Research on PVDF Nanofibers For High-Performance Energy Storage Devices

Technology Background And Goals

This report aims to provide a comprehensive overview of the development history, current status, and future trends in the field of polyvinylidene fluoride (PVDF) nanofibers for high-performance energy storage devices. This includes tracing the key milestones and technological advancements that have shaped the evolution of PVDF nanofibers, as well as identifying the critical challenges and bottlenecks that need to be addressed.

The report will delve into the fundamental principles and working mechanisms of PVDF nanofibers, highlighting their unique properties and advantages for energy storage applications. It will also explore the various fabrication techniques and strategies employed to produce high-quality PVDF nanofibers with tailored morphologies and functionalities, enabling enhanced energy storage performance.

PVDF Nanofibers Market Demand Analysis

- Market Size and Growth

The global market for high-performance energy storage devices is rapidly expanding, driven by the increasing demand for renewable energy sources and electric vehicles. PVDF nanofibers have emerged as a promising material for next-generation energy storage solutions due to their unique properties. - Applications and Demand Drivers

The primary applications of PVDF nanofibers in energy storage devices include lithium-ion batteries, supercapacitors, and fuel cells. The demand is fueled by the need for higher energy density, longer cycle life, and improved safety in these applications. - Industry Trends and Opportunities

The energy storage industry is witnessing a shift towards sustainable and eco-friendly materials. PVDF nanofibers offer advantages such as high electrochemical stability, flexibility, and lightweight, aligning with the industry's sustainability goals. - Regional Market Analysis

The Asia-Pacific region is expected to dominate the PVDF nanofibers market due to the presence of major electronics and automotive manufacturing hubs. North America and Europe are also significant markets, driven by the adoption of renewable energy and electric vehicles.

Technology Status And Challenges

- Current Status

PVDF nanofibers have been extensively studied for energy storage applications due to their high dielectric constant, good mechanical properties, and electroactive behavior. Researchers have developed various fabrication techniques, including electrospinning, to produce PVDF nanofibers with controlled morphology and crystalline phases. - Technical Challenges

Achieving high crystallinity and desired phase (β or γ) in PVDF nanofibers is challenging due to the rapid solidification during electrospinning. Controlling the fiber diameter, alignment, and surface properties is also crucial for optimizing the energy storage performance. - Geographical Distribution

Research on PVDF nanofibers for energy storage is widely distributed globally, with significant contributions from institutions in the United States, China, South Korea, and several European countries.

Current Technical Solutions

01 PVDF Nanofibers for Energy Storage

Polyvinylidene fluoride (PVDF) nanofibers have been explored for use in high-performance energy storage devices, such as supercapacitors and lithium-ion batteries. The nanofiber structure provides a high surface area and porosity, which can enhance the electrochemical performance and energy storage capabilities of these devices.- PVDF Nanofibers for Energy Storage: Polyvinylidene fluoride (PVDF) nanofibers have been explored for high-performance energy storage devices like supercapacitors and lithium-ion batteries due to their high surface area and porosity, enhancing electrochemical performance and energy storage capabilities.

- Fabrication Techniques: Various methods like electrospinning, phase separation, and template-assisted techniques have been developed for fabricating PVDF nanofibers, allowing precise control over morphology, diameter, and alignment, which influence the performance of energy storage devices.

- Conductive Composite Nanofibers: To enhance electrical conductivity and electrochemical properties, conductive additives such as carbon nanotubes, graphene, and metal oxides have been incorporated into PVDF nanofiber structures, resulting in improved charge transport and energy storage capabilities.

- Supercapacitor Electrodes: PVDF nanofibers have been explored as electrode materials for supercapacitors due to their high surface area, porosity, and electrochemical stability, facilitating ion transport and charge storage, leading to improved capacitance and energy density.

- Lithium-ion Battery Applications: PVDF nanofibers have been investigated as potential components in lithium-ion batteries, such as separators, binders, and electrode materials, enhancing ionic conductivity, mechanical strength, and electrochemical performance in these battery systems.

02 Fabrication Techniques

Various methods have been developed for the fabrication of PVDF nanofibers, including electrospinning, phase separation, and template-assisted techniques. These methods allow for precise control over the nanofiber morphology, diameter, and alignment, which can influence the performance of energy storage devices.Expand Specific Solutions03 Conductive Composite Nanofibers

To enhance the electrical conductivity and electrochemical properties of PVDF nanofibers, conductive additives such as carbon nanotubes, graphene, and metal oxides have been incorporated into the nanofiber structure. These composite nanofibers can exhibit improved charge transfer and energy storage capabilities.Expand Specific Solutions04 Supercapacitor Electrodes

PVDF nanofibers have been explored as electrode materials for supercapacitors due to their high surface area, porosity, and electrochemical stability. The nanofiber structure can facilitate ion transport and charge storage, leading to improved capacitance and energy density in supercapacitors.Expand Specific Solutions05 Lithium-ion Battery Applications

PVDF nanofibers have been investigated as potential components in lithium-ion batteries, such as separators, binders, and electrode materials. The nanofiber structure can enhance ionic conductivity, mechanical strength, and electrochemical performance in lithium-ion batteries.Expand Specific Solutions

Main Player Analysis

Penn State Research Foundation

Shaanxi University of Science & Technology

Key Technology Interpretation

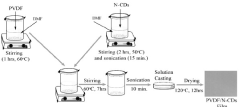

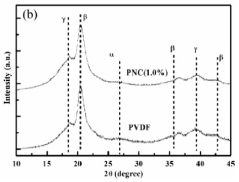

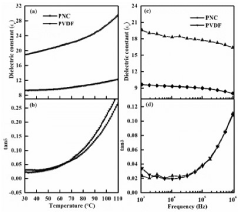

- The use of Nitrogen-doped carbon dots (N-CDs) as filler in the PVDF matrix to develop nanocomposite film with better energy storage density, high breakdown strength, and low toxicity.

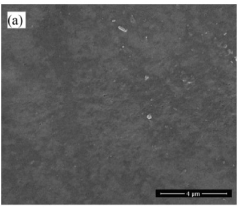

- The synthesis of PVDF/N-CDs nanocomposite dielectric film by solution cast process using magnetic stirring and ultra-sonication.

- The development of a non-toxic capacitive energy storage device made up of PVDF/N-CDs nanocomposite film with high dielectric constant and high breakdown strength for high energy storage electronic device applications.