Application Of PVDF-Based Electroactive Polymers For Energy Harvesting

Technology Background And Goals

This report provides a comprehensive overview of the development history and evolution trends in the field of PVDF-based electroactive polymers for energy harvesting applications. This includes tracing the key milestones and technological breakthroughs that have shaped the progress of this technology over time. Additionally, it aims to clearly define the expected technological goals and advancements that researchers and developers are striving to achieve in this domain.

By examining the historical trajectory and identifying the driving forces behind the advancements in PVDF-based electroactive polymers, this section lays the foundation for understanding the current state of the technology and its future potential. It sets the context for the subsequent sections of the technology foresight report, enabling a more informed analysis of market demands, technological challenges, and potential innovation pathways.

Market Demand Analysis

- Market Potential

PVDF-based electroactive polymers have significant potential in energy harvesting applications due to their unique piezoelectric properties and ability to convert mechanical energy into electrical energy. This technology can be utilized in various sectors, including wearable electronics, structural health monitoring, and renewable energy systems. - Emerging Applications

Emerging applications for PVDF-based energy harvesters include self-powered sensors for Internet of Things (IoT) devices, energy-efficient building materials, and portable power sources for consumer electronics. These applications are driven by the increasing demand for sustainable and efficient energy solutions. - Market Drivers

Key market drivers for PVDF-based energy harvesters include the growing adoption of renewable energy technologies, the need for energy-efficient solutions in various industries, and the increasing demand for wearable and portable electronics. - Market Challenges

Challenges in the market include the relatively high cost of PVDF materials, the need for improved energy conversion efficiency, and the integration of these materials into existing systems and infrastructures. - Market Trends

Trends in the market include the development of flexible and lightweight PVDF-based energy harvesters, the integration of these materials into smart textiles and wearable devices, and the exploration of hybrid energy harvesting systems combining PVDF with other energy sources.

Technology Status And Challenges

- Technological Maturity

PVDF-based electroactive polymers have reached a relatively mature stage, with established manufacturing processes and commercial applications in various fields. - Key Challenges

Improving energy conversion efficiency, enhancing mechanical durability, and reducing production costs remain significant challenges for widespread adoption. - Geographical Distribution

Research and development efforts are concentrated in regions with strong materials science and energy technology industries, such as North America, Europe, and East Asia.

Current Technical Solutions

01 PVDF-based Electroactive Polymers

Polyvinylidene fluoride (PVDF) and its copolymers exhibit piezoelectric properties, enabling energy harvesting from mechanical sources like vibrations or pressure into electrical energy for sensors, actuators, and generators.- PVDF-based Electroactive Polymers for Energy Harvesting: Polyvinylidene fluoride (PVDF) and its copolymers are piezoelectric polymers suitable for energy harvesting applications, converting mechanical energy into electrical energy. They can be used in sensors, actuators, and generators.

- Fabrication and Processing Techniques: Fabrication and processing methods like electrospinning, solution casting, melt processing, and poling influence the crystalline structure, dipole orientation, and performance of PVDF-based electroactive polymers.

- Composite and Nanostructured Materials: Incorporating nanofillers or forming nanostructures with PVDF-based polymers can enhance their piezoelectric properties and energy harvesting capabilities, improving mechanical and electrical properties.

- Device Configurations and Applications: PVDF-based energy harvesters can be integrated into various device configurations like cantilevers, membranes, and stacked structures for applications in wireless sensor nodes, wearable electronics, and self-powered systems.

- Characterization and Modeling: Characterization techniques and modeling approaches are used to understand the performance, behavior, and energy harvesting potential of PVDF-based systems, optimizing device designs and conversion efficiency.

02 Fabrication and Processing Methods

Techniques like electrospinning, solution casting, and melt processing, along with processing conditions, influence the crystalline structure, polarization, and piezoelectric properties of PVDF-based electroactive polymers.Expand Specific Solutions03 Composite and Nanostructured Materials

Combining PVDF-based polymers with materials like ceramics, carbon nanotubes, or graphene can form composites or nanostructures with enhanced piezoelectric, mechanical, and electrical properties for energy harvesting.Expand Specific Solutions04 Device Structures and Configurations

The design and configuration of energy harvesting devices, such as cantilevers, membranes, or stacked structures, using PVDF-based electroactive polymers, optimize energy conversion and output.Expand Specific Solutions05 Applications in Energy Harvesting

PVDF-based electroactive polymers find applications in energy harvesting systems like wearable devices, structural health monitoring, and wireless sensor networks, enabling self-powered or low-power electronic devices.Expand Specific Solutions

Main Player Analysis

Arkema France SA

FUJIFILM Corp.

Key Technology Interpretation

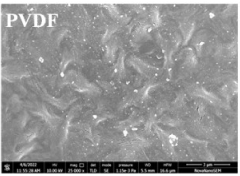

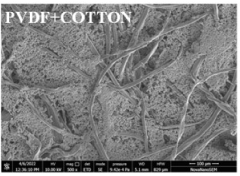

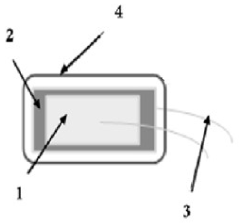

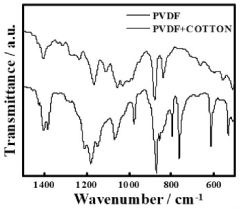

- The use of a composite material consisting of poly(vinylidene fluoride) (PVDF) and cotton as the active piezoelectric layer.

- The encapsulation of the PVDF-cotton composite with poly(dimethyl siloxane) and a curing agent, providing protection and mechanical stability.

- The use of a simple and cost-effective fabrication method involving sandwiching the PVDF-cotton composite between metallic foils and electrodes.