How to Promote The Circulation Of PVDF (Polyvinylidene Fluoride)?

Technology Background And Goals

This technical report promotes the circulation and recycling of PVDF (polyvinylidene fluoride), a high-performance fluoropolymer widely used in various industries. PVDF possesses exceptional properties such as chemical resistance, thermal stability, and mechanical strength, making it suitable for applications like lithium-ion batteries, membranes, and coatings.

However, the current linear production and disposal model for PVDF leads to significant waste and environmental concerns. Promoting a circular economy approach for PVDF is crucial to address these challenges and achieve sustainable resource management. This involves developing efficient recycling technologies, establishing collection and sorting systems, and fostering a collaborative ecosystem among stakeholders across the PVDF value chain.

PVDF Market Demand Analysis

- Market Size and Growth

Analyze the current and projected market size for PVDF products, including key application areas like lithium-ion batteries, membranes, and coatings. Provide estimates of market growth rates and potential market saturation levels. - Regional Demand Analysis

Examine the regional distribution of PVDF demand, highlighting major markets and emerging regions. Identify factors driving demand in different geographical areas, such as industrialization, environmental regulations, and technological advancements. - Application Trends

Explore the evolving application landscape for PVDF, including emerging applications in areas like energy storage, water treatment, and advanced materials. Assess the potential impact of these new applications on market demand. - Competitive Landscape

Analyze the competitive dynamics in the PVDF market, including major players, their market shares, and competitive strategies. Identify potential threats from substitute materials or alternative technologies. - Regulatory and Environmental Factors

Evaluate the impact of regulatory frameworks and environmental concerns on PVDF demand. Consider factors like emissions regulations, sustainability initiatives, and the push for greener technologies.

Technology Status And Challenges

- Current Status

PVDF technology has made significant progress, with applications in various fields like energy storage, filtration, and sensors. However, challenges remain in improving material properties, processing techniques, and cost-effectiveness. - Technical Challenges

Key challenges include enhancing mechanical strength, thermal stability, and electroactive properties of PVDF materials. Developing eco-friendly and scalable manufacturing processes is also crucial. - Geographical Distribution

Major PVDF research and development hubs are located in the United States, Europe, and Asia, particularly in countries like China, Japan, and South Korea, where significant investments have been made.

Technology Evolution Path

Current Technical Solutions

01 PVDF Membrane Fabrication Methods

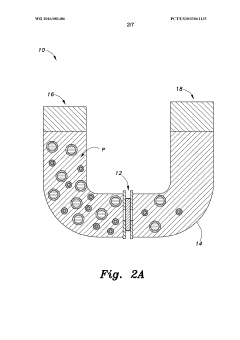

Involving the fabrication methods of PVDF membranes, including solution immersion, phase inversion, and electrospinning, to prepare PVDF membranes and control their structure and performance. These methods can regulate parameters like pore size, porosity, and thickness to obtain the desired membrane properties.- PVDF Membrane Electrode Fabrication Methods: Involving the use of different fabrication methods to prepare PVDF membrane electrodes, such as solution immersion, electrospinning, and hot-pressing, to control the structure and performance of the PVDF membrane. These methods can regulate parameters like thickness, porosity, and crystalline phase, optimizing cycling stability and ion transport performance in electrochemical applications.

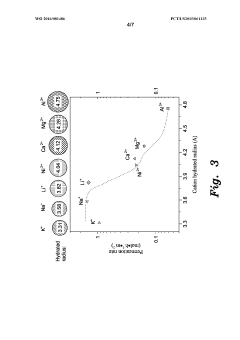

- Modification of PVDF Membrane Electrodes: Enhancing the electrochemical performance and cycling stability of PVDF membrane electrodes through modification techniques like doping, compositing, and functionalization. For instance, doping with conductive polymers, introducing inorganic nanomaterials, or grafting functional groups can improve ion transport ability, electrochemical activity, and mechanical strength.

- Applications of PVDF Membrane Electrodes in Batteries: PVDF membrane electrodes have promising applications in energy storage devices like lithium-ion batteries and supercapacitors. The excellent ion transport properties, high mechanical strength, and chemical stability of PVDF membranes make them suitable as separators, electrode materials, or electrolyte additives, enhancing cycling stability and safety performance.

- Applications of PVDF Membrane Electrodes in Other Electrochemical Devices: Apart from energy storage applications, PVDF membrane electrodes can also be utilized in fuel cells, electrolyzers, sensors, and other electrochemical devices. The outstanding performance of PVDF membranes offers potential applications as proton exchange membranes, ion-selective membranes, or electrode materials in these fields.

- Structural and Performance Characterization of PVDF Membrane Electrodes: Characterizing the structure and performance of PVDF membrane electrodes is crucial for optimizing their properties. Common techniques like scanning electron microscopy, X-ray diffraction, and electrochemical impedance spectroscopy provide insights into morphology, crystalline phase, and ion transport dynamics, guiding further modification and application.

02 PVDF Membrane Battery Applications

PVDF membranes can be used as separators in lithium-ion batteries, exhibiting good ion conductivity and mechanical strength. PVDF membranes can also be employed in supercapacitors, fuel cells, and other electrochemical devices, serving as ion transport and separator components.03 PVDF Membrane Filtration Applications

PVDF membranes possess excellent chemical and thermal stability, making them suitable for microfiltration, ultrafiltration, and other filtration applications. PVDF membranes can be used for water treatment, food processing, biomedicine, and other industries, purifying various liquids or gases.04 Fabrication of PVDF Composite Membranes

To impart special functions to PVDF membranes, they can be composited with other materials like metal oxides, polymers, and nanomaterials. Composite membranes with properties like anti-fouling, catalytic activity, and responsiveness can be obtained through methods like in-situ growth, blending, and coating.05 Structure and Performance of PVDF Membranes

Investigating the microstructure, crystalline phase, hydrophilicity/hydrophobicity, and other properties of PVDF membranes, and correlating them with fabrication processes and post-treatment methods. Controlling the structure of PVDF membranes can optimize their performance to meet various application requirements.

Main Player Analysis

Arkema, Inc.

Wanhua Chemical Group Co., Ltd.

Key Technology Interpretation

- The use of a polyvinylidene fluoride (PVDF) supporting substrate as a key component in the desalination membrane.

- The integration of two-dimensional metal carbide materials into the desalination membrane structure.

- The combination of PVDF supporting substrate and two-dimensional metal carbide materials in a desalination membrane design.

Potential Innovation Direction

Economic Analysis

The economic impact of promoting the circulation of PVDF (Polyvinylidene Fluoride) is substantial, given its significant presence in high-performance applications, including the chemical processing industry, electronics, and renewable energy sectors. Enhancing the circulation of PVDF can lead to increased economic efficiency and sustainability by reducing waste and improving material utilization. This, in turn, can lower production costs and provide economic incentives for industries relying on PVDF, enhancing their competitiveness in the market.

Furthermore, facilitating PVDF recycling and reuse may reduce dependency on raw material extraction, addressing both economic and environmental concerns. This sustainable approach could attract investment and stimulate job creation in the recycling and materials recovery sectors. The reduction in environmental compliance costs due to optimized resource use also provides economic benefits for companies, strengthening their balance sheets.

Global market trends indicate an increasing demand for sustainable materials, reflecting a shift toward a circular economy. Thus, industries that embrace sustainable PVDF practices may find themselves well-positioned to capture market opportunities, meeting consumer demand for greener products while contributing positively to their economic landscape. As such, the broader adoption of PVDF circulation aligns with economic strategies that prioritize sustainability and resource efficiency.

Policy And Regulatory Impact

Understanding the policy and regulatory impact on promoting the circulation of PVDF (Polyvinylidene Fluoride) is crucial in shaping strategic directions and overcoming market barriers. The regulatory framework can significantly influence supply chain dynamics, production methodologies, and market access for PVDF products. Governments may impose regulations pertaining to environmental considerations and material safety, which could necessitate compliance with specific standards or certifications. This can affect the production cost and timeline, as manufacturers may need to adapt to new regulations through technological innovations or process modifications.

Moreover, policies promoting renewable energy sources and sustainability could spur the increased adoption of PVDF, given its application in emerging technologies like lithium-ion batteries and solar photovoltaics. Incentives and subsidies for green technology adoption could further enhance PVDF's marketability. However, policies restricting chemical emissions and promoting circular economies may pressure manufacturers to invest in recycling technologies, potentially increasing research and development expenditures.

Navigating these regulatory requirements successfully can provide a competitive advantage by ensuring product viability in various markets. Thus, staying abreast of evolving policies and proactively engaging with regulatory bodies can facilitate smoother entry and operation within the markets, ultimately promoting the broader circulation and acceptance of PVDF products globally.