How to Improve The Wettability Of PVDF (Polyvinylidene Fluoride)?

Technology Background And Goals

In this report, you will learn how to improve the wettability of PVDF (polyvinylidene fluoride), a highly non-polar and hydrophobic fluoropolymer. Enhancing its wettability is crucial for various applications, such as membrane filtration, biomedical devices, and energy storage systems.

Several approaches have been explored to modify the surface properties of PVDF, including chemical treatments, plasma treatments, and the incorporation of hydrophilic additives or nanofillers. However, these methods often face challenges in terms of long-term stability, environmental impact, or scalability. Developing a sustainable and effective solution to improve the wettability of PVDF while maintaining its desirable properties remains an active area of research.

PVDF Market Demand Analysis

- Market Size and Growth

The global PVDF market is projected to reach $1.2 billion by 2027, growing at a CAGR of 6.2% from 2020 to 2027. The increasing demand for PVDF in various applications, such as lithium-ion batteries, water treatment membranes, and coatings, is driving market growth. - Key Application Areas

- Lithium-ion Batteries: PVDF is widely used as a binder in lithium-ion battery electrodes due to its excellent electrochemical stability and high dielectric constant.

- Water Treatment Membranes: PVDF's hydrophobic nature and chemical resistance make it suitable for water treatment membranes, such as ultrafiltration and microfiltration.

- Coatings and Paints: PVDF coatings offer excellent weatherability, UV resistance, and chemical resistance, making them ideal for architectural and industrial applications.

- Regional Market Dynamics

Asia Pacific is the largest and fastest-growing market for PVDF, driven by the increasing demand from the lithium-ion battery and water treatment industries in countries like China, Japan, and South Korea. - Market Trends and Drivers

- Growing Demand for Lithium-ion Batteries: The increasing adoption of electric vehicles and renewable energy storage systems is fueling the demand for PVDF as a binder in lithium-ion batteries.

- Stringent Environmental Regulations: Stricter regulations regarding water treatment and industrial emissions are driving the demand for PVDF membranes and coatings.

- Technological Advancements: Ongoing research and development efforts to improve the properties and performance of PVDF are expected to create new market opportunities.

Technology Status And Challenges

- Fluoropolymer Properties

PVDF is a highly non-reactive and pure thermoplastic fluoropolymer with excellent chemical resistance, thermal stability, and mechanical strength. - Hydrophobicity Challenge

Despite its desirable properties, PVDF suffers from poor wettability and hydrophobicity, limiting its applications in areas requiring surface interactions. - Surface Modification Techniques

Various surface modification techniques have been explored to improve PVDF wettability, including plasma treatment, chemical grafting, and nanocomposite coatings. - Plasma Treatment

Plasma treatment introduces polar functional groups on the PVDF surface, enhancing its hydrophilicity and adhesion properties. - Chemical Grafting

Grafting hydrophilic polymers or molecules onto the PVDF surface can improve its wettability and biocompatibility. - Nanocomposite Coatings

Incorporating hydrophilic nanoparticles or nanostructures into PVDF matrices can create roughened surfaces with improved wettability. - Challenges and Limitations

Challenges include achieving long-term stability, controlling surface morphology, and maintaining bulk properties after surface modifications.

Current Technical Solutions

01 Surface Modification for Wettability

Various techniques like plasma treatment, chemical etching, polymer grafting, and nanoparticle incorporation modify PVDF surfaces to enhance wettability for better adhesion or compatibility with aqueous solutions.- Surface Modification for Wettability: Various techniques like plasma treatment, chemical etching, and hydrophilic coatings can modify PVDF surfaces to enhance wettability, enabling better adhesion or compatibility with aqueous solutions.

- Controlled Wettability Membranes: PVDF membranes with tailored wettability, achieved by incorporating hydrophilic/hydrophobic additives during formation, enable their use in filtration, separation, or sensing applications.

- Enhanced Wettability Composites: Combining PVDF with inorganic fillers or polymers forms composites with improved wettability, suitable for various applications due to the incorporation of hydrophilic components or roughened surfaces.

- Patterned Wettability Surfaces: PVDF surfaces can be patterned with micro/nanostructures to create regions with different wettability characteristics, enabling applications in microfluidics, self-cleaning, or anti-fouling coatings.

- Tunable Wettability Electrospun Fibers: Electrospinning produces PVDF-based fibrous mats with controlled wettability, achieved through hydrophilic/hydrophobic additives or post-treatments, enabling applications in filtration, tissue engineering, or protective textiles.

02 Controlled Wettability Membranes

PVDF membranes with tailored wettability, achieved through hydrophilic/hydrophobic additives, coatings, or pore structure control, are used in water filtration, oil-water separation, and biomedical devices.Expand Specific Solutions03 Enhanced Wettability Composites

PVDF composites with improved wettability are formed by combining with inorganic fillers, polymers, or nanoparticles, enabling applications like self-cleaning surfaces or biomedical devices through hydrophilic components or hierarchical structures.Expand Specific Solutions04 Wettability for Energy Storage

Tailored wettability of PVDF in energy storage devices like batteries and supercapacitors improves electrolyte-electrode interface, ion transport, and overall performance and stability.Expand Specific Solutions05 Tunable Wettability Coatings

PVDF coatings with adjustable wettability, achieved through additives, hierarchical structures, or surface treatments, enable self-cleaning, anti-fouling, or controlled adhesion properties.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Kureha Corp.

Key Technology Interpretation

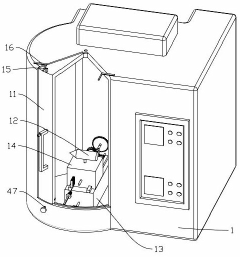

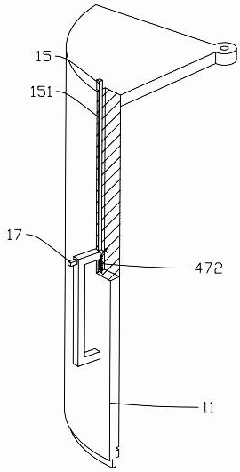

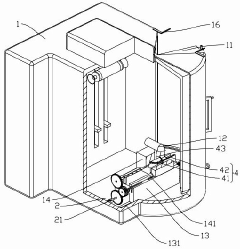

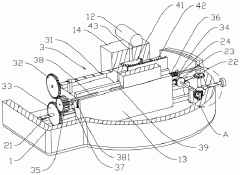

- By arranging the first support base and the second support base and driving them to move through the first driving assembly and the second driving assembly, when the operator opens the movable door, the clamping device can move toward the movable door until it can be reached by the operator. position to facilitate the operator to replace or disassemble the workpiece on the clamping device

PVDF Wettability Improvement Economic Analysis

Economic analysis of improving the wettability of PVDF (Polyvinylidene Fluoride) primarily focuses on evaluating the cost-effectiveness and market implications of this enhancement. Enhancing wettability can significantly impact the material's application in various industries such as filtration, membrane technology, and coatings. Improved wettability often translates to better performance, potentially leading to increased product demand and market share within these sectors.

The modification of PVDF to enhance its wettability may involve additional material costs and processing steps. It's crucial to assess whether these costs can be offset by the increased efficiency and functionality provided by improved wettability. Cost-benefit analysis will play a vital role in determining the viability of investing in wettability improvement technologies.

Moreover, by enhancing wettability, PVDF can broaden its applications, potentially penetrating markets that require high hydrophilicity without compromising chemical resistance. This expansion could lead to revenue growth and competitive advantage in emerging markets where such material characteristics are essential. Overall, the economic analysis should deliberate both direct financial impacts and strategic benefits of tapping into new market opportunities facilitated by technological advancements in PVDF wettability.

PVDF Wettability Improvement Policy And Regulatory Impact

The wettability of PVDF (Polyvinylidene Fluoride) can be significantly impacted by policy and regulatory factors, as these dictate the guidelines and safety standards for the chemical treatments and surface modifications used to enhance PVDF's wettability. Regulatory agencies, such as the Environmental Protection Agency (EPA) in the United States or the European Chemicals Agency (ECHA) in Europe, enforce rigorous standards that must be adhered to during the development and application processes of these materials. Compliance with such regulations ensures that any chemical modifications do not pose environmental or health risks, compelling companies to innovate within these defined boundaries.

Moreover, industry standards provided by organizations like the International Organization for Standardization (ISO) influence the methods for testing and improving the wettability of PVDF. These standards encourage consistency and reliability in the industry, guiding research efforts towards sustainable solutions that align with global expectations. Policies encouraging sustainable and eco-friendly materials are also propelling industries to explore bio-based or less toxic chemicals for improving wettability, pushing forward the development of innovative and safer approaches that align with circular economy principles.

Ultimately, understanding and navigating these regulatory landscapes is crucial for the successful advancement of PVDF wettability technologies, allowing companies to sustainably enhance product performance while remaining compliant with international standards.