LS3 Engine Power Enhancements: Turbo vs Supercharger

LS3 Engine Evolution and Enhancement Objectives

The LS3 engine, introduced by General Motors in 2008, represents a significant evolution in the LS engine family that began with the LS1 in 1997. This 6.2L V8 aluminum block engine was designed as a high-performance powerplant, initially producing 430 horsepower and 424 lb-ft of torque in its stock configuration. The development trajectory of the LS3 has been characterized by continuous refinements in combustion efficiency, materials technology, and power delivery systems.

The evolution of the LS3 engine has been driven by advancements in several key areas. First, the implementation of rectangular port cylinder heads with straighter intake runners allowed for improved airflow compared to its predecessors. Second, the incorporation of higher-flow injectors and an enhanced fuel delivery system enabled more precise fuel management. Third, the adoption of a higher-lift camshaft profile contributed to increased volumetric efficiency across a broader RPM range.

Current enhancement objectives for the LS3 platform center primarily on increasing power output while maintaining reliability and drivability. The stock LS3 architecture provides an excellent foundation for power enhancement, with its robust bottom end, efficient cooling system, and responsive electronic control unit. However, achieving significant power gains beyond the factory specifications requires forced induction solutions, with turbocharging and supercharging representing the two primary approaches.

The technical goals for LS3 power enhancement typically include increasing horsepower and torque across the entire RPM range, minimizing throttle response lag, ensuring thermal stability under high-load conditions, and maintaining emissions compliance where required. Additionally, modern enhancement objectives often include considerations for fuel efficiency and compatibility with alternative fuels.

Market trends indicate growing interest in bolt-on power enhancement solutions that can be implemented without extensive engine modifications. This has driven development toward more sophisticated plug-and-play forced induction systems specifically engineered for the LS3 platform. The aftermarket has responded with increasingly refined turbocharger and supercharger kits that address installation complexity and tuning requirements.

Looking forward, the technical trajectory for LS3 enhancement is likely to incorporate more advanced electronic control strategies, materials science innovations for heat management, and hybrid forced induction approaches that combine the benefits of both turbocharging and supercharging. The continued refinement of variable geometry turbochargers and electronically controlled superchargers represents promising avenues for future development in this space.

Market Demand Analysis for High-Performance V8 Engines

The high-performance V8 engine market has experienced significant growth over the past decade, driven by increasing consumer demand for powerful vehicles that deliver exhilarating driving experiences. The LS3 engine, a 6.2L V8 powerplant developed by General Motors, has become particularly popular among performance enthusiasts seeking substantial horsepower and torque improvements through aftermarket modifications.

Market research indicates that the global high-performance engine market was valued at approximately $27 billion in 2022, with V8 engines representing nearly 35% of this segment. Annual growth rates have consistently remained between 5-7%, outpacing the broader automotive market. This trend is projected to continue despite increasing environmental regulations and the rise of electric vehicles.

Consumer demographics reveal that high-performance V8 engine buyers typically fall into three distinct categories: traditional muscle car enthusiasts (predominantly male, aged 35-60), younger performance-oriented drivers (25-40), and professional motorsport participants. These segments demonstrate different priorities regarding power enhancement methods, with the first group often preferring superchargers for their heritage appeal, while younger enthusiasts frequently opt for turbochargers due to their tuning flexibility.

Regional analysis shows North America dominating the market with 45% share, followed by Europe (25%) and Asia-Pacific (20%). The American market particularly values the LS3 platform due to its widespread availability, robust aftermarket support, and excellent response to forced induction modifications.

Industry surveys indicate that approximately 65% of LS3 engine owners consider power enhancement modifications within the first two years of ownership. Among these consumers, 72% express interest in forced induction options, with the market split relatively evenly between turbocharger and supercharger preferences.

Price sensitivity analysis reveals that consumers are willing to invest between $4,000-$12,000 for quality forced induction systems, depending on power gains and installation complexity. This represents a significant aftermarket opportunity, with complete turbocharger or supercharger kits for the LS3 typically retailing between $5,500-$8,500.

The market is further influenced by social media and online communities, where performance metrics and installation experiences are widely shared. YouTube videos featuring LS3 power enhancement installations regularly achieve millions of views, indicating substantial interest in these modifications and creating a self-reinforcing market demand cycle.

Current Forced Induction Technologies and Limitations

The LS3 engine, a 6.2L V8 powerplant developed by General Motors, offers substantial performance potential through forced induction. Currently, two primary technologies dominate the forced induction landscape for this platform: turbocharging and supercharging. Each presents distinct advantages and limitations that must be carefully considered when planning power enhancement strategies.

Turbocharging systems for the LS3 utilize exhaust gas energy to drive a turbine, which in turn compresses intake air. Single turbo setups typically offer cost advantages and simplified installation, while twin-turbo configurations provide improved throttle response and potentially higher power ceilings. The primary limitation of turbocharging is turbo lag—the delay between throttle input and boost delivery—though modern designs with ball-bearing turbos and optimized wastegate systems have significantly reduced this effect.

Supercharging technology, by contrast, provides immediate boost response as it draws power directly from the engine's crankshaft. Centrifugal superchargers operate similarly to turbos but with mechanical drive, offering progressive power delivery that increases with engine RPM. Roots and twin-screw superchargers deliver more immediate low-end torque but may create greater parasitic drag on the engine. The primary limitation of superchargers is their inherent efficiency deficit, as they consume engine power to generate boost.

Heat management represents a critical limitation for both technologies. Compressed air generates substantial heat, reducing air density and increasing the risk of detonation. Intercooling systems are therefore essential components, with air-to-air intercoolers being common for turbo applications while air-to-water heat exchangers are frequently employed with superchargers due to packaging constraints.

Current installation limitations also merit consideration. Turbocharging the LS3 often requires significant exhaust system modifications and may present packaging challenges in stock engine bays. Supercharger systems typically offer more straightforward installation but may require hood modifications to accommodate their height.

Fuel system limitations become apparent as boost levels increase. The stock LS3 fuel system typically supports approximately 500-550 wheel horsepower before requiring upgrades to injectors, fuel pumps, and pressure regulators. Additionally, the factory engine management system presents calibration limitations that necessitate aftermarket solutions for optimal performance and reliability.

Durability concerns emerge as a significant limitation at higher power levels. The stock LS3 connecting rods become a potential failure point beyond approximately 650-700 horsepower, while piston and ring durability may be compromised under sustained high-boost operation. These mechanical limitations often necessitate internal engine modifications to support advanced forced induction applications.

Turbocharger vs Supercharger Implementation Solutions

01 LS3 Engine Power Output and Performance Characteristics

The LS3 engine is known for its high power output and performance characteristics. It features advanced design elements that contribute to its power generation capabilities, including optimized combustion chambers, efficient fuel delivery systems, and enhanced airflow. These features collectively enable the LS3 engine to deliver substantial horsepower and torque, making it suitable for high-performance applications in various vehicles.- LS3 Engine Power Output and Performance Specifications: The LS3 engine is known for its high power output capabilities, typically producing between 420-430 horsepower in stock form. This small-block V8 engine features a 6.2L displacement and is designed to deliver optimal performance across various applications. The engine's power characteristics include strong torque production throughout the RPM range, making it suitable for performance vehicles and specialized applications requiring significant power output.

- Power Enhancement Modifications for LS3 Engines: Various modifications can be implemented to increase the power output of LS3 engines beyond factory specifications. These include aftermarket camshaft installations, cylinder head modifications, intake manifold upgrades, and exhaust system improvements. Advanced tuning of the engine control unit (ECU) allows for optimized fuel delivery and ignition timing to maximize power gains from these modifications. Performance packages can increase output to over 500 horsepower while maintaining reliability.

- LS3 Engine Power Management Systems: Power management systems for LS3 engines incorporate advanced electronic controls to optimize performance under various operating conditions. These systems monitor and adjust parameters such as air-fuel ratios, ignition timing, and valve timing to balance power output with efficiency and emissions. Variable valve timing and cylinder deactivation technologies can be employed to enhance power delivery while improving fuel economy when full power is not required.

- LS3 Engine Power Integration in Vehicle Systems: The integration of LS3 engines into vehicle systems requires specialized mounting, cooling, and transmission interfaces to effectively harness the engine's power. Powertrain control modules are calibrated specifically for the LS3's performance characteristics to ensure optimal power delivery across the operating range. Driveline components must be engineered to handle the engine's torque output, while cooling systems need to manage the thermal load generated during high-power operation.

- Alternative Applications of LS3 Engine Power: Beyond traditional automotive applications, LS3 engines are utilized in various alternative settings where their power characteristics provide advantages. These include marine propulsion systems, industrial power generation, specialized equipment, and performance motorsport applications. The engine's power density and reliability make it suitable for these diverse applications, with specific modifications implemented to optimize performance for each use case.

02 Power Management and Control Systems for LS3 Engines

Advanced power management and control systems are implemented in LS3 engines to optimize performance and efficiency. These systems include electronic control units (ECUs) that regulate fuel injection, ignition timing, and air-fuel ratios. Additionally, sensors throughout the engine monitor operating conditions to adjust parameters in real-time, ensuring optimal power delivery while maintaining reliability and fuel efficiency under various operating conditions.Expand Specific Solutions03 LS3 Engine Power Enhancement Modifications

Various modifications can be implemented to enhance the power output of LS3 engines. These include aftermarket components such as high-flow intake systems, performance exhaust manifolds, upgraded camshafts, and forced induction systems like superchargers or turbochargers. Additionally, engine tuning and calibration adjustments can optimize the air-fuel mixture and ignition timing to extract maximum power while maintaining engine reliability.Expand Specific Solutions04 Cooling and Thermal Management for LS3 Engine Power

Effective cooling and thermal management systems are crucial for maintaining optimal LS3 engine power output. These systems include advanced radiator designs, high-efficiency water pumps, oil coolers, and precision-controlled cooling fans. Proper thermal management prevents power loss due to heat-related issues and ensures consistent performance during extended high-output operation, while also contributing to the overall longevity and reliability of the engine.Expand Specific Solutions05 Integration of LS3 Engines in Vehicle Powertrain Systems

The integration of LS3 engines into vehicle powertrain systems involves specialized components and configurations to effectively harness and transmit the engine's power. This includes robust transmission systems, optimized gear ratios, advanced driveline components, and electronic integration with vehicle systems. The powertrain integration is designed to maximize power delivery to the wheels while maintaining drivability, reliability, and compliance with emissions standards across various vehicle applications.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers Analysis

The LS3 engine power enhancement market is in a mature growth phase, with turbocharging and supercharging technologies representing established but evolving solutions. The market size continues to expand as performance enthusiasts seek greater power from GM's popular V8 platform. Technologically, major players demonstrate varying approaches: Ford Global Technologies and GM Global Technology Operations lead with comprehensive factory solutions, while specialized firms like HKS, SuperTurbo Technologies, and Bostic Motors offer aftermarket innovations. Traditional automotive manufacturers (Toyota, Hyundai, BYD) incorporate these technologies into their performance lines, while component specialists like Eaton and Denso focus on system optimization. Academic institutions such as South China University of Technology and University of Michigan contribute research advancing both technologies' efficiency and reliability.

Ford Global Technologies LLC

Eaton Corp.

Key Patents and Innovations in Forced Induction Systems

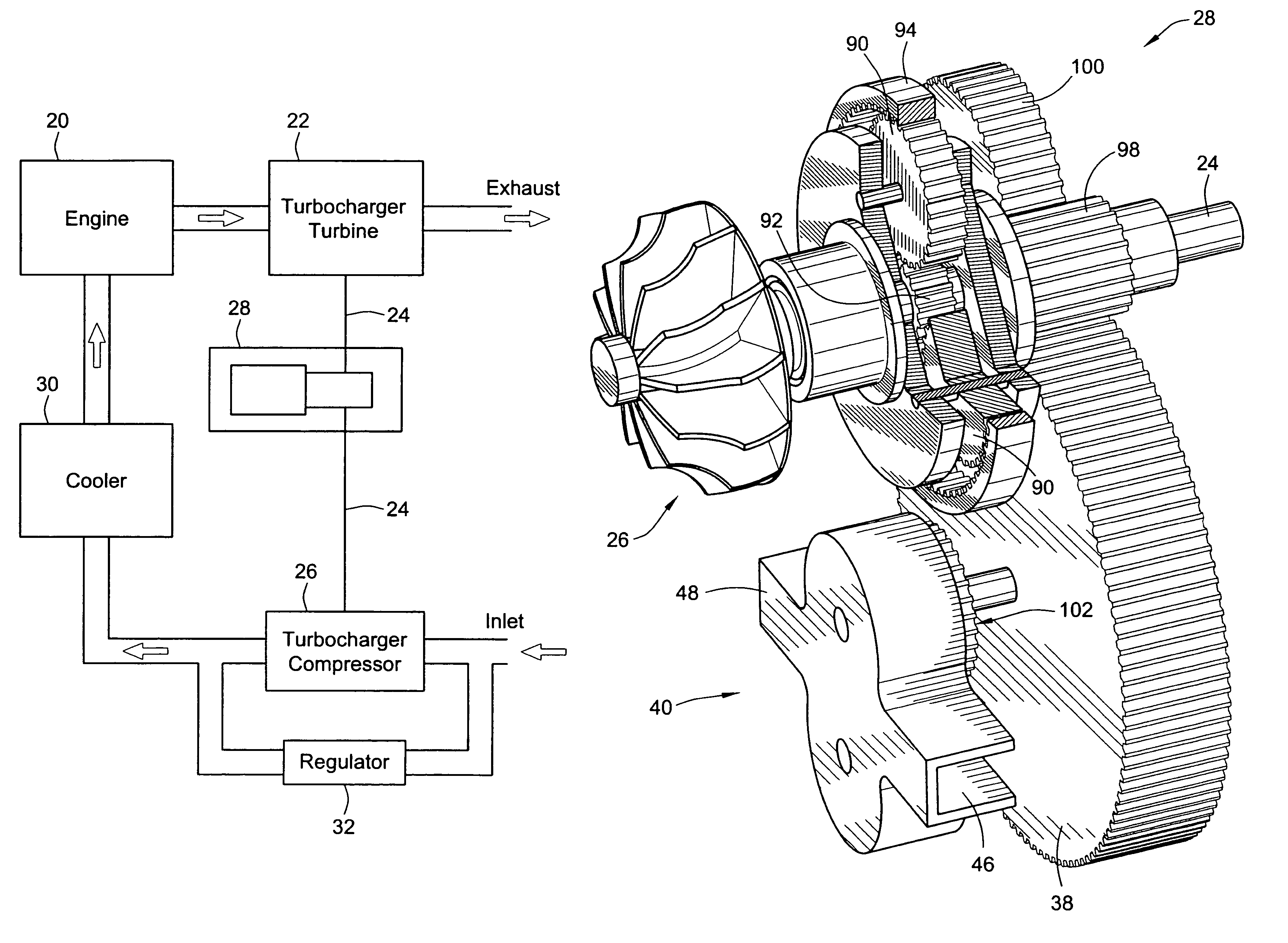

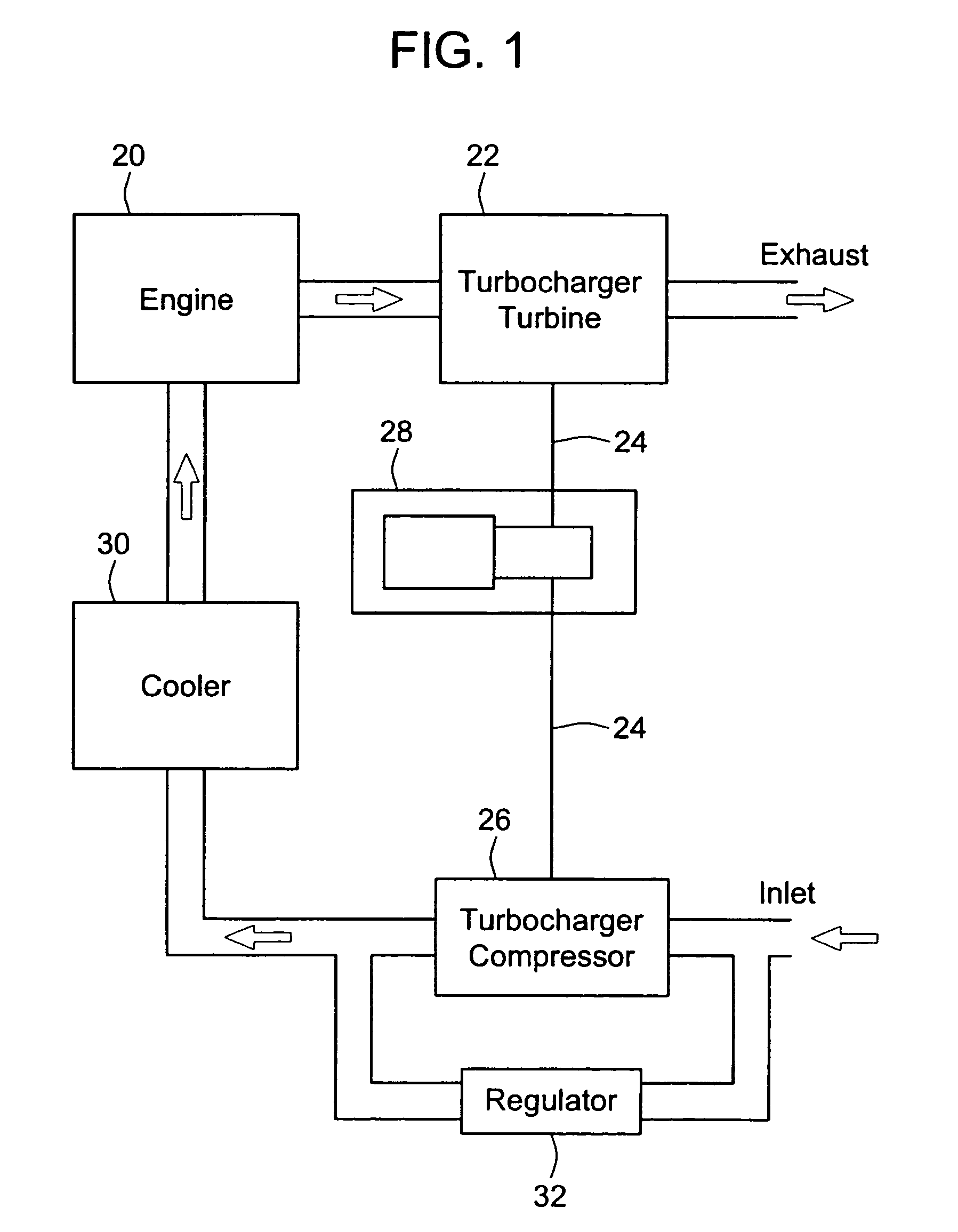

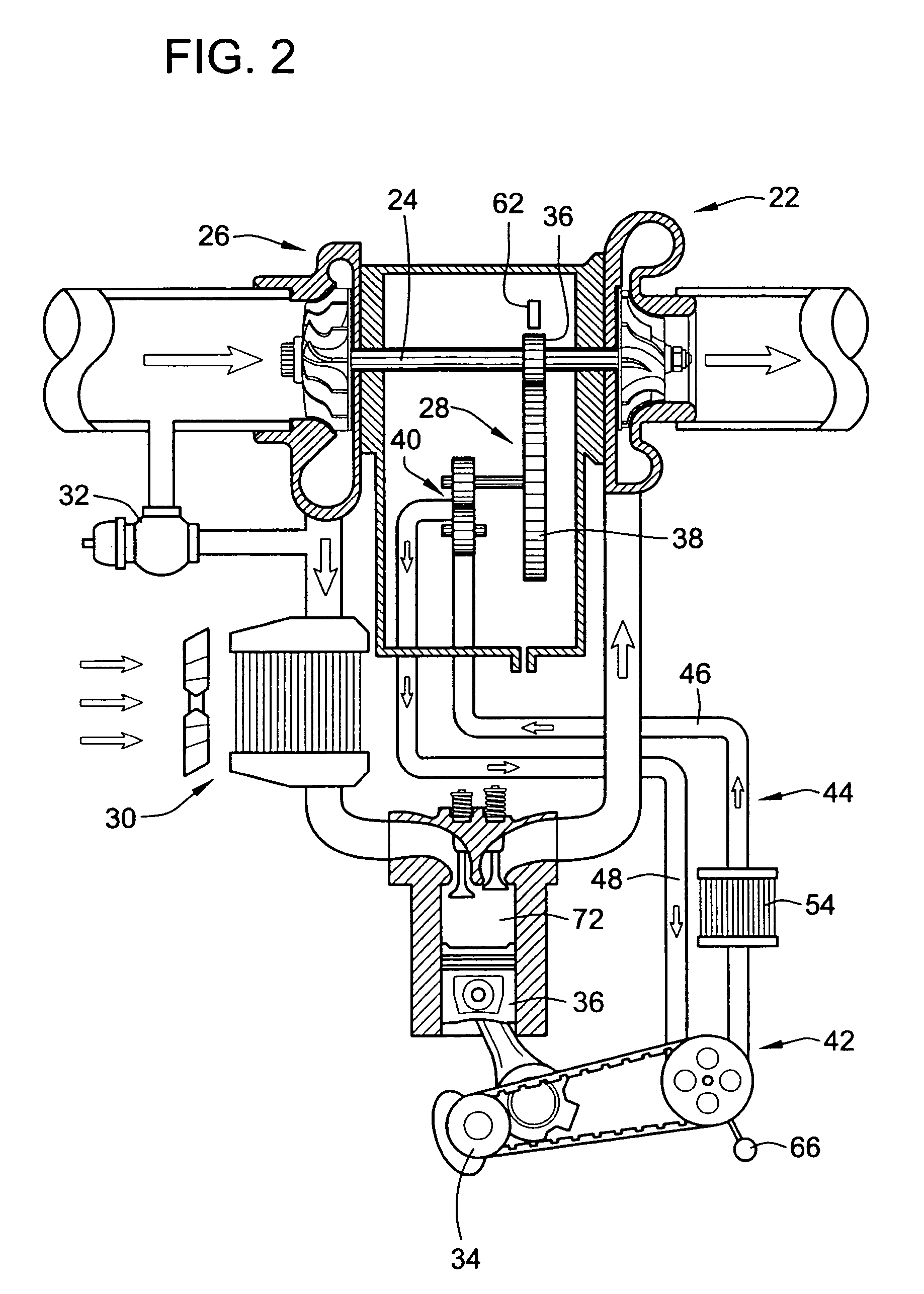

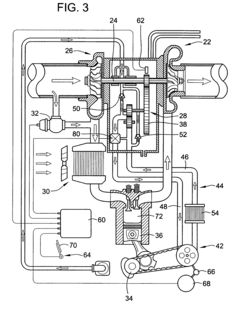

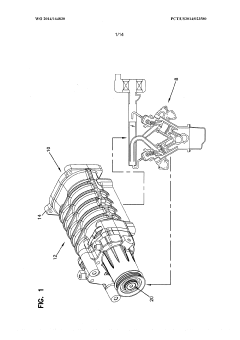

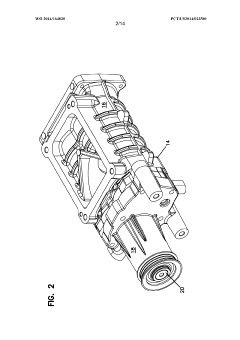

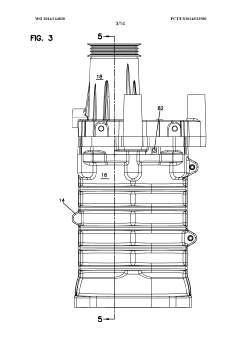

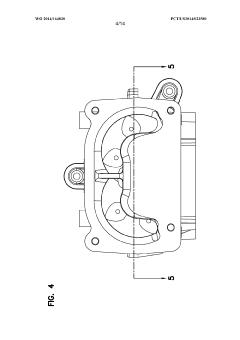

- A super-turbocharger system that combines a turbocharger and a supercharger using a hydraulic pump to drive the turbocharger to specific speeds, recovering excess energy by diverting it to the crankshaft, eliminating the need for wastegates and enhancing efficiency through a planetary gear system and variable displacement hydraulic pump.

- A supercharger configuration that effectively seals the rotor cavity from the drive assembly cavity, utilizing a ring seal arrangement and air vent system to minimize air leakage and maintain low pressure on oil seals, directing excess air back into the engine intake system to maintain fuel efficiency and performance.

Emissions Compliance Strategies for Modified LS3 Engines

Emissions compliance represents a critical challenge for LS3 engine modifications, particularly when implementing power enhancement technologies like turbochargers or superchargers. These forced induction systems significantly alter the combustion characteristics and emissions profile of the engine, necessitating comprehensive strategies to maintain regulatory compliance.

The primary emissions concerns for modified LS3 engines include increased nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (HC), and particulate matter. Turbochargers typically generate higher exhaust gas temperatures than superchargers, potentially exacerbating NOx formation. Conversely, superchargers may contribute to increased HC emissions due to their impact on air-fuel mixture distribution.

Advanced catalytic converter systems specifically designed for forced induction applications offer a primary solution pathway. High-flow catalytic converters with increased precious metal loading can effectively manage the elevated exhaust temperatures and flow rates associated with turbocharged and supercharged LS3 engines. Dual-stage catalytic systems have demonstrated particular efficacy, with the first stage optimized for high-temperature operation and the second for emissions reduction efficiency.

Electronic engine management recalibration represents another crucial compliance strategy. Modern programmable engine control units (ECUs) enable precise tuning of fuel delivery, ignition timing, and boost control to optimize both performance and emissions. Closed-loop wideband oxygen sensor systems provide real-time feedback for maintaining ideal air-fuel ratios across various operating conditions, significantly reducing emissions during both steady-state and transient operation.

Exhaust gas recirculation (EGR) systems, when properly integrated with forced induction, can substantially reduce NOx emissions by lowering combustion temperatures. Water-methanol injection systems serve a dual purpose by both reducing intake temperatures and suppressing detonation, allowing for more aggressive timing without increasing emissions.

For vehicles in regions with particularly stringent emissions requirements, selective catalytic reduction (SCR) technology using diesel exhaust fluid (DEF) has been successfully adapted to high-performance gasoline applications. This approach has demonstrated NOx reduction capabilities exceeding 90% in some modified LS3 implementations.

Compliance testing protocols must evolve beyond standard dynamometer testing to include real-world driving cycles that capture the full operational envelope of modified engines. Portable emissions measurement systems (PEMS) enable comprehensive data collection across various driving conditions, providing valuable insights for further refinement of emissions control strategies.

Cost-Benefit Analysis of Turbo vs Supercharger Systems

When evaluating power enhancement options for the LS3 engine, a comprehensive cost-benefit analysis reveals significant differences between turbocharger and supercharger systems. Initial investment for turbocharger systems typically ranges from $4,000 to $7,000 for quality components, while supercharger kits generally cost between $3,500 and $6,000, making superchargers slightly more affordable at the outset.

Installation complexity factors heavily into total implementation costs. Turbocharger systems require extensive exhaust system modifications, intercooler placement, and oil line connections, often necessitating 15-20 hours of professional labor. Supercharger installations are comparatively straightforward, typically requiring 8-12 hours of labor, resulting in lower installation costs by approximately 30-40%.

Long-term operational economics favor turbochargers in certain scenarios. While superchargers continuously draw engine power (approximately 15-20% parasitic loss), turbochargers utilize otherwise wasted exhaust energy. At sustained high speeds or during highway cruising, turbocharged LS3 engines can demonstrate 5-10% better fuel efficiency than their supercharged counterparts.

Maintenance considerations reveal another cost dimension. Turbochargers operate in extreme heat environments, with bearings and seals typically requiring replacement every 75,000-100,000 miles at costs ranging from $800-$1,500. Superchargers generally require less frequent maintenance, with rebuild intervals of 100,000+ miles at lower average service costs of $500-$1,000.

Performance benefits must be weighed against these costs. Superchargers deliver immediate power enhancement with linear power delivery, ideal for street applications and drag racing. Turbochargers provide potentially higher maximum power outputs but with characteristic lag, making them better suited for high-speed applications where maintaining boost is possible.

Resale value considerations favor supercharged vehicles, which typically retain 60-70% of the modification investment when selling, compared to 40-55% for turbocharged vehicles, due to perceived reliability and simpler installation reversal.

The final cost-benefit equation depends heavily on intended use. For daily drivers seeking reliable, immediate power gains with minimal maintenance concerns, superchargers offer better overall value despite higher operational costs. For high-performance applications where maximum power potential and efficiency at sustained high speeds are priorities, turbochargers present a more favorable long-term investment despite higher initial complexity and maintenance requirements.