The Ultimate Guide to Enhancing The Structural Stability Of PVDF-Based Nanocomposites

Technology Background And Goals

This technical report provides an comprehensive analysis on enhancing the structural stability of PVDF-based nanocomposites, which have gained significant attention due to their exceptional properties and potential applications in various fields.

This research aims to address the challenges associated with improving the interfacial interactions between the polymer matrix and nanofillers, as well as mitigating the agglomeration of nanoparticles. By exploring innovative approaches, such as surface modification techniques, compatibilizers, or novel processing methods, the goal is to achieve better dispersion and stronger interfacial bonding, ultimately leading to enhanced mechanical, thermal, and electrical properties of the nanocomposites.

Market Demand Analysis

- Market Potential

PVDF-based nanocomposites have a wide range of applications, including energy storage, filtration, sensors, and biomedical devices, owing to their unique properties like high dielectric constant, chemical resistance, and biocompatibility. The global market for these materials is projected to grow significantly in the coming years. - Demand Drivers

The increasing demand for lightweight and high-performance materials in various industries, such as automotive, aerospace, and electronics, is driving the market growth. Additionally, the rising need for sustainable and eco-friendly materials is boosting the adoption of PVDF-based nanocomposites. - Industry Trends

The trend towards miniaturization and the development of flexible electronics is creating new opportunities for PVDF-based nanocomposites. Furthermore, the growing emphasis on energy storage solutions and the development of advanced filtration systems are expected to drive market growth. - Regional Analysis

Asia-Pacific region is expected to dominate the market due to the presence of major manufacturing hubs and the increasing demand for advanced materials in various industries. North America and Europe are also significant markets, driven by the adoption of PVDF-based nanocomposites in the automotive and aerospace sectors.

Technology Status And Challenges

- Technological Landscape

PVDF-based nanocomposites have gained significant attention due to their enhanced mechanical, thermal, and electrical properties compared to pure PVDF. The development of these nanocomposites has progressed through various stages, incorporating different nanofillers and processing techniques. - Key Challenges

Despite advancements, several challenges persist, including achieving uniform dispersion of nanofillers, optimizing interfacial interactions between PVDF and nanofillers, and maintaining structural stability under various environmental conditions. - Geographical Distribution

Research on PVDF-based nanocomposites is globally distributed, with major contributions from the United States, Europe, and Asia, particularly China, Japan, and South Korea.

Current Technical Solutions

01 Improved Thermal Stability

Nanofillers like carbon nanotubes, graphene, or metal oxides can enhance the thermal stability and operating temperature range of PVDF-based nanocomposites.- Improved Thermal Stability: Incorporating nanofillers like carbon nanotubes, graphene, or metal oxides can enhance the thermal stability and structural integrity of PVDF-based nanocomposites.

- Enhanced Mechanical Properties: Nanofillers such as carbon nanotubes, clay nanoparticles, or metal oxides can improve the tensile strength, modulus, toughness, and durability of PVDF-based nanocomposites.

- Improved Barrier Properties: Incorporating nanofillers like clay nanoparticles or graphene can create a tortuous path, enhancing the barrier properties against gases, moisture, or solvents in PVDF-based nanocomposites.

- Tailored Electrical Properties: Conductive nanofillers like carbon nanotubes, graphene, or metal nanoparticles can tailor the electrical properties, such as conductivity and dielectric properties, of PVDF-based nanocomposites.

- Enhanced Flame Retardancy: Incorporating nanofillers like metal hydroxides, phosphates, or layered silicates can improve the flame retardancy and fire resistance of PVDF-based nanocomposites.

02 Enhanced Mechanical Properties

Nanofillers like clay, carbon nanotubes, or metal oxides can improve the tensile strength, modulus, and impact resistance of PVDF-based nanocomposites.Expand Specific Solutions03 Improved Barrier Properties

Nanofillers like clay, graphene, or metal oxides can enhance the barrier properties against gases, moisture, and other substances in PVDF-based nanocomposites.Expand Specific Solutions04 Tailored Electrical Properties

Conductive nanofillers like carbon nanotubes, graphene, or metal particles can improve electrical properties like conductivity, dielectric constant, and electromagnetic shielding in PVDF-based nanocomposites.Expand Specific Solutions05 Enhanced Flame Retardancy

Flame retardant nanofillers like metal hydroxides, phosphates, or nanoclays can improve the flame retardancy and fire resistance of PVDF-based nanocomposites.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Solvay SA

Key Technology Interpretation

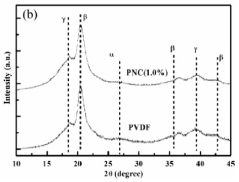

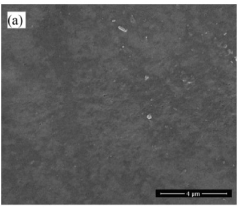

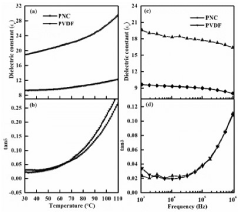

- The use of Nitrogen-doped carbon dots (N-CDs) as filler in the PVDF matrix to develop nanocomposite film with better energy storage density, high breakdown strength, and low toxicity.

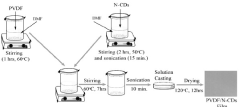

- The synthesis of PVDF/N-CDs nanocomposite dielectric film by solution cast process using magnetic stirring and ultra-sonication.

- The development of a non-toxic capacitive energy storage device made up of PVDF/N-CDs nanocomposite film with high dielectric constant and high breakdown strength for high energy storage electronic device applications.

PVDF-Based Nanocomposites Structural Stability Enhancement Economic Analysis

The economic impact of PVDF-based nanocomposites for enhanced structural stability is significant, predominantly influencing industries such as aerospace, automotive, and electronics. These industries demand materials that can provide high stability and performance under varying environmental conditions. The introduction of PVDF-based nanocomposites aids in reducing material costs due to their superior performance attributes that lower the need for frequent replacements and maintenance. Moreover, these materials contribute to the lightweighting of vehicles and machinery, leading to enhanced fuel efficiency and reduced emissions, which align with increasingly stringent regulatory standards on environmental sustainability.

The adoption of PVDF-based nanocomposites can spawn new markets and business opportunities, particularly in the development of advanced components and systems that leverage their unique mechanical and thermal properties. This could lead to economic growth through the creation of high-tech jobs and increased investments in research and development. Additionally, the global competitiveness of companies utilizing these nanocomposites is likely to be strengthened, as they can differentiate their products with advanced material technologies. However, the economic benefits are contingent on overcoming initial high costs of development and scaling production, necessitating strategic partnerships and governmental incentives to fully realize their potential.

PVDF-Based Nanocomposites Structural Stability Enhancement Policy And Regulatory Impact

Policy and regulatory impacts on PVDF-based nanocomposites for enhanced structural stability are crucial, as they directly influence research directions, investment, and commercialization. Current regulations pertaining to material safety and environmental sustainability play a significant role. Rules around chemical composition, nanomaterial usage, and waste management could drive innovation towards safer and more sustainable alternatives. Compliance with international standards, such as ISO and ASTM, ensures that PVDF-based nanocomposites meet quality and safety requirements, fostering global market acceptance.

Government policies promoting green technology and materials science advancements may enhance funding opportunities, supporting the development of PVDF-based nanocomposites. Additionally, patent laws impact how innovations within this field are protected and commercialized, potentially affecting competitive dynamics. Trade regulations and tariffs also influence the global supply chain of raw materials and finished products, impacting cost structures and market accessibility.

Overall, understanding the policy and regulatory landscape is integral for stakeholders in the PVDF-based nanocomposites sector to successfully navigate challenges and leverage opportunities for technological advancement and market penetration.