How to Improve The Energy Density Of PVDF-Based Electrolytes For High-Energy Density Batteries

Technology Background And Goals

In this in-depth technical report, you will get information and innovative approaches to enhance the energy density of PVDF-based electrolytes for high-energy density batteries. This involves investigating novel material compositions, structural designs, and fabrication techniques that can overcome the limitations of current PVDF electrolyte systems.

Potential research directions include developing advanced PVDF-based polymer electrolyte membranes with higher ionic conductivity and electrochemical stability, incorporating functional additives or fillers to improve mechanical and thermal properties, and optimizing the electrode-electrolyte interface for efficient ion transport and charge transfer. Exploring alternative polymer matrices or hybrid electrolyte systems that synergize the advantages of PVDF and other materials could also lead to breakthroughs in energy density.

Market Demand Analysis

- Market Size and Growth

The market for PVDF-based electrolytes for high-energy density batteries is expected to experience significant growth in the coming years, driven by the increasing demand for electric vehicles and renewable energy storage solutions. - Key Applications

PVDF-based electrolytes find applications in lithium-ion batteries, lithium-polymer batteries, and other advanced battery technologies used in electric vehicles, consumer electronics, and grid-scale energy storage systems. - Demand Drivers

- Rising adoption of electric vehicles and hybrid electric vehicles

- Growing need for high-performance and safe battery technologies

- Increasing demand for renewable energy storage solutions

- Advancements in battery technology and materials science

- Regional Market Dynamics

The demand for PVDF-based electrolytes is particularly high in regions with strong automotive and electronics industries, such as Asia-Pacific, Europe, and North America. Emerging economies like China and India are also expected to contribute significantly to market growth. - Competitive Landscape

The market for PVDF-based electrolytes is highly competitive, with major players including chemical companies, battery manufacturers, and research institutions. Key players are investing in research and development to improve the performance and safety of PVDF-based electrolytes.

Technology Status And Challenges

- Technology Evolution

Tracing the development of PVDF-based electrolytes, from early polymer electrolyte research to current high-energy density applications. - Key Challenges

Identifying major hurdles like low ionic conductivity, poor interfacial stability, and safety concerns that limit the performance of PVDF-based electrolytes. - Geographical Distribution

Highlighting research hotspots and major players in PVDF electrolyte development across different regions and countries.

Current Technical Solutions

01 PVDF-based Electrolytes for Li-ion Batteries

PVDF as a binder improves ionic conductivity and mechanical stability, enhancing energy density and cycle life.- PVDF-based Electrolytes for Li-ion Batteries: PVDF as a binder enhances ionic conductivity and mechanical stability, improving energy density and cycle life.

- PVDF-based Gel Polymer Electrolytes: Gel polymer electrolytes offer high ionic conductivity, mechanical strength, and enhanced safety and energy density.

- PVDF-based Composite Electrolytes: Incorporating fillers like ceramics or inorganic salts improves ionic conductivity, mechanical properties, thermal stability, and energy density.

- PVDF-based Solid Electrolytes: Solid electrolytes prevent leakage, offer thermal stability, and enable high-energy-density lithium-ion batteries with improved safety.

- PVDF-based Electrolytes with Additives: Additives like ionic liquids or plasticizers enhance ionic conductivity, electrochemical stability, interfacial properties, energy density, and cycle life.

02 PVDF-based Gel Polymer Electrolytes

Combining liquid and solid electrolyte advantages, these electrolytes offer high ionic conductivity, mechanical strength, and improved safety and energy density.Expand Specific Solutions03 PVDF-based Composite Electrolytes

Fillers like ceramics or inorganic salts enhance ionic conductivity, thermal stability, mechanical properties, and energy density and safety.Expand Specific Solutions04 PVDF-based Solid Polymer Electrolytes

Solid polymer electrolytes enable solid-state lithium-ion batteries with high ionic conductivity, mechanical strength, improved energy density, and safety.Expand Specific Solutions05 PVDF-based Electrolytes for Li-S Batteries

Tailored PVDF-based electrolytes improve cycle life and safety of lithium-sulfur batteries with potential for higher energy density.Expand Specific Solutions

Main Player Analysis

Sony Group Corp.

Jiangsu Contemporary Amperex Technology Ltd.

Key Technology Interpretation

- The use of a solid polymer electrolyte, which improves the safety and stability of the lithium metal battery.

- The ability to store additional energy electrostatically, in addition to the electrochemical energy storage of a common battery.

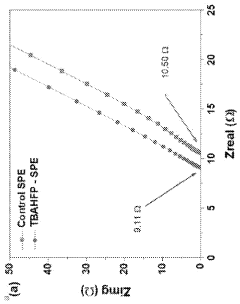

- The use of a small amount of tetrabutylammonium-hexafluorophosphate (tba-hfp) as an additive in the solid polymer electrolyte. this additive enhances charge separation at the various electrolyte/electrode interfaces.

PVDF-Based Electrolytes Energy Density Improvement Economic Analysis

Conducting an economic analysis of PVDF-based electrolytes for high-energy density batteries involves understanding both the production cost and market potential. The primary cost factors include raw materials, production processes, and scale of manufacturing. PVDF, being a specialized fluoropolymer, adds to the cost due to its complex synthesis and the proprietary nature of its production. However, its benefits, such as high electrochemical stability and compatibility with lithium-ion systems, justify its consideration.

On the market side, the demand for high-energy density batteries is increasing, driven by the electric vehicle (EV) market and the necessity for efficient energy storage solutions. PVDF-based electrolytes present an opportunity for producers to capitalize on this demand by offering safer and higher performance batteries. Despite initial high production costs, economies of scale could potentially reduce these costs, making PVDF-based electrolytes economically viable in the long run.

Furthermore, regulatory incentives and advancements in production technology could further lower costs and enhance adoption. The balance between innovation and cost-effectiveness will largely determine the financial success and widespread integration of this technology in diverse applications.

PVDF-Based Electrolytes Energy Density Improvement Policy And Regulatory Impact

The development of PVDF-based electrolytes for high-energy density batteries is profoundly influenced by policy and regulatory frameworks. Globally, the push for cleaner energy solutions and tighter regulations on carbon emissions significantly bolster research into high-energy density batteries. Governments are increasingly offering subsidies and tax incentives to support the advancement of battery technology, which directly benefits the development of PVDF-based electrolytes. In countries with stringent environmental policies, regulatory requirements ensure that new battery technologies, including those involving PVDF-based electrolytes, adhere to high safety and environmental standards. This includes mandates on recycling and waste management, which could affect the cost and feasibility of large-scale implementation of such technologies.

Furthermore, regional regulations on the transport and handling of advanced battery materials also dictate the pace and direction of research. Compliance with these regulations ensures that PVDF-based electrolytes can meet international safety and environmental standards, thereby enhancing market acceptance. As policymakers continue to escalate efforts to meet renewable energy targets, the regulatory landscape is expected to become increasingly favorable for the development and commercialization of innovative energy storage solutions. However, the technical community must remain agile to adapt to evolving regulations and leverage policy incentives effectively to spearhead advancements in this promising field.