LS3 Engine: How to Monitor Knock Sensor Function

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Knock Detection Background and Objectives

Engine knock detection has evolved significantly since the early days of internal combustion engines. Initially identified as a mechanical problem causing premature engine wear and potential failure, knock detection has transformed into a sophisticated electronic monitoring system critical for modern engine performance and longevity. The LS3 engine, a 6.2L V8 powerplant developed by General Motors, represents a pinnacle in this evolution, employing advanced knock detection systems to optimize performance while protecting engine components.

The historical progression of knock detection technology spans from rudimentary mechanical solutions to today's integrated electronic systems. Early detection relied on driver awareness of audible knocking sounds, followed by basic mechanical sensors in the mid-20th century. The electronic revolution of the 1980s introduced the first generation of electronic knock sensors, while the 1990s saw the integration of these systems with engine control units (ECUs). The LS3 engine, introduced in 2007, features a state-of-the-art knock detection system that builds upon decades of technological advancement.

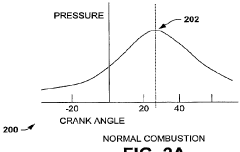

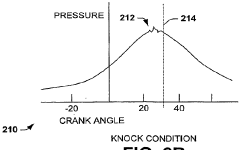

Knock in the LS3 engine occurs when the air-fuel mixture in the combustion chamber ignites prematurely or irregularly, creating pressure waves that resonate against the cylinder walls. This phenomenon, technically known as detonation, can cause significant damage to pistons, connecting rods, and cylinder heads if left unaddressed. The primary objective of knock detection in the LS3 is to identify these events in real-time, allowing the engine management system to make immediate adjustments to prevent damage.

The technical goals for LS3 knock detection systems include achieving high sensitivity to detect even minor knock events, maintaining accuracy across various operating conditions, ensuring rapid response times to prevent engine damage, and implementing robust filtering to distinguish between normal engine noise and actual knock events. Additionally, modern systems aim for seamless integration with other engine management functions and diagnostic capabilities for system self-monitoring.

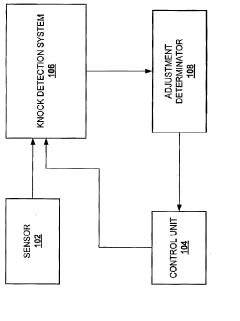

Current LS3 knock detection technology utilizes piezoelectric sensors mounted on the engine block to detect vibrations characteristic of knock events. These sensors convert mechanical vibrations into electrical signals, which are then processed by the Engine Control Module (ECM) using sophisticated algorithms to filter out normal engine noise and identify true knock events. When knock is detected, the ECM typically responds by retarding ignition timing in the affected cylinder, adjusting fuel delivery, or modifying other parameters to eliminate the knock condition.

The ongoing evolution of knock detection technology aims to enhance sensitivity, reduce false positives, and integrate with predictive engine management strategies. Future developments may include machine learning algorithms for more accurate detection and advanced sensor technologies capable of distinguishing between different types of abnormal combustion events.

The historical progression of knock detection technology spans from rudimentary mechanical solutions to today's integrated electronic systems. Early detection relied on driver awareness of audible knocking sounds, followed by basic mechanical sensors in the mid-20th century. The electronic revolution of the 1980s introduced the first generation of electronic knock sensors, while the 1990s saw the integration of these systems with engine control units (ECUs). The LS3 engine, introduced in 2007, features a state-of-the-art knock detection system that builds upon decades of technological advancement.

Knock in the LS3 engine occurs when the air-fuel mixture in the combustion chamber ignites prematurely or irregularly, creating pressure waves that resonate against the cylinder walls. This phenomenon, technically known as detonation, can cause significant damage to pistons, connecting rods, and cylinder heads if left unaddressed. The primary objective of knock detection in the LS3 is to identify these events in real-time, allowing the engine management system to make immediate adjustments to prevent damage.

The technical goals for LS3 knock detection systems include achieving high sensitivity to detect even minor knock events, maintaining accuracy across various operating conditions, ensuring rapid response times to prevent engine damage, and implementing robust filtering to distinguish between normal engine noise and actual knock events. Additionally, modern systems aim for seamless integration with other engine management functions and diagnostic capabilities for system self-monitoring.

Current LS3 knock detection technology utilizes piezoelectric sensors mounted on the engine block to detect vibrations characteristic of knock events. These sensors convert mechanical vibrations into electrical signals, which are then processed by the Engine Control Module (ECM) using sophisticated algorithms to filter out normal engine noise and identify true knock events. When knock is detected, the ECM typically responds by retarding ignition timing in the affected cylinder, adjusting fuel delivery, or modifying other parameters to eliminate the knock condition.

The ongoing evolution of knock detection technology aims to enhance sensitivity, reduce false positives, and integrate with predictive engine management strategies. Future developments may include machine learning algorithms for more accurate detection and advanced sensor technologies capable of distinguishing between different types of abnormal combustion events.

Market Demand for Advanced Knock Detection Systems

The automotive industry has witnessed a significant surge in demand for advanced knock detection systems, particularly for high-performance engines like the LS3. This growing market interest stems from increasingly stringent emission regulations, rising consumer expectations for engine performance and longevity, and the automotive industry's push toward more efficient combustion technologies.

Global emission standards, including Euro 7 in Europe and Tier 3 in the United States, have compelled manufacturers to optimize combustion processes while minimizing harmful emissions. Advanced knock detection systems play a crucial role in this optimization by enabling engines to operate closer to their efficiency limits without risking damage from detonation events.

Market research indicates that the global engine management system market, which includes knock detection technologies, is projected to grow at a compound annual growth rate of approximately 7% through 2028. The performance automotive segment, where LS3 engines are predominantly used, shows even stronger growth potential due to increasing consumer interest in aftermarket performance upgrades and tuning solutions.

Vehicle manufacturers and aftermarket suppliers are responding to this demand by developing more sophisticated knock detection and monitoring systems. These systems not only detect knock events but also provide diagnostic capabilities to ensure the knock sensors themselves are functioning correctly—a critical feature for performance engines like the LS3 where operating margins are narrower.

The commercial vehicle sector represents another significant market segment, with fleet operators increasingly recognizing the value of advanced engine monitoring systems in reducing maintenance costs and extending engine life. For these operators, the ability to continuously monitor knock sensor function translates directly to improved operational reliability and reduced downtime.

Geographically, North America dominates the market for advanced knock detection systems for LS3 and similar performance engines, followed by Europe and Asia-Pacific. The aftermarket segment in these regions is particularly robust, with performance enthusiasts willing to invest in premium solutions that offer enhanced engine protection and optimization capabilities.

Consumer surveys reveal that engine reliability ranks among the top three concerns for performance vehicle owners, creating a receptive market for technologies that provide real-time monitoring of critical engine parameters, including knock sensor functionality. This consumer sentiment is driving demand for more sophisticated user interfaces that can communicate sensor status and engine health metrics in an accessible manner.

The integration of knock detection systems with broader vehicle diagnostics and telematics platforms represents an emerging trend, with market analysts predicting substantial growth in connected vehicle technologies that incorporate engine health monitoring as a core feature.

Global emission standards, including Euro 7 in Europe and Tier 3 in the United States, have compelled manufacturers to optimize combustion processes while minimizing harmful emissions. Advanced knock detection systems play a crucial role in this optimization by enabling engines to operate closer to their efficiency limits without risking damage from detonation events.

Market research indicates that the global engine management system market, which includes knock detection technologies, is projected to grow at a compound annual growth rate of approximately 7% through 2028. The performance automotive segment, where LS3 engines are predominantly used, shows even stronger growth potential due to increasing consumer interest in aftermarket performance upgrades and tuning solutions.

Vehicle manufacturers and aftermarket suppliers are responding to this demand by developing more sophisticated knock detection and monitoring systems. These systems not only detect knock events but also provide diagnostic capabilities to ensure the knock sensors themselves are functioning correctly—a critical feature for performance engines like the LS3 where operating margins are narrower.

The commercial vehicle sector represents another significant market segment, with fleet operators increasingly recognizing the value of advanced engine monitoring systems in reducing maintenance costs and extending engine life. For these operators, the ability to continuously monitor knock sensor function translates directly to improved operational reliability and reduced downtime.

Geographically, North America dominates the market for advanced knock detection systems for LS3 and similar performance engines, followed by Europe and Asia-Pacific. The aftermarket segment in these regions is particularly robust, with performance enthusiasts willing to invest in premium solutions that offer enhanced engine protection and optimization capabilities.

Consumer surveys reveal that engine reliability ranks among the top three concerns for performance vehicle owners, creating a receptive market for technologies that provide real-time monitoring of critical engine parameters, including knock sensor functionality. This consumer sentiment is driving demand for more sophisticated user interfaces that can communicate sensor status and engine health metrics in an accessible manner.

The integration of knock detection systems with broader vehicle diagnostics and telematics platforms represents an emerging trend, with market analysts predicting substantial growth in connected vehicle technologies that incorporate engine health monitoring as a core feature.

Current Knock Sensor Technology and Challenges

Knock sensors in the LS3 engine serve as critical components for detecting engine knock, a phenomenon that occurs when fuel combusts prematurely in the engine's cylinders. Current knock sensor technology primarily utilizes piezoelectric elements that convert mechanical vibrations into electrical signals. These sensors are strategically mounted on the engine block to detect specific vibration frequencies associated with knock events, typically in the 5-8 kHz range for the LS3 engine.

The predominant design in modern LS3 engines incorporates two knock sensors positioned on opposite sides of the engine block. This dual-sensor configuration enables more accurate detection across all cylinders and improves the system's ability to distinguish between normal engine noise and actual knock events. The sensors connect to the Engine Control Module (ECM) through shielded wiring to minimize electromagnetic interference that could compromise signal integrity.

Despite advancements, knock sensor technology faces several significant challenges. Signal-to-noise ratio remains a persistent issue, as distinguishing between actual knock events and normal engine vibrations becomes increasingly difficult at higher RPMs or under heavy loads. This challenge is particularly pronounced in high-performance applications of the LS3 engine where operating conditions are more extreme.

Environmental factors present another substantial challenge. Temperature variations can affect sensor sensitivity and calibration, potentially leading to false positives or missed knock events. Sensors must maintain consistent performance across the wide temperature range experienced in engine environments, from cold starts to full operating temperature.

Sensor degradation over time represents a critical reliability concern. The piezoelectric elements may experience sensitivity reduction after prolonged exposure to engine vibration and heat cycles. This degradation is often gradual and difficult to detect through conventional diagnostic methods, creating a significant monitoring challenge.

Current monitoring systems typically rely on indirect methods to verify knock sensor functionality. These include monitoring signal patterns during specific operating conditions or comparing signals between multiple sensors. However, these methods cannot always detect partial sensor failure or gradual degradation, which may still allow the sensor to produce signals within acceptable parameters while missing actual knock events.

The integration with modern engine management systems presents additional complexity. As ECMs become more sophisticated, the knock detection algorithms must continuously evolve to maintain accuracy while processing signals from potentially degrading sensors. This creates a moving target for monitoring methodologies that must adapt to both sensor characteristics and ECM interpretation parameters.

The predominant design in modern LS3 engines incorporates two knock sensors positioned on opposite sides of the engine block. This dual-sensor configuration enables more accurate detection across all cylinders and improves the system's ability to distinguish between normal engine noise and actual knock events. The sensors connect to the Engine Control Module (ECM) through shielded wiring to minimize electromagnetic interference that could compromise signal integrity.

Despite advancements, knock sensor technology faces several significant challenges. Signal-to-noise ratio remains a persistent issue, as distinguishing between actual knock events and normal engine vibrations becomes increasingly difficult at higher RPMs or under heavy loads. This challenge is particularly pronounced in high-performance applications of the LS3 engine where operating conditions are more extreme.

Environmental factors present another substantial challenge. Temperature variations can affect sensor sensitivity and calibration, potentially leading to false positives or missed knock events. Sensors must maintain consistent performance across the wide temperature range experienced in engine environments, from cold starts to full operating temperature.

Sensor degradation over time represents a critical reliability concern. The piezoelectric elements may experience sensitivity reduction after prolonged exposure to engine vibration and heat cycles. This degradation is often gradual and difficult to detect through conventional diagnostic methods, creating a significant monitoring challenge.

Current monitoring systems typically rely on indirect methods to verify knock sensor functionality. These include monitoring signal patterns during specific operating conditions or comparing signals between multiple sensors. However, these methods cannot always detect partial sensor failure or gradual degradation, which may still allow the sensor to produce signals within acceptable parameters while missing actual knock events.

The integration with modern engine management systems presents additional complexity. As ECMs become more sophisticated, the knock detection algorithms must continuously evolve to maintain accuracy while processing signals from potentially degrading sensors. This creates a moving target for monitoring methodologies that must adapt to both sensor characteristics and ECM interpretation parameters.

Existing LS3 Knock Sensor Monitoring Solutions

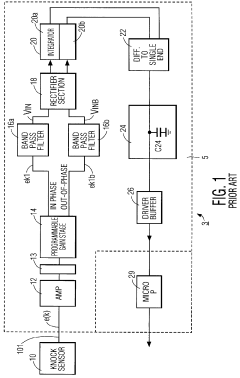

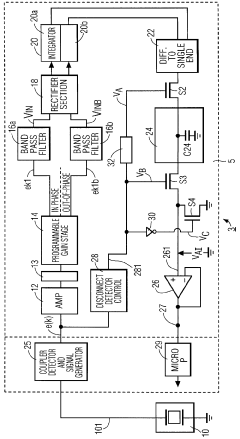

01 Knock sensor detection and signal processing methods

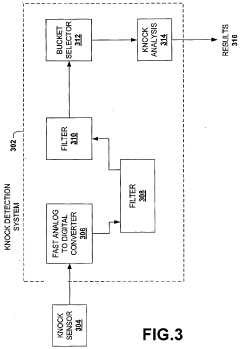

Various methods for detecting and processing knock sensor signals in engines, particularly LS3 engines. These methods involve analyzing vibration patterns, filtering noise, and using signal processing algorithms to accurately identify engine knock events. The systems typically use piezoelectric sensors to convert mechanical vibrations into electrical signals, which are then processed to determine if knock is occurring and its severity.- Knock sensor detection and signal processing: Knock sensors are used to detect engine knock by converting mechanical vibrations into electrical signals. These signals are then processed to identify knock events. The processing involves filtering, amplification, and analysis of frequency components to distinguish knock from normal engine noise. Advanced signal processing techniques can improve the accuracy of knock detection and reduce false positives, enabling better engine control and protection.

- Engine control systems with knock detection integration: Modern engine control systems integrate knock sensor data to optimize engine performance while preventing damage. These systems continuously monitor knock sensor signals and adjust ignition timing, fuel injection, and other parameters in real-time. When knock is detected, the control system can retard ignition timing or make other adjustments to eliminate knock while maintaining optimal performance. This integration allows for more aggressive tuning while ensuring engine protection.

- LS3-specific knock sensor implementation: The LS3 engine employs specific knock sensor mounting locations and configurations to effectively monitor combustion. These sensors are strategically placed on the engine block to detect vibrations from each cylinder. The LS3's knock monitoring system is calibrated to account for the engine's specific vibration characteristics and operating conditions. This specialized implementation ensures accurate knock detection across the engine's operating range, allowing for optimal performance tuning.

- Adaptive knock threshold and learning algorithms: Advanced knock monitoring systems employ adaptive thresholds and learning algorithms to improve detection accuracy. These systems can adjust sensitivity based on engine operating conditions, ambient factors, and fuel quality. Machine learning techniques allow the system to recognize patterns in sensor data and distinguish between normal engine noise and actual knock events. Over time, these adaptive systems build a profile of the engine's behavior, enabling more precise knock detection and control.

- Diagnostic and monitoring functions for knock sensors: Knock sensor monitoring systems include diagnostic capabilities to ensure proper sensor function. These diagnostics can detect sensor failures, wiring issues, or signal degradation that might compromise knock detection. The monitoring functions continuously evaluate sensor performance and can alert the driver or technician when issues are detected. Some systems include redundancy features or alternative detection methods to maintain engine protection even when sensor problems occur.

02 Adaptive knock control systems

Advanced systems that adaptively adjust engine parameters based on knock sensor feedback. These systems continuously monitor knock sensor signals and dynamically modify ignition timing, fuel injection, and other parameters to prevent damaging knock while maintaining optimal performance. The adaptive nature allows the system to learn from previous conditions and adjust control strategies accordingly for different operating conditions of the LS3 engine.Expand Specific Solutions03 Integration with engine management systems

Knock sensor monitoring functions integrated with broader engine management systems. These integrated systems coordinate knock detection with other engine parameters such as air-fuel ratio, exhaust gas recirculation, and variable valve timing to optimize overall engine performance. The integration enables comprehensive engine protection while maintaining efficiency and power output in LS3 engines.Expand Specific Solutions04 Diagnostic and fault detection systems

Systems designed to diagnose problems with knock sensors and related components in LS3 engines. These diagnostic systems can detect sensor failures, wiring issues, or signal processing problems, and provide appropriate alerts or fault codes. Some implementations include self-testing capabilities that periodically verify knock sensor functionality and accuracy to ensure reliable engine protection.Expand Specific Solutions05 Advanced knock prediction and prevention

Innovative systems that not only detect knock but predict and prevent it before it occurs. These systems use predictive algorithms, machine learning, or model-based approaches to anticipate conditions likely to cause knock in LS3 engines. By analyzing multiple sensor inputs and engine operating conditions, these systems can proactively adjust parameters to avoid knock situations while maximizing performance and efficiency.Expand Specific Solutions

Major Players in Automotive Knock Sensor Industry

The knock sensor monitoring in LS3 engines represents a mature technology within the automotive powertrain control sector, currently in a growth phase with increasing integration of advanced diagnostics. The market is dominated by established OEMs and tier-1 suppliers, with Robert Bosch GmbH, Continental Automotive, and DENSO leading in sensor technology development. Toyota, GM, Honda, and Ford have incorporated proprietary knock detection systems in their engine management platforms, while specialized suppliers like Infineon and Hitachi Automotive Systems provide semiconductor components critical for signal processing. The technology continues to evolve toward more sophisticated real-time monitoring capabilities with enhanced noise filtering algorithms and integration with broader engine management systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced knock sensor monitoring systems for LS3 engines that utilize piezoelectric sensors coupled with intelligent signal processing algorithms. Their solution employs a dual-channel approach where vibration signals are continuously monitored and compared against adaptive threshold values that adjust based on engine operating conditions. The system features real-time frequency analysis that can distinguish between normal combustion noise and actual knock events through specialized bandpass filtering (typically 5-15 kHz range where knock frequencies are most prominent). Bosch's implementation includes self-diagnostic capabilities that periodically verify sensor functionality by analyzing signal characteristics during known operating conditions, ensuring the knock detection system remains reliable throughout the engine's lifetime. Their latest systems incorporate machine learning algorithms that improve detection accuracy by learning from historical engine operation patterns[1][3].

Strengths: Industry-leading signal processing algorithms with exceptional noise filtering capabilities; comprehensive self-diagnostic features; adaptive threshold technology that minimizes false positives. Weaknesses: Higher implementation cost compared to basic systems; requires more computational resources; calibration complexity for different engine variants.

Toyota Motor Corp.

Technical Solution: Toyota's approach to LS3 engine knock sensor monitoring integrates their proprietary Engine Control Module (ECM) with sophisticated digital signal processing. Their system employs multiple knock sensors strategically positioned on the engine block to triangulate and precisely identify the cylinder experiencing detonation. Toyota's solution features adaptive noise cancellation technology that filters out mechanical noise and vibrations unrelated to knock events. The system continuously performs rationality checks by comparing sensor readings against a comprehensive map of expected vibration patterns across various engine speeds and loads. Toyota has implemented a two-stage monitoring process: primary real-time monitoring for immediate spark retard adjustments, and secondary diagnostic monitoring that tracks sensor performance over time to detect degradation. Their latest generation includes closed-loop verification that confirms spark timing adjustments actually mitigated knock events when detected[2][5].

Strengths: Exceptional accuracy in cylinder-specific knock detection; robust noise cancellation algorithms; comprehensive long-term sensor health monitoring. Weaknesses: System complexity requires significant calibration effort; higher component cost due to multiple sensor implementation; increased ECU processing demands.

Key Technical Innovations in Knock Detection

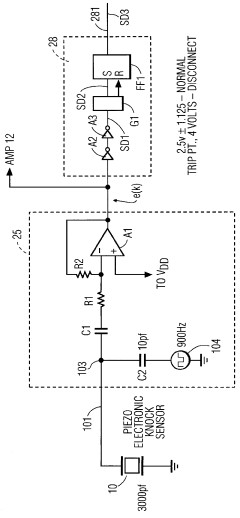

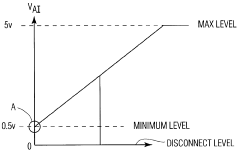

Knock sensor system for detecting and responding to a disconnect condition

PatentInactiveUS5942677A

Innovation

- A system that detects a knock sensor disconnect condition by using a storage capacitor to produce a control signal, clamping the input of the output amplifier to a reference potential, allowing a single line to indicate both normal and disconnect signals, preventing engine interference.

Knock detection system and method

PatentWO2007092438A2

Innovation

- A detection system comprising an analog to digital converter, filters, and an analyzer that selects and analyzes frequency subsets based on operational characteristics to identify engine knock, allowing for adaptable knock detection across various engine conditions.

Regulatory Compliance for Engine Management Systems

Engine management systems must adhere to stringent regulatory frameworks established by various governmental bodies worldwide. For the LS3 engine's knock sensor monitoring, compliance with emissions standards represents a primary regulatory concern. The U.S. Environmental Protection Agency (EPA) and California Air Resources Board (CARB) mandate specific On-Board Diagnostic (OBD-II) requirements that directly impact knock sensor monitoring implementation. These regulations require continuous monitoring of components that could affect emissions when malfunctioning, with knock sensors falling under this category due to their role in preventing engine damage and maintaining optimal combustion efficiency.

European regulations, particularly Euro 6/7 standards, impose additional requirements for engine management systems. These standards specify performance criteria for monitoring systems and establish thresholds for malfunction indicator light (MIL) activation. For knock sensor monitoring in the LS3 engine, compliance necessitates detection capabilities that can identify both electrical faults and degraded performance conditions within specified operating parameters.

The regulatory landscape also includes specific technical requirements for monitoring frequency and detection thresholds. For knock sensors, regulations typically require monitoring once per driving cycle under conditions where knock would normally be expected. The system must detect both circuit continuity issues and functional performance degradation that would cause emissions to exceed 1.5 times the applicable standards.

Compliance documentation represents another critical aspect of regulatory requirements. Engine manufacturers must maintain detailed technical documentation demonstrating how their knock sensor monitoring systems meet applicable standards. This documentation typically includes test data, validation methodologies, and failure mode analyses that verify the monitoring system's effectiveness across the engine's operating range.

Certification procedures involve rigorous testing to verify compliance. For knock sensor monitoring systems, this includes demonstrating reliable fault detection across various operating conditions and proving the system's robustness against false positives that could trigger unnecessary service events. The LS3 engine's knock sensor monitoring system must pass these certification tests before the engine can be legally sold in regulated markets.

Future regulatory trends indicate increasingly stringent requirements for diagnostic system performance. Emerging regulations are moving toward more comprehensive real-world monitoring capabilities and expanded operating condition coverage. For knock sensor monitoring, this suggests future systems may need enhanced sensitivity and more sophisticated signal processing algorithms to maintain compliance while avoiding false detections.

European regulations, particularly Euro 6/7 standards, impose additional requirements for engine management systems. These standards specify performance criteria for monitoring systems and establish thresholds for malfunction indicator light (MIL) activation. For knock sensor monitoring in the LS3 engine, compliance necessitates detection capabilities that can identify both electrical faults and degraded performance conditions within specified operating parameters.

The regulatory landscape also includes specific technical requirements for monitoring frequency and detection thresholds. For knock sensors, regulations typically require monitoring once per driving cycle under conditions where knock would normally be expected. The system must detect both circuit continuity issues and functional performance degradation that would cause emissions to exceed 1.5 times the applicable standards.

Compliance documentation represents another critical aspect of regulatory requirements. Engine manufacturers must maintain detailed technical documentation demonstrating how their knock sensor monitoring systems meet applicable standards. This documentation typically includes test data, validation methodologies, and failure mode analyses that verify the monitoring system's effectiveness across the engine's operating range.

Certification procedures involve rigorous testing to verify compliance. For knock sensor monitoring systems, this includes demonstrating reliable fault detection across various operating conditions and proving the system's robustness against false positives that could trigger unnecessary service events. The LS3 engine's knock sensor monitoring system must pass these certification tests before the engine can be legally sold in regulated markets.

Future regulatory trends indicate increasingly stringent requirements for diagnostic system performance. Emerging regulations are moving toward more comprehensive real-world monitoring capabilities and expanded operating condition coverage. For knock sensor monitoring, this suggests future systems may need enhanced sensitivity and more sophisticated signal processing algorithms to maintain compliance while avoiding false detections.

Diagnostic Tools and Methods for Knock Sensor Validation

Effective monitoring of knock sensor function in the LS3 engine requires specialized diagnostic tools and methodologies. Modern automotive diagnostic systems offer multiple approaches for validating knock sensor operation, ranging from basic scanner tools to advanced oscilloscope analysis.

Scanner-based diagnostics represent the first line of assessment for knock sensor functionality. Professional-grade scan tools can access the Engine Control Module (ECM) to retrieve both active and historical Diagnostic Trouble Codes (DTCs) related to knock sensor circuits. These tools can also display real-time data parameters including knock retard values and sensor voltage readings during engine operation, providing immediate feedback on sensor responsiveness to controlled detonation events.

Oscilloscope testing delivers more detailed insights into knock sensor signal characteristics. By connecting a digital storage oscilloscope to the knock sensor circuit, technicians can visualize the actual waveform produced by the sensor. A properly functioning knock sensor generates distinctive voltage spikes when engine knock occurs, with amplitude typically ranging from 50-500mV depending on knock intensity. Waveform analysis allows for precise evaluation of signal quality, noise interference, and response time.

Specialized knock sensor simulators have emerged as valuable validation tools. These devices generate controlled vibration patterns that mimic combustion knock at specific frequencies (typically 5-8 kHz for the LS3). When applied to the knock sensor while monitoring ECM response, technicians can verify the entire knock detection system without inducing potentially damaging detonation in the engine.

Advanced dynamometer testing provides the most comprehensive knock sensor validation. By gradually adjusting ignition timing under controlled load conditions, technicians can induce light detonation while monitoring both knock sensor signals and ECM response. This methodology confirms not only sensor functionality but also proper calibration of the engine's knock control strategy.

Thermal testing has proven essential for identifying intermittent knock sensor issues. Since sensor failures often occur at specific temperature ranges, diagnostic procedures may include monitoring sensor output during controlled heating and cooling cycles. This approach helps identify sensors that function normally at ambient temperatures but fail under actual operating conditions.

Circuit integrity testing complements functional diagnostics by verifying the electrical aspects of the knock sensor system. This includes resistance measurements (typically 100kΩ-2MΩ for piezoelectric knock sensors), insulation testing, and connector inspection to identify potential wiring issues that could compromise sensor performance without triggering obvious fault codes.

Scanner-based diagnostics represent the first line of assessment for knock sensor functionality. Professional-grade scan tools can access the Engine Control Module (ECM) to retrieve both active and historical Diagnostic Trouble Codes (DTCs) related to knock sensor circuits. These tools can also display real-time data parameters including knock retard values and sensor voltage readings during engine operation, providing immediate feedback on sensor responsiveness to controlled detonation events.

Oscilloscope testing delivers more detailed insights into knock sensor signal characteristics. By connecting a digital storage oscilloscope to the knock sensor circuit, technicians can visualize the actual waveform produced by the sensor. A properly functioning knock sensor generates distinctive voltage spikes when engine knock occurs, with amplitude typically ranging from 50-500mV depending on knock intensity. Waveform analysis allows for precise evaluation of signal quality, noise interference, and response time.

Specialized knock sensor simulators have emerged as valuable validation tools. These devices generate controlled vibration patterns that mimic combustion knock at specific frequencies (typically 5-8 kHz for the LS3). When applied to the knock sensor while monitoring ECM response, technicians can verify the entire knock detection system without inducing potentially damaging detonation in the engine.

Advanced dynamometer testing provides the most comprehensive knock sensor validation. By gradually adjusting ignition timing under controlled load conditions, technicians can induce light detonation while monitoring both knock sensor signals and ECM response. This methodology confirms not only sensor functionality but also proper calibration of the engine's knock control strategy.

Thermal testing has proven essential for identifying intermittent knock sensor issues. Since sensor failures often occur at specific temperature ranges, diagnostic procedures may include monitoring sensor output during controlled heating and cooling cycles. This approach helps identify sensors that function normally at ambient temperatures but fail under actual operating conditions.

Circuit integrity testing complements functional diagnostics by verifying the electrical aspects of the knock sensor system. This includes resistance measurements (typically 100kΩ-2MΩ for piezoelectric knock sensors), insulation testing, and connector inspection to identify potential wiring issues that could compromise sensor performance without triggering obvious fault codes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!