LS3 Engine vs LS3 Crate Engine: Cost-Benefit Analysis

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Evolution and Performance Objectives

The LS3 engine represents a significant milestone in General Motors' small-block V8 evolution, building upon the legacy of the LS platform introduced in 1997. Developed as part of the Gen IV small-block family, the LS3 made its debut in 2008 with the Chevrolet Corvette C6, marking a substantial advancement in performance capabilities over its predecessors. The engine's development was driven by increasing demands for higher power output while maintaining reliability and meeting stricter emissions standards.

The technical evolution of the LS3 incorporated several key improvements over previous LS engines. Engineers increased displacement to 6.2 liters (376 cubic inches), up from the LS2's 6.0 liters. This was achieved through a larger bore diameter of 4.065 inches while maintaining the traditional 3.622-inch stroke. The cylinder heads underwent significant redesign with rectangular intake ports replacing the cathedral ports of earlier generations, allowing for improved airflow characteristics and combustion efficiency.

Performance objectives for the LS3 centered around delivering substantial power increases without sacrificing drivability or durability. The factory-rated output of 430 horsepower at 5,900 RPM and 424 lb-ft of torque at 4,600 RPM represented approximately a 30 horsepower gain over the LS2. These improvements were achieved through higher compression ratios (10.7:1), enhanced valvetrain components, and revised camshaft profiles optimized for mid-range torque and high-end power.

The LS3 crate engine program emerged as GM recognized the growing aftermarket demand for factory-engineered performance solutions. The crate engine variant was developed with specific objectives: to provide enthusiasts with a turnkey solution featuring factory reliability, warranty support, and consistent performance characteristics. GM Performance Parts (later renamed Chevrolet Performance) established rigorous testing protocols to ensure crate engines met or exceeded the durability standards of production engines.

The technological trajectory of LS3 development has continued beyond its initial release, with subsequent variants like the LS3 L99 (featuring Active Fuel Management) and higher-performance derivatives such as the LS7 and LS9. These engines share core architecture while pushing performance boundaries further, demonstrating the platform's adaptability and engineering headroom.

Market trends have influenced the evolution of both production and crate LS3 engines, with increasing demand for higher output versions and specialized applications. This has led to the development of enhanced crate packages with upgraded components, higher compression ratios, and more aggressive camshaft profiles to meet the needs of various motorsport and high-performance street applications.

The technical evolution of the LS3 incorporated several key improvements over previous LS engines. Engineers increased displacement to 6.2 liters (376 cubic inches), up from the LS2's 6.0 liters. This was achieved through a larger bore diameter of 4.065 inches while maintaining the traditional 3.622-inch stroke. The cylinder heads underwent significant redesign with rectangular intake ports replacing the cathedral ports of earlier generations, allowing for improved airflow characteristics and combustion efficiency.

Performance objectives for the LS3 centered around delivering substantial power increases without sacrificing drivability or durability. The factory-rated output of 430 horsepower at 5,900 RPM and 424 lb-ft of torque at 4,600 RPM represented approximately a 30 horsepower gain over the LS2. These improvements were achieved through higher compression ratios (10.7:1), enhanced valvetrain components, and revised camshaft profiles optimized for mid-range torque and high-end power.

The LS3 crate engine program emerged as GM recognized the growing aftermarket demand for factory-engineered performance solutions. The crate engine variant was developed with specific objectives: to provide enthusiasts with a turnkey solution featuring factory reliability, warranty support, and consistent performance characteristics. GM Performance Parts (later renamed Chevrolet Performance) established rigorous testing protocols to ensure crate engines met or exceeded the durability standards of production engines.

The technological trajectory of LS3 development has continued beyond its initial release, with subsequent variants like the LS3 L99 (featuring Active Fuel Management) and higher-performance derivatives such as the LS7 and LS9. These engines share core architecture while pushing performance boundaries further, demonstrating the platform's adaptability and engineering headroom.

Market trends have influenced the evolution of both production and crate LS3 engines, with increasing demand for higher output versions and specialized applications. This has led to the development of enhanced crate packages with upgraded components, higher compression ratios, and more aggressive camshaft profiles to meet the needs of various motorsport and high-performance street applications.

Market Analysis for LS3 and Crate Engine Options

The LS3 engine market has experienced significant growth over the past decade, driven by increasing demand from automotive enthusiasts, racing teams, and restoration projects. The market for LS3 engines can be segmented into two primary categories: factory-installed engines in production vehicles and aftermarket crate engines sold directly to consumers and shops. Current market data indicates that the global automotive engine market, which includes the LS3 segment, is valued at approximately $95 billion, with performance engines representing a growing niche within this broader market.

Consumer demand for LS3 engines stems from several key factors. Performance enthusiasts value the LS3's reputation for reliability, substantial power output (430 horsepower in stock form), and extensive aftermarket support. The restoration and custom build communities prize these engines for their compact design and adaptability to various vehicle platforms. Additionally, the racing sector continues to show strong interest due to the engine's proven track record in competitive environments.

Market research reveals distinct customer segments with varying priorities. Professional builders and racing teams typically prioritize performance specifications and customization potential over initial cost. In contrast, individual enthusiasts and hobbyists often balance performance desires with budget constraints, making the cost-benefit analysis particularly relevant for this segment.

The pricing structure in the market shows significant variation. Factory LS3 engines, when purchased as part of a salvage operation, typically range from $4,000 to $7,000 depending on condition, mileage, and included components. Crate engines from General Motors Performance Parts command premium prices between $7,500 and $9,500 for base models, with specialized high-output versions exceeding $11,000.

Market trends indicate growing interest in crate engine solutions despite their higher initial cost. This preference is supported by the comprehensive warranty coverage, guaranteed performance specifications, and elimination of unknown variables associated with used engines. The convenience factor of ready-to-install packages has expanded the potential customer base beyond traditional mechanical experts to include enthusiasts with moderate technical skills.

Regional analysis shows particularly strong demand in North America, with the Southern and Western United States representing the largest markets for both engine types. International markets, particularly Australia, Europe, and parts of Asia, show increasing adoption rates as global motorsport communities embrace LS architecture.

Future market projections suggest continued growth for both segments, with crate engines likely gaining additional market share as consumers increasingly value reliability and warranty protection. The emergence of e-commerce platforms specializing in performance parts has also expanded market reach, allowing smaller shops and individual buyers easier access to both engine options.

Consumer demand for LS3 engines stems from several key factors. Performance enthusiasts value the LS3's reputation for reliability, substantial power output (430 horsepower in stock form), and extensive aftermarket support. The restoration and custom build communities prize these engines for their compact design and adaptability to various vehicle platforms. Additionally, the racing sector continues to show strong interest due to the engine's proven track record in competitive environments.

Market research reveals distinct customer segments with varying priorities. Professional builders and racing teams typically prioritize performance specifications and customization potential over initial cost. In contrast, individual enthusiasts and hobbyists often balance performance desires with budget constraints, making the cost-benefit analysis particularly relevant for this segment.

The pricing structure in the market shows significant variation. Factory LS3 engines, when purchased as part of a salvage operation, typically range from $4,000 to $7,000 depending on condition, mileage, and included components. Crate engines from General Motors Performance Parts command premium prices between $7,500 and $9,500 for base models, with specialized high-output versions exceeding $11,000.

Market trends indicate growing interest in crate engine solutions despite their higher initial cost. This preference is supported by the comprehensive warranty coverage, guaranteed performance specifications, and elimination of unknown variables associated with used engines. The convenience factor of ready-to-install packages has expanded the potential customer base beyond traditional mechanical experts to include enthusiasts with moderate technical skills.

Regional analysis shows particularly strong demand in North America, with the Southern and Western United States representing the largest markets for both engine types. International markets, particularly Australia, Europe, and parts of Asia, show increasing adoption rates as global motorsport communities embrace LS architecture.

Future market projections suggest continued growth for both segments, with crate engines likely gaining additional market share as consumers increasingly value reliability and warranty protection. The emergence of e-commerce platforms specializing in performance parts has also expanded market reach, allowing smaller shops and individual buyers easier access to both engine options.

Technical Specifications and Limitations Comparison

The LS3 engine and LS3 crate engine share fundamental architecture but differ significantly in several technical aspects. The standard LS3 engine, found in production vehicles like the Chevrolet Corvette C6 and Camaro SS, delivers 430 horsepower and 424 lb-ft of torque in its factory configuration. In contrast, the LS3 crate engine typically offers enhanced performance specifications, with variants producing between 430-525 horsepower depending on the specific package and calibration.

From a materials perspective, both utilize an aluminum block and heads, but crate engines often feature upgraded internal components. The crate variants may include forged pistons and connecting rods rather than the cast components found in production engines, significantly improving durability under high-stress conditions. Additionally, crate engines frequently incorporate higher-quality fasteners and gaskets designed for repeated disassembly and maintenance.

Cooling system capabilities represent another notable difference. Production LS3 engines are designed for specific vehicle applications with integrated cooling systems, while crate engines may require additional external components for proper thermal management. This limitation necessitates careful planning during installation to ensure adequate cooling capacity, particularly in high-performance applications.

The electronic control systems also diverge substantially. Factory LS3 engines utilize vehicle-specific ECU programming integrated with numerous vehicle systems. Crate engines typically come with standalone control modules or require aftermarket ECU solutions, offering greater tuning flexibility but demanding more complex integration. This distinction creates both opportunities for performance optimization and challenges for seamless vehicle integration.

Emissions compliance presents a significant limitation for crate engine applications. Production LS3 engines meet federal and state emissions requirements for their model year, whereas crate engines may not carry the same certifications. This limitation restricts their legal use in certain jurisdictions, particularly for on-road applications in states with stringent emissions regulations like California.

Warranty coverage differs dramatically between the options. Factory engines carry the vehicle manufacturer's warranty when installed in production vehicles, typically 3-5 years or 36,000-60,000 miles. Crate engines generally offer more limited coverage, often 12-24 months with no mileage provision, and warranty terms may be voided by certain modifications or applications. This disparity represents a significant consideration in the total cost of ownership calculation.

From a materials perspective, both utilize an aluminum block and heads, but crate engines often feature upgraded internal components. The crate variants may include forged pistons and connecting rods rather than the cast components found in production engines, significantly improving durability under high-stress conditions. Additionally, crate engines frequently incorporate higher-quality fasteners and gaskets designed for repeated disassembly and maintenance.

Cooling system capabilities represent another notable difference. Production LS3 engines are designed for specific vehicle applications with integrated cooling systems, while crate engines may require additional external components for proper thermal management. This limitation necessitates careful planning during installation to ensure adequate cooling capacity, particularly in high-performance applications.

The electronic control systems also diverge substantially. Factory LS3 engines utilize vehicle-specific ECU programming integrated with numerous vehicle systems. Crate engines typically come with standalone control modules or require aftermarket ECU solutions, offering greater tuning flexibility but demanding more complex integration. This distinction creates both opportunities for performance optimization and challenges for seamless vehicle integration.

Emissions compliance presents a significant limitation for crate engine applications. Production LS3 engines meet federal and state emissions requirements for their model year, whereas crate engines may not carry the same certifications. This limitation restricts their legal use in certain jurisdictions, particularly for on-road applications in states with stringent emissions regulations like California.

Warranty coverage differs dramatically between the options. Factory engines carry the vehicle manufacturer's warranty when installed in production vehicles, typically 3-5 years or 36,000-60,000 miles. Crate engines generally offer more limited coverage, often 12-24 months with no mileage provision, and warranty terms may be voided by certain modifications or applications. This disparity represents a significant consideration in the total cost of ownership calculation.

Current Installation and Integration Solutions

01 Cost-benefit analysis of LS3 engine implementation

Cost-benefit analysis methodologies can be applied to evaluate the economic viability of implementing LS3 engines in various applications. These analyses consider factors such as initial investment costs, operational expenses, performance benefits, and long-term value. By comparing the costs associated with purchasing and installing an LS3 engine against the potential benefits in terms of power output, fuel efficiency, and durability, stakeholders can make informed decisions about engine selection.- Cost-benefit analysis of LS3 engines: Cost-benefit analysis methodologies can be applied to evaluate the economic value of LS3 engines versus LS3 crate engines. These analyses consider factors such as initial purchase cost, installation expenses, maintenance requirements, and long-term performance benefits. The evaluation helps determine whether the premium price of factory-built crate engines justifies their reliability and warranty advantages compared to rebuilding or sourcing used engines.

- Performance optimization systems for LS3 engines: Various systems and methods exist for optimizing the performance of LS3 engines, whether factory-installed or crate versions. These include electronic control modules, fuel management systems, and performance tuning software that can enhance horsepower, torque, and fuel efficiency. The optimization technologies allow users to maximize the return on investment for either engine option by extending service life and improving operational characteristics.

- Supply chain and inventory management for LS3 engines: Supply chain and inventory management systems specifically designed for automotive components like LS3 engines help dealers and repair shops optimize their inventory levels. These systems track availability, pricing fluctuations, and delivery timeframes for both complete crate engines and individual components. Efficient inventory management reduces costs associated with overstocking or emergency ordering, improving the overall cost-benefit ratio for businesses dealing with LS3 engines.

- Agricultural and industrial applications of LS3 engines: LS3 engines and their crate variants have applications beyond automotive use, including agricultural machinery and industrial equipment. The cost-benefit considerations in these sectors differ from traditional automotive applications, with factors such as continuous duty cycles, environmental conditions, and specialized power requirements playing important roles. The adaptability of LS3 engines to various industrial applications can provide economic advantages through standardization and simplified maintenance procedures.

- Predictive maintenance and lifecycle management: Advanced predictive maintenance systems and lifecycle management tools help optimize the long-term cost-benefit ratio of LS3 engines. These technologies use sensors, data analytics, and machine learning to predict potential failures before they occur, schedule maintenance efficiently, and track the overall health of the engine throughout its service life. By extending engine lifespan and reducing catastrophic failures, these systems improve the return on investment for both factory and crate LS3 engines.

02 Performance optimization systems for LS3 crate engines

Various systems and methods exist for optimizing the performance of LS3 crate engines across different applications. These optimization techniques may involve electronic control systems, mechanical modifications, or specialized tuning approaches that enhance power output, torque delivery, and efficiency. Performance optimization can be achieved through computer-aided analysis, real-time monitoring, and adaptive control algorithms that adjust engine parameters based on operating conditions.Expand Specific Solutions03 Supply chain management for LS3 engine components

Supply chain management systems specifically designed for LS3 engine components help optimize inventory levels, reduce procurement costs, and ensure timely availability of parts. These systems incorporate demand forecasting, supplier relationship management, and logistics optimization to minimize the total cost of ownership while maintaining quality standards. Efficient supply chain management directly impacts the cost-benefit ratio of LS3 crate engines by reducing acquisition costs and minimizing downtime due to parts availability.Expand Specific Solutions04 Comparative analysis frameworks for engine selection

Structured frameworks for comparing different engine options, including LS3 crate engines, enable objective evaluation based on multiple criteria. These frameworks consider factors such as initial cost, installation requirements, performance characteristics, maintenance needs, and long-term reliability. By applying standardized evaluation metrics, users can assess the relative advantages and disadvantages of LS3 engines compared to alternatives, supporting evidence-based decision-making for specific applications.Expand Specific Solutions05 Integration systems for LS3 engines in specialized applications

Specialized integration systems facilitate the implementation of LS3 engines in various applications, addressing compatibility challenges and optimizing performance in specific use cases. These systems may include custom mounting solutions, electronic interfaces, cooling adaptations, and exhaust configurations designed to maximize the cost-benefit ratio of LS3 crate engines in particular environments. Integration technologies help mitigate installation costs while preserving the performance advantages of the LS3 platform.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS3 engine market is in a mature phase, characterized by established players like GM Global Technology Operations LLC and Ford Global Technologies LLC dominating the OEM segment, while aftermarket crate engine solutions offer cost-effective alternatives. The market size is substantial, driven by performance vehicle enthusiasts and restoration projects, with an estimated annual value exceeding $500 million. Technologically, the LS3 platform has reached high maturity, with GM leading innovation through continuous refinements, while companies like Weichai Power and Great Wall Motor Co. have developed competitive alternatives. Ford maintains strong market presence through performance variants, creating a competitive ecosystem where price-performance ratio increasingly determines consumer choice between factory and crate engine options.

GM Global Technology Operations LLC

Technical Solution: GM's LS3 engine technology represents a significant advancement in small-block V8 design. The standard LS3 engine, introduced in 2008, features an aluminum block with 6.2L displacement, producing 430 horsepower and 424 lb-ft of torque. GM's crate engine program offers the LS3 in various configurations, including the enhanced LS376/480 and LS376/525 versions with upgraded camshafts. The crate engines come fully assembled with intake manifold, throttle body, ignition system, and water pump. GM's manufacturing process for crate engines includes specialized quality control measures, with each engine hot-tested before shipping to ensure optimal performance. The company has invested in advanced casting techniques for the aluminum blocks, resulting in tighter tolerances and improved durability compared to production line engines.

Strengths: Factory warranty support, consistent quality control, and compatibility with GM vehicle electronics systems. The crate engines offer plug-and-play convenience with included controllers and harnesses. Weaknesses: Higher initial cost compared to salvaged engines, and potential compatibility issues when installing in non-GM vehicles requiring additional adaptation components.

Ford Global Technologies LLC

Technical Solution: Ford's approach to competing with the LS3 platform involves their Coyote and Godzilla engine families. While not direct LS3 competitors, Ford's crate engine program offers similar cost-benefit considerations. Ford's 5.0L Coyote crate engines deliver comparable performance to the LS3 with 460 horsepower in Gen 3 form, utilizing dual overhead cam design versus the LS3's pushrod architecture. Ford's crate engines include the control pack with PCM, wiring harness, and sensors for turnkey installation. Ford's manufacturing process for crate engines involves specialized assembly lines separate from production engines, with additional quality control steps and performance testing. Their crate engines feature forged internals and CNC-ported cylinder heads not typically found in production versions, justifying the premium pricing structure compared to salvage yard alternatives.

Strengths: Advanced DOHC technology offering better high-RPM performance and potentially better fuel efficiency than the LS3. Ford's control packs are comprehensive and well-documented. Weaknesses: Generally higher cost than comparable LS3 crate engines, more complex design with additional moving parts, and typically requires more space for installation due to wider cylinder heads.

Key Engineering Innovations in LS3 Architecture

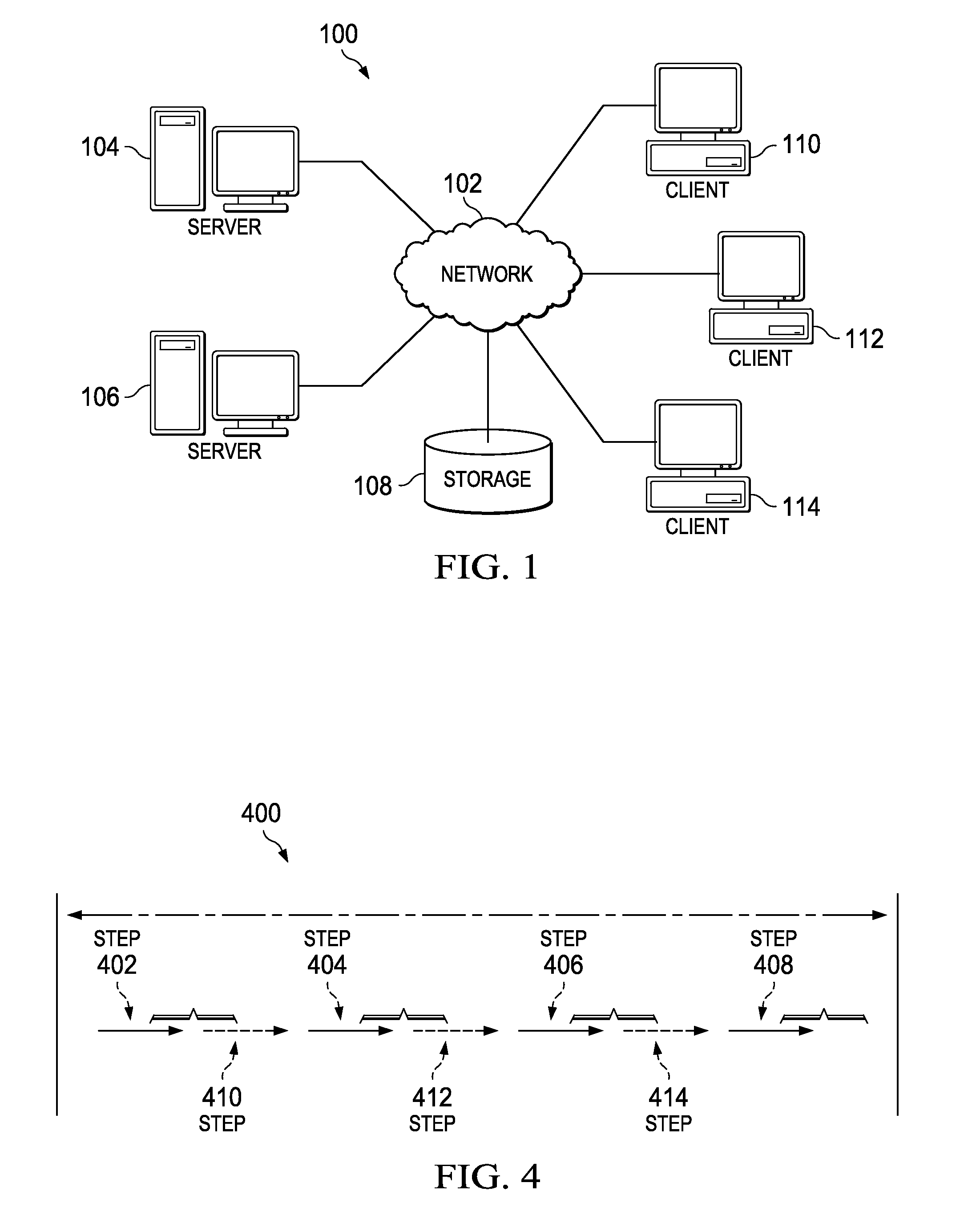

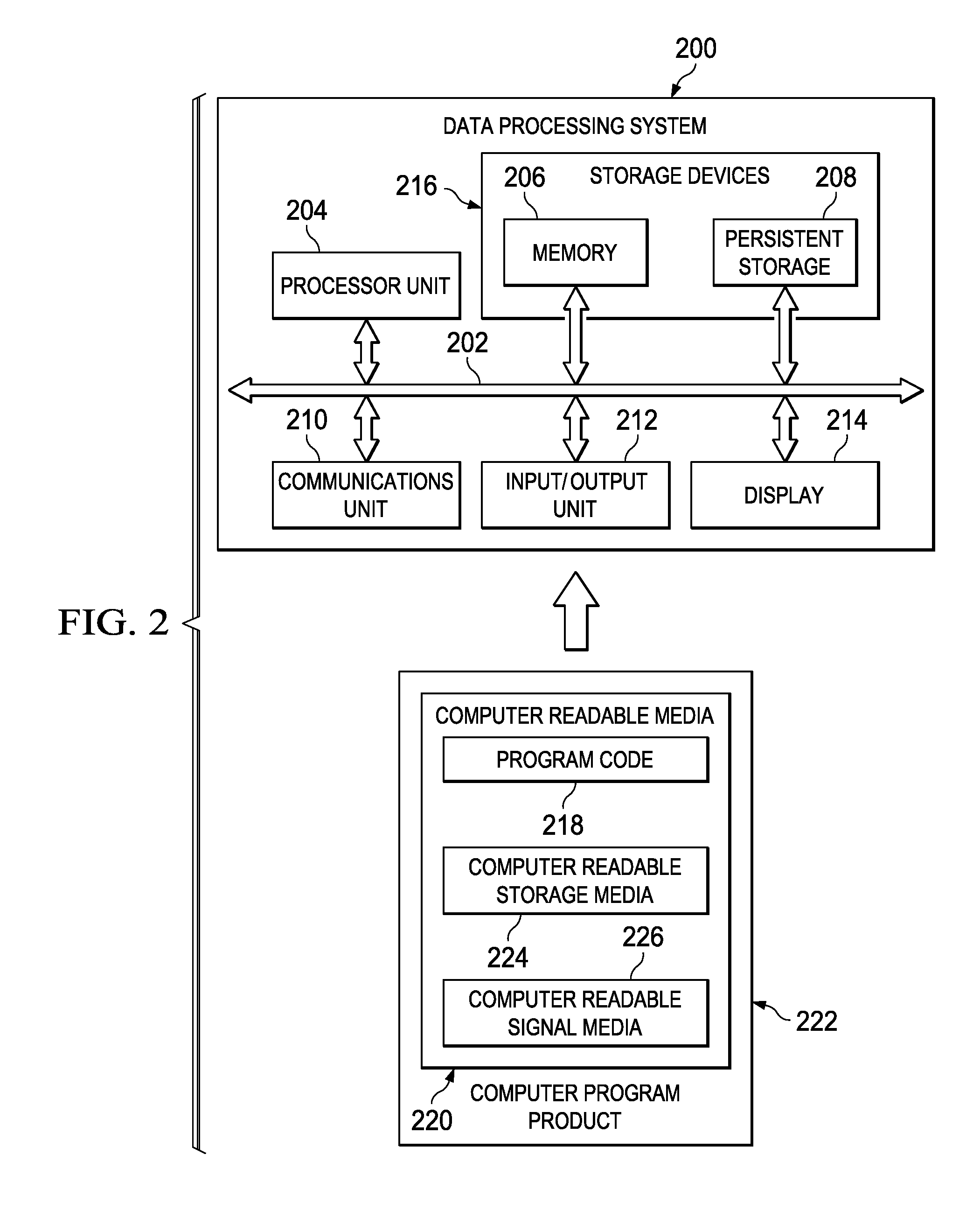

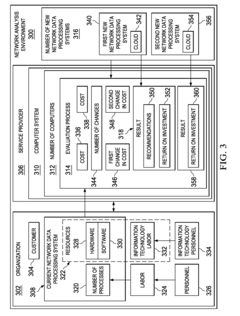

Cost benefit based analysis system for network environments

PatentInactiveUS20110246376A1

Innovation

- A method that identifies the number of processes, labor, and resources in a current network data processing system, calculates labor and resource costs, and assesses changes in these costs when migrating to a new system, such as a cloud environment, to determine whether the change provides desired cost benefits.

Total Cost of Ownership Analysis

When evaluating the total cost of ownership between an LS3 Engine and an LS3 Crate Engine, it is essential to consider all financial aspects beyond the initial purchase price. The acquisition cost represents only the beginning of a comprehensive financial commitment that extends throughout the engine's operational life.

For the LS3 Engine sourced from a salvage vehicle, the initial cost typically ranges from $2,500 to $4,000, depending on mileage and condition. However, this lower entry price comes with additional expenses. Refurbishment costs, including potential machine work, replacement of worn components, and necessary upgrades, can add $1,500 to $3,000. Labor costs for removal from the donor vehicle and subsequent installation must also be factored in, potentially adding another $1,000 to $2,500.

In contrast, the LS3 Crate Engine commands a higher initial investment of $7,500 to $9,000, but arrives in factory-new condition with comprehensive warranty coverage, typically 24 to 36 months. This warranty significantly reduces short-term risk exposure and potential repair costs during the covered period.

Maintenance costs over a five-year ownership period reveal notable differences. The salvage LS3 Engine often requires more frequent oil changes, potential cooling system flushes, and earlier replacement of components like water pumps and accessory drives. These maintenance requirements can accumulate to approximately $2,000 to $3,500 over five years, compared to $1,200 to $2,000 for the Crate Engine during the same period.

Fuel efficiency considerations also impact the total ownership cost. A properly rebuilt salvage engine can approach factory specifications, but variations in quality of rebuilding work may result in 5-10% lower fuel efficiency compared to the precisely calibrated Crate Engine. For vehicles driven 12,000 miles annually, this efficiency gap translates to approximately $200-$400 in additional fuel costs per year.

Resale value represents another critical factor in the ownership equation. After five years, a vehicle with a documented Crate Engine installation typically retains 40-50% of the engine's value, while a salvage engine installation generally retains only 20-30%, representing a significant difference in long-term asset depreciation.

When all factors are calculated over a five-year ownership period, the total cost difference narrows considerably despite the substantial gap in initial purchase price. The salvage LS3 Engine's total ownership cost typically ranges from $8,000 to $12,000, while the Crate Engine's total cost falls between $10,000 and $13,500, demonstrating that the premium paid for factory reliability often translates to lower long-term expenses.

For the LS3 Engine sourced from a salvage vehicle, the initial cost typically ranges from $2,500 to $4,000, depending on mileage and condition. However, this lower entry price comes with additional expenses. Refurbishment costs, including potential machine work, replacement of worn components, and necessary upgrades, can add $1,500 to $3,000. Labor costs for removal from the donor vehicle and subsequent installation must also be factored in, potentially adding another $1,000 to $2,500.

In contrast, the LS3 Crate Engine commands a higher initial investment of $7,500 to $9,000, but arrives in factory-new condition with comprehensive warranty coverage, typically 24 to 36 months. This warranty significantly reduces short-term risk exposure and potential repair costs during the covered period.

Maintenance costs over a five-year ownership period reveal notable differences. The salvage LS3 Engine often requires more frequent oil changes, potential cooling system flushes, and earlier replacement of components like water pumps and accessory drives. These maintenance requirements can accumulate to approximately $2,000 to $3,500 over five years, compared to $1,200 to $2,000 for the Crate Engine during the same period.

Fuel efficiency considerations also impact the total ownership cost. A properly rebuilt salvage engine can approach factory specifications, but variations in quality of rebuilding work may result in 5-10% lower fuel efficiency compared to the precisely calibrated Crate Engine. For vehicles driven 12,000 miles annually, this efficiency gap translates to approximately $200-$400 in additional fuel costs per year.

Resale value represents another critical factor in the ownership equation. After five years, a vehicle with a documented Crate Engine installation typically retains 40-50% of the engine's value, while a salvage engine installation generally retains only 20-30%, representing a significant difference in long-term asset depreciation.

When all factors are calculated over a five-year ownership period, the total cost difference narrows considerably despite the substantial gap in initial purchase price. The salvage LS3 Engine's total ownership cost typically ranges from $8,000 to $12,000, while the Crate Engine's total cost falls between $10,000 and $13,500, demonstrating that the premium paid for factory reliability often translates to lower long-term expenses.

Warranty and Support Ecosystem

The warranty and support ecosystem surrounding LS3 engines represents a critical factor in the cost-benefit analysis between factory-installed and crate engine options. General Motors offers a comprehensive warranty package for factory-installed LS3 engines, typically covering 3 years or 36,000 miles for bumper-to-bumper protection, with powertrain coverage extending to 5 years or 60,000 miles. This manufacturer warranty integrates seamlessly with the vehicle's overall protection plan, providing owners with a unified support structure.

In contrast, Chevrolet Performance LS3 crate engines come with a more limited 24-month/50,000-mile warranty that specifically covers parts defects, not labor or consequential damages. This distinction creates significant implications for long-term ownership costs, as post-warranty repairs for crate engine installations typically fall entirely on the owner, including both parts and labor expenses.

The dealer service network represents another crucial component of this ecosystem. Factory LS3 engines benefit from GM's extensive authorized service center network, where technicians receive specialized training on these powerplants. These facilities maintain comprehensive diagnostic equipment and proprietary software tools that may not be available to independent shops working with crate engine installations. Additionally, factory engine owners can access standardized repair procedures and consistent service quality across the dealer network.

For crate engine installations, the support infrastructure varies considerably based on the installer's expertise and resources. While specialized performance shops may offer exceptional knowledge for modified applications, their warranty terms, diagnostic capabilities, and long-term support commitments often lack the standardization found in manufacturer-backed systems. This variability introduces an element of risk that must be factored into the overall value proposition.

Parts availability constitutes another critical dimension of the support ecosystem. Factory LS3 engines benefit from GM's established supply chain, ensuring consistent parts availability through the dealer network for the engine's expected service life. Crate engine owners may face more complex sourcing scenarios, particularly for components unique to performance applications or when dealing with modifications that deviate from standard specifications.

Technical support resources also differ significantly between these options. Factory engine owners can access manufacturer-provided documentation, technical service bulletins, and recall coverage. Crate engine customers must often rely on a combination of performance community knowledge, installer expertise, and Chevrolet Performance's more limited technical support channels, which may not address installation-specific issues or interactions with modified vehicle systems.

In contrast, Chevrolet Performance LS3 crate engines come with a more limited 24-month/50,000-mile warranty that specifically covers parts defects, not labor or consequential damages. This distinction creates significant implications for long-term ownership costs, as post-warranty repairs for crate engine installations typically fall entirely on the owner, including both parts and labor expenses.

The dealer service network represents another crucial component of this ecosystem. Factory LS3 engines benefit from GM's extensive authorized service center network, where technicians receive specialized training on these powerplants. These facilities maintain comprehensive diagnostic equipment and proprietary software tools that may not be available to independent shops working with crate engine installations. Additionally, factory engine owners can access standardized repair procedures and consistent service quality across the dealer network.

For crate engine installations, the support infrastructure varies considerably based on the installer's expertise and resources. While specialized performance shops may offer exceptional knowledge for modified applications, their warranty terms, diagnostic capabilities, and long-term support commitments often lack the standardization found in manufacturer-backed systems. This variability introduces an element of risk that must be factored into the overall value proposition.

Parts availability constitutes another critical dimension of the support ecosystem. Factory LS3 engines benefit from GM's established supply chain, ensuring consistent parts availability through the dealer network for the engine's expected service life. Crate engine owners may face more complex sourcing scenarios, particularly for components unique to performance applications or when dealing with modifications that deviate from standard specifications.

Technical support resources also differ significantly between these options. Factory engine owners can access manufacturer-provided documentation, technical service bulletins, and recall coverage. Crate engine customers must often rely on a combination of performance community knowledge, installer expertise, and Chevrolet Performance's more limited technical support channels, which may not address installation-specific issues or interactions with modified vehicle systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!