Unraveling the Evolution of PVDF-Based Piezoelectric Energy Harvesters

PVDF-Based Piezoelectric Energy Harvesters Technology Background And Goals

This technical report provides a comprehensive overview of the development history and evolution trends in the field of PVDF-based piezoelectric energy harvesters. This includes tracing the key milestones and technological breakthroughs that have shaped the progress of this technology over time. Additionally, it aims to clearly define the expected technological goals and advancements that researchers and developers are striving to achieve in this domain.

By examining the historical trajectory and identifying the driving forces behind the advancements in PVDF-based piezoelectric energy harvesting, this section will lay the foundation for understanding the current state of the art and potential future directions. It will also highlight the significance and motivations behind pursuing this technology, setting the stage for further analysis and exploration in subsequent sections of the report.

Market Demand Analysis

- Market Potential

PVDF-based piezoelectric energy harvesters have significant market potential due to the increasing demand for sustainable and self-powered electronic devices. The global market for energy harvesting systems is projected to grow substantially in the coming years, driven by the need for efficient and environmentally-friendly energy solutions. - Applications

These harvesters can be utilized in various applications, including wearable electronics, wireless sensor networks, structural health monitoring systems, and Internet of Things (IoT) devices. The ability to convert ambient vibrations into electrical energy makes them suitable for powering low-power electronics in remote or inaccessible locations. - Industry Trends

The market demand for PVDF-based piezoelectric energy harvesters is influenced by several industry trends, such as the growing adoption of smart devices, the increasing focus on energy efficiency and sustainability, and the development of flexible and lightweight electronics. - Market Drivers

- Rising demand for self-powered and maintenance-free electronic devices

- Advancements in materials science and manufacturing processes

- Increasing investments in research and development

- Government initiatives and regulations promoting sustainable energy solutions

- Market Challenges

- Limited power output and energy conversion efficiency

- Integration challenges with existing electronic systems

- Competition from alternative energy harvesting technologies

- Lack of standardization and regulatory frameworks

Technology Status And Challenges

- Technology Evolution

Piezoelectric materials have been studied for decades, with PVDF emerging as a promising candidate for energy harvesting due to its high piezoelectric coefficient, flexibility, and chemical stability. - Current Challenges

Key challenges include low output power density, material degradation over time, and integration with electronic circuits for efficient energy conversion and storage. - Geographical Distribution

Research on PVDF-based piezoelectric energy harvesters is widespread, with major contributions from the United States, Europe, and Asia, particularly China, South Korea, and Japan.

Current Technical Solutions

01 Vibration Energy Harvesting

PVDF-based piezoelectric energy harvesters convert mechanical vibrations into electrical energy, utilizing the piezoelectric properties of PVDF to generate an electrical charge when subjected to mechanical stress or deformation caused by vibrations. They can harvest energy from various sources like machinery, vehicles, or human motion.- Vibration Energy Harvesting: PVDF-based piezoelectric energy harvesters convert mechanical vibrations into electrical energy, utilizing the piezoelectric properties of PVDF to generate an electrical output when subjected to deformation or vibration. They can harvest energy from various sources like machinery vibrations, human motion, or environmental vibrations.

- Improved Energy Conversion Efficiency: Researchers have developed PVDF-based piezoelectric energy harvesters with enhanced energy conversion efficiency, incorporating techniques like optimized electrode configurations, improved material properties, or novel structural designs to maximize energy output from mechanical vibrations.

- Wearable and Implantable Applications: PVDF-based piezoelectric energy harvesters have been developed for wearable and implantable applications, designed to be lightweight, flexible, and biocompatible, suitable for powering wearable electronics or implantable medical devices by harvesting energy from body movements or biological processes.

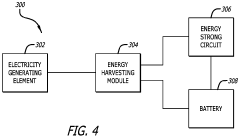

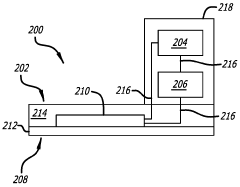

- Integrated Energy Storage and Management: Some PVDF-based piezoelectric energy harvesters incorporate energy storage and management systems like batteries or supercapacitors to store harvested energy and regulate its distribution, providing a reliable and efficient power source for various applications.

- Novel Configurations and Materials: Researchers have explored novel configurations and materials for PVDF-based piezoelectric energy harvesters, including composite materials, nanostructured PVDF, or unique device architectures, to enhance performance, broaden frequency range, or enable new applications.

02 Improved Energy Conversion Efficiency

Researchers have developed PVDF-based piezoelectric energy harvesters with enhanced energy conversion efficiency, incorporating techniques like optimized electrode configurations, improved material properties, or novel structural designs to maximize energy output from mechanical vibrations.Expand Specific Solutions03 Wearable and Flexible Applications

PVDF-based piezoelectric energy harvesters have been developed for wearable and flexible applications, leveraging the flexibility and lightweight nature of PVDF to create conformable and unobtrusive energy harvesters for energy harvesting from human motion or integration into clothing or accessories.Expand Specific Solutions04 Improved Durability and Reliability

Researchers have focused on enhancing the durability and reliability of PVDF-based piezoelectric energy harvesters, improving mechanical properties, environmental resistance, and long-term stability to ensure reliable operation under various conditions.Expand Specific Solutions05 Integrated Energy Storage and Management

Some PVDF-based piezoelectric energy harvesters incorporate energy storage and management systems like batteries or supercapacitors to store harvested energy and regulate its distribution, providing a more efficient and practical solution for powering electronic devices or sensors.Expand Specific Solutions

Main Player Analysis

Korea Institute of Ceramic Engineering & Technology

Nitto Denko Corp.

Key Technology Interpretation

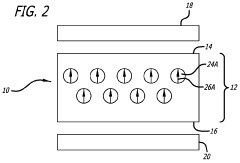

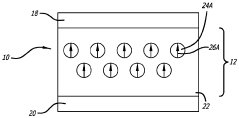

- A piezoelectric harvester that includes a piezoelectric layer made of a cross-linked silicone elastomeric matrix and piezoelectric particles dispersed within the matrix, providing flexibility and high piezoelectric coefficients.

- The use of elastic electrodes, such as carbon-based electrodes, on the upper and lower sides of the piezoelectric layer, allowing for flexibility and conformity to non-planar surfaces.

- The method for preparing the piezoelectric harvesting composite, involving a mixture of silicone oligomer and piezoelectric particles, enabling the formation of the cross-linked elastomeric matrix with dispersed piezoelectric particles.

PVDF-Based Piezoelectric Energy Harvesters Environmental Impact Analysis

PVDF-based piezoelectric energy harvesters present a promising technology for sustainable energy generation, however, their environmental impact requires careful evaluation. Firstly, PVDF, being a type of polymer, can pose challenges in terms of biodegradability and recycling. The production process of PVDF involves chemical synthesis that can potentially release harmful by-products, contributing to environmental pollution. Additionally, any large-scale deployment of PVDF-based harvesters might lead to increased plastic waste if end-of-life management strategies are not well established.

Nevertheless, PVDF-based piezoelectric materials offer significant environmental advantages. They can be instrumental in reducing reliance on non-renewable energy sources, thus decreasing carbon footprint. By harnessing ambient vibrations and mechanical stresses in infrastructure, vehicles, or wearable devices, these harvesters can support energy-efficient solutions without the need for batteries, thus also mitigating the environmental issues associated with battery disposal.

To minimize adverse environmental impacts, it is crucial to promote the development of recycling technologies for PVDF materials and to refine manufacturing processes to lower emissions. Additionally, integrating these materials into a circular economy framework could enhance the sustainability profile of PVDF-based piezoelectric devices, making them not only an innovative but also a responsible choice for energy harvesting applications.

PVDF-Based Piezoelectric Energy Harvesters Policy And Regulatory Impact

Regulatory policies related to environmental sustainability and renewable energy incentives can significantly impact the development and adoption of these technologies. Governments are increasingly prioritizing green tech solutions to reduce carbon footprints, and piezoelectric energy harvesters fall within this domain. Subsidies, tax breaks, and grants for research and development in clean energy are likely to propel advancements and reduce production costs, enhancing market competitiveness.

Additionally, standardization and certification requirements will play a crucial role. The establishment of international standards for performance and safety can foster greater industry adoption by ensuring product reliability and consumer trust. These regulations also influence cross-border trade policies, impacting the global supply chain and market penetration.

Furthermore, intellectual property laws regarding patent protection for innovations in piezoelectric technology can affect the competitive landscape. Robust IP frameworks encourage technological advancements by protecting innovators' rights, while overly stringent regulations might stifle innovation if not balanced correctly. As regulatory landscapes evolve, continuous monitoring and strategic adaptation to these changes are crucial for stakeholders in the piezoelectric energy harvester market.