PVDF Nanofiber Composites For High-Capacity Electrodes

Technology Background and Goals

This report focuses on developing high-capacity electrode materials based on polyvinylidene fluoride (PVDF) nanofiber composites for advanced energy storage applications.

PVDF nanofibers possess unique properties such as high surface area, mechanical flexibility, and excellent electrochemical stability, making them promising candidates for electrode materials. By incorporating various functional nanomaterials into the PVDF nanofiber matrix, the resulting composites can exhibit enhanced electrochemical performance, including high specific capacity, good rate capability, and long cycle life.

PVDF Nanofiber Composites Market Demand Analysis

- Market Size and Growth

The market for high-capacity electrode materials, including PVDF nanofiber composites, is driven by the increasing demand for energy storage solutions in various applications such as electric vehicles, renewable energy systems, and portable electronics. The global market for advanced battery materials is projected to grow at a significant rate due to the transition towards sustainable energy sources and the adoption of electric vehicles. - Application Areas

PVDF nanofiber composites find applications in lithium-ion batteries, supercapacitors, and other energy storage devices. The demand for high-performance and high-capacity electrodes is particularly strong in the automotive industry, where electric vehicles require efficient and reliable energy storage systems. Additionally, the growing need for grid-scale energy storage solutions for renewable energy sources contributes to the market demand. - Industry Trends

The industry is witnessing a trend towards developing more sustainable and environmentally friendly materials for energy storage applications. PVDF nanofiber composites offer advantages in terms of high surface area, improved conductivity, and enhanced electrochemical performance, making them attractive candidates for next-generation electrode materials. Furthermore, the demand for lightweight and compact energy storage solutions is driving the development of nanostructured materials like PVDF nanofiber composites.

Technology Status and Challenges

- Current Status

PVDF nanofiber composites have emerged as a promising material for high-capacity electrodes due to their high surface area, porosity, and electrochemical stability. Researchers have explored various synthesis methods and composite materials to enhance their performance. - Technical Challenges

Key challenges include improving electrical conductivity, mechanical strength, and cycle stability of the composites. Controlling nanofiber morphology, optimizing composite composition, and enhancing electrode-electrolyte interfaces are also crucial. - Geographical Distribution

Research on PVDF nanofiber composites is globally distributed, with significant contributions from the United States, China, South Korea, and European countries. Collaboration between academia and industry is driving advancements in this field.

Current Technical Solutions

01 High Capacitance

PVDF nanofiber composites with fillers or additives exhibit high capacitance values, suitable for energy storage devices and supercapacitors.- High Energy Storage Capacity: PVDF nanofiber composites with enhanced energy storage capacity for applications like supercapacitors and batteries. Conductive fillers or nanoparticles in the PVDF matrix improve electrochemical properties and increase specific capacitance or energy density.

- Improved Mechanical Properties: PVDF nanofiber composites with enhanced mechanical properties like tensile strength, flexibility, and toughness. Reinforcing agents like carbon nanotubes or graphene in the PVDF matrix improve overall mechanical performance.

- Enhanced Thermal Properties: PVDF nanofiber composites with improved thermal properties like thermal conductivity and stability. Thermally conductive fillers or phase change materials in the PVDF matrix enhance thermal management capabilities.

- Improved Filtration and Separation: PVDF nanofiber composites for filtration and separation applications due to high surface area and tunable pore size. Functional additives or surface modifications enhance filtration efficiency, selectivity, and fouling resistance.

- Enhanced Biocompatibility and Bioactivity: PVDF nanofiber composites for biomedical applications like tissue engineering and drug delivery. Biocompatible and bioactive components in the PVDF matrix improve cell adhesion, proliferation, and tissue integration.

02 Conductive Fillers

Conductive fillers like carbon nanotubes, graphene, or metal oxides in PVDF nanofiber composites enhance electrical conductivity and electrochemical performance for energy storage and conversion applications.Expand Specific Solutions03 Improved Mechanical Properties

PVDF nanofiber composites reinforced with fillers or additives enhance mechanical properties like tensile strength, flexibility, and toughness while maintaining electroactive properties.Expand Specific Solutions04 Energy Harvesting

PVDF nanofiber composites with excellent piezoelectric properties and high surface area-to-volume ratio can be used in energy harvesting applications like piezoelectric nanogenerators.Expand Specific Solutions05 Improved Thermal Stability

PVDF nanofiber composites modified with additives or fillers enhance thermal stability, suitable for applications requiring high-temperature operation or thermal cycling.Expand Specific Solutions

Main Player Analysis

Dalian Institute of Chemical Physics Chinese Academy of Sci

Massachusetts Institute of Technology

Key Technology Interpretation

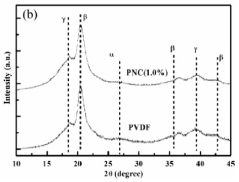

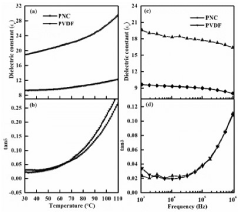

- The use of Nitrogen-doped carbon dots (N-CDs) as filler in the PVDF matrix to develop nanocomposite film with better energy storage density, high breakdown strength, and low toxicity.

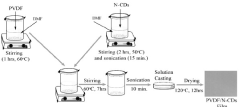

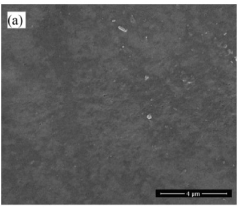

- The synthesis of PVDF/N-CDs nanocomposite dielectric film by solution cast process using magnetic stirring and ultra-sonication, which allows for a simple and scalable fabrication method.

- The development of a capacitive energy storage device using the PVDF/N-CDs nanocomposite film as the dielectric material, with silver paste as electrodes, enabling high energy storage and low toxicity.