How to Improve The Structural Stability Of PVDF (Polyvinylidene Fluoride)?

Technology Background And Goals

However, the structural stability of PVDF can be compromised under certain conditions, leading to performance degradation and limiting its potential applications. This research aims to address this challenge by exploring innovative approaches to improve the structural integrity of PVDF, enabling its broader adoption and unlocking new possibilities in various industries.

PVDF Market Demand Analysis

- Market Size and Growth

PVDF has a substantial and growing market, driven by its applications in lithium-ion batteries, membranes, and coatings. The global PVDF market is projected to reach $1.2 billion by 2027, with a CAGR of 6.2% from 2022 to 2027. - Key Application Areas

- Lithium-ion batteries: PVDF is widely used as a binder in electrodes, contributing to the growing demand from the electric vehicle and renewable energy sectors.

- Membranes: PVDF membranes are used in water treatment, biopharmaceuticals, and chemical processing due to their chemical resistance and thermal stability.

- Coatings: PVDF coatings are valued for their durability, weather resistance, and corrosion protection in construction and automotive industries.

- Regional Market Dynamics

Asia Pacific dominates the PVDF market, driven by the rapid growth of end-use industries in countries like China, India, and South Korea. North America and Europe also have significant demand, particularly in the automotive and construction sectors. - Emerging Trends

- Increasing demand for sustainable and energy-efficient solutions is driving the adoption of PVDF in renewable energy and water treatment applications.

- The growing electric vehicle market is expected to boost the demand for PVDF as a binder material in lithium-ion batteries.

- The development of new PVDF-based composites and blends with improved properties is opening up new application areas.

Technology Status And Challenges

- Technological Challenges

PVDF faces challenges in achieving optimal structural stability, including:- Crystallinity control for desired properties

- Enhancing mechanical strength and toughness

- Improving thermal and chemical resistance

- Limitations in Processing

Processing techniques like melt extrusion and electrospinning can affect PVDF's structural integrity, leading to:- Uneven crystalline phase distribution

- Defects and voids in the polymer matrix

- Reduced mechanical and functional properties

- Environmental Degradation

PVDF is susceptible to degradation from external factors:- UV radiation can cause chain scission and crosslinking

- Oxidation and hydrolysis can weaken polymer bonds

- Thermal cycling can induce structural changes

Current Technical Solutions

01 PVDF Crystalline Structure and Phase Transition

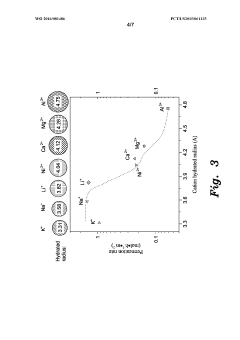

PVDF exhibits different crystalline phases, with the β phase being desirable for its piezoelectric and ferroelectric properties. The crystalline structure and phase transition can be influenced by processing conditions, additives, and external fields.- PVDF Structural and Thermal Stability: PVDF exhibits excellent thermal and structural stability, maintaining good mechanical properties and chemical stability at high temperatures. Its structural and thermal stability can be further enhanced through modifications or additives, expanding its application range.

- PVDF Structure and Crystalline Structure: PVDF possesses various crystalline structures, such as α and β phases, which determine its performance. By controlling the preparation process and additives, the crystalline structure of PVDF can be tailored to optimize its properties.

- PVDF Structure and Mechanical Properties: The structural characteristics of PVDF contribute to its exceptional mechanical properties, including high strength and modulus. By adjusting factors like molecular weight, molecular weight distribution, and crystallinity, the mechanical properties of PVDF can be further improved.

- PVDF Structure and Electrical Properties: PVDF exhibits excellent dielectric and piezoelectric properties, closely related to its unique semi-crystalline structure. By controlling the polarization process and additives, the electrical properties of PVDF can be further optimized.

- PVDF Structure and Other Properties: The structural features of PVDF also determine its excellent chemical stability, corrosion resistance, and biocompatibility. Through structural design and modifications, the application range of PVDF can be further expanded.

02 PVDF Copolymers and Composites

PVDF can be copolymerized or combined with fillers and additives to form composites with enhanced properties, such as improved mechanical strength, thermal stability, or electrical conductivity, exhibiting improved structural stability and performance.Expand Specific Solutions03 PVDF Processing and Fabrication Techniques

The structural stability of PVDF can be influenced by processing and fabrication techniques like electrospinning, solution casting, or melt extrusion, affecting its crystalline structure, orientation, and morphology, impacting its structural stability and performance.Expand Specific Solutions04 PVDF Surface Modification and Functionalization

Surface modification and functionalization techniques, such as plasma treatment, chemical grafting, or functional group incorporation, can enhance the structural stability and performance of PVDF, improving interfacial adhesion, hydrophilicity, or biocompatibility.Expand Specific Solutions05 PVDF Applications and Structural Stability Requirements

PVDF finds applications in various fields like energy storage, sensors, filtration, and biomedical devices, each with specific structural stability requirements. Understanding these requirements and tailoring the PVDF structure and properties accordingly is crucial for optimal performance and durability.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Wanhua Chemical Group Co., Ltd.

Key Technology Interpretation

- The use of a polyvinylidene fluoride (PVDF) supporting substrate as a base material for the desalination membrane.

- The combination of a two-dimensional metal carbide layer with the PVDF supporting substrate to create a desalination membrane.

- The potential for the PVDF-based desalination membrane to have improved stability and performance compared to existing membranes.

PVDF Structural Stability Improvement Economic Analysis

Improving the structural stability of PVDF (Polyvinylidene Fluoride) has significant economic implications that span various industries. PVDF is widely used in sectors such as electronics, construction, and filtration due to its unique properties, like high corrosion resistance and electrical insulation capabilities. Enhancements in its structural stability can lead to increased longevity and performance, reducing the need for frequent replacements and maintenance. This, in turn, can lead to substantial cost savings for manufacturers and end-users, making PVDF-based products more competitive in the market.

Furthermore, with countries globally pushing for more sustainable and longer-lasting materials, PVDF with improved stability aligns well with these trends, opening new opportunities for market penetration. Companies that successfully enhance PVDF stability can capitalize on these trends, potentially expanding their market share and driving growth. Additionally, this could spur innovation, as firms invest in developing more advanced applications for PVDF, thereby fostering economic growth within the relevant sectors. As the market evolves, these enhancements could redefine industry standards and drive future economic developments through enhanced product offerings and environmental compliance.

PVDF Structural Stability Improvement Policy And Regulatory Impact

When considering the improvement of the structural stability of PVDF (Polyvinylidene Fluoride), understanding the policy and regulatory impact is crucial for guiding R&D efforts and market adoption. Regulations related to chemical manufacturing and environmental standards are critical. As PVDF is often used in applications involving exposure to harsh chemical environments, compliance with stringent environmental regulations is necessary. This includes ensuring that the production processes adhere to laws aimed at reducing harmful emissions and waste by-products, as dictated by agencies like the Environmental Protection Agency (EPA) or its international counterparts.

Additionally, global policy trends favoring sustainable materials and energy-efficient solutions can affect the direction of research. Incentives for using polymers with long life cycles and less environmental footprint may provide opportunities for PVDF enhancement, positioning it favorably against alternatives. Intellectual property laws also play a vital role; securing patents for novel compositions or processes is essential to protect innovation and secure competitive advantages.

Furthermore, trade policies can influence the supply chain and costs associated with raw materials needed for PVDF production, while import-export restrictions may impact market accessibility. Keeping abreast of these policy and regulatory frameworks ensures that innovations in PVDF stability not only achieve technical success but are also aligned with economic and legal landscapes, facilitating smoother adoption and commercialization.