Improving The Performance Of PVDF-Based Binders For High-Performance Electrode Materials

Technology Background And Goals

This report aims to investigate and develop high-performance PVDF-based binders for electrode materials, in order to enhance the overall performance of energy storage devices such as lithium-ion batteries, supercapacitors and more.

This technology background section will provide an overview of the historical development and current state of PVDF-based binders in electrode materials. It will discuss the key challenges and limitations faced by existing binder systems, highlighting the need for improved performance and the potential benefits of advanced PVDF-based binders. Additionally, it will outline the specific technical goals and targets to be achieved through this research, such as improved electrochemical stability, enhanced adhesion, and increased cycle life.

PVDF-Based Binders Market Demand Analysis

- Market Size and Growth

The global market for PVDF-based binders is projected to experience significant growth, driven by the increasing demand for high-performance electrode materials in various applications, including lithium-ion batteries, supercapacitors, and fuel cells. - Key Application Areas

The major application areas driving the demand for PVDF-based binders include:- Lithium-ion batteries for electric vehicles and energy storage systems

- Supercapacitors for high-power applications and energy harvesting

- Fuel cells for clean energy generation and transportation

- Regional Market Dynamics

The Asia-Pacific region is expected to dominate the PVDF-based binders market, driven by the rapid growth of the electric vehicle industry and the increasing adoption of renewable energy technologies in countries like China, Japan, and South Korea. - Competitive Landscape

The PVDF-based binders market is highly competitive, with major players including Solvay, Arkema, Kureha Corporation, and Daikin Industries. These companies are investing in research and development to improve the performance and cost-effectiveness of their PVDF-based binder products.

Technology Status And Challenges

- Polymer Properties

PVDF is a semi-crystalline polymer with excellent chemical resistance, thermal stability, and mechanical strength. Its unique properties make it suitable for binder applications in high-performance electrode materials. - Challenges in Electrode Binding

Achieving good adhesion between the active material and current collector while maintaining high ionic conductivity and mechanical integrity during cycling is a key challenge for PVDF-based binders. - Electrochemical Stability

PVDF binders must be electrochemically stable within the operating voltage range of the electrode material to prevent degradation and ensure long-term performance. - Processability and Compatibility

The processability of PVDF binders, including their solubility in common solvents and compatibility with electrode slurry components, can impact the manufacturing process and electrode performance. - Morphological Control

Controlling the morphology and porosity of the PVDF binder layer is crucial for facilitating efficient ion transport and accommodating volume changes during cycling.

Current Technical Solutions

01 PVDF-based Binders for Li-ion Battery Electrodes

PVDF-based binders are widely used in lithium-ion battery electrodes due to their excellent electrochemical stability, good adhesion, and compatibility with electrode materials, improving cycle life and rate capability.- PVDF-based Binders for Li-ion Battery Electrodes: PVDF-based binders are widely used in lithium-ion battery electrodes due to their excellent electrochemical stability and ability to form strong adhesion between the active material and current collector, improving cycle life and rate capability.

- PVDF-based Binders for Electrode Slurry Formulations: PVDF-based binders are used in electrode slurry formulations to provide good dispersion and binding properties, optimizing rheological properties and improving coating quality with various additives and solvents.

- Improved PVDF-based Binders: Modified PVDF-based binders with enhanced adhesion, better dispersion, and increased ionic conductivity have been developed through copolymerization, grafting, or blending with other polymers or additives.

- PVDF-based Binders for Solid-State Batteries: PVDF-based binders facilitate the formation of a stable solid-electrolyte interface and improve the interfacial contact between the electrode and solid electrolyte in solid-state batteries.

- PVDF-based Binders for Other Energy Storage Applications: PVDF-based binders have been explored for use in supercapacitors, fuel cells, and redox flow batteries, providing benefits in terms of electrode integrity and performance.

02 PVDF-based Binders for Electrode Slurry Formulations

PVDF-based binders are used in electrode slurry formulations to improve dispersion and binding properties, enhancing homogeneity, stability, and battery life.Expand Specific Solutions03 PVDF-based Binders with Improved Mechanical and Thermal Properties

Modified PVDF-based binders with improved mechanical and thermal properties enhance structural integrity and thermal stability of electrodes, leading to better battery performance and safety.Expand Specific Solutions04 PVDF-based Binders for High-Energy-Density Batteries

PVDF-based binders are being explored for use in high-energy-density batteries, such as lithium-sulfur and lithium-air batteries, improving cycling stability and electrochemical performance.Expand Specific Solutions05 PVDF-based Binders with Improved Ionic Conductivity

PVDF-based binders with enhanced ionic conductivity have been developed, improving rate capability and power density of lithium-ion batteries by facilitating ion transport within the electrode structure.Expand Specific Solutions

Main Player Analysis

LG Chem Ltd.

DuPont de Nemours, Inc.

Key Technology Interpretation

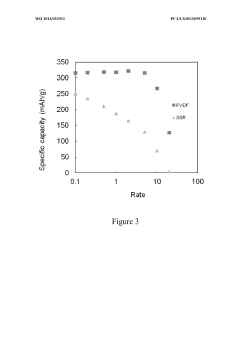

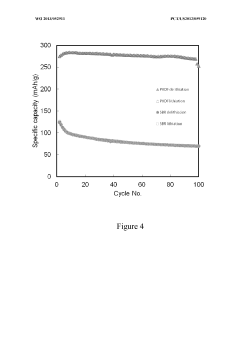

- Combining PVDF and SBR binders to leverage the superior performance of PVDF and strong binding force of SBR for improved electrode performance.

- Using less PVDF binder to reduce material costs while maintaining or improving electrode performance.

- Surface modification of active material particles to improve compatibility and interaction with the binder system.

PVDF-Based Binders Performance Improvement Economic Analysis

PVDF-based binders are increasingly preferred due to their superior electrochemical stability and mechanical properties, which are critical for enhancing battery performance. The production costs of PVDF-based binders can be significant due to the complex chemical processes involved and the need for high-purity materials. This can affect their market price and, consequently, the overall cost of battery production.

Despite higher initial costs, the long-term economic benefits provided by PVDF-based binders could potentially offset these costs, particularly in demanding applications such as electric vehicles and large-scale energy storage systems. The improved cycle stability and energy density of batteries using PVDF-based binders can lead to lower costs per cycle over the battery's lifespan, offering economic advantages.

Market demand for PVDF-based binders is expected to grow in parallel with the rising demand for advanced batteries. However, competition from alternative binder technologies and fluctuations in raw material prices could influence future cost structures. Companies must strategically source materials and optimize manufacturing processes to remain competitive while meeting increasing market demands.

PVDF-Based Binders Performance Improvement Policy And Regulatory Impact

The realm of PVDF-based binders for high-performance electrode materials is deeply influenced by policy and regulatory impacts, as these factors steer research priorities, funding allocations, and market accessibility. Regulatory bodies often dictate the permissible compounds and methods used in electrode production, which, in turn, affects the development and utilization of PVDF-based binders. Compliance with environmental standards requires ongoing innovation to reduce ecological footprints, compelling researchers to explore PVDF variations that enhance recyclability and minimize hazardous waste.

Simultaneously, government incentives and subsidies for renewable energy storage initiatives drive the investment in high-performance electrode technologies, where PVDF-based binders can play a pivotal role. Industry standards, such as those set by the International Electrotechnical Commission (IEC) and other relevant organizations, mandate quality and safety benchmarks that PVDF-based binders must meet, influencing their formulation and application strategies.

Moreover, trade policies and international agreements can impact the availability and cost of raw materials for PVDF production, which must be factored into strategic planning and supply chain management. Overall, a comprehensive understanding of the policy landscape is crucial for stakeholders in leveraging PVDF-based binders effectively within the constraints and opportunities presented by the regulatory environment.