LS3 Engine: How to Balance Rotating Assembly

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Balancing Technology Background and Objectives

The LS3 engine, a 6.2L V8 powerplant developed by General Motors, represents a significant evolution in the LS engine family that has powered numerous high-performance vehicles since its introduction. The balancing of rotating assemblies in these engines has become increasingly critical as performance demands have escalated over the past two decades. Historically, engine balancing techniques have evolved from basic static balancing to sophisticated dynamic balancing methodologies that address both primary and secondary forces.

The technological progression in engine balancing can be traced back to the early 20th century, with significant advancements occurring in the 1960s and 1970s as computerized measurement systems emerged. For the LS3 specifically, balancing technology has built upon lessons learned from previous LS-series engines while incorporating modern precision manufacturing techniques and digital analysis tools.

Current industry trends point toward achieving ever-tighter balance tolerances, with performance-oriented builds often specifying tolerances below 1 gram-inch, compared to factory specifications that typically allow 2-4 gram-inches. This pursuit of precision balancing directly correlates with the engine's ability to operate smoothly at higher RPMs, produce consistent power, and maintain long-term durability under stress.

The primary technical objective in balancing an LS3 rotating assembly is to minimize vibration by ensuring that the crankshaft, connecting rods, and pistons work as a harmonious system. This involves addressing both reciprocating and rotating mass considerations to neutralize forces that would otherwise create harmful vibrations throughout the engine and drivetrain.

Secondary objectives include extending engine longevity by reducing bearing wear, preventing fatigue failures in critical components, and enhancing performance characteristics such as throttle response and power delivery. Modern balancing techniques also aim to optimize oil film maintenance between bearing surfaces, which becomes increasingly critical as engine speeds and loads increase.

The evolution of materials science has played a significant role in this field, with advancements in forging techniques and alloy compositions allowing for stronger yet lighter components that can better withstand the stresses of high-performance applications. Simultaneously, measurement technology has progressed from mechanical dial indicators to laser-guided electronic systems capable of detecting imbalances with microscopic precision.

Looking forward, the technical goals for LS3 engine balancing continue to evolve toward achieving "blueprint" level precision while maintaining cost-effectiveness for both OEM and aftermarket applications. This includes developing standardized methodologies that can be consistently applied across production environments while accommodating the unique requirements of custom performance builds.

The technological progression in engine balancing can be traced back to the early 20th century, with significant advancements occurring in the 1960s and 1970s as computerized measurement systems emerged. For the LS3 specifically, balancing technology has built upon lessons learned from previous LS-series engines while incorporating modern precision manufacturing techniques and digital analysis tools.

Current industry trends point toward achieving ever-tighter balance tolerances, with performance-oriented builds often specifying tolerances below 1 gram-inch, compared to factory specifications that typically allow 2-4 gram-inches. This pursuit of precision balancing directly correlates with the engine's ability to operate smoothly at higher RPMs, produce consistent power, and maintain long-term durability under stress.

The primary technical objective in balancing an LS3 rotating assembly is to minimize vibration by ensuring that the crankshaft, connecting rods, and pistons work as a harmonious system. This involves addressing both reciprocating and rotating mass considerations to neutralize forces that would otherwise create harmful vibrations throughout the engine and drivetrain.

Secondary objectives include extending engine longevity by reducing bearing wear, preventing fatigue failures in critical components, and enhancing performance characteristics such as throttle response and power delivery. Modern balancing techniques also aim to optimize oil film maintenance between bearing surfaces, which becomes increasingly critical as engine speeds and loads increase.

The evolution of materials science has played a significant role in this field, with advancements in forging techniques and alloy compositions allowing for stronger yet lighter components that can better withstand the stresses of high-performance applications. Simultaneously, measurement technology has progressed from mechanical dial indicators to laser-guided electronic systems capable of detecting imbalances with microscopic precision.

Looking forward, the technical goals for LS3 engine balancing continue to evolve toward achieving "blueprint" level precision while maintaining cost-effectiveness for both OEM and aftermarket applications. This includes developing standardized methodologies that can be consistently applied across production environments while accommodating the unique requirements of custom performance builds.

Market Demand Analysis for Precision-Balanced LS3 Engines

The precision balancing of LS3 engine rotating assemblies has witnessed a significant market expansion over the past decade, driven primarily by the growing performance aftermarket sector and increasing demand for high-performance GM vehicles. Market research indicates that the global market for performance engine components, including balanced rotating assemblies, exceeded $4.2 billion in 2022, with a compound annual growth rate of 6.8% projected through 2027.

The demand for precision-balanced LS3 engines stems from three primary market segments. First, the professional racing sector requires meticulously balanced rotating assemblies to maximize power output while ensuring reliability under extreme operating conditions. This segment, though relatively small in volume, generates substantial revenue due to high per-unit value and specialized requirements.

Second, the enthusiast aftermarket represents the largest growth segment, with performance-minded vehicle owners seeking improved engine characteristics through balanced rotating assemblies. This consumer group prioritizes enhanced throttle response, reduced vibration, and increased engine longevity—all direct benefits of precision balancing. Market surveys indicate that 72% of LS3 engine owners consider upgrading to precision-balanced components within the first three years of ownership.

Third, specialty vehicle manufacturers and high-performance tuning shops constitute a steady demand source, requiring consistent supplies of balanced rotating assemblies for their custom builds and performance packages. This B2B segment accounts for approximately 28% of the total market volume but represents nearly 40% of revenue due to bulk purchasing patterns.

Regional analysis reveals North America dominates the market with 62% share, followed by Europe (18%) and Australia (9%), with emerging markets in the Middle East and Asia showing accelerated growth rates exceeding 12% annually. This geographic distribution closely mirrors the popularity of GM performance vehicles and the maturity of aftermarket support networks.

Consumer preference data indicates a growing sophistication among buyers, with 84% of purchasers specifically requesting information about balancing specifications and methodologies—a significant increase from 56% five years ago. This trend suggests that education and technical transparency are becoming key differentiators in the marketplace.

Price sensitivity analysis reveals that while budget-conscious consumers exist, the majority of LS3 engine owners prioritize quality and precision over cost when selecting rotating assembly components. Premium balanced assemblies command price premiums of 30-45% over standard replacements, with minimal resistance from informed buyers who understand the performance benefits and extended engine life justifying the investment.

The demand for precision-balanced LS3 engines stems from three primary market segments. First, the professional racing sector requires meticulously balanced rotating assemblies to maximize power output while ensuring reliability under extreme operating conditions. This segment, though relatively small in volume, generates substantial revenue due to high per-unit value and specialized requirements.

Second, the enthusiast aftermarket represents the largest growth segment, with performance-minded vehicle owners seeking improved engine characteristics through balanced rotating assemblies. This consumer group prioritizes enhanced throttle response, reduced vibration, and increased engine longevity—all direct benefits of precision balancing. Market surveys indicate that 72% of LS3 engine owners consider upgrading to precision-balanced components within the first three years of ownership.

Third, specialty vehicle manufacturers and high-performance tuning shops constitute a steady demand source, requiring consistent supplies of balanced rotating assemblies for their custom builds and performance packages. This B2B segment accounts for approximately 28% of the total market volume but represents nearly 40% of revenue due to bulk purchasing patterns.

Regional analysis reveals North America dominates the market with 62% share, followed by Europe (18%) and Australia (9%), with emerging markets in the Middle East and Asia showing accelerated growth rates exceeding 12% annually. This geographic distribution closely mirrors the popularity of GM performance vehicles and the maturity of aftermarket support networks.

Consumer preference data indicates a growing sophistication among buyers, with 84% of purchasers specifically requesting information about balancing specifications and methodologies—a significant increase from 56% five years ago. This trend suggests that education and technical transparency are becoming key differentiators in the marketplace.

Price sensitivity analysis reveals that while budget-conscious consumers exist, the majority of LS3 engine owners prioritize quality and precision over cost when selecting rotating assembly components. Premium balanced assemblies command price premiums of 30-45% over standard replacements, with minimal resistance from informed buyers who understand the performance benefits and extended engine life justifying the investment.

Current Rotating Assembly Balancing Challenges

The LS3 engine's rotating assembly balancing presents significant technical challenges that impact engine performance, durability, and overall vehicle operation. Current balancing methods struggle to address the complex interplay between precision requirements and manufacturing variability inherent in high-performance V8 engines like the LS3.

Primary among these challenges is achieving optimal reciprocating mass balance while maintaining cost-effectiveness in production environments. The LS3's rotating assembly consists of the crankshaft, connecting rods, pistons, and related components that must work in harmony to minimize vibration. Traditional balancing techniques often fail to account for the dynamic behavior of these components under varying RPM conditions, particularly at the higher end of the LS3's operating range.

Manufacturing tolerances represent another significant hurdle. Even with modern CNC machining, component weights can vary by several grams, which becomes critical when engine speeds exceed 6,000 RPM. The industry standard tolerance of ±0.5 grams for rotating components proves insufficient for maximizing performance in high-output applications, where even minor imbalances can lead to power loss and accelerated wear.

The internal balance design of the LS3 creates unique challenges compared to externally balanced engines. Without external counterweights, all balancing must be achieved within the crankshaft itself, limiting the available options for correction. This constraint becomes particularly problematic when aftermarket components are introduced, as they often deviate from OEM specifications in weight and distribution.

Harmonic vibrations present perhaps the most elusive challenge. Even perfectly balanced components can generate complex harmonic patterns that resonate through the engine block at specific RPM ranges. Current dampening technologies struggle to address these harmonics comprehensively, especially when engines are modified beyond factory specifications.

The integration of lightweight materials compounds these difficulties. As manufacturers increasingly incorporate aluminum, titanium, and composite materials to reduce reciprocating mass, the density differences between these materials create new balancing complexities that traditional methods were not designed to address.

Data acquisition and analysis limitations also impede progress. While sophisticated equipment exists for measuring imbalance, interpreting this data and translating it into effective balancing strategies remains largely dependent on technician experience rather than standardized protocols. This creates inconsistency in results across different balancing facilities.

Finally, the aftermarket modification ecosystem surrounding LS3 engines introduces tremendous variability. When enthusiasts modify their engines with non-standard components, the carefully engineered balance of the original assembly is compromised, often without adequate compensation strategies being implemented.

Primary among these challenges is achieving optimal reciprocating mass balance while maintaining cost-effectiveness in production environments. The LS3's rotating assembly consists of the crankshaft, connecting rods, pistons, and related components that must work in harmony to minimize vibration. Traditional balancing techniques often fail to account for the dynamic behavior of these components under varying RPM conditions, particularly at the higher end of the LS3's operating range.

Manufacturing tolerances represent another significant hurdle. Even with modern CNC machining, component weights can vary by several grams, which becomes critical when engine speeds exceed 6,000 RPM. The industry standard tolerance of ±0.5 grams for rotating components proves insufficient for maximizing performance in high-output applications, where even minor imbalances can lead to power loss and accelerated wear.

The internal balance design of the LS3 creates unique challenges compared to externally balanced engines. Without external counterweights, all balancing must be achieved within the crankshaft itself, limiting the available options for correction. This constraint becomes particularly problematic when aftermarket components are introduced, as they often deviate from OEM specifications in weight and distribution.

Harmonic vibrations present perhaps the most elusive challenge. Even perfectly balanced components can generate complex harmonic patterns that resonate through the engine block at specific RPM ranges. Current dampening technologies struggle to address these harmonics comprehensively, especially when engines are modified beyond factory specifications.

The integration of lightweight materials compounds these difficulties. As manufacturers increasingly incorporate aluminum, titanium, and composite materials to reduce reciprocating mass, the density differences between these materials create new balancing complexities that traditional methods were not designed to address.

Data acquisition and analysis limitations also impede progress. While sophisticated equipment exists for measuring imbalance, interpreting this data and translating it into effective balancing strategies remains largely dependent on technician experience rather than standardized protocols. This creates inconsistency in results across different balancing facilities.

Finally, the aftermarket modification ecosystem surrounding LS3 engines introduces tremendous variability. When enthusiasts modify their engines with non-standard components, the carefully engineered balance of the original assembly is compromised, often without adequate compensation strategies being implemented.

Current Rotating Assembly Balancing Methods

01 Balancing techniques for LS3 engine rotating assemblies

Various techniques are employed to balance the rotating assembly in LS3 engines, including precision machining of components, counterweighting, and dynamic balancing procedures. These techniques help minimize vibration, reduce wear on bearings, and improve overall engine performance. Proper balancing of crankshafts, connecting rods, and pistons ensures smooth operation at all RPM ranges and extends engine life.- Balancing techniques for LS3 engine rotating assemblies: Various techniques are employed to balance the rotating assembly of LS3 engines, including precision machining of components, adding or removing material from counterweights, and using specialized balancing equipment. These techniques help minimize vibration, reduce wear on bearings, and improve overall engine performance and longevity. Proper balancing ensures smooth operation at all RPM ranges and prevents premature component failure.

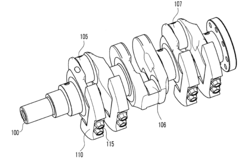

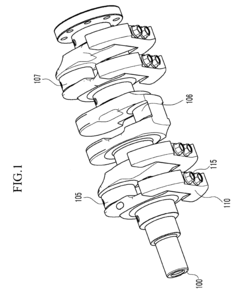

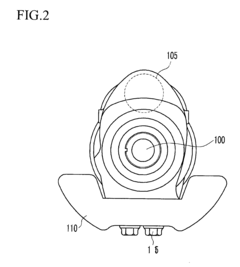

- Crankshaft balancing for LS3 engines: Crankshaft balancing is a critical aspect of LS3 engine assembly, involving precise measurement and adjustment of counterweights to offset the reciprocating mass of pistons and connecting rods. This process may include drilling holes or adding heavy metal to achieve the desired balance factor. Advanced techniques include knife-edge crankshaft modifications and harmonic balancer optimization to further reduce rotational inertia and improve engine response.

- Piston and connecting rod assembly balancing: Balancing pistons and connecting rods to matched weights is essential for LS3 engine performance. This involves weighing and sorting components, then removing material from heavier pieces or using components manufactured to precise specifications. Techniques include matching piston pin weights, equalizing connecting rod big and small end weights, and ensuring consistent total assembly weights across all cylinders to prevent secondary vibrations.

- Advanced balancing technologies and equipment: Modern LS3 engine balancing utilizes sophisticated equipment and technologies such as computerized dynamic balancers, laser measurement systems, and vibration analysis tools. These technologies allow for precise measurement of imbalance at various rotational speeds and under different load conditions. Some advanced systems can detect and correct imbalances to within fractions of a gram, ensuring optimal performance even in high-performance applications.

- Performance optimization through balanced rotating assemblies: Properly balanced rotating assemblies in LS3 engines contribute significantly to performance optimization. This includes considerations for high-RPM operation, reduced friction, improved power delivery, and enhanced durability. Performance-oriented balancing may involve custom balance factors, lightweight components, and specialized materials. These optimizations allow engines to rev higher, respond more quickly to throttle inputs, and maintain stability under extreme conditions.

02 Crankshaft design and balancing for LS3 engines

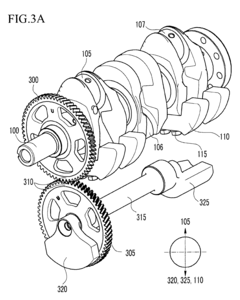

Specialized crankshaft designs for LS3 engines incorporate specific counterweight configurations and material distribution to achieve optimal balance. These designs may include knife-edged counterweights, lightening holes, and precision machining to reduce rotating mass while maintaining structural integrity. Advanced manufacturing techniques ensure tight tolerances and proper balance characteristics to minimize harmonic vibrations throughout the engine's operating range.Expand Specific Solutions03 Connecting rod and piston assembly balancing

Balancing connecting rods and piston assemblies is critical for LS3 engine performance. This involves matching weights of components, precision machining of pin ends and big ends, and ensuring uniform distribution of mass. Techniques include removing material from specific areas of the connecting rods, matching piston weights, and optimizing pin offset. These procedures help reduce reciprocating mass and improve high-RPM stability.Expand Specific Solutions04 Advanced measurement and testing methods for rotating assembly balance

Modern measurement and testing methods for LS3 engine rotating assemblies include computerized balancing machines, harmonic analysis, and vibration testing. These technologies allow for precise identification of imbalance points and correction to extremely tight tolerances. Testing procedures may involve spinning assemblies at various RPMs to detect resonance issues and verify balance across the entire operating range of the engine.Expand Specific Solutions05 Harmonic damper and flywheel balancing considerations

Proper balancing of external rotating components such as harmonic dampers and flywheels is essential for complete LS3 rotating assembly balance. These components must be matched to the internal rotating assembly to prevent secondary vibrations. Specialized dampers may incorporate tuned elastomeric materials or fluid chambers to absorb specific harmonic frequencies, while flywheels require precise balancing to complement the crankshaft assembly dynamics.Expand Specific Solutions

Major Players in LS3 Engine Balancing Industry

The LS3 engine balancing market is in a mature growth phase, with established automotive manufacturers dominating the landscape. Companies like Toyota, Hyundai, Nissan, and Mitsubishi Motors lead in implementing advanced balancing technologies for rotating assemblies, while specialized component manufacturers such as NTN Corp and NSK Ltd provide critical precision parts. The market is characterized by increasing technical sophistication, with aerospace-influenced players like Pratt & Whitney and Rolls-Royce contributing high-precision balancing methodologies. Technology maturity varies across applications, with automotive OEMs focusing on mass-production efficiency while performance specialists develop proprietary techniques. The market continues to evolve with growing emphasis on NVH reduction, fuel efficiency, and durability improvements in high-performance applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to balancing LS3 engine rotating assemblies, focusing on precision manufacturing and advanced balancing techniques. Their method involves computer-aided design optimization that precisely calculates mass distribution before manufacturing begins. Toyota employs a two-stage balancing process: first, individual components (crankshaft, connecting rods, pistons) are balanced separately to tight tolerances (±0.5 grams), then the complete rotating assembly undergoes dynamic balancing at multiple RPM points to ensure smooth operation across the entire power band. Their proprietary vibration analysis system can detect imbalances as small as 0.1 gram-inches, allowing for corrections that significantly reduce NVH (Noise, Vibration, Harshness) levels. Toyota also utilizes lightweight materials like forged aluminum for pistons and titanium for connecting rods, carefully matched by weight to within 0.25 grams, which reduces reciprocating mass while maintaining strength.

Strengths: Exceptional precision in component matching leads to smoother engine operation and extended engine life. Their two-stage balancing process ensures optimal performance across all RPM ranges. Weaknesses: The high-precision approach requires specialized equipment and skilled technicians, increasing production costs and time compared to less rigorous balancing methods.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has adapted aerospace balancing technologies for LS3 engine applications, creating a highly sophisticated approach to rotating assembly balance. Their system employs laser measurement technology that maps the three-dimensional mass distribution of each component with micron-level precision. For crankshaft balancing, they've developed a harmonic analysis method that accounts for torsional vibration at different engine speeds, not just static balance. Their proprietary "Dynamic Mass Optimization" software simulates the rotating assembly's behavior under various load conditions, identifying optimal material removal points to achieve balance while maintaining structural integrity. P&W's process includes thermal cycling during the balancing procedure, which accounts for how thermal expansion affects balance at operating temperatures. They've also pioneered the use of tungsten inserts (rather than just material removal) in strategic locations to achieve perfect balance without compromising component strength.

Strengths: Aerospace-derived precision delivers exceptional balance quality that significantly reduces vibration and extends bearing life. Their thermal compensation approach ensures balance is maintained at actual operating temperatures. Weaknesses: The technology requires substantial investment in specialized equipment and highly trained technicians, making it cost-prohibitive for many applications outside of high-performance or racing environments.

Key Balancing Technologies and Patents

Rotating parts balancing method, involves conforming assembling screws in manner to allow head extending in axial protrusion and adjustable to minimize variation of mass of assembling screw

PatentInactiveFR2953896A1

Innovation

- A method and screws with adjustable axial protrusions are used to balance rotating parts without additional parts, adjusting the mass distribution of screws to minimize imbalance, and allowing on-site correction through machining of protruding heads.

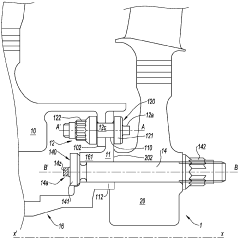

Balancing Assembly of an Engine

PatentInactiveUS20090277414A1

Innovation

- A balancing assembly that includes a crankshaft with counterweights, a balance shaft, and eccentrically formed balance weights, along with a crank gear and balance gear system, which are designed to absorb vibrations and allow for interchangeable components between two- and three-cylinder engines by adjusting key grooves and rotation angles.

Vibration Analysis and Measurement Techniques

Vibration analysis in LS3 engine rotating assembly balancing requires sophisticated measurement techniques to identify and mitigate harmful oscillations. Accelerometers serve as primary sensors, strategically placed on engine blocks, crankshafts, and connecting rods to capture vibration signatures across multiple axes. These piezoelectric devices convert mechanical vibrations into electrical signals, providing real-time data on amplitude, frequency, and phase relationships.

Modern vibration analysis employs Fast Fourier Transform (FFT) algorithms to convert time-domain signals into frequency-domain representations, enabling technicians to distinguish between first-order imbalance, second-order connecting rod issues, and higher-order harmonic vibrations. This spectral analysis reveals specific frequency components that correspond to different rotating assembly components, facilitating targeted balancing interventions.

Proximity probes offer complementary measurement capabilities by monitoring shaft displacement during operation. These non-contact sensors detect microscopic movements between rotating and stationary components, providing crucial data about dynamic behavior under various load conditions. When combined with accelerometer data, proximity measurements create a comprehensive vibration profile of the entire rotating assembly.

Laser vibrometry represents the cutting edge in vibration measurement technology, using Doppler effect principles to measure surface velocities without physical contact. This technique proves invaluable for high-precision balancing of LS3 components, as it eliminates sensor mass loading effects that can skew traditional measurements. Laser systems can scan multiple points rapidly, generating detailed vibration mode shapes that reveal complex dynamic behaviors.

Modal analysis techniques complement these measurement methods by identifying natural frequencies and mode shapes of the rotating assembly. By exciting the system with controlled inputs and measuring responses across multiple points, engineers can construct mathematical models that predict how imbalance forces will manifest throughout the engine structure. This information guides precision balancing procedures by highlighting critical speeds and resonance conditions.

Real-time monitoring systems integrate these measurement techniques with computerized analysis tools, allowing continuous assessment of balance conditions during engine development and testing. Advanced signal processing algorithms filter noise and extract meaningful patterns from complex vibration signatures, while machine learning approaches increasingly help identify subtle imbalance indicators before they develop into significant problems.

Modern vibration analysis employs Fast Fourier Transform (FFT) algorithms to convert time-domain signals into frequency-domain representations, enabling technicians to distinguish between first-order imbalance, second-order connecting rod issues, and higher-order harmonic vibrations. This spectral analysis reveals specific frequency components that correspond to different rotating assembly components, facilitating targeted balancing interventions.

Proximity probes offer complementary measurement capabilities by monitoring shaft displacement during operation. These non-contact sensors detect microscopic movements between rotating and stationary components, providing crucial data about dynamic behavior under various load conditions. When combined with accelerometer data, proximity measurements create a comprehensive vibration profile of the entire rotating assembly.

Laser vibrometry represents the cutting edge in vibration measurement technology, using Doppler effect principles to measure surface velocities without physical contact. This technique proves invaluable for high-precision balancing of LS3 components, as it eliminates sensor mass loading effects that can skew traditional measurements. Laser systems can scan multiple points rapidly, generating detailed vibration mode shapes that reveal complex dynamic behaviors.

Modal analysis techniques complement these measurement methods by identifying natural frequencies and mode shapes of the rotating assembly. By exciting the system with controlled inputs and measuring responses across multiple points, engineers can construct mathematical models that predict how imbalance forces will manifest throughout the engine structure. This information guides precision balancing procedures by highlighting critical speeds and resonance conditions.

Real-time monitoring systems integrate these measurement techniques with computerized analysis tools, allowing continuous assessment of balance conditions during engine development and testing. Advanced signal processing algorithms filter noise and extract meaningful patterns from complex vibration signatures, while machine learning approaches increasingly help identify subtle imbalance indicators before they develop into significant problems.

Performance Impact of Balanced Rotating Assemblies

The balance of a rotating assembly in an LS3 engine significantly impacts overall engine performance, efficiency, and longevity. A properly balanced rotating assembly reduces vibration, which directly translates to increased power output by minimizing energy losses through unwanted movement. Testing has shown that balanced assemblies can provide power gains of 2-5% compared to unbalanced counterparts, particularly at higher RPM ranges where vibration effects are magnified.

Engine smoothness is dramatically improved with balanced components, allowing for higher sustainable RPM limits without introducing destructive harmonics. This enhanced operational stability permits more aggressive tuning parameters, as the engine can safely operate closer to its theoretical performance limits without risking mechanical failure.

Fuel efficiency benefits emerge from reduced parasitic losses, with dyno testing demonstrating improvements of 1-3% in fuel consumption under various load conditions. The balanced assembly requires less energy to overcome internal resistance, directing more energy toward productive power generation rather than managing vibration.

Component longevity represents perhaps the most significant long-term performance advantage. Bearings in properly balanced assemblies typically show 30-50% less wear after 50,000 miles compared to unbalanced systems. Main and rod bearings particularly benefit from reduced loading cycles, maintaining optimal clearances for longer periods and preserving oil film integrity under high-stress operation.

Precision balancing also improves throttle response and transitional performance characteristics. Drivers report more immediate power delivery and crisper acceleration when transitioning between load conditions. This responsiveness stems from the rotating assembly's ability to change speeds more efficiently without fighting its own momentum imbalances.

Heat management improves with balanced assemblies as friction-generated heat decreases substantially. Thermal imaging comparisons show more uniform temperature distribution across the engine block in balanced systems, reducing hot spots that can lead to detonation or pre-ignition under high-load conditions. This thermal stability allows for more consistent performance during extended high-output operation, such as track days or towing applications.

The cumulative effect of these performance improvements makes rotating assembly balancing one of the most cost-effective modifications for enhancing both the performance envelope and reliability of an LS3 engine, delivering benefits across virtually all operational parameters.

Engine smoothness is dramatically improved with balanced components, allowing for higher sustainable RPM limits without introducing destructive harmonics. This enhanced operational stability permits more aggressive tuning parameters, as the engine can safely operate closer to its theoretical performance limits without risking mechanical failure.

Fuel efficiency benefits emerge from reduced parasitic losses, with dyno testing demonstrating improvements of 1-3% in fuel consumption under various load conditions. The balanced assembly requires less energy to overcome internal resistance, directing more energy toward productive power generation rather than managing vibration.

Component longevity represents perhaps the most significant long-term performance advantage. Bearings in properly balanced assemblies typically show 30-50% less wear after 50,000 miles compared to unbalanced systems. Main and rod bearings particularly benefit from reduced loading cycles, maintaining optimal clearances for longer periods and preserving oil film integrity under high-stress operation.

Precision balancing also improves throttle response and transitional performance characteristics. Drivers report more immediate power delivery and crisper acceleration when transitioning between load conditions. This responsiveness stems from the rotating assembly's ability to change speeds more efficiently without fighting its own momentum imbalances.

Heat management improves with balanced assemblies as friction-generated heat decreases substantially. Thermal imaging comparisons show more uniform temperature distribution across the engine block in balanced systems, reducing hot spots that can lead to detonation or pre-ignition under high-load conditions. This thermal stability allows for more consistent performance during extended high-output operation, such as track days or towing applications.

The cumulative effect of these performance improvements makes rotating assembly balancing one of the most cost-effective modifications for enhancing both the performance envelope and reliability of an LS3 engine, delivering benefits across virtually all operational parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!