Developing PVDF-Based Nanocomposite Materials For Improved Wettability

Background And Goals

This technical report explores the potential of developing nanocomposite materials based on polyvinylidene fluoride (PVDF) with improved wettability for various applications. PVDF is a highly non-polar polymer with excellent chemical resistance, thermal stability, and mechanical properties, but its hydrophobic nature limits its applications in areas where wettability is crucial.

Enhancing the wettability of PVDF-based nanocomposites can be achieved by incorporating hydrophilic nanofillers or modifying the surface properties of PVDF. Potential strategies include blending PVDF with hydrophilic polymers, grafting hydrophilic functional groups onto PVDF chains, or introducing nanofillers with high surface energy, such as metal oxides or carbon-based nanomaterials. The improved wettability of these nanocomposites can enable their use in applications like membranes for water treatment, biomedical devices, and protective coatings.

Market Demand Analysis

- Market Size and Growth

The market for PVDF-based nanocomposite materials with improved wettability is expected to witness significant growth in the coming years. This growth is driven by the increasing demand for advanced materials in various industries, including construction, automotive, aerospace, and electronics. - Key Applications

PVDF-based nanocomposites with enhanced wettability find applications in:- Protective coatings for corrosion resistance and self-cleaning surfaces

- Membranes for water purification and desalination

- Biomedical devices and implants with improved biocompatibility

- Sensors and actuators for environmental monitoring

- Market Drivers

- Increasing demand for sustainable and eco-friendly materials

- Growing need for advanced materials in emerging technologies

- Stringent regulations regarding environmental protection and energy efficiency

- Regional Trends

The market for PVDF-based nanocomposites with improved wettability is expected to be concentrated in regions with a strong focus on research and development, such as North America, Europe, and Asia-Pacific.

Materials Status And Challenges

- Historical Development

Tracing the evolution of PVDF-based nanocomposites, from early research on polymer blends to the incorporation of various nanofillers for enhanced properties. - Wettability Challenges

Discussing the inherent hydrophobic nature of PVDF and the need for surface modification to improve wettability for applications like membranes and coatings. - Nanofillers and Composites

Exploring the use of hydrophilic nanofillers like clays, metal oxides, and carbon nanotubes to create nanocomposites with improved wettability. - Fabrication Techniques

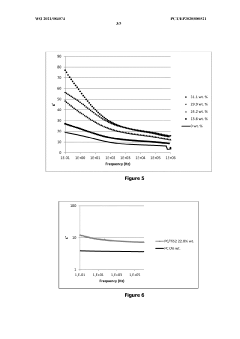

Outlining various methods for synthesizing PVDF nanocomposites, such as solution casting, melt blending, and in-situ polymerization, and their impact on wettability. - Characterization Methods

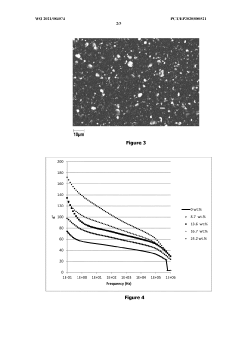

Discussing analytical techniques like contact angle measurements, surface energy calculations, and microscopy for evaluating the wettability of PVDF nanocomposites.

Current Technical Solutions

01 Improved Wettability

Incorporating hydrophilic nanoparticles or modifying the surface with hydrophilic functional groups enhances the wettability of PVDF-based nanocomposites, improving adhesion, compatibility, and interfacial interactions.- Improved Wettability: Incorporating hydrophilic nanoparticles or modifying the surface with functional groups enhances the wettability of PVDF-based nanocomposites, improving adhesion, compatibility, and interfacial interactions.

- Superhydrophobic Properties: Incorporating low surface energy nanoparticles or creating hierarchical micro/nanostructures imparts superhydrophobic, self-cleaning, anti-fouling, and water-repellent properties to PVDF-based nanocomposites.

- Tunable Wettability: The wettability of PVDF-based nanocomposites can be tuned by controlling the type, concentration, and distribution of nanofillers or surface modifiers, enabling the development of materials with desired wetting properties.

- Stimuli-Responsive Wettability: PVDF-based nanocomposites can exhibit stimuli-responsive wettability, where their surface wetting properties change in response to external stimuli like temperature, pH, or electric fields, enabling controllable wetting behavior.

- Hierarchical Structures for Wettability Control: Creating hierarchical micro/nanostructures on the surface of PVDF-based nanocomposites, inspired by natural surfaces like lotus leaves, can impart superhydrophobic or superhydrophilic properties for wettability control.

02 Superhydrophobic Properties

Incorporating low surface energy nanoparticles or creating hierarchical micro/nanostructures renders PVDF-based nanocomposites superhydrophobic, exhibiting excellent water repellency, self-cleaning, and anti-fouling characteristics.Expand Specific Solutions03 Tunable Wettability

The wettability of PVDF-based nanocomposites can be tuned by controlling the composition, surface morphology, and chemical functionalization of nanofillers, enabling the development of materials with desired wetting properties.Expand Specific Solutions04 Stimuli-Responsive Wettability

PVDF-based nanocomposites can exhibit stimuli-responsive wettability, where their surface wetting properties can be reversibly switched between hydrophilic and hydrophobic states in response to external stimuli like temperature, pH, light, or electric fields.Expand Specific Solutions05 Hierarchical Surface Structures for Wettability Control

The wettability of PVDF-based nanocomposites can be controlled by creating hierarchical surface structures at micro and nanoscale levels through techniques like phase separation, templating, or surface modification, leading to unique wetting properties.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Solvay SA

Key Technology Interpretation

- Incorporating TiS2 particles into a polymer matrix to increase the relative permittivity of the nanocomposite material.

- Utilizing core-shell structured fillers or treating nanoparticles with coupling agents to reduce dielectric losses while maintaining high relative permittivity.

- Preferentially orienting the fillers within the polymer matrix to lower dielectric losses.

PVDF-Based Nanocomposite Materials Wettability Improvement Economic Analysis

The economic analysis of developing PVDF-based nanocomposite materials for improved wettability should consider several key factors to understand the financial viability and set a pathway for strategic investment. First, the cost implications of sourcing raw materials, especially high-purity polyvinylidene fluoride (PVDF) and compatible nanofillers, need to be analyzed. This includes evaluating the price fluctuations in the global supply chain and assessing the cost-effectiveness of alternative fillers that offer similar enhancements in wettability.

Furthermore, the manufacturing process's scalability and efficiency must be gauged to ensure competitive production costs. This aspect involves technological advancements that can reduce energy consumption and waste generation, directly affecting unit costs and sustainability.

Market demand projections for these advanced materials in industries like membranes, coatings, and biomedical applications must also be considered. Assessing current demand trends and future potential growth can help in forecasting revenue streams and evaluating the return on investment.

Lastly, regulatory costs, such as compliance with environmental and safety standards, must be factored into the analysis. Meeting these requirements can pose additional financial burdens but is essential for market entry and sustainability in the long term. This economic analysis will guide resource allocation towards the most promising opportunities within this technology area.

PVDF-Based Nanocomposite Materials Wettability Improvement Environmental Impact

The environmental impact of developing PVDF-based nanocomposite materials for improved wettability is a crucial consideration in the advancement of green and sustainable materials science. PVDF (polyvinylidene fluoride) is known for its excellent chemical resistance, thermal stability, and mechanical properties. However, the integration of nanocomposites can result in environmental concerns, particularly regarding the lifecycle of such materials. The production process of PVDF-based nanocomposites involves nanoscale additives, which might pose a risk of nanoparticle release into the environment during both manufacturing and end-of-life disposal. This raises concerns about potential toxicological effects on ecosystems and human health.

On the positive side, improving wettability through these composites could enhance their efficiency in applications such as water purification and membrane technologies, thus contributing to environmental sustainability. By reducing energy consumption and increasing resource efficiency in these applications, the overall environmental footprint can be potentially decreased. Furthermore, the development of recycling and reusability strategies for these nanocomposites will be essential in mitigating their environmental impact. By focusing on eco-friendly processes and lifecycle assessments, it's possible to balance the technological benefits with environmental responsibility, ensuring that advancements in PVDF-based nanocomposite materials support broader sustainability goals.