How to Improve The Structural Stability Of Cross-Linked PVDF Networks?

Cross-Linked PVDF Networks Technology Background And Goals

This technical report aims to investigate and develop strategies for enhancing the structural stability of cross-linked polyvinylidene fluoride (PVDF) networks. PVDF is a highly non-reactive and pure thermoplastic fluoropolymer with exceptional chemical resistance, thermal stability, and mechanical properties. However, its linear structure and lack of cross-linking can limit its structural integrity and durability in certain applications.

Cross-linking PVDF through various techniques, such as radiation or chemical methods, can introduce covalent bonds between polymer chains, forming a three-dimensional network structure. This process can significantly improve the material's resistance to solvents, heat, and mechanical stress, making it suitable for demanding applications in industries like aerospace, automotive, and oil and gas. The research aims to explore innovative cross-linking approaches, optimize cross-link density and distribution, and understand the structure-property relationships to achieve superior structural stability in cross-linked PVDF networks.

Market Demand Analysis

- Market Size and Growth

The global market for polyvinylidene fluoride (PVDF) is projected to experience substantial growth, driven by increasing demand from various industries such as energy, electronics, and construction. The cross-linked PVDF networks find applications in lithium-ion batteries, membranes, and high-performance coatings. - Industry Trends

The demand for cross-linked PVDF networks is fueled by the growing need for lightweight, durable, and chemically resistant materials. The trend towards sustainable energy solutions and the adoption of electric vehicles are expected to drive the demand for PVDF-based lithium-ion batteries. - Key Applications

- Lithium-ion batteries: Cross-linked PVDF networks are used as binders in the electrodes of lithium-ion batteries, enhancing their performance and safety.

- Membranes: PVDF membranes find applications in water treatment, desalination, and chemical separations due to their chemical resistance and thermal stability.

- Coatings: Cross-linked PVDF coatings are used in various industries, such as construction, automotive, and aerospace, due to their excellent weathering resistance and durability.

- Regional Market Dynamics

The Asia-Pacific region is expected to dominate the cross-linked PVDF networks market due to the presence of major manufacturing hubs and the growing demand for lithium-ion batteries in the region. North America and Europe are also significant markets, driven by the adoption of sustainable energy solutions and stringent environmental regulations.

Technology Status And Challenges

- Polymer Structure

PVDF is a semi-crystalline polymer with a unique molecular structure that allows for cross-linking and formation of stable networks. - Cross-Linking Methods

Various cross-linking techniques, such as radiation, chemical, and thermal methods, have been explored to enhance the structural stability of PVDF networks. - Challenges in Cross-Linking

Achieving uniform cross-linking, controlling the degree of cross-linking, and maintaining desired properties like flexibility and dielectric performance are key challenges. - Structural Characterization

Advanced techniques like X-ray diffraction, FTIR, and thermal analysis are employed to study the structural changes and cross-linking efficiency in PVDF networks.

Current Technical Solutions

01 Cross-linking methods

Radiation-induced, chemical cross-linking using agents, or a combination can cross-link PVDF networks, improving structural stability and mechanical properties.- Cross-linking methods for PVDF networks: Various cross-linking techniques can improve the structural stability and mechanical properties of PVDF networks, such as chemical cross-linking using agents or radiation-induced cross-linking.

- Structural modifications for enhanced stability: Incorporating reinforcing fillers, nanoparticles, or additives into the PVDF matrix can enhance the mechanical strength, thermal stability, and chemical resistance of cross-linked PVDF networks.

- Applications of cross-linked PVDF networks: Cross-linked PVDF networks with improved stability can find applications in water treatment membranes, energy storage devices, and protective coatings.

- Characterization and testing: Analytical techniques like mechanical testing, thermal analysis, spectroscopy, and microscopy can characterize and evaluate the structural stability and properties of cross-linked PVDF networks.

- Modeling and simulation: Computational modeling and simulation can study the structural stability and behavior of cross-linked PVDF networks under various conditions, providing insights into cross-linking mechanisms and aiding in design optimization.

02 Structural modifications

Incorporating reinforcing fillers, nanoparticles, or additives into the PVDF matrix can enhance the mechanical strength, thermal stability, and chemical resistance of cross-linked networks.Expand Specific Solutions03 Applications

Cross-linked PVDF networks with enhanced stability can be used in water treatment membranes, energy storage devices, and protective coatings due to improved mechanical and chemical properties.Expand Specific Solutions04 Characterization and testing

Mechanical testing, thermal analysis, spectroscopy, and microscopy can characterize the cross-linking degree, morphology, and performance of cross-linked PVDF networks under different conditions.Expand Specific Solutions05 Modeling and simulation

Computational modeling and simulation can study the structural stability and behavior of cross-linked PVDF networks, providing insights into cross-linking mechanisms, predicting properties, and guiding design optimization.Expand Specific Solutions

Main Player Analysis

Flexterra, Inc.

Kureha Corp.

Key Technology Interpretation

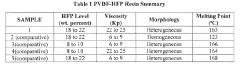

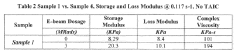

- The PVDF copolymer contains a high level (>14 and preferably greater than 16 wt%) of a fluorinated comonomer, and has a high molecular weight as measured by the melt viscosity at 230°C and 100 sec-1 of 18 to 40 kpoise, which improves crosslinking efficiency and performance.

- The PVDF copolymer can be effectively cross-linked with a low level of radiation, resulting in improved thermal stability and color stability compared to conventional PVDF resins.

- The cross-linked PVDF copolymer composition exhibits improved rheological properties, such as higher viscosity and storage modulus, indicating a higher degree of crosslinking at lower radiation dosages compared to conventional PVDF resins.

Cross-Linked PVDF Networks Structural Stability Improvement Economic Analysis

The economic impact of cross-linked PVDF networks focusing on enhancing structural stability can be significant in various industries. The improvement of structural stability in materials, such as cross-linked PVDF, directly influences the market dynamics of sectors where durability and reliability are paramount, like aerospace, automotive, and construction. The enhanced properties of cross-linked PVDF, including resistance to environmental degradation and mechanical stress, offer potential for reducing maintenance costs and extending product lifecycles, key factors that drive cost savings and operational efficiency within these markets.

Moreover, the adoption of cross-linked PVDF networks could stimulate innovation and competition among key players, leading to a diverse range of applications and products. This can result in increased investment in research and development, fostering technological advancements and potentially new patents or proprietary technologies. In markets driven by sustainability, these networks can contribute to reducing the carbon footprint through improved energy efficiency and material sustainability, increasing their attractiveness to eco-conscious consumers and regulators.

Additionally, as industries pivot towards advanced materials with superior performance characteristics, companies that successfully integrate these technologies may gain a competitive advantage, leading to expanded market share and business growth, further influencing the economic landscape by creating new revenue streams and job opportunities in tech- and engineering-driven sectors.

Cross-Linked PVDF Networks Structural Stability Improvement Policy And Regulatory Impact

The development and deployment of cross-linked PVDF (polyvinylidene fluoride) networks for enhanced structural stability are influenced by several policy and regulatory considerations. Firstly, material safety regulations play a crucial role, as PVDF-based materials must comply with environmental and health guidelines, particularly concerning their production processes and disposal methods. It is essential to adhere to international standards such as those outlined by the RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), which govern chemical usage and ensure that PVDF materials do not pose risks to human health or the environment.

Moreover, the intellectual property framework impacts the landscape significantly. Companies investing in PVDF technology must navigate patent laws to protect innovations and avoid infringement, fostering a competitive yet collaborative environment for technological advancement. Regulatory bodies may also influence market dynamics by offering incentives for sustainable materials, aligning with broader green technology and carbon reduction goals. This could include subsidies or tax breaks for companies that develop environmentally friendly cross-linked PVDF products.

Lastly, building and construction standards affecting the adoption of PVDF materials need consideration, as these regulations determine market entry and acceptance. Awareness and compliance with local building codes and standards will facilitate smoother integration into existing practices. Understanding these policy and regulatory impacts is vital for successful implementation and advancement of cross-linked PVDF networks.