PVDF-Based Sensors For Structural Health Monitoring

PVDF-Based Sensors Technology Background And Goals

This technical report provides a comprehensive overview of the development history and evolution trends in the field of PVDF-based sensors for structural health monitoring. This section will delve into the key milestones and technological advancements that have shaped this domain, shedding light on the driving forces behind its progress. Additionally, it will clearly articulate the anticipated technological goals and desired outcomes that serve as the guiding principles for future research and development efforts in this area.

By establishing a solid foundation through an in-depth examination of the technology's background and objectives, this section aims to set the stage for a thorough exploration of the subsequent aspects outlined in the directory, ultimately contributing to a well-rounded and insightful technology research report.

PVDF-Based Sensors Market Demand Analysis

- Market Size and Growth

The global market for PVDF-based sensors in structural health monitoring is expected to witness significant growth, driven by the increasing demand for advanced monitoring systems in various industries, such as construction, aerospace, and transportation. - Key Applications

PVDF-based sensors find applications in monitoring structural integrity, detecting cracks and deformations, and assessing the overall health of critical infrastructure, including bridges, buildings, aircraft, and pipelines. - Industry Trends

The adoption of PVDF-based sensors is driven by the need for real-time monitoring, early detection of potential failures, and preventive maintenance strategies. The trend towards smart infrastructure and the Internet of Things (IoT) further fuels the demand for these sensors. - Regional Demand

The demand for PVDF-based sensors is particularly high in regions with aging infrastructure and stringent safety regulations, such as North America and Europe. Emerging economies with rapid infrastructure development, like Asia-Pacific, also present significant growth opportunities.

Technology Status And Challenges

- PVDF Material Properties

PVDF (polyvinylidene fluoride) is a semi-crystalline polymer with excellent piezoelectric, pyroelectric, and ferroelectric properties, making it suitable for sensor applications. - Sensor Fabrication Techniques

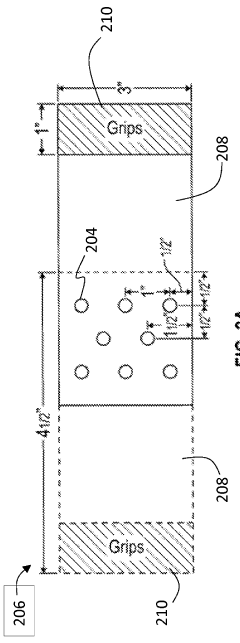

Various techniques are employed for fabricating PVDF-based sensors, including spin-coating, electrospinning, and solution casting. The choice of technique affects sensor performance and cost. - Sensor Integration Challenges

Integrating PVDF sensors into structural components poses challenges, such as ensuring proper adhesion, minimizing signal attenuation, and protecting sensors from environmental factors. - Signal Processing and Conditioning

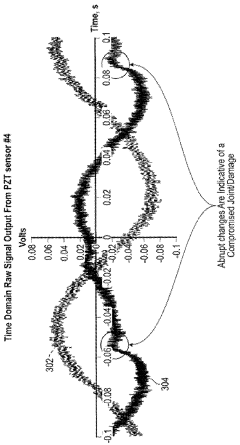

PVDF sensors generate weak signals, necessitating advanced signal processing and conditioning techniques to enhance signal quality and reliability. - Sensor Durability and Lifetime

The long-term durability and lifetime of PVDF sensors under harsh environmental conditions, such as extreme temperatures, humidity, and mechanical stress, require further investigation.

Current Technical Solutions

01 PVDF Sensors for Structural Health Monitoring

Polyvinylidene fluoride (PVDF) piezoelectric polymer sensors can detect and measure strain, vibration, and damage in structures like buildings, bridges, and aircraft, offering flexibility, lightweight, and easy integration.- PVDF Sensors for Structural Health Monitoring: Polyvinylidene fluoride (PVDF) piezoelectric sensors can detect strain, vibration, and damage in structures like buildings, bridges, and aircraft, offering flexibility, lightweight, and easy integration.

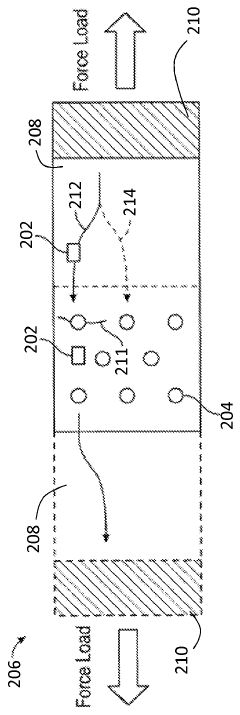

- PVDF Sensor Fabrication and Integration: Techniques for fabricating and integrating PVDF sensors into structures include depositing PVDF films, patterning electrodes, encapsulation, and embedding into composites or attaching to surfaces, influencing sensor performance and durability.

- Signal Processing and Data Analysis: Signal conditioning, feature extraction, pattern recognition, and machine learning algorithms are used to process and analyze PVDF sensor signals for accurate structural health monitoring and damage detection.

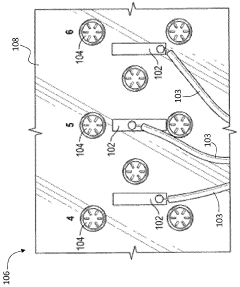

- Applications in Structural Health Monitoring: PVDF sensors are used to monitor the health of buildings, bridges, aircraft, wind turbines, and pipelines, detecting and locating cracks, delamination, impact damage, and other structural defects, particularly in harsh environments and for continuous monitoring.

- Wireless and Energy-Harvesting Systems: PVDF sensor systems can be designed with wireless communication and energy-harvesting capabilities, enabling remote monitoring, eliminating wired connections and external power sources, and facilitating deployment in hard-to-reach areas.

02 Damage Detection and Localization

Embedded or surface-mounted PVDF sensors can detect changes in strain or vibration patterns caused by damage like cracks or delamination, enabling damage identification and localization in structures.Expand Specific Solutions03 Vibration Monitoring

PVDF sensors can detect and measure vibrations in structures caused by wind, seismic activity, and operational loads, allowing assessment of structural integrity and performance.Expand Specific Solutions04 Strain Monitoring

PVDF sensors can monitor strain in structures caused by loads, temperature changes, and material deformations, providing data for assessing structural integrity and performance.Expand Specific Solutions05 Structural Health Monitoring Systems

PVDF sensors can be integrated into structural health monitoring systems, incorporating multiple sensors, data acquisition, and analysis algorithms for real-time monitoring of structural integrity and performance.Expand Specific Solutions

Main Player Analysis

Lockheed Martin Corp.

The Boeing Co.

Key Technology Interpretation

- The sensor is configured to convert strain on the surface of a structural member to electric energy, enabling self-powered operation.

- The gate controls the distribution of the generated electric energy between energy storage and data collection/processing, allowing for efficient energy management.

- The module integrates sensing, energy harvesting, data collection, and wireless data transmission capabilities into a single self-contained unit.

Economic Analysis

The economic evaluation of PVDF-based sensors for structural health monitoring (SHM) hinges on several critical factors that determine their market viability and investment potential. These sensors, leveraging piezoelectric properties of PVDF, offer cost-effective and versatile solutions for real-time monitoring of structural integrity in various industries, including civil engineering, aerospace, and automotive sectors. The implementation of these sensors can significantly reduce maintenance costs and enhance safety by providing early warnings of structural failures. However, the economic competitiveness of PVDF-based sensors must be considered against alternative SHM technologies, such as fiber optic sensors and MEMS-based solutions, which might have differing cost-performance ratios.

In terms of manufacturing and scalability, PVDF sensors benefit from relatively lower production costs due to simpler fabrication processes and the widespread availability of raw materials. This economic advantage positions them as attractive options for large-scale deployments. Furthermore, as the demand for smart infrastructure grows globally, driven by urbanization and the need for resilient construction, the market potential for PVDF sensors likewise expands. Nonetheless, the initial investment costs related to sensor integration and data management systems could be significant entry barriers for some industries. Overall, the economic analysis indicates promising opportunities for PVDF-based sensors, contingent upon advancements in cost-efficient fabrication technologies and integration methodologies.

Environmental Impact

The environmental impact of PVDF-based sensors for structural health monitoring is a critical aspect to consider in their development and deployment. Polyvinylidene fluoride, or PVDF, is a polymer that offers excellent piezoelectric properties, making it suitable for sensing applications. However, like many polymers, it is derived from petrochemicals, which raises concerns about its environmental footprint in terms of raw material extraction and carbon emissions during production. One of the advantages of PVDF is its durability and resistance to harsh environmental conditions, which can prolong the lifespan of sensors made from this material, potentially reducing waste. However, the end-of-life disposal of PVDF sensors poses challenges, as the material is not biodegradable and can contribute to environmental pollution if not properly recycled or managed.

Efforts to mitigate these impacts include exploring recycling processes specific to PVDF, as well as developing biodegradable alternatives or composites that maintain the beneficial properties of PVDF while reducing environmental harm. Furthermore, the application of PVDF-based sensors in structural health monitoring can lead to more sustainable infrastructure management by facilitating early detection of structural issues, thereby preventing catastrophic failures and conserving resources through timely maintenance. Nonetheless, balancing the environmental costs associated with PVDF production and disposal with its benefits in extending the life and safety of structures remains an ongoing challenge in this field.