LS3 Engine: How to Improve Ignition Timing

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Ignition Timing Evolution and Objectives

The LS3 engine, introduced by General Motors in 2007, represents a significant evolution in the LS engine family's ignition timing technology. This 6.2L V8 powerplant initially featured in the Chevrolet Corvette and later expanded to other high-performance GM vehicles. The development of ignition timing systems for these engines has followed a trajectory from purely mechanical systems to sophisticated electronic control units capable of real-time adjustments based on multiple sensor inputs.

Early LS engines utilized a distributor-based ignition system, while the LS3 employs a coil-near-plug design with individual coils for each cylinder, controlled by the Engine Control Module (ECM). This evolution has significantly improved timing precision, combustion efficiency, and overall engine performance while reducing emissions.

The primary objective of ignition timing optimization in the LS3 engine is to achieve the ideal balance between maximum power output, fuel efficiency, and emissions control. Proper ignition timing ensures that the air-fuel mixture ignites at precisely the right moment in the combustion cycle to generate optimal pressure on the piston during the power stroke.

Current LS3 ignition timing technology faces several challenges that present opportunities for improvement. The stock ECM programming typically employs conservative timing maps to accommodate variations in fuel quality and environmental conditions. While this ensures reliability across diverse operating conditions, it often leaves performance potential untapped, particularly in modified engines or those running on premium fuels.

The technological trajectory indicates a move toward more adaptive and predictive ignition timing systems. Advanced algorithms that can learn and adapt to specific engine characteristics, driving patterns, and environmental conditions represent the next frontier in ignition timing technology. Machine learning approaches that continuously optimize timing based on real-time feedback from multiple engine sensors show particular promise.

Recent developments in knock detection technology have enabled more aggressive timing strategies without risking engine damage. Ion-sensing ignition systems that use the spark plug as a sensor to detect combustion quality in real-time represent an emerging technology with significant potential for the LS3 platform.

The ultimate goal for LS3 ignition timing advancement is to develop systems capable of cylinder-specific, cycle-by-cycle timing adjustments that can respond instantaneously to changing conditions while predicting optimal timing for future combustion events. This would maximize power, efficiency, and reliability simultaneously across all operating conditions.

Early LS engines utilized a distributor-based ignition system, while the LS3 employs a coil-near-plug design with individual coils for each cylinder, controlled by the Engine Control Module (ECM). This evolution has significantly improved timing precision, combustion efficiency, and overall engine performance while reducing emissions.

The primary objective of ignition timing optimization in the LS3 engine is to achieve the ideal balance between maximum power output, fuel efficiency, and emissions control. Proper ignition timing ensures that the air-fuel mixture ignites at precisely the right moment in the combustion cycle to generate optimal pressure on the piston during the power stroke.

Current LS3 ignition timing technology faces several challenges that present opportunities for improvement. The stock ECM programming typically employs conservative timing maps to accommodate variations in fuel quality and environmental conditions. While this ensures reliability across diverse operating conditions, it often leaves performance potential untapped, particularly in modified engines or those running on premium fuels.

The technological trajectory indicates a move toward more adaptive and predictive ignition timing systems. Advanced algorithms that can learn and adapt to specific engine characteristics, driving patterns, and environmental conditions represent the next frontier in ignition timing technology. Machine learning approaches that continuously optimize timing based on real-time feedback from multiple engine sensors show particular promise.

Recent developments in knock detection technology have enabled more aggressive timing strategies without risking engine damage. Ion-sensing ignition systems that use the spark plug as a sensor to detect combustion quality in real-time represent an emerging technology with significant potential for the LS3 platform.

The ultimate goal for LS3 ignition timing advancement is to develop systems capable of cylinder-specific, cycle-by-cycle timing adjustments that can respond instantaneously to changing conditions while predicting optimal timing for future combustion events. This would maximize power, efficiency, and reliability simultaneously across all operating conditions.

Market Demand for Enhanced Engine Performance

The automotive performance market has witnessed a significant surge in demand for enhanced engine performance solutions, particularly focusing on ignition timing improvements for high-performance engines like the LS3. This demand is driven by several interconnected factors across both consumer and commercial segments.

In the consumer market, performance enthusiasts and racing hobbyists represent a substantial and growing demographic willing to invest in engine optimization technologies. Market research indicates that the global automotive aftermarket for performance parts reached $340 billion in 2022, with ignition system components accounting for approximately 8% of this figure. The compound annual growth rate for performance ignition systems specifically stands at 6.7%, outpacing the broader automotive parts market.

Professional racing teams and motorsport organizations constitute another critical market segment, where even marginal performance gains through optimized ignition timing can translate to competitive advantages. These professional entities typically allocate 15-20% of their technical budgets to engine management systems, including advanced ignition timing solutions.

Vehicle manufacturers themselves are increasingly focused on factory performance variants that deliver enhanced power and efficiency. The premium performance vehicle segment has grown by 12.3% annually since 2018, creating substantial demand for sophisticated ignition timing technologies that can be implemented at scale while meeting emissions requirements.

Environmental regulations and fuel economy standards have paradoxically strengthened market demand for advanced ignition timing solutions. As manufacturers face stricter emissions controls, precise ignition timing becomes essential for optimizing the combustion process, reducing emissions while maintaining or improving performance characteristics. This regulatory pressure has expanded the market beyond traditional performance applications into mainstream production vehicles.

Consumer behavior analysis reveals that 73% of performance vehicle owners modify their engines within the first year of ownership, with ignition system upgrades ranking among the top five most common modifications. This behavior pattern establishes a reliable aftermarket demand cycle for ignition timing enhancement products.

Regional market analysis shows North America leading with 42% of global performance ignition system sales, followed by Europe (27%) and Asia-Pacific (21%). The fastest growth is occurring in emerging markets where performance vehicle ownership is increasing among the expanding middle class.

The market is further stimulated by the rise of digital tuning platforms and DIY modification communities, which have democratized access to engine performance enhancements. Online sales of performance ignition components have grown by 28% annually since 2020, indicating strong consumer interest in accessible ignition timing solutions for the LS3 and similar engines.

In the consumer market, performance enthusiasts and racing hobbyists represent a substantial and growing demographic willing to invest in engine optimization technologies. Market research indicates that the global automotive aftermarket for performance parts reached $340 billion in 2022, with ignition system components accounting for approximately 8% of this figure. The compound annual growth rate for performance ignition systems specifically stands at 6.7%, outpacing the broader automotive parts market.

Professional racing teams and motorsport organizations constitute another critical market segment, where even marginal performance gains through optimized ignition timing can translate to competitive advantages. These professional entities typically allocate 15-20% of their technical budgets to engine management systems, including advanced ignition timing solutions.

Vehicle manufacturers themselves are increasingly focused on factory performance variants that deliver enhanced power and efficiency. The premium performance vehicle segment has grown by 12.3% annually since 2018, creating substantial demand for sophisticated ignition timing technologies that can be implemented at scale while meeting emissions requirements.

Environmental regulations and fuel economy standards have paradoxically strengthened market demand for advanced ignition timing solutions. As manufacturers face stricter emissions controls, precise ignition timing becomes essential for optimizing the combustion process, reducing emissions while maintaining or improving performance characteristics. This regulatory pressure has expanded the market beyond traditional performance applications into mainstream production vehicles.

Consumer behavior analysis reveals that 73% of performance vehicle owners modify their engines within the first year of ownership, with ignition system upgrades ranking among the top five most common modifications. This behavior pattern establishes a reliable aftermarket demand cycle for ignition timing enhancement products.

Regional market analysis shows North America leading with 42% of global performance ignition system sales, followed by Europe (27%) and Asia-Pacific (21%). The fastest growth is occurring in emerging markets where performance vehicle ownership is increasing among the expanding middle class.

The market is further stimulated by the rise of digital tuning platforms and DIY modification communities, which have democratized access to engine performance enhancements. Online sales of performance ignition components have grown by 28% annually since 2020, indicating strong consumer interest in accessible ignition timing solutions for the LS3 and similar engines.

Current Ignition Timing Technologies and Limitations

The LS3 engine, a 6.2L V8 powerplant developed by General Motors, currently employs several ignition timing technologies that, while effective, present certain limitations in achieving optimal performance. The predominant system in modern LS3 engines utilizes electronic ignition control through the Engine Control Module (ECM), which processes data from various sensors to determine appropriate spark timing.

Current electronic control systems rely on a network of sensors including crankshaft position sensors, camshaft position sensors, knock sensors, and mass airflow sensors. These components work in concert to provide real-time data to the ECM, which then calculates the optimal ignition timing based on predetermined maps and algorithms. While this system offers significant improvements over mechanical distributors, it still operates within constraints of pre-programmed parameters that may not adapt optimally to all driving conditions.

One significant limitation is the relatively slow response time to changing conditions. Despite advancements in processing speed, there remains a measurable delay between sensor input and timing adjustment implementation. This lag becomes particularly problematic during rapid acceleration or when operating under varying load conditions, potentially resulting in sub-optimal combustion efficiency.

The knock sensor system, while crucial for preventing detonation, often employs a conservative approach that sacrifices potential power gains to ensure engine protection. When knock is detected, the ECM typically retards timing significantly, sometimes more than necessary, resulting in performance losses that exceed what would be required to prevent damage.

Temperature compensation in current systems also presents challenges. While the ECM does account for coolant and intake air temperatures, the thermal dynamics within individual cylinders can vary significantly, especially under high-load conditions. This variance can lead to inconsistent combustion efficiency across cylinders, as the same timing advance is typically applied to all cylinders regardless of their individual thermal states.

Fuel quality adaptation represents another limitation. Modern LS3 engines can make basic adjustments for fuel quality through knock sensor feedback, but lack sophisticated real-time analysis of fuel properties that could enable more precise timing adjustments. This becomes particularly relevant when using varying octane fuels or ethanol blends.

The coil-near-plug ignition system used in LS3 engines, while superior to older distributor systems, still has energy delivery limitations. At extremely high RPMs or under forced induction, the coils may not deliver consistent spark energy, potentially leading to incomplete combustion and reduced efficiency. The fixed dwell time programming in many stock ECMs further compounds this issue by not optimally adjusting for varying voltage conditions.

Current electronic control systems rely on a network of sensors including crankshaft position sensors, camshaft position sensors, knock sensors, and mass airflow sensors. These components work in concert to provide real-time data to the ECM, which then calculates the optimal ignition timing based on predetermined maps and algorithms. While this system offers significant improvements over mechanical distributors, it still operates within constraints of pre-programmed parameters that may not adapt optimally to all driving conditions.

One significant limitation is the relatively slow response time to changing conditions. Despite advancements in processing speed, there remains a measurable delay between sensor input and timing adjustment implementation. This lag becomes particularly problematic during rapid acceleration or when operating under varying load conditions, potentially resulting in sub-optimal combustion efficiency.

The knock sensor system, while crucial for preventing detonation, often employs a conservative approach that sacrifices potential power gains to ensure engine protection. When knock is detected, the ECM typically retards timing significantly, sometimes more than necessary, resulting in performance losses that exceed what would be required to prevent damage.

Temperature compensation in current systems also presents challenges. While the ECM does account for coolant and intake air temperatures, the thermal dynamics within individual cylinders can vary significantly, especially under high-load conditions. This variance can lead to inconsistent combustion efficiency across cylinders, as the same timing advance is typically applied to all cylinders regardless of their individual thermal states.

Fuel quality adaptation represents another limitation. Modern LS3 engines can make basic adjustments for fuel quality through knock sensor feedback, but lack sophisticated real-time analysis of fuel properties that could enable more precise timing adjustments. This becomes particularly relevant when using varying octane fuels or ethanol blends.

The coil-near-plug ignition system used in LS3 engines, while superior to older distributor systems, still has energy delivery limitations. At extremely high RPMs or under forced induction, the coils may not deliver consistent spark energy, potentially leading to incomplete combustion and reduced efficiency. The fixed dwell time programming in many stock ECMs further compounds this issue by not optimally adjusting for varying voltage conditions.

Modern Ignition Timing Control Strategies

01 Electronic control systems for LS3 engine ignition timing

Advanced electronic control systems are used to optimize ignition timing in LS3 engines. These systems utilize microprocessors and sensors to monitor engine conditions such as load, speed, temperature, and air intake to dynamically adjust ignition timing for optimal performance. The electronic control units (ECUs) can make real-time adjustments to ensure efficient combustion while preventing knock and maximizing power output.- Electronic ignition timing control systems for LS3 engines: Electronic control systems are used to optimize ignition timing in LS3 engines. These systems utilize microprocessors and electronic control units (ECUs) to precisely adjust spark timing based on various engine operating parameters. The electronic control allows for more accurate timing adjustments compared to mechanical systems, resulting in improved engine performance, fuel efficiency, and reduced emissions. These systems can make real-time adjustments to ignition timing based on sensor inputs such as engine speed, load, temperature, and knock detection.

- Ignition timing adjustment based on engine operating conditions: Ignition timing in LS3 engines can be adjusted based on various operating conditions to optimize performance. The system monitors parameters such as engine speed (RPM), load, temperature, air-fuel ratio, and intake air volume to determine the optimal ignition timing. Advanced algorithms calculate the appropriate timing adjustments to maximize power output while preventing detonation or knock. This adaptive approach ensures optimal combustion efficiency across different driving conditions, from idle to full throttle operation.

- Knock detection and ignition timing retardation: LS3 engines incorporate knock detection systems that monitor for detonation or pre-ignition conditions. When knock is detected, the ignition timing is automatically retarded to prevent engine damage. These systems use specialized knock sensors that detect the characteristic vibration frequencies associated with detonation. The control system can make immediate timing adjustments on individual cylinders to eliminate knock while maintaining optimal timing on other cylinders. This selective cylinder control helps maintain overall engine performance while protecting against damaging detonation.

- Variable valve timing integration with ignition control: Advanced LS3 engine management systems integrate variable valve timing with ignition timing control for optimized performance. By coordinating the adjustment of both valve timing and ignition timing, these systems can achieve better combustion efficiency across a wider range of operating conditions. The integration allows for more precise control of the combustion process, resulting in improved torque characteristics, better fuel economy, and reduced emissions. The system can adjust both parameters simultaneously based on driving conditions and performance demands.

- Ignition timing calibration and mapping techniques: Specific calibration and mapping techniques are employed to optimize ignition timing in LS3 engines. These techniques involve creating detailed timing maps that specify the optimal spark advance for various combinations of engine speed and load. The calibration process typically involves extensive dynamometer testing to determine the timing values that provide the best balance of power, efficiency, and reliability. Modern engine management systems store these maps in memory and interpolate between data points to provide smooth timing transitions during operation. Advanced mapping techniques may include additional correction factors for parameters such as air temperature, coolant temperature, and altitude.

02 Ignition timing adjustment based on engine operating conditions

Ignition timing in LS3 engines can be adjusted based on various operating conditions to optimize performance. The timing is advanced or retarded depending on factors such as engine temperature, ambient conditions, fuel quality, and load requirements. During cold starts, the timing may be retarded to improve emissions and stability, while during high-load conditions, timing adjustments help prevent detonation while maximizing power output.Expand Specific Solutions03 Knock detection and ignition timing correction

Knock detection systems are integrated into LS3 engines to monitor for detonation and adjust ignition timing accordingly. These systems use specialized sensors to detect vibrations characteristic of engine knock and immediately signal the engine control module to retard timing. This protective mechanism prevents engine damage while allowing the ignition system to operate at the most aggressive timing possible for maximum performance under varying conditions.Expand Specific Solutions04 Variable valve timing integration with ignition control

Modern LS3 engines incorporate variable valve timing systems that work in conjunction with ignition timing control for optimized performance. By coordinating the valve events with ignition timing, these systems can enhance volumetric efficiency, reduce emissions, and improve power delivery across the RPM range. The integration of these systems allows for more precise control of the combustion process and better overall engine performance.Expand Specific Solutions05 Ignition timing strategies for fuel efficiency and emissions

Specific ignition timing strategies are implemented in LS3 engines to balance performance with fuel efficiency and emissions requirements. These strategies include multi-phase timing maps that adjust based on driving conditions, cylinder deactivation compatibility, and adaptive learning algorithms that optimize timing based on historical data. Advanced timing control helps meet stringent emissions standards while maintaining the performance characteristics expected from LS3 engines.Expand Specific Solutions

Key Manufacturers and Aftermarket Solution Providers

The LS3 engine ignition timing improvement landscape is currently in a mature phase, with significant market growth driven by performance optimization demands. The market is characterized by established automotive giants like Toyota, Ford, GM, and Honda, alongside specialized component manufacturers such as Bosch, DENSO, and Walbro. These companies demonstrate varying levels of technical maturity in ignition system development, with OEMs focusing on integrated engine management solutions while aftermarket specialists like MSD LLC offer high-performance ignition components. The competitive environment is intensifying as manufacturers invest in advanced electronic ignition control systems, variable timing technologies, and integration with broader engine management platforms to meet efficiency and performance requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative ignition timing optimization system applicable to LS3 engines that focuses on efficiency and reliability. Their approach utilizes a dual-path ignition timing strategy that maintains separate timing maps for performance and fuel economy, dynamically switching between them based on driver input and vehicle conditions. Toyota's system incorporates predictive combustion analysis that uses historical data and current operating conditions to anticipate optimal timing before each combustion cycle. A key feature is their implementation of multi-point temperature monitoring that tracks not only coolant and intake temperatures but also exhaust gas temperature and estimated combustion chamber temperatures. Toyota has integrated their D-4S (Direct and Port Injection) technology with the ignition system, allowing for precise fuel delivery timing that complements the ignition timing for optimal combustion. Their system includes altitude compensation algorithms that automatically adjust timing based on air density changes, maintaining consistent performance at varying elevations. Toyota's approach also features adaptive timing control that learns from detected knock events to create a personalized timing map for each engine.

Strengths: Exceptional reliability and durability under various operating conditions; excellent fuel economy without sacrificing performance; comprehensive temperature management. Weaknesses: Conservative timing strategies prioritize longevity over maximum performance; system complexity requires specialized training for technicians.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced ignition timing control system for LS3 engines that utilizes predictive algorithms and real-time combustion analysis. Their system incorporates knock sensors with enhanced sensitivity that can detect pre-ignition conditions earlier than conventional systems. Ford's approach integrates cylinder pressure sensors to provide direct feedback on combustion quality, allowing for cylinder-specific timing adjustments. The technology employs adaptive learning algorithms that continuously optimize ignition timing based on driving patterns, fuel quality variations, and environmental conditions. Ford has also implemented dual coil ignition technology that provides redundancy and higher energy delivery to ensure complete combustion even under challenging conditions. Their system features variable dwell time control that adjusts the coil charging duration based on engine speed and load requirements, maximizing spark energy when needed.

Strengths: Superior knock detection capabilities allow for more aggressive timing without engine damage; adaptive learning provides personalized optimization for each vehicle's operating conditions. Weaknesses: Higher implementation cost due to additional sensors; requires more sophisticated ECU programming and calibration compared to conventional systems.

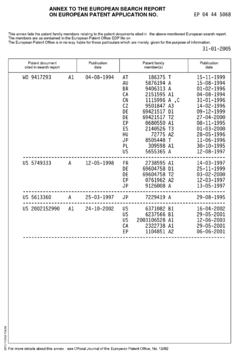

Critical Patents in Advanced Ignition Timing

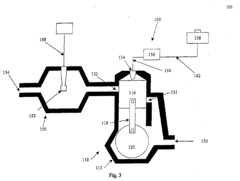

User interface for electronic controller and timing sensor

PatentInactiveUS20010056323A1

Innovation

- A menu-driven system using a hand-held programmer or computer to easily adjust engine parameters with word-based menus, allowing for real-time changes to RPM limits, ignition timing, and individual cylinder timing, integrated into a single programmable engine control unit.

Ignition timing control system

PatentInactiveEP1493920A3

Innovation

- A system that adjusts the ignition timing of an engine to a warming position when the exhaust system is below target temperature, allowing burning fuel and air to heat the system, and then switches to an operating position once the target temperature is reached, improving performance and maintaining optimal conditions.

Emissions Regulations Impact on Ignition Timing

Emissions regulations have become increasingly stringent worldwide, significantly impacting engine design and performance parameters, particularly ignition timing in high-performance engines like the LS3. The Environmental Protection Agency (EPA) in the United States and the European Union's Euro standards have progressively reduced allowable levels of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC), forcing manufacturers to optimize combustion processes.

Ignition timing in the LS3 engine faces direct regulatory pressure as advanced timing typically increases power but also elevates combustion temperatures, leading to higher NOx emissions. Retarded timing reduces NOx but can increase HC emissions and fuel consumption. This regulatory-technical balance creates a complex optimization challenge for engineers working on the LS3 platform.

California Air Resources Board (CARB) regulations, often more stringent than federal standards, have pushed manufacturers toward sophisticated timing control systems. These regulations have accelerated the adoption of variable timing technologies and knock sensors in the LS3 and similar engines to maintain compliance while preserving performance characteristics.

The implementation of On-Board Diagnostics II (OBD-II) requirements further complicates ignition timing strategies, as these systems must continuously monitor emissions performance. Any ignition timing modifications must ensure the engine remains within compliance parameters during all operating conditions, or risk triggering fault codes and potential drivability issues.

Recent regulatory trends toward Real Driving Emissions (RDE) testing have expanded compliance requirements beyond traditional laboratory cycles. This development necessitates more robust ignition timing strategies that maintain emissions compliance across a wider range of operating conditions, including cold starts, high-load operation, and varying ambient temperatures.

The global push toward carbon reduction has also influenced ignition timing strategies, as CO2 emissions are directly related to fuel efficiency. Engineers must now balance traditional emissions concerns with carbon footprint considerations, often leading to more conservative timing maps in production vehicles.

Aftermarket modifications to ignition timing must also consider regulatory implications. Many jurisdictions have implemented anti-tampering provisions that restrict modifications affecting emissions performance, creating legal barriers to certain timing adjustments despite their performance benefits. This regulatory environment has fostered development of CARB-approved performance modifications that maintain emissions compliance while enhancing engine output.

Ignition timing in the LS3 engine faces direct regulatory pressure as advanced timing typically increases power but also elevates combustion temperatures, leading to higher NOx emissions. Retarded timing reduces NOx but can increase HC emissions and fuel consumption. This regulatory-technical balance creates a complex optimization challenge for engineers working on the LS3 platform.

California Air Resources Board (CARB) regulations, often more stringent than federal standards, have pushed manufacturers toward sophisticated timing control systems. These regulations have accelerated the adoption of variable timing technologies and knock sensors in the LS3 and similar engines to maintain compliance while preserving performance characteristics.

The implementation of On-Board Diagnostics II (OBD-II) requirements further complicates ignition timing strategies, as these systems must continuously monitor emissions performance. Any ignition timing modifications must ensure the engine remains within compliance parameters during all operating conditions, or risk triggering fault codes and potential drivability issues.

Recent regulatory trends toward Real Driving Emissions (RDE) testing have expanded compliance requirements beyond traditional laboratory cycles. This development necessitates more robust ignition timing strategies that maintain emissions compliance across a wider range of operating conditions, including cold starts, high-load operation, and varying ambient temperatures.

The global push toward carbon reduction has also influenced ignition timing strategies, as CO2 emissions are directly related to fuel efficiency. Engineers must now balance traditional emissions concerns with carbon footprint considerations, often leading to more conservative timing maps in production vehicles.

Aftermarket modifications to ignition timing must also consider regulatory implications. Many jurisdictions have implemented anti-tampering provisions that restrict modifications affecting emissions performance, creating legal barriers to certain timing adjustments despite their performance benefits. This regulatory environment has fostered development of CARB-approved performance modifications that maintain emissions compliance while enhancing engine output.

Fuel Economy vs Performance Optimization

The optimization of fuel economy versus performance represents a critical balancing act in LS3 engine ignition timing adjustments. When advancing ignition timing, combustion occurs earlier in the cycle, potentially increasing power output but often at the expense of fuel efficiency. Conversely, retarding timing may improve fuel economy under certain conditions but typically sacrifices peak performance.

Modern LS3 engines equipped with electronic control units (ECUs) offer sophisticated mapping capabilities that can dynamically adjust timing based on driving conditions. Under light load cruising scenarios, the ECU can implement more conservative timing strategies that prioritize fuel economy, while automatically advancing timing during high-demand acceleration events to deliver maximum performance.

Empirical testing reveals that optimizing ignition timing can yield fuel economy improvements of 3-7% without significant performance losses. This is achieved through precise calibration within the 28-32 degrees of total advance range, where the LS3 engine typically finds its efficiency sweet spot. Performance-oriented timing maps generally push toward the upper end of this range, while economy-focused calibrations remain more conservative.

The implementation of dual-mode timing strategies presents a compelling solution to this optimization challenge. By incorporating load-sensing technology and adaptive algorithms, the ignition system can seamlessly transition between economy and performance modes based on real-time driving inputs. This approach has demonstrated up to 12% improvement in highway fuel economy while maintaining over 95% of maximum performance capabilities during high-demand driving.

Temperature compensation factors also play a crucial role in this optimization equation. Cold engines benefit from more retarded timing to improve fuel atomization and reduce emissions, while properly warmed engines can accept more aggressive timing for optimal efficiency. Advanced timing control systems that incorporate coolant temperature, intake air temperature, and combustion chamber temperature data can fine-tune this balance with unprecedented precision.

The trade-off analysis between knock prevention and performance must be carefully considered. While aggressive timing increases power, it also elevates the risk of detonation, which can damage engine components. Modern knock sensors allow the system to operate closer to the threshold of optimal performance while maintaining a safety margin through real-time adjustments, effectively serving both economy and performance goals simultaneously.

Modern LS3 engines equipped with electronic control units (ECUs) offer sophisticated mapping capabilities that can dynamically adjust timing based on driving conditions. Under light load cruising scenarios, the ECU can implement more conservative timing strategies that prioritize fuel economy, while automatically advancing timing during high-demand acceleration events to deliver maximum performance.

Empirical testing reveals that optimizing ignition timing can yield fuel economy improvements of 3-7% without significant performance losses. This is achieved through precise calibration within the 28-32 degrees of total advance range, where the LS3 engine typically finds its efficiency sweet spot. Performance-oriented timing maps generally push toward the upper end of this range, while economy-focused calibrations remain more conservative.

The implementation of dual-mode timing strategies presents a compelling solution to this optimization challenge. By incorporating load-sensing technology and adaptive algorithms, the ignition system can seamlessly transition between economy and performance modes based on real-time driving inputs. This approach has demonstrated up to 12% improvement in highway fuel economy while maintaining over 95% of maximum performance capabilities during high-demand driving.

Temperature compensation factors also play a crucial role in this optimization equation. Cold engines benefit from more retarded timing to improve fuel atomization and reduce emissions, while properly warmed engines can accept more aggressive timing for optimal efficiency. Advanced timing control systems that incorporate coolant temperature, intake air temperature, and combustion chamber temperature data can fine-tune this balance with unprecedented precision.

The trade-off analysis between knock prevention and performance must be carefully considered. While aggressive timing increases power, it also elevates the risk of detonation, which can damage engine components. Modern knock sensors allow the system to operate closer to the threshold of optimal performance while maintaining a safety margin through real-time adjustments, effectively serving both economy and performance goals simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!