PVDF Nanocomposites For Improving The Energy Density Of High Energy Density Capacitors

PVDF Nanocomposites Technology Background And Goals

In this report, you will find the potential of PVDF (polyvinylidene fluoride) nanocomposites in enhancing the energy density of high energy density capacitors. PVDF is a promising material for capacitor applications due to its high dielectric constant, low dielectric loss, and excellent thermal and chemical stability.

Incorporating nanofillers into the PVDF matrix can further improve its dielectric properties and energy storage capabilities. Various nanofillers, such as ceramic nanoparticles, carbon nanotubes, and graphene, have been investigated for their ability to increase the dielectric permittivity and breakdown strength of PVDF nanocomposites.

The research aims to develop novel PVDF nanocomposite formulations with optimized filler types, concentrations, and dispersion techniques to achieve higher energy densities while maintaining desirable electrical and mechanical properties. This could lead to the development of compact, high-performance capacitors for applications in energy storage systems, power electronics, and pulsed power devices.

PVDF Nanocomposites Market Demand Analysis

- Market Size and Growth

The market for high energy density capacitors is rapidly expanding, driven by the increasing demand for energy storage solutions in various applications such as electric vehicles, renewable energy systems, and consumer electronics. - Key Applications

Major applications include:- Electric vehicles (EVs) and hybrid electric vehicles (HEVs)

- Renewable energy systems (e.g., wind and solar power)

- Consumer electronics (e.g., smartphones, laptops)

- Industrial equipment and machinery

- Market Trends and Drivers

- Growing demand for energy-efficient and environmentally-friendly technologies

- Increasing adoption of electric vehicles and renewable energy sources

- Advancements in materials science and nanotechnology

- Government policies and regulations promoting energy storage solutions

- Regional Market Analysis

The market for high energy density capacitors is globally distributed, with major regions including North America, Europe, Asia-Pacific, and others. The Asia-Pacific region is expected to witness the highest growth due to the increasing adoption of electric vehicles and renewable energy sources.

Technology Status And Challenges

- Current Status

PVDF nanocomposites have emerged as a promising material for enhancing the energy density of high-energy capacitors. Researchers have explored various nanofillers, such as ceramic nanoparticles, carbon nanotubes, and graphene, to improve the dielectric properties of PVDF. - Technical Challenges

Key challenges include achieving uniform dispersion of nanofillers, optimizing the interfacial interactions between PVDF and nanofillers, and controlling the nanocomposite morphology to maximize the dielectric performance. - Geographical Distribution

Research on PVDF nanocomposites is being conducted globally, with major contributions from the United States, China, South Korea, and several European countries.

Current Technical Solutions

01 Enhanced Energy Density

PVDF nanocomposites formulated with nanofillers like ceramic nanoparticles, carbon nanotubes, or graphene to improve energy density and dielectric properties, increasing permittivity and energy storage capability.- Enhanced Energy Density: PVDF nanocomposites with improved energy density and dielectric properties through incorporation of nanofillers like ceramic nanoparticles, carbon nanotubes, or graphene, increasing permittivity and energy storage capability.

- Improved Mechanical Properties: PVDF nanocomposites with enhanced tensile strength, toughness, and flexibility by incorporating nanofillers like carbon nanotubes, graphene, or nanofibers.

- Enhanced Thermal Properties: PVDF nanocomposites with improved thermal conductivity, heat resistance, and thermal stability through incorporation of nanofillers like ceramic nanoparticles, carbon nanotubes, or graphene, suitable for high-temperature applications.

- Improved Electrical Properties: PVDF nanocomposites with enhanced electrical conductivity, dielectric properties, and electromagnetic shielding effectiveness by incorporating conductive nanofillers like carbon nanotubes, graphene, or metal nanoparticles.

- Improved Processability: PVDF nanocomposites with enhanced melt flow and rheological properties, facilitating processing techniques like extrusion, injection molding, or 3D printing, through incorporation of nanofillers.

02 Improved Mechanical Properties

PVDF nanocomposites with enhanced tensile strength, toughness, and flexibility through incorporation of nanofillers like carbon nanotubes, graphene, or nanofibers, suitable for various applications.Expand Specific Solutions03 Enhanced Thermal Properties

PVDF nanocomposites with improved thermal conductivity, thermal stability, and heat dissipation capabilities through incorporation of nanofillers like ceramic nanoparticles, carbon nanotubes, or graphene.Expand Specific Solutions04 Improved Electrical Properties

PVDF nanocomposites with enhanced electrical conductivity, dielectric properties, and electromagnetic shielding capabilities through incorporation of conductive nanofillers like carbon nanotubes, graphene, or metal nanoparticles.Expand Specific Solutions05 Improved Processing and Manufacturing

Various processing and manufacturing techniques like melt compounding, solution casting, electrospinning, or 3D printing for producing PVDF nanocomposites with desired properties and structures, allowing fabrication of films, fibers, or complex shapes.Expand Specific Solutions

Main Player Analysis

Powdermet, Inc.

Solvay SA

Key Technology Interpretation

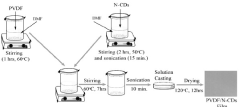

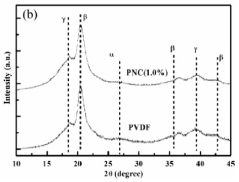

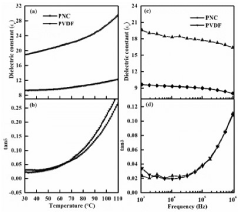

- The use of Nitrogen-doped carbon dots (N-CDs) as filler in the PVDF matrix to develop nanocomposite film with better energy storage density, high breakdown strength, and low toxicity.

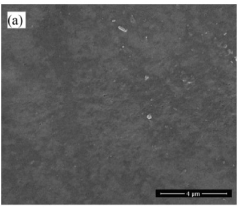

- The synthesis of PVDF/N-CDs nanocomposite dielectric film by solution cast process using magnetic stirring and ultra-sonication, which is a simple and cost-effective method.

- The use of fast drying silver paste as contacts on both sides of the nanocomposite dielectric film to apply electric field for capacitive energy storage device.