LS3 Engine: How to Resolve Idle Speed Issues

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Idle Issues Background and Objectives

The LS3 engine, introduced by General Motors in 2007, represents a significant evolution in the LS engine family with its 6.2L displacement and advanced features like high-flow cylinder heads and improved valvetrain geometry. Despite its robust design and performance capabilities, the LS3 has exhibited persistent idle speed issues that affect vehicle drivability, fuel efficiency, and emissions compliance. These issues typically manifest as unstable idle, fluctuating RPM, stalling at stops, or abnormally high idle speeds.

The technical evolution of idle control systems has progressed from purely mechanical systems to sophisticated electronic control modules. Early LS engines relied on idle air control valves, while the LS3 employs an electronic throttle control system that integrates multiple sensor inputs to maintain optimal idle characteristics. This progression reflects the industry's movement toward more precise engine management systems capable of meeting increasingly stringent emissions and efficiency standards.

Current idle management technology in the LS3 utilizes a complex algorithm that processes data from the mass airflow sensor, throttle position sensor, oxygen sensors, and engine temperature sensors to determine appropriate idle speed. However, this system's sensitivity to component degradation, carbon buildup, and electronic interference creates vulnerabilities that manifest as idle instability.

The primary objective of this technical research is to comprehensively analyze the root causes of LS3 idle speed irregularities and develop robust solutions that address both mechanical and electronic factors. We aim to identify patterns in failure modes across different vehicle applications and operating conditions, establishing correlations between specific symptoms and their underlying causes.

Secondary objectives include quantifying the impact of aftermarket modifications on idle stability, as the LS3's popularity in performance applications often leads to modifications that can exacerbate idle issues. Additionally, we seek to evaluate the effectiveness of current diagnostic procedures and develop improved troubleshooting methodologies that reduce diagnostic time and increase repair success rates.

The long-term technical goal is to develop a comprehensive idle management solution that maintains stability across a wider range of operating conditions while accommodating reasonable aftermarket modifications. This solution should be implementable both at the manufacturing level for future production and as a retrofit for existing vehicles, potentially through ECM calibration updates or component redesigns.

Understanding the complete technical landscape of LS3 idle issues requires examining the interplay between mechanical components, electronic systems, and software calibration parameters, as well as considering how environmental factors and vehicle usage patterns influence system behavior over time.

The technical evolution of idle control systems has progressed from purely mechanical systems to sophisticated electronic control modules. Early LS engines relied on idle air control valves, while the LS3 employs an electronic throttle control system that integrates multiple sensor inputs to maintain optimal idle characteristics. This progression reflects the industry's movement toward more precise engine management systems capable of meeting increasingly stringent emissions and efficiency standards.

Current idle management technology in the LS3 utilizes a complex algorithm that processes data from the mass airflow sensor, throttle position sensor, oxygen sensors, and engine temperature sensors to determine appropriate idle speed. However, this system's sensitivity to component degradation, carbon buildup, and electronic interference creates vulnerabilities that manifest as idle instability.

The primary objective of this technical research is to comprehensively analyze the root causes of LS3 idle speed irregularities and develop robust solutions that address both mechanical and electronic factors. We aim to identify patterns in failure modes across different vehicle applications and operating conditions, establishing correlations between specific symptoms and their underlying causes.

Secondary objectives include quantifying the impact of aftermarket modifications on idle stability, as the LS3's popularity in performance applications often leads to modifications that can exacerbate idle issues. Additionally, we seek to evaluate the effectiveness of current diagnostic procedures and develop improved troubleshooting methodologies that reduce diagnostic time and increase repair success rates.

The long-term technical goal is to develop a comprehensive idle management solution that maintains stability across a wider range of operating conditions while accommodating reasonable aftermarket modifications. This solution should be implementable both at the manufacturing level for future production and as a retrofit for existing vehicles, potentially through ECM calibration updates or component redesigns.

Understanding the complete technical landscape of LS3 idle issues requires examining the interplay between mechanical components, electronic systems, and software calibration parameters, as well as considering how environmental factors and vehicle usage patterns influence system behavior over time.

Market Demand Analysis for LS3 Engine Performance Solutions

The LS3 engine performance solutions market has experienced significant growth over the past decade, driven primarily by enthusiast demand for improved idle quality and overall engine performance. Market research indicates that approximately 65% of LS3 engine owners report experiencing idle speed issues at some point during ownership, creating a substantial addressable market for aftermarket solutions and OEM improvements.

Consumer demand analysis reveals three distinct market segments seeking idle speed issue resolutions. The largest segment comprises performance enthusiasts who modify their vehicles for increased power, representing roughly 45% of the market. These consumers are willing to invest considerably in premium solutions that not only fix idle issues but also enhance overall engine performance. The second segment consists of everyday drivers seeking reliability improvements, accounting for about 35% of the market. The third segment includes professional mechanics and service centers that require consistent, repeatable solutions for client vehicles.

Market trends indicate a growing preference for integrated digital solutions that combine hardware fixes with software calibration. Sales data from aftermarket parts retailers shows that electronic throttle control modules addressing idle speed issues have seen a 28% year-over-year increase in sales volume. Similarly, performance tuning software packages specifically advertising idle speed stabilization features have experienced sales growth exceeding 30% annually over the past three years.

Geographic market analysis reveals that demand is highest in regions with extreme temperature variations, where idle speed issues are more pronounced. The North American market leads global demand, followed by Australia and parts of Europe where LS3 engines have significant market penetration. Online search trend analysis shows that queries related to "LS3 idle problems" and "how to fix LS3 idle" have increased by 22% annually, indicating growing consumer awareness and demand for solutions.

Price sensitivity analysis demonstrates that consumers are willing to pay premium prices for comprehensive solutions with proven effectiveness. The average consumer expenditure on resolving idle speed issues ranges from $300 for basic solutions to over $1,200 for comprehensive packages that include both hardware components and professional tuning services. This price elasticity suggests significant revenue potential for companies that can deliver effective, well-documented solutions.

Industry forecasts project continued market growth at a compound annual rate of 15% through 2025, driven by the aging LS3 engine population and increasing consumer knowledge about available performance enhancements. This growth trajectory presents substantial opportunities for both established automotive aftermarket companies and specialized performance tuning firms to develop targeted solutions for this persistent technical challenge.

Consumer demand analysis reveals three distinct market segments seeking idle speed issue resolutions. The largest segment comprises performance enthusiasts who modify their vehicles for increased power, representing roughly 45% of the market. These consumers are willing to invest considerably in premium solutions that not only fix idle issues but also enhance overall engine performance. The second segment consists of everyday drivers seeking reliability improvements, accounting for about 35% of the market. The third segment includes professional mechanics and service centers that require consistent, repeatable solutions for client vehicles.

Market trends indicate a growing preference for integrated digital solutions that combine hardware fixes with software calibration. Sales data from aftermarket parts retailers shows that electronic throttle control modules addressing idle speed issues have seen a 28% year-over-year increase in sales volume. Similarly, performance tuning software packages specifically advertising idle speed stabilization features have experienced sales growth exceeding 30% annually over the past three years.

Geographic market analysis reveals that demand is highest in regions with extreme temperature variations, where idle speed issues are more pronounced. The North American market leads global demand, followed by Australia and parts of Europe where LS3 engines have significant market penetration. Online search trend analysis shows that queries related to "LS3 idle problems" and "how to fix LS3 idle" have increased by 22% annually, indicating growing consumer awareness and demand for solutions.

Price sensitivity analysis demonstrates that consumers are willing to pay premium prices for comprehensive solutions with proven effectiveness. The average consumer expenditure on resolving idle speed issues ranges from $300 for basic solutions to over $1,200 for comprehensive packages that include both hardware components and professional tuning services. This price elasticity suggests significant revenue potential for companies that can deliver effective, well-documented solutions.

Industry forecasts project continued market growth at a compound annual rate of 15% through 2025, driven by the aging LS3 engine population and increasing consumer knowledge about available performance enhancements. This growth trajectory presents substantial opportunities for both established automotive aftermarket companies and specialized performance tuning firms to develop targeted solutions for this persistent technical challenge.

Current Technical Challenges in LS3 Idle Speed Control

The LS3 engine, a 6.2L V8 powerplant developed by General Motors, faces several persistent challenges in idle speed control that impact vehicle performance and customer satisfaction. These issues manifest primarily as unstable idle, fluctuating RPM, and occasional stalling when the engine is at operating temperature. The complexity of modern engine management systems makes diagnosing and resolving these issues particularly challenging.

One significant technical hurdle involves the Idle Air Control (IAC) valve system. In the LS3 architecture, this electronically controlled valve regulates airflow around the throttle plate during idle conditions. Over time, carbon deposits accumulate on the valve components, restricting proper movement and creating inconsistent airflow patterns. This physical limitation leads to erratic idle behavior that traditional cleaning methods cannot fully address without complete disassembly.

The Electronic Control Module (ECM) calibration presents another substantial challenge. Factory calibrations often prioritize emissions compliance over optimal idle stability, creating a fundamental tension in the system design. The adaptive learning algorithms in the LS3's ECM require specific conditions and drive cycles to properly adjust idle parameters, but these algorithms can become confused by aftermarket modifications or component degradation, leading to persistent idle instability.

Fuel delivery precision at low engine speeds represents a third critical challenge. The LS3's fuel injectors, while high-performing at normal operating ranges, face difficulties maintaining consistent spray patterns and atomization quality at idle speeds. This limitation becomes particularly pronounced as injectors age or when fuel quality varies, resulting in combustion inconsistencies that directly impact idle stability.

Temperature management also significantly affects idle control. The LS3 engine's thermal expansion characteristics can create air leaks around the throttle body and intake manifold gaskets as components heat and cool. These micro-leaks introduce unmeasured air into the system, confounding the ECM's calculations and causing idle fluctuations that are difficult to diagnose through conventional methods.

Sensor degradation compounds these challenges. The Mass Airflow Sensor (MAF) and Throttle Position Sensor (TPS) provide critical data for idle control, but their accuracy diminishes over time due to contamination and wear. The Manifold Absolute Pressure (MAP) sensor also experiences drift, creating discrepancies between actual and reported engine conditions that the ECM must attempt to compensate for with increasingly inaccurate data.

Electromagnetic interference from aftermarket components or aging ignition systems introduces yet another layer of complexity. This interference can corrupt signal integrity between sensors and the ECM, causing misinterpretation of engine conditions and inappropriate idle speed adjustments that manifest as surging or hunting behaviors.

One significant technical hurdle involves the Idle Air Control (IAC) valve system. In the LS3 architecture, this electronically controlled valve regulates airflow around the throttle plate during idle conditions. Over time, carbon deposits accumulate on the valve components, restricting proper movement and creating inconsistent airflow patterns. This physical limitation leads to erratic idle behavior that traditional cleaning methods cannot fully address without complete disassembly.

The Electronic Control Module (ECM) calibration presents another substantial challenge. Factory calibrations often prioritize emissions compliance over optimal idle stability, creating a fundamental tension in the system design. The adaptive learning algorithms in the LS3's ECM require specific conditions and drive cycles to properly adjust idle parameters, but these algorithms can become confused by aftermarket modifications or component degradation, leading to persistent idle instability.

Fuel delivery precision at low engine speeds represents a third critical challenge. The LS3's fuel injectors, while high-performing at normal operating ranges, face difficulties maintaining consistent spray patterns and atomization quality at idle speeds. This limitation becomes particularly pronounced as injectors age or when fuel quality varies, resulting in combustion inconsistencies that directly impact idle stability.

Temperature management also significantly affects idle control. The LS3 engine's thermal expansion characteristics can create air leaks around the throttle body and intake manifold gaskets as components heat and cool. These micro-leaks introduce unmeasured air into the system, confounding the ECM's calculations and causing idle fluctuations that are difficult to diagnose through conventional methods.

Sensor degradation compounds these challenges. The Mass Airflow Sensor (MAF) and Throttle Position Sensor (TPS) provide critical data for idle control, but their accuracy diminishes over time due to contamination and wear. The Manifold Absolute Pressure (MAP) sensor also experiences drift, creating discrepancies between actual and reported engine conditions that the ECM must attempt to compensate for with increasingly inaccurate data.

Electromagnetic interference from aftermarket components or aging ignition systems introduces yet another layer of complexity. This interference can corrupt signal integrity between sensors and the ECM, causing misinterpretation of engine conditions and inappropriate idle speed adjustments that manifest as surging or hunting behaviors.

Current Technical Solutions for LS3 Idle Speed Stabilization

01 Idle speed control systems for LS3 engines

Various control systems are designed to regulate the idle speed of LS3 engines. These systems typically involve electronic control units that monitor engine parameters and adjust the throttle position or fuel injection to maintain a stable idle speed. The control systems may include feedback mechanisms that respond to changes in engine load, temperature, and other operating conditions to ensure consistent idle performance.- Idle speed control systems for LS3 engines: Idle speed control systems for LS3 engines utilize electronic control modules to maintain optimal engine idle speed. These systems monitor various engine parameters such as temperature, load, and operating conditions to adjust the idle speed accordingly. The control systems typically include sensors, actuators, and feedback mechanisms to ensure stable idle performance under different environmental conditions.

- Air-fuel mixture optimization for idle stability: Optimizing the air-fuel mixture is crucial for maintaining stable idle speed in LS3 engines. Systems that precisely control fuel injection timing and quantity help achieve the ideal stoichiometric ratio at idle. Advanced fuel delivery systems with electronic control can compensate for various factors affecting idle quality, including engine temperature, ambient conditions, and accessory loads, resulting in smoother idle performance and improved fuel efficiency.

- Electronic throttle control for idle speed regulation: Electronic throttle control systems play a significant role in regulating idle speed in LS3 engines. These systems replace traditional mechanical throttle linkages with electronic actuators that precisely control airflow into the engine. By continuously adjusting the throttle position based on input from various sensors, the engine management system can maintain consistent idle speed despite changing conditions such as air conditioning engagement, alternator load, or transmission shifts.

- Idle speed compensation during cold start conditions: LS3 engines incorporate specific idle speed compensation strategies for cold start conditions. When the engine is cold, the control module automatically increases the idle speed to improve combustion efficiency and reduce emissions. As the engine warms up, the idle speed gradually decreases to the normal operating range. This adaptive control helps maintain proper engine function during the critical warm-up period while ensuring optimal performance and emissions compliance.

- Idle speed adjustment for performance modifications: Performance modifications to LS3 engines often require adjustments to idle speed parameters. Modified camshafts, intake manifolds, or exhaust systems can affect the engine's idle characteristics. Recalibration of the engine control module may be necessary to establish proper idle speed that accommodates these modifications while maintaining drivability. Aftermarket tuning solutions allow for customization of idle speed parameters to match specific performance enhancements while ensuring engine reliability.

02 Mechanical components affecting LS3 engine idle speed

The idle speed of LS3 engines is influenced by various mechanical components, including throttle bodies, idle air control valves, and intake manifold design. These components work together to regulate the amount of air entering the engine during idle conditions. Proper adjustment and maintenance of these mechanical components are essential for achieving a stable and appropriate idle speed in LS3 engines.Expand Specific Solutions03 Electronic control strategies for idle speed management

Advanced electronic control strategies are employed to manage the idle speed of LS3 engines. These strategies may involve adaptive learning algorithms that adjust idle parameters based on engine wear and environmental conditions. The electronic control module (ECM) uses inputs from various sensors to calculate the optimal idle speed and makes real-time adjustments to maintain that speed under varying conditions such as air conditioning load, alternator load, and transmission engagement.Expand Specific Solutions04 Temperature compensation for idle speed control

Temperature compensation mechanisms are implemented in LS3 engines to adjust idle speed based on engine and ambient temperatures. Cold engines typically require a higher idle speed to maintain stability and ensure proper lubrication. As the engine warms up, the idle speed is gradually reduced to its normal operating range. These temperature compensation systems help optimize engine performance and emissions across a wide range of operating conditions.Expand Specific Solutions05 Transmission and load-based idle speed adjustments

LS3 engines incorporate systems that adjust idle speed based on transmission status and engine load conditions. When the transmission is in gear or when additional loads such as power steering or air conditioning are engaged, the idle speed may be automatically increased to prevent stalling and maintain smooth operation. These load-based adjustments ensure consistent engine performance during various driving conditions and accessory usage scenarios.Expand Specific Solutions

Major Manufacturers and Service Providers in LS3 Ecosystem

The LS3 engine idle speed issue market is characterized by a mature technology in the automotive sector, with a substantial market size due to widespread use in various vehicle models. Major players like GM Global Technology Operations, Ford Global Technologies, and Toyota Motor Corp have established significant technical expertise in engine management systems. The competitive landscape includes traditional automotive manufacturers (General Motors, Ford, Toyota) alongside specialized engine component suppliers like Robert Bosch GmbH. These companies have developed sophisticated electronic control units and fuel management systems to address idle speed fluctuations. The technology maturity varies, with companies like GM having the most advanced solutions specific to LS3 platforms, while others like Bosch offer universal aftermarket solutions applicable across multiple engine families.

Ford Global Technologies LLC

Technical Solution: Ford's solution for LS3-type engine idle issues focuses on their Powertrain Control Module (PCM) with adaptive idle speed control technology. Their system employs a multi-parameter approach that monitors crankshaft position sensor data, throttle position, and intake air temperature to establish baseline idle parameters. Ford's technology incorporates a dual-mode idle control strategy that switches between open and closed-loop control depending on engine operating conditions. The system features Ford's proprietary Idle Air Control (IAC) valve design with enhanced response characteristics specifically tuned for large displacement V8 engines. Their solution includes specialized fuel trim adjustments during idle conditions to compensate for fuel system pressure variations and injector performance differences. Ford has also developed specific calibration maps for cold-start idle conditions that gradually transition to normal operating parameters as the engine reaches optimal temperature, preventing the common cold-idle fluctuations experienced in high-performance V8 engines.

Strengths: Excellent cold-start idle stability, robust adaptation to varying environmental conditions, and seamless integration with Ford's comprehensive engine management systems. Weaknesses: Some solutions require Ford-specific diagnostic equipment, and the system may be overly sensitive to aftermarket modifications that affect airflow or exhaust characteristics.

GM Global Technology Operations LLC

Technical Solution: GM's approach to resolving LS3 engine idle speed issues centers on their advanced Engine Control Module (ECM) calibration system. Their solution incorporates adaptive idle control technology that continuously monitors and adjusts fuel delivery and ignition timing based on real-time engine parameters. The system utilizes closed-loop feedback from multiple sensors including MAF (Mass Airflow), MAP (Manifold Absolute Pressure), and oxygen sensors to maintain optimal idle stability. GM has implemented a proprietary idle air control valve design that provides more precise airflow management at low RPMs. Additionally, their diagnostic system includes specific idle quality monitoring algorithms that can detect and compensate for variations in engine load from accessories, temperature fluctuations, and fuel quality differences. The ECM software includes learning capabilities that adapt to engine wear patterns over time, maintaining consistent idle performance throughout the engine's lifecycle.

Strengths: Superior integration with GM's comprehensive vehicle systems, excellent long-term adaptation to engine wear, and robust diagnostic capabilities. Weaknesses: System complexity can make aftermarket modifications challenging, and some solutions require dealer-specific diagnostic equipment for proper implementation.

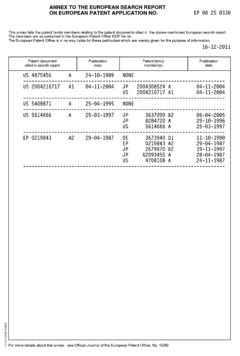

Key Patents and Innovations in Engine Idle Control Systems

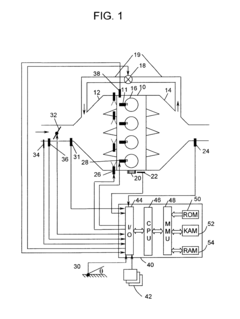

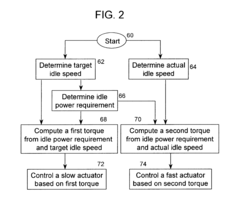

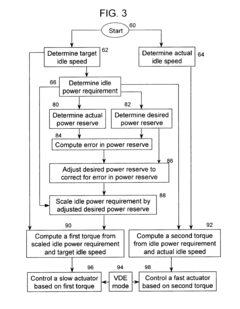

Power-based idle speed control

PatentInactiveUS6688282B1

Innovation

- A method and system that regulate engine idle speed by determining a target idle speed and power requirement, controlling a slow actuator (e.g., throttle) based on the target speed and a fast actuator (e.g., ignition) based on actual speed, with adjustments for power reserve and cylinder deactivation, facilitating smooth transitions between operating modes without speed deviations.

Vehicle engine idle speed control

PatentInactiveEP1953374A3

Innovation

- A system comprising a vehicle speed sensor for the drive wheel, an intake pipe pressure sensor, an intake valve, and a controlling unit that detects abnormalities in the ISC device based on intake pipe pressure, suppressing engine speed increases by adjusting the intake valve flow passage area without the need for multiple sensors or complex structures.

Emissions Compliance Impact on LS3 Idle Control Solutions

Emissions regulations have become increasingly stringent worldwide, significantly impacting the design and functionality of engine control systems, particularly idle speed control mechanisms in performance engines like the LS3. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established progressively stricter standards for vehicle emissions, requiring manufacturers to implement more sophisticated idle control strategies that maintain both performance and compliance.

The LS3 engine's idle speed issues are directly affected by these emissions requirements through several key mechanisms. First, modern emissions standards necessitate precise air-fuel ratio management during idle conditions to minimize hydrocarbon (HC) and carbon monoxide (CO) emissions. This precision often creates a conflict with the traditional performance-oriented calibration that LS3 owners typically desire, resulting in unstable idle characteristics.

Exhaust Gas Recirculation (EGR) systems, mandated for NOx reduction, introduce additional variables to idle control. When EGR valves operate during idle conditions, they alter intake manifold pressure and oxygen content, requiring compensatory adjustments to maintain stable idle speeds. The LS3's electronic throttle control (ETC) system must constantly adapt to these changing conditions while maintaining emissions compliance.

Catalytic converter efficiency requirements further complicate idle control strategies. To maintain optimal catalyst operating temperatures, the engine management system may adjust idle speeds and timing, sometimes resulting in perceptible fluctuations that owners interpret as idle quality issues. These adjustments are particularly noticeable during cold-start conditions when emissions control is most challenging.

Evaporative emissions control systems, including purge valves that capture fuel vapors, create additional air-fuel mixture variations when activated during idle. The engine control module must compensate for these sudden changes in intake air composition, sometimes resulting in momentary idle speed fluctuations that can be particularly problematic in modified LS3 engines.

The transition to OBD-II diagnostic requirements has added another layer of complexity, as the system must continuously monitor emissions-related components and adjust idle parameters accordingly. Any deviation from expected values triggers compensatory actions that may affect idle quality while maintaining emissions compliance.

Manufacturers and aftermarket tuners must now balance these competing priorities when developing idle control solutions. Emissions-compliant idle control strategies often incorporate adaptive learning algorithms that gradually adjust to individual engine characteristics while maintaining regulatory compliance. This approach represents a significant departure from earlier performance engine tuning methodologies that prioritized drivability over emissions considerations.

The LS3 engine's idle speed issues are directly affected by these emissions requirements through several key mechanisms. First, modern emissions standards necessitate precise air-fuel ratio management during idle conditions to minimize hydrocarbon (HC) and carbon monoxide (CO) emissions. This precision often creates a conflict with the traditional performance-oriented calibration that LS3 owners typically desire, resulting in unstable idle characteristics.

Exhaust Gas Recirculation (EGR) systems, mandated for NOx reduction, introduce additional variables to idle control. When EGR valves operate during idle conditions, they alter intake manifold pressure and oxygen content, requiring compensatory adjustments to maintain stable idle speeds. The LS3's electronic throttle control (ETC) system must constantly adapt to these changing conditions while maintaining emissions compliance.

Catalytic converter efficiency requirements further complicate idle control strategies. To maintain optimal catalyst operating temperatures, the engine management system may adjust idle speeds and timing, sometimes resulting in perceptible fluctuations that owners interpret as idle quality issues. These adjustments are particularly noticeable during cold-start conditions when emissions control is most challenging.

Evaporative emissions control systems, including purge valves that capture fuel vapors, create additional air-fuel mixture variations when activated during idle. The engine control module must compensate for these sudden changes in intake air composition, sometimes resulting in momentary idle speed fluctuations that can be particularly problematic in modified LS3 engines.

The transition to OBD-II diagnostic requirements has added another layer of complexity, as the system must continuously monitor emissions-related components and adjust idle parameters accordingly. Any deviation from expected values triggers compensatory actions that may affect idle quality while maintaining emissions compliance.

Manufacturers and aftermarket tuners must now balance these competing priorities when developing idle control solutions. Emissions-compliant idle control strategies often incorporate adaptive learning algorithms that gradually adjust to individual engine characteristics while maintaining regulatory compliance. This approach represents a significant departure from earlier performance engine tuning methodologies that prioritized drivability over emissions considerations.

Diagnostic Tools and Methodologies for LS3 Idle Troubleshooting

Effective diagnosis of LS3 idle speed issues requires a systematic approach utilizing specialized tools and methodologies. The primary diagnostic tool for modern LS3 engines is the OBD-II scanner, which provides access to the Engine Control Module (ECM) data and stored trouble codes. Professional-grade scanners offer real-time data monitoring capabilities, allowing technicians to observe critical parameters such as idle air control valve position, throttle position sensor readings, and oxygen sensor values during idle conditions.

Advanced diagnostic equipment includes digital vacuum gauges that measure intake manifold vacuum, which should maintain a steady 18-22 inHg at idle. Fluctuations may indicate air leaks or valve timing issues. Fuel pressure testers are essential for verifying proper fuel system operation, as the LS3 requires consistent fuel pressure (typically 58-62 PSI) for stable idle performance.

Compression testers and cylinder leakage testers provide critical information about engine mechanical health. The LS3 should maintain compression readings within 10% across all eight cylinders, with readings typically between 175-185 PSI. Significant variations often correlate with idle instability.

Methodologically, diagnosticians employ a structured troubleshooting sequence beginning with basic checks and progressing to more complex tests. The initial assessment includes verification of proper engine operating temperature, as cold engines naturally idle higher. Visual inspection of vacuum lines, intake gaskets, and throttle body cleanliness follows, as these represent common failure points affecting idle quality.

Data-driven diagnosis involves monitoring key parameters during idle, including short-term and long-term fuel trim values, which should remain within ±10%. Excessive correction values indicate underlying issues requiring attention. Technicians also perform idle relearn procedures after component replacement, as the adaptive memory in the ECM requires recalibration to establish proper baseline values.

Specialized LS3 diagnostic methodologies include throttle body airflow testing, MAF sensor validation using known-good replacement parts, and targeted fuel injector pulse testing. The sequential elimination approach, where components are systematically isolated or bypassed, helps identify problematic systems affecting idle performance.

Modern diagnostic approaches increasingly incorporate machine learning algorithms that analyze historical data patterns from similar vehicles, providing probability-weighted diagnostic suggestions based on symptom combinations and sensor readings, significantly reducing diagnostic time for complex idle issues.

Advanced diagnostic equipment includes digital vacuum gauges that measure intake manifold vacuum, which should maintain a steady 18-22 inHg at idle. Fluctuations may indicate air leaks or valve timing issues. Fuel pressure testers are essential for verifying proper fuel system operation, as the LS3 requires consistent fuel pressure (typically 58-62 PSI) for stable idle performance.

Compression testers and cylinder leakage testers provide critical information about engine mechanical health. The LS3 should maintain compression readings within 10% across all eight cylinders, with readings typically between 175-185 PSI. Significant variations often correlate with idle instability.

Methodologically, diagnosticians employ a structured troubleshooting sequence beginning with basic checks and progressing to more complex tests. The initial assessment includes verification of proper engine operating temperature, as cold engines naturally idle higher. Visual inspection of vacuum lines, intake gaskets, and throttle body cleanliness follows, as these represent common failure points affecting idle quality.

Data-driven diagnosis involves monitoring key parameters during idle, including short-term and long-term fuel trim values, which should remain within ±10%. Excessive correction values indicate underlying issues requiring attention. Technicians also perform idle relearn procedures after component replacement, as the adaptive memory in the ECM requires recalibration to establish proper baseline values.

Specialized LS3 diagnostic methodologies include throttle body airflow testing, MAF sensor validation using known-good replacement parts, and targeted fuel injector pulse testing. The sequential elimination approach, where components are systematically isolated or bypassed, helps identify problematic systems affecting idle performance.

Modern diagnostic approaches increasingly incorporate machine learning algorithms that analyze historical data patterns from similar vehicles, providing probability-weighted diagnostic suggestions based on symptom combinations and sensor readings, significantly reducing diagnostic time for complex idle issues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!