How to Improve The Mechanical Properties Of PVDF?

Technology Background And Goals

This report aims to investigate and enhance the mechanical properties of PVDF (polyvinylidene fluoride), a highly non-reactive and pure thermoplastic fluoropolymer. PVDF exhibits exceptional chemical resistance, thermal stability, and mechanical strength, making it suitable for various applications, including membranes, sensors, and energy storage devices.

However, the mechanical properties of PVDF, such as tensile strength, elongation at break, and impact resistance, can be further improved to broaden its application scope and meet the increasing demands of industries. Enhancing these properties is crucial for developing high-performance PVDF-based materials and expanding their potential applications in fields like aerospace, automotive, and construction.

PVDF Market Demand Analysis

- Market Size and Growth

PVDF has a substantial and growing market, driven by its unique properties and diverse applications. The global PVDF market was valued at around $1.2 billion in 2021 and is projected to reach $1.8 billion by 2028, with a CAGR of around 6% during the forecast period. - Key Application Areas

The major application areas for PVDF include:- Lithium-ion battery binders and separators

- Membranes for water treatment and desalination

- Coatings and linings for chemical resistance

- Piping systems for corrosive environments

- Automotive and aerospace components

- Regional Market Dynamics

The Asia-Pacific region dominates the PVDF market, driven by the rapid growth of industries like electronics, automotive, and water treatment. North America and Europe also have significant demand, particularly in the chemical processing and energy sectors. - Market Drivers

- Increasing demand for lithium-ion batteries in electric vehicles and energy storage systems

- Growing need for advanced water treatment solutions

- Rising demand for high-performance materials in the automotive and aerospace industries

- Stringent environmental regulations driving the need for corrosion-resistant materials

- Market Challenges

- High production costs and limited availability of raw materials

- Competition from alternative materials like polytetrafluoroethylene (PTFE)

- Fluctuations in raw material prices and energy costs

Technology Status And Challenges

- Challenges in Mechanical Properties

PVDF exhibits relatively low mechanical strength and toughness, limiting its applications in areas requiring high mechanical performance. - Processing Difficulties

The high melt viscosity and poor melt processability of PVDF pose challenges in manufacturing processes like extrusion and injection molding. - Thermal Stability Issues

PVDF can undergo thermal degradation at high temperatures, leading to reduced mechanical properties and performance limitations. - Crystallinity and Morphology Control

Controlling the crystalline structure and morphology of PVDF is crucial for optimizing its mechanical properties, but remains a challenge. - Compatibility with Fillers and Additives

Incorporating fillers and additives to enhance mechanical properties can be difficult due to compatibility issues with the PVDF matrix.

Current Technical Solutions

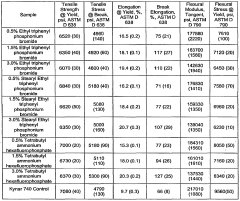

01 PVDF Mechanical Properties and Processing

PVDF exhibits excellent mechanical properties such as high tensile strength, flexibility, and chemical resistance. Various processing methods, including extrusion, injection molding, and electrospinning, can be employed to fabricate PVDF products with desired mechanical characteristics.- PVDF Mechanical Properties and Processing: PVDF exhibits excellent mechanical properties like high tensile strength, flexibility, and chemical resistance. Various processing methods, including extrusion, injection molding, and electrospinning, can fabricate PVDF products with desired mechanical characteristics.

- PVDF Composites and Nanocomposites: Incorporating fillers or nanofillers like carbon nanotubes, graphene, and inorganic particles can enhance PVDF's mechanical properties, forming composites or nanocomposites with improved strength, toughness, and thermal stability.

- PVDF Electroactive Properties and Applications: PVDF's unique electroactive properties, including piezoelectricity and ferroelectricity, make it suitable for sensors, actuators, and energy harvesting devices, where its mechanical properties play a crucial role.

- PVDF Porous Structures and Membranes: PVDF can be fabricated into porous structures and membranes with tailored mechanical properties for applications like filtration, separation, and biomedical devices, where mechanical strength and flexibility are essential.

- PVDF Blends and Copolymers: Blending PVDF with other polymers or copolymerizing it can modify its mechanical properties, tailoring them for specific applications with unique combinations of mechanical, thermal, and chemical properties.

02 PVDF Composites and Nanocomposites

The mechanical properties of PVDF can be enhanced by incorporating various fillers or nanofillers, such as carbon nanotubes, graphene, and inorganic particles, to form composites or nanocomposites. These composites exhibit improved mechanical strength, toughness, and thermal stability.Expand Specific Solutions03 PVDF Electroactive Properties and Applications

PVDF exhibits unique electroactive properties, including piezoelectricity and ferroelectricity, which make it suitable for various applications such as sensors, actuators, and energy harvesting devices. The mechanical properties of PVDF play a crucial role in these applications.Expand Specific Solutions04 PVDF Porous Structures and Membranes

PVDF can be fabricated into porous structures and membranes with tailored mechanical properties for various applications, such as filtration, separation, and biomedical devices. The mechanical properties of these structures are influenced by factors like porosity, pore size distribution, and surface morphology.Expand Specific Solutions05 PVDF Blends and Copolymers

PVDF can be blended with other polymers or copolymerized to modify its mechanical properties and tailor them for specific applications. These blends and copolymers exhibit unique combinations of mechanical, thermal, and chemical properties.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

DuPont de Nemours, Inc.

Key Technology Interpretation

- Modifying PVDF with onium salts to increase its melting point, reduce heat distortion, and improve piezoelectric properties.

- Combining PVDF with nanoclays and annealing to produce PVDF with increased melting point and piezoelectric properties.

- Nucleating PVDF with clay-modified functionalized ammonium cations to increase its melting point.

PVDF Mechanical Properties Improvement Economic Analysis

Strengthening PVDF can lead to enhanced product performance, which aligns with the growing demand for high-performance materials in various industries, such as electronics, automotive, and construction. By improving its mechanical properties, PVDF could see increased adoption, translating to higher profit margins due to the material's value-added capabilities.

Moreover, the enhancement of PVDF’s properties may reduce dependency on more expensive, alternative high-performance polymers, thereby lowering overall production costs. This improvement also presents opportunities for companies to differentiate themselves through innovative applications, potentially leading to increased market share and competitive advantage. Investing in research and development to bolster PVDF's properties could foster economic growth across the supply chain, from raw material suppliers to end-product manufacturers. Additionally, enhanced durability and performance characteristics could result in lower lifecycle costs for products utilizing improved PVDF, making them more attractive to cost-sensitive markets.

In summary, the economic benefits of enhancing PVDF's mechanical properties could significantly impact market dynamics by opening new applications, reducing costs, and increasing competitiveness in high-performance materials.

PVDF Mechanical Properties Improvement Policy And Regulatory Impact

The policy and regulatory impact on improving the mechanical properties of PVDF (polyvinylidene fluoride) is multifaceted and can significantly influence research directions and material applications. Regulatory standards focusing on environmental safety and material recycling can drive R&D efforts towards developing PVDF composites that are not only robust but also environmentally compatible. For instance, strict regulations about phasing out harmful additives may prompt innovations in additive technology to enhance mechanical properties without compromising safety.

Additionally, favorable government policies, such as tax incentives or funding for advanced materials research, can accelerate the development of enhanced PVDF variants. Policies that encourage or mandate the use of advanced materials in construction and electronics might heighten demand, indirectly fostering innovations in PVDF through increased market pressure. International standards and trade regulations can also impact material development, necessitating consistent quality and performance metrics for global competitiveness.

Overall, understanding and navigating these regulatory landscapes is crucial for stakeholders in the PVDF domain to harness opportunities, align with global standards, and overcome barriers, ensuring that advancements in mechanical properties align with broader environmental and safety goals.