Research on PVDF (Polyvinylidene Fluoride) With Large Specific Surface Area

Background And Goals

This technical report focuses on developing polyvinylidene fluoride (PVDF) materials with a large specific surface area, which can significantly enhance their performance in various applications, such as energy storage, filtration, and catalysis.

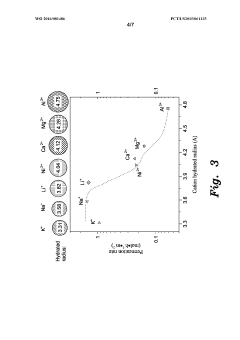

Achieving a high specific surface area for PVDF is challenging due to its semi-crystalline nature and the tendency to form dense structures during synthesis. However, recent advancements in nanotechnology and material engineering have opened up new possibilities for creating PVDF with a highly porous structure and increased surface area. Strategies like electrospinning, templating, and controlled phase separation have shown promising results in fabricating PVDF nanofibers, aerogels, and porous membranes with specific surface areas ranging from hundreds to thousands of square meters per gram.

PVDF Market Demand Analysis

- Market Size and Growth

PVDF membranes with large specific surface area have a significant market potential due to their applications in water treatment, energy storage, and biomedical fields. The global market is expected to grow steadily, driven by increasing demand for efficient filtration and separation technologies. - Key Application Areas

- Water treatment: PVDF membranes are widely used in reverse osmosis, ultrafiltration, and microfiltration processes for water purification and desalination.

- Energy storage: PVDF membranes are employed in lithium-ion batteries and supercapacitors as separators, enabling high energy density and power density.

- Biomedical: PVDF membranes find applications in hemodialysis, protein separation, and tissue engineering due to their biocompatibility and controlled porosity.

- Market Drivers

- Increasing demand for clean water and efficient water treatment solutions.

- Growing adoption of renewable energy sources and the need for advanced energy storage systems.

- Advancements in biomedical technologies and the demand for high-performance membranes.

- Regional Trends

The Asia-Pacific region is expected to dominate the market due to rapid industrialization and population growth, leading to increased demand for water treatment and energy storage solutions. North America and Europe also exhibit significant market potential due to stringent environmental regulations and technological advancements.

Technology Status And Challenges

- Current Status

PVDF is a semi-crystalline polymer with excellent chemical resistance, thermal stability, and piezoelectric properties. It has been widely used in various applications, such as membranes, sensors, and energy storage devices. - Technical Challenges

One major challenge is the low specific surface area of conventional PVDF materials, which limits their performance in applications like energy storage and separation membranes. Increasing the specific surface area while maintaining the desirable properties of PVDF is a key research focus. - Geographical Distribution

Research on high surface area PVDF is being conducted globally, with major contributions from countries like the United States, China, South Korea, and European nations. Collaboration between academic and industrial research groups is common in this field.

Current Technical Solutions

01 PVDF Membrane Preparation and Properties

Covers preparation methods and properties of PVDF membranes, including techniques for controlling specific surface area and pore size distribution. Applications include filtration, separation, and energy storage.- PVDF Membrane Preparation and Properties: Covers preparation methods and properties of PVDF membranes, including techniques for controlling specific surface area, porosity, and other characteristics. Applications include filtration, separation, and energy storage.

- PVDF Composite Membranes and Modifications: Focuses on developing PVDF composite membranes by combining PVDF with inorganic fillers, polymers, or functional groups to enhance specific surface area, hydrophilicity, or other properties for various applications.

- PVDF Membrane Fabrication Techniques: Covers techniques like electrospinning, phase inversion, and others for fabricating PVDF membranes with controlled specific surface area, pore size distribution, and other properties.

- PVDF Membrane Applications and Devices: Focuses on applications of PVDF membranes in fields like water treatment, energy storage, and biomedical devices, including design and fabrication of devices incorporating PVDF membranes with tailored properties.

- Characterization and Analysis of PVDF Membranes: Covers techniques and methods for characterizing and analyzing specific surface area, pore structure, and other properties of PVDF membranes for quality control, performance evaluation, and optimization.

02 PVDF Composite Membranes and Modifications

Focuses on developing PVDF composite membranes by incorporating additives or modifying PVDF polymer to enhance specific surface area, hydrophilicity, or other properties for improved performance in applications like water treatment or energy storage.Expand Specific Solutions03 PVDF Membrane Fabrication Techniques

Covers techniques like electrospinning, phase inversion, and stretching methods for fabricating PVDF membranes with controlled specific surface area, porosity, and morphology for different applications.Expand Specific Solutions04 PVDF Membrane Applications and Devices

Focuses on applications and devices utilizing PVDF membranes with controlled specific surface area and other properties, including water treatment, energy storage, gas separation, and biomedical devices.Expand Specific Solutions05 Characterization and Evaluation of PVDF Membranes

Covers techniques and methods for characterizing and evaluating specific surface area, pore structure, and other properties of PVDF membranes for understanding membrane performance and optimizing fabrication processes.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Zhonghao Chenguang Research Institute of Chemical Ind Co Ltd

Key Technology Interpretation

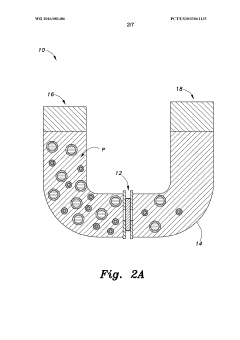

- The use of polyvinylidene fluoride (PVDF) as a supporting substrate for the two-dimensional metal carbide desalination membrane.

- The combination of two-dimensional metal carbide and PVDF supporting substrate for desalination applications.

- ^|Optimize the fabrication process and parameters to control the morphology, porosity, and surface properties of the PVDF supporting substrate, which could influence the overall performance and efficiency of the desalination membrane.