain expensive Ta2O5, GeO2, ZrO2, or Y2O3.

Owner:OMG CO LTD

Optical glass, preform for precision press molding, method for manufacturing preform for precision press molding, optical element, and method for manufacturing optical element

ActiveUS8012896B2Low propertyExcellent glass stabilityGlass pressing apparatusGlass rolling apparatusRefractive indexOptical glass

The present invention relates to an optical glass having optical constants in the form of a refractive index nd of 1.70 or higher and an Abbé number nud of 50 or higher, a preform for precision press molding comprised of this glass, an optical element comprised of this glass, and methods for manufacturing the preform and the optical element.

Owner:HOYA CORP

Optical glass

ActiveCN103351101AHigh refractive indexExcellent glass stabilityOptical surface grinding machinesOptical elementsRefractive indexOptical glass

An optical glass that is an oxide glass having a very high refractive index in spite of its low-dispersion property, having excellent glass stability and having less susceptibility to coloring.

Owner:HOYA CORP

Optical glass

The present invention provides an optical glass, containing, in % by weight on an oxide basis, 30 to 50% of P2O5, 18 to 43% of BaO, 2 to 12% of B2O3, 1.4 to 5% of Al2O3, more than 0 to 6% of Li2O, more than 0 to 9% of La2O3, 0.1 to 8% of MgO, 0 to 10% of CaO, 0 to 15% of SrO, 0 to 5% of ZnO, 0 to 7% of Gd2O3, and 0 to 3% of SiO2, and having optical constants of a refractive index nd of 1.59 to 1.63 and an Abbe number νd of 63 to 68.

Owner:ASAHI GLASS CO LTD

Optical glass, preform for precision press-molding, optical element, and methods for manufacturing the same

InactiveUS7855158B2Excellent glass stabilityLow melting pointGlass reforming apparatusGlass severing apparatusMetallurgyRefractive index

Provided is an optical glass comprising, denoted as molar percentages:10 to 20 percent SiO2,5 to 40 percent B2O3,SiO2+B2O3=15 to 50 percent,0 to 10 percent Li2O,12 to 36 percent ZnO,where 3×Li2O+ZnO≧18 percent,5 to 30 percent La2O3,0 to 20 percent Gd2O3,0 to 10 percent Y2O3,La2O3+Gd2O3=10 to 30 percent,La2O3 / SIGMA(Σ)RE2O3=0.67 to 0.95(where SIGMA(Σ)RE2O3=La2O3+Gd2O3+Y2O3+Yb2O3+Sc2O3+Lu2O3),0.5 to 10 percent ZrO2,1 to 15 percent Ta2O5,1 to 20 percent WO3,Ta2O5 / WO3≦2.5 (molar ratio),0 to 8 percent Nb2O5,0 to 8 percent TiO2; andhaving a refractive index nd of not less than 1.87 andan Abbé number nu(v)d of not less than 35 but less then 40.A method for manufacturing a preform for precision press molding by separating a glass melt gob from a glass melt obtained by mixing, heating, and melting glass starting materials, and forming a preform in a glass melt gob cooling step, said mixing, heating, and melting of glass starting materials is conducted so as to obtain the above optical glass.

Owner:HOYA CORP

Optical glass, preform for precision press molding, optical element and method of manufacturing thereof

InactiveUS8039408B2Excellent glass stabilityLow propertyGlass furnace apparatusGlass forming apparatusRefractive indexOptical glass

The optical glass of the present invention has a refractive index nd of 1.70 or greater and an Abbé number of 50 or greater. Given as mole percentages, it comprises:B2O320 to 80 percent,SiO20 to 30 percent,Li2O1 to 25 percent;ZnO0 to 20 percent,La2O34 to 30 percent,Gd2O31 to 25 percent,Y2O30 to 20 percent,ZrO20 to 5 percent,MgO0 to 25 percent,CaO0 to 15 percent,SrO0 to 10 percent,with the combined quantity of the above components being 97 percent or greater. The molar ratio of {ZnO / (La2O3+Gd2O3+Y2O3)} is 0.8 or less and the molar ratio of {(CaO +SrO+BaO) / (La2O3+Gd2O3+Y2O3)} is 0.8 or less. Ta2O5 may be incorporated as an optional component, with the molar ratio {(ZrO2+Ta2O5) / (La2O3+Gd2O3+Y2O3)}being 0.4 or less. The present invention further relates to a preform for precision press molding comprised of this glass, an optical element comprised of this glass, and methods of manufacturing the same.

Owner:HOYA CORP

Glass for magnetic recording medium substrate, magnetic recording medium substrate, magnetic recording medium and glass spacer for magnetic recording and reproducing apparatus

ActiveUS11081133B2Increase resistanceImprove rigidityBase layers for recording layersVacuum evaporation coatingVitrificationAlkali metal oxide

A glass for magnetic recording medium substrate is an amorphous oxide glass. In terms of mol %, SiO2 content ranges from 45 to 68%, Al2O3 from 5 to 20%, total content of SiO2 and Al2O3 60 to 80%, B2O3 from 0 to 5%, MgO from 3 to 28%, CaO from 0 to 18%, total content of BaO and SrO 0 to 2%, total content of alkali earth metal oxides from 12 to 30%, total content of alkali metal oxides from 3.5 to 15%, and at least one kind selected from the group made of Sn oxide and Ce oxide being included, a total content of Sn oxide and Ce oxide ranges from 0.05 to 2.00%, a glass transition temperature ≥625° C., a Young's modulus ≥83 GPa, a specific gravity ≤2.85, and an average linear expansion coefficient at 100 to 300° C.≥48×10−7 / ° C.

Owner:HOYA CORP

Optical glass and use thereof

ActiveUS20150045204A1Excellent glass stabilityLittle colorationGlass furnace apparatusGlass drawing apparatusRefractive indexOptical glass

An aspect of the present invention relates to optical glass, which is oxide glass, having a refractive index nd ranging from 1.95 to 2.50 and an Abbé number νd ranging from 18 to 40, including essential components in the form of Si4+, B3+, La3+, Ti4+, Nb5+, and at least one from among Gd3+, Y3+, and Yb3+, including, denoted as cation %, 1 to 30% of Si4+, 1 to 50% of B3+, wherein a total of Si4+ and B3+ ranges from 5 to 55%, a total of 11 to 70% of La3+, Gd3+, Y3+, and Yb3+, with 10 to 50% of La3+, a total of 23 to 70% of Ti4+, Nb5+, Ta5+, and W6+, with equal to or greater than 1% of Nb5+ and greater than 22% of Ti4+.

Owner:HOYA CORP

Optical glass

ActiveUS20130210604A1Excellent glass stabilityStable supplyGlass forming apparatusRefractive indexGlass transition

An optical glass having high-refractivity and low-dispersion properties and containing, by mol %, 0.1 to 40% of SiO2, 10 to 50% of B2O3, wherein the mass ratio of the content of SiO2 to the content of B2O3, SiO2 / B2O3, is 1 or less, 0.5 to 22% of ZnO, 5 to 50% of La2O3, and optionally other ingredients. The optical glass has a refractive index nd of 1.86 to 1.95 and an Abbe's number vd of (2.36−nd) / 0.014 or more but less than 38, and a glass transition temperature of equal to or greater than 640° C.

Owner:HOYA CORP

Optical glass, precision press-molding preform, optical element and their production processes as well as image-sensing device

ActiveUS20110034315A1Good precisionIncrease resistanceGlass drawing apparatusGlass forming apparatusRefractive indexOptical glass

An optical glass that is an oxide glass and comprises, by cationic %,20 to 40% of a total of Si4+ and B3+,15 to 40% of a total of Nb5+, Ti4+, W6+ and Zr4+,0.2 to 20% of a total of Zn2+, Ba2+, Sr2+ and Ca2+, and15 to 55% of a total of Li+, Na+ and K+,the cationic ratio of the content of B3+ to the total content of B3+ and Si4+ being 0.01-0.5,the cationic ratio of the content of Zr4+ to the total content of Nb5+, Ti4+, W6+ and Zr4+ being 0.05 or less,the molar ratio of the total content of Zn2+ and Ba2+ to the total content of Zn2+, Ba2+, Sr2+ and Ca2+ being 0.8-1,the optical glass having a refractive index nd of 1.815 or more and an Abbe's number νd of 29 or less.

Owner:HOYA CORP

Optical glass

A P2O5—BaO—ZnO—Nb2O5 type optical glass contains 25-50 wt. % P2O5, 15-35 wt. % BaO, 1-25 wt. ZnO, and 3-10 wt. % Nb2O5. The optical glass has a high refractive index (particularly preferably the refractive index nd of 1.6 or more), low dispersion (an Abbe number υd of 42 or more), a low deformation point, and improved resistance to devitrification upon molding, and is suitable for precision-mold press molding or other molding processes and also suitable for transfer of a fine structure.

Owner:NIHON YAMAMURA GLASS CO LTD +1

Optical toughened glass

The invention provides an optical toughened glass. The glass comprises SiO2, CaO, MgO, Al2O3, Na2O, B2O3, K2O, BaO, MoO3, CdO, La2O3, Gd2O3, Y2O3 and Yb2O3. After expensive Ta2O5 is discarded, the glass having excellent glass stability, high refractive index and low chromatic dispersion is obtained through adopting the co-existence form of the La2O3, Gd2O3, Y2O3 and Yb2O3, MoO3 can reduce the generation amount of nickel sulfide stones, and MoO3 and CdO are mixed to inhibit smoke generated in the glass production process, so the safety in the glass production process is ensured, and the self-explosion possibility of the glass is reduced.

Owner:重庆品信玻璃有限公司

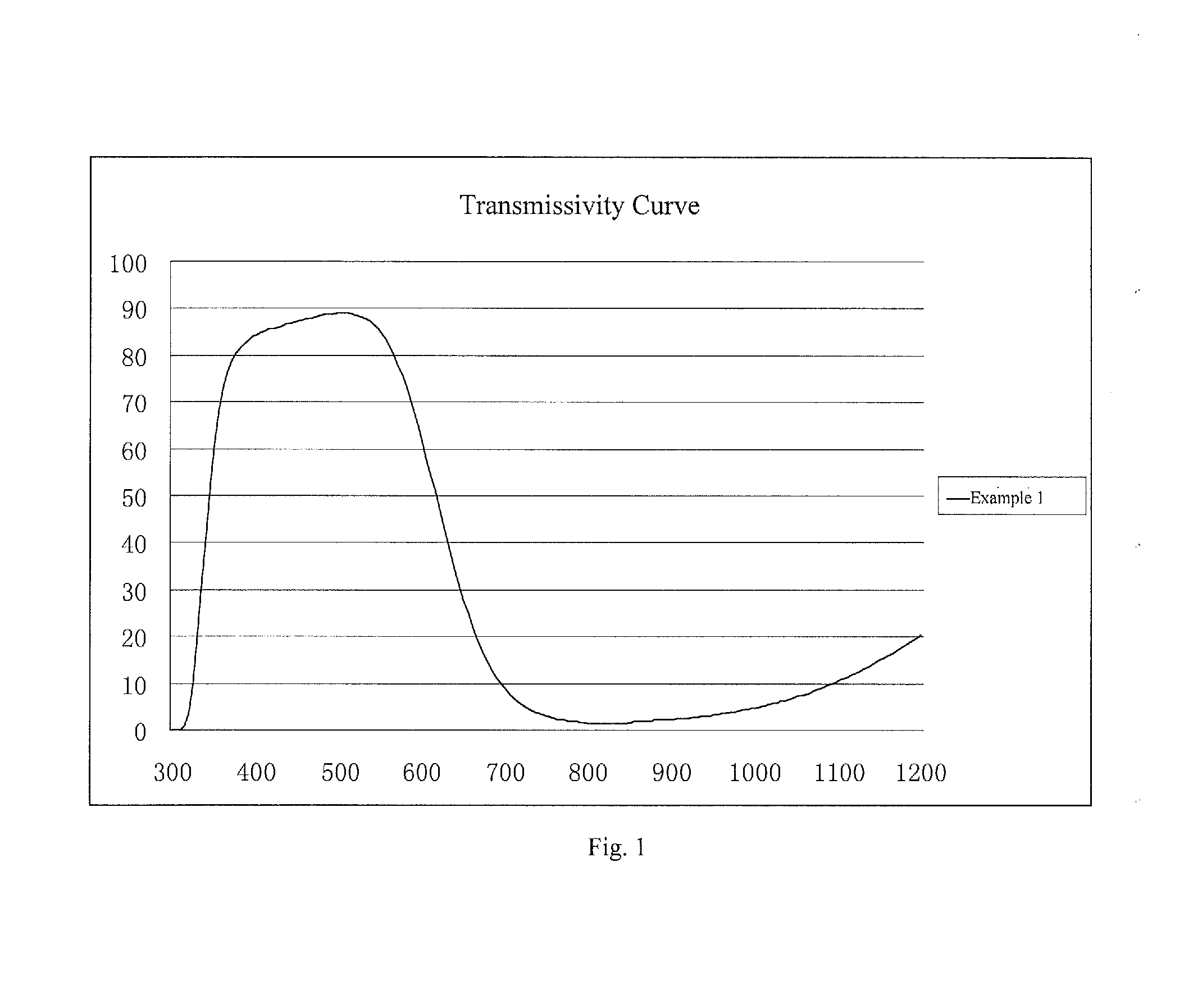

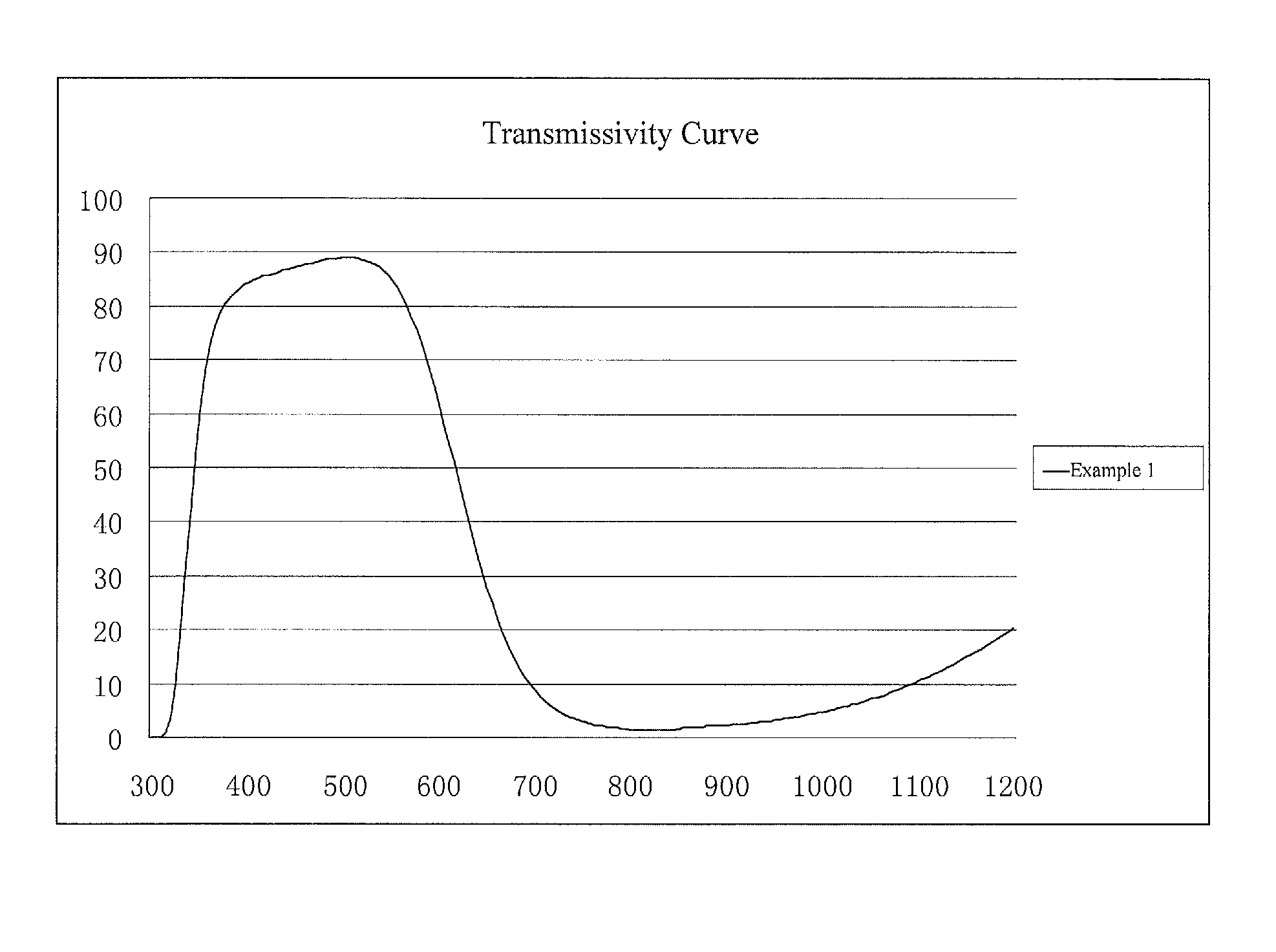

Near-infrared light absorbing glass, element and filter

ActiveUS20150329411A1Improve homogeneityImprove transmittanceOptical filtersSpectral modifiersTransmittanceLength wave

Provided is a near-infrared light absorbing glass with a near-infrared light absorbing element and a near-infrared light absorbing filter. When the length of the near-infrared light absorbing glass is 1 mm, transmissivity is more than 80% at the wavelength of 400 nm, and more than 85% at the wavelength of 500 nm. The near-infrared light absorbing glass contains P5+, Al3+, Li+, R2+ and Cu2+ represented by positive ions, wherein R2+ represents Mg2+, Ca2+, Sr2+ and Ba2+. Meanwhile, the near-infrared light absorbing glass contains O2− and F− represented by negative ions. Water durability (DW) of the near-infrared light absorbing glass reaches Class 1 and acid durability (DA) reaches above Class 4. In this invention, fluorphosphate glass is used as the matrix glass and the components are designed specially, so that the melting temperature of glass can be effectively lowered and the chemical stability of the glass can be excellent.

Owner:CDGM OPTICAL GLASS

Optical glass, prefabricated part for precise compression molding and optical element

ActiveCN101439929BNot easy to crystallizeExcellent glass stabilityGlass pressing apparatusCompression moldingOptical glass

The invention provides optical glass for precision compression, a preformed unit for precision compression and an optical element, wherein the nd is between 1.65 and 1.75, vd is between 50 and 60 and the transformation temperature Tg is less than 540 DEG C. The optical glass comprises the following compositions by weight percentage: 0 to 15 percent of SiO2, 28 to 43 percent of B2O3, 21 to 35 percent of La2O3, 0 to 15 percent of Gd2O3, Y2O3 and Yb2O3, 3 to 13 percent of ZnO, 1 to 8 percent of Li2O, Na2O and K2O, 1 to 20 percent of MgO, CaO, SrO and BaO, 0 to 8 percent of ZrO2, 0 to 0.1 percent of Sb2O3, 0 to 0.5 percent of SnO2, and 0 to 3 percent of Ta2O5, WO3, Nb2O5 and TiO2. The optical glass prolongs the service life of a mould, realizes high-efficiency production, and simultaneously can also reduce the production cost of the optical element.

Owner:CDGM OPTICAL GLASS

Optical glass

ActiveCN103351100BHigh refractive indexExcellent glass stabilityOptical surface grinding machinesOptical elementsRefractive indexOptical glass

An optical glass that is an oxide glass having a very high refractive index in spite of its low-dispersion property, having excellent glass stability and having less susceptibility to coloring.

Owner:HOYA CORP

Optical glass, preform for precision press-molding, process for the production of the preform, optical element, and process for the production of the element

InactiveUS7700507B2High refractive indexExcellent glass stabilityGlass pressing apparatusGlass reforming apparatusRefractive indexOptical glass

An optical glass which has an Abbe's number (νd) of 50 to 59, has the property of not easily reacting with a press mold, a low-temperature softening property, excellent glass stability and high refractivity, and is suitable for precision press-molding. The optical glass comprising B2O3 and SiO2 as essential components and having a B2O3 and SiO2 total content (B2O3+SiO2) of 45 to 70 by mol % and an SiO2 content / B2O3 content molar ratio (SiO2 / B2O3) of from 0.1 to 0.5, the optical glass further comprising, by mol %, 5 to 15% of La2O3, 0.1 to 8% of Gd2O3, provided that the total content of La2O3 and Gd2O3 is 8% or more, 0 to 10% of Y2O3, 3 to 18% of Li2O, provided that the molar ratio of the content of Li2O to the total content of B2O3 and SiO2 [Li2O / (B2O3+SiO2)] is over 0 but not more than 0.2, 0.1 to 15% of ZnO, 2 to 20% of CaO, 0 to 5% of BaO, provided that the content of BaO is smaller than the content of ZnO, 0 to 5% of SrO, 0 to 5% of MgO, provided that the molar ratio of the total content of MgO, CaO, SrO and BaO to the total content of B2O3 and SiO2 [(MgO+CaO+SrO+BaO) / (B2O3+SiO2) is from 0.1 to 0.4, and 0 to 5% of ZrO2, and having a refractive index (nd) and an Abbe's number (νd) which satisfy the equation (1),νd≧308.5−150×nd (in which 50≦νd≦59) (1).

Owner:HOYA CORP

Optical glass

ActiveCN101613184BHigh refractive indexExcellent glass stabilityOptical surface grinding machinesOptical elementsRefractive indexOptical glass

The invention provides an optical glass having a very high refractive index in spite of its low-dispersion property, having excellent glass stability and having less susceptibility to coloring. An optical glass is an oxide glass and is characterized in that the optical glass comprises, by cationic %, 0 to 30% of Si<4>, 10 to 55% of B<3>, less than 5% of total of Li<>, Na<> and K<>, less than 5% of total of Mg<2>, Ca<2> and Sr<2>, 0 to 8% of Ba<2>, 0.1 to 15% of Zn<2>, 10 to 50% of La<3>, 0 to 20% of Gd<3>, 0 to 15% of Y<3>, 0 to 10% of Yb<3>, 0 to 20% of Zr<4>, 0.1 to 22% of Ti<4>, 0 to 20% of Nb<5>, 0 to 8% of Ta<5>, 0 to 5% of W<6>, 0 to 8% of Ge<4>, 0 to 10% of Bi<3>, and 0 to 10% of Ai<3>, the cationic ratio of the content of Si<4> to the content of B<3>, Si<4> / B<3>, being less than 1.0, the total content of Nb2O5 and Ta2O5 as oxides being less than 14 mass %, the optical glass having a refractive index nd of 1.92 to 2.2 and an Abbe's number nud of 25 to 45.

Owner:HOYA CORP

Near-infrared light absorbing glass, element and filter

Provided is a near-infrared light absorbing glass with a near-infrared light absorbing element and a near-infrared light absorbing filter. When the length of the near-infrared light absorbing glass is 1 mm, transmissivity is more than 80% at the wavelength of 400 nm, and more than 85% at the wavelength of 500 nm. The near-infrared light absorbing glass contains P5+, Al3+, Li+, R2+ and Cu2+ represented by positive ions, wherein R2+ represents Mg2+, Ca2+, Sr2+ and Ba2+. Meanwhile, the near-infrared light absorbing glass contains O2− and F− represented by negative ions. Water durability (DW) of the near-infrared light absorbing glass reaches Class 1 and acid durability (DA) reaches above Class 4. In this invention, fluorphosphate glass is used as the matrix glass and the components are designed specially, so that the melting temperature of glass can be effectively lowered and the chemical stability of the glass can be excellent.

Owner:CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com