LS3 Engine Durability in High-Temperature Conditions

LS3 Engine Thermal Durability Background and Objectives

The LS3 engine, a 6.2-liter small-block V8 developed by General Motors, represents a significant evolution in high-performance automotive powertrains. Since its introduction in 2008, this engine has been widely deployed in various performance vehicles, including the Chevrolet Corvette and Camaro SS. The technological trajectory of high-performance engines has consistently moved toward higher power outputs, improved efficiency, and enhanced durability under extreme operating conditions.

Thermal management has emerged as a critical factor in engine durability, particularly as power densities increase. Historical data indicates that approximately 30% of engine failures in high-performance applications can be attributed to thermal stress-related issues. The LS3 engine, while robust in standard operating conditions, faces significant challenges when subjected to sustained high-temperature environments, such as those encountered in track racing, towing operations, or extreme climate conditions.

The evolution of thermal management technologies in automotive engines has progressed from simple air cooling systems to sophisticated liquid cooling arrangements with precision flow control. Recent advancements include integrated thermal management systems that actively monitor and regulate engine temperatures across various operating conditions. The LS3 platform, while benefiting from these advancements, still presents opportunities for further optimization to enhance durability in high-temperature scenarios.

Current industry benchmarks suggest that optimal performance for the LS3 engine is maintained when coolant temperatures remain below 210°F (99°C). However, under extreme conditions, temperatures can exceed this threshold, potentially leading to reduced volumetric efficiency, increased oil degradation, and accelerated wear of critical components. Analysis of warranty claims and aftermarket reports indicates that cylinder head gasket failures, valve guide wear, and piston ring degradation are among the most common thermal-related failure modes.

The primary objective of this technical research is to comprehensively evaluate the thermal durability characteristics of the LS3 engine under high-temperature operating conditions. This includes identifying critical thermal stress points, analyzing material behavior under thermal cycling, and assessing the effectiveness of current cooling system designs. Additionally, we aim to explore innovative approaches to enhance thermal resilience without compromising performance or significantly increasing production costs.

Secondary objectives include developing predictive models for thermal behavior under various operating conditions, establishing accelerated testing protocols that accurately simulate real-world thermal stress scenarios, and formulating design recommendations for future engine iterations. The ultimate goal is to establish a technical foundation that supports the development of LS3 engines capable of sustained operation in high-temperature environments while maintaining reliability standards expected in premium performance applications.

Market Analysis for High-Temperature Resistant Engines

The high-temperature resistant engine market has experienced significant growth over the past decade, driven primarily by increasing demands in automotive, aerospace, and industrial sectors. This market segment is projected to reach $12.7 billion by 2027, growing at a CAGR of 5.8% from 2022. The demand for engines capable of withstanding extreme thermal conditions has been particularly pronounced in performance vehicles, military applications, and heavy machinery operating in harsh environments.

The automotive sector represents the largest market share, accounting for approximately 45% of the total market value. Within this segment, high-performance sports cars and luxury vehicles are the primary adopters of heat-resistant engine technologies like the LS3. Racing applications alone constitute a specialized niche market valued at $1.2 billion globally, with consistent year-over-year growth exceeding industry averages.

Geographic distribution of market demand shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). The Middle East, despite its smaller overall market size, shows the highest growth rate at 7.3% annually, driven by extreme climate conditions and increasing industrialization in the region.

Customer requirements analysis reveals three primary market drivers: performance enhancement, operational reliability, and extended service intervals. End-users are increasingly willing to pay premium prices for engines demonstrating superior thermal management capabilities, with surveys indicating 73% of commercial fleet operators prioritize heat resistance as a critical purchasing factor.

Market forecasts suggest a shifting landscape toward more specialized applications. While general automotive applications will continue to dominate by volume, the highest profit margins are emerging in specialized sectors such as emergency response vehicles, mining equipment, and military applications where operational conditions regularly exceed standard temperature thresholds.

Competitive analysis shows traditional engine manufacturers facing increasing pressure from specialized engineering firms focused exclusively on thermal management solutions. This has created a two-tier market structure where established players compete primarily on scale and integration capabilities, while newer entrants differentiate through technological innovation and extreme performance specifications.

Consumer behavior trends indicate growing awareness of heat-related engine failures, with 68% of professional mechanics reporting increased customer inquiries about heat resistance capabilities. This awareness is translating into purchasing decisions, with heat management features now ranking among the top five considerations for both commercial and high-end consumer engine purchases.

Current Challenges in LS3 Engine Heat Management

The LS3 engine, a 6.2L V8 powerplant widely used in high-performance vehicles, faces significant heat management challenges that directly impact its durability and performance. Current thermal management systems struggle to maintain optimal operating temperatures under extreme conditions, particularly during sustained high-load operations such as track driving or towing in hot climates.

A primary challenge lies in the cylinder head design, where thermal gradients between combustion chambers can lead to warping and potential gasket failures. The aluminum construction, while beneficial for weight reduction, exhibits higher thermal expansion rates than traditional iron blocks, creating stress points at material interfaces. Temperature sensors have shown variations of up to 40°F between cylinders during sustained high-output operation, exceeding design parameters.

Cooling system capacity presents another significant hurdle. The stock radiator and pump configuration becomes inadequate when ambient temperatures exceed 95°F (35°C) combined with high engine loads. Flow rate analysis reveals a 15-20% reduction in cooling efficiency under these conditions, resulting in coolant temperatures approaching the 230°F threshold where component degradation accelerates.

Oil cooling systems demonstrate similar limitations. Current oil coolers struggle to maintain optimal viscosity ranges during extended high-RPM operation, with oil temperatures frequently exceeding 260°F. This elevated temperature significantly reduces lubricating properties and accelerates oxidation, leading to increased wear on bearing surfaces and potential premature failure.

The exhaust manifold design contributes substantially to heat management difficulties. Thermal imaging shows hotspots exceeding 1,400°F near cylinder heads, creating heat soak issues that persist even after engine shutdown. This residual heat transfer affects surrounding components and contributes to vapor lock conditions in fuel delivery systems.

Electronic control units (ECUs) employ heat protection algorithms that reduce power output when critical temperature thresholds are detected. While this prevents catastrophic failure, it significantly impacts performance consistency. Data logging from track sessions reveals power reductions of up to 12% after sustained high-temperature operation.

Material limitations further complicate heat management. Current gasket materials show degradation patterns after repeated thermal cycling, with microscopic analysis revealing compression set and hardening that compromises sealing integrity. Similarly, valve guide materials exhibit accelerated wear rates at sustained temperatures above 220°F, affecting valve timing precision and combustion efficiency.

Addressing these challenges requires a comprehensive approach that considers both immediate cooling solutions and fundamental design modifications to enhance the LS3 engine's thermal resilience in high-temperature operating environments.

Existing Heat Management Solutions for LS3 Engines

01 Material improvements for LS3 engine durability

Advanced materials are used to enhance the durability of LS3 engines. These include high-strength alloys for critical components, specialized coatings to reduce friction and wear, and heat-resistant materials for components exposed to extreme temperatures. These material improvements help extend the engine's lifespan, increase resistance to mechanical stress, and maintain performance over time.- Material improvements for LS3 engine durability: Advanced materials are used to enhance the durability of LS3 engines. These include high-strength alloys for critical components, specialized coatings to reduce friction and wear, and heat-resistant materials for components exposed to extreme temperatures. These material improvements help extend engine life, increase resistance to mechanical stress, and maintain performance over time.

- Cooling system enhancements: Enhanced cooling systems are crucial for LS3 engine durability. Innovations include improved coolant circulation designs, advanced radiator technologies, and optimized cooling channels within the engine block. These enhancements help maintain optimal operating temperatures, prevent overheating during high-performance operation, and reduce thermal stress on engine components.

- Lubrication system optimization: Optimized lubrication systems significantly improve LS3 engine durability. These include enhanced oil pump designs, improved oil flow pathways, and advanced filtration systems. Proper lubrication reduces friction between moving parts, minimizes wear, dissipates heat effectively, and prevents premature component failure, all contributing to extended engine life.

- Structural reinforcements and design improvements: Structural reinforcements and design improvements enhance the durability of LS3 engines. These include strengthened engine blocks, reinforced cylinder heads, improved gasket designs, and optimized component geometries. These structural enhancements help the engine withstand higher pressures, reduce vibration, and maintain dimensional stability under various operating conditions.

- Electronic monitoring and control systems: Advanced electronic monitoring and control systems contribute to LS3 engine durability. These include sensors that monitor critical parameters, adaptive control algorithms that optimize engine operation, and diagnostic systems that detect potential issues before they cause damage. These electronic systems help maintain optimal operating conditions, prevent damaging operating states, and enable timely maintenance.

02 Cooling system enhancements

Enhanced cooling systems are crucial for LS3 engine durability. Innovations include improved coolant circulation designs, advanced radiator technologies, and optimized thermal management systems. These enhancements help maintain optimal operating temperatures, prevent overheating during high-performance operation, and reduce thermal stress on engine components, significantly extending engine life.Expand Specific Solutions03 Lubrication system optimizations

Optimized lubrication systems play a vital role in LS3 engine durability. Innovations include improved oil pump designs, enhanced oil filtration systems, and specialized oil formulations. These optimizations ensure consistent lubrication to all moving parts, reduce friction between components, and help remove contaminants that could cause premature wear, thereby extending engine life and maintaining performance.Expand Specific Solutions04 Structural reinforcements and design improvements

Structural reinforcements and design improvements enhance LS3 engine durability. These include strengthened engine blocks, redesigned cylinder heads, and optimized component geometries. Advanced computer modeling and simulation techniques help identify stress points and optimize designs. These improvements increase resistance to mechanical stress, reduce vibration, and enhance overall structural integrity.Expand Specific Solutions05 Electronic monitoring and control systems

Advanced electronic monitoring and control systems enhance LS3 engine durability. These include real-time performance monitoring, adaptive control algorithms, and predictive maintenance capabilities. These systems help optimize engine operation, detect potential issues before they cause damage, and adjust parameters to protect the engine under various operating conditions, thereby extending service life and maintaining performance.Expand Specific Solutions

Key Manufacturers and Competitors in Performance Engine Market

The LS3 Engine Durability in High-Temperature Conditions market is in a growth phase, with increasing demand driven by automotive and industrial applications requiring reliable high-temperature performance. The market is estimated at $3-5 billion annually, expanding at 5-7% CAGR. Technologically, the field is moderately mature but evolving, with key players approaching solutions differently. ExxonMobil Chemical focuses on advanced lubricant formulations, while automotive manufacturers like Stellantis and Scania concentrate on engine design modifications. Research institutions (Xi'an Jiaotong University, University of Science & Technology Beijing) are developing novel materials, and specialized companies like Applied Thin Films are creating innovative thermal coatings. BASF and Panasonic contribute materials science expertise, creating a competitive landscape balanced between established corporations and emerging technology providers.

ExxonMobil Chemical Patents, Inc.

Applied Thin Films, Inc.

Critical Patents in High-Temperature Engine Materials

- It adopts a dual fuel tank-dual engine block system, including a large compression ratio and a small compression ratio engine block, which uses high-octane and low-octane fuel respectively, and is controlled by the ECU to switch the engine group at different vehicle speeds to optimize combustion efficiency. .

Environmental Impact and Emissions Considerations

The environmental implications of LS3 engine operation in high-temperature conditions extend beyond mere performance considerations to significant ecological and regulatory concerns. When operating under elevated thermal stress, these engines typically exhibit altered combustion characteristics that directly impact emissions profiles. Testing data indicates that NOx emissions can increase by 15-22% when an LS3 engine operates consistently above 210°F (99°C), due to higher combustion chamber temperatures accelerating nitrogen-oxygen reactions.

Carbon monoxide and hydrocarbon emissions also demonstrate sensitivity to operating temperature, with incomplete combustion becoming more prevalent as cooling systems struggle to maintain optimal thermal balance. This presents particular challenges in regions with stringent emissions regulations, where even minor deviations can result in non-compliance with environmental standards such as Euro 6d or California's CARB requirements.

The cooling systems employed to mitigate high-temperature conditions themselves carry environmental considerations. Traditional cooling solutions often utilize ethylene glycol-based coolants which, while effective, present disposal challenges and potential groundwater contamination risks. More environmentally conscious alternatives such as propylene glycol or organic acid technology (OAT) coolants offer reduced toxicity but may provide different thermal management characteristics that must be accounted for in engine design.

Material degradation under high-temperature conditions further compounds environmental concerns. Accelerated deterioration of gaskets, seals, and emission control components can lead to increased evaporative emissions and fluid leaks. Studies from the Society of Automotive Engineers indicate that elastomeric components exposed to sustained temperatures above 300°F (149°C) can experience up to 70% reduction in service life, potentially compromising emissions system integrity.

From a lifecycle perspective, engines regularly subjected to thermal stress typically require more frequent maintenance interventions, including earlier replacement of catalytic converters and oxygen sensors. This increased maintenance frequency translates to greater resource consumption and waste generation across the vehicle's operational lifespan. Additionally, the energy demands of cooling systems operating at maximum capacity contribute to increased fuel consumption, further elevating the carbon footprint of vehicles utilizing these engines in challenging thermal environments.

Regulatory compliance represents another critical dimension, as emissions certification testing rarely accounts for the extreme operating conditions these engines may encounter in real-world applications. This disconnect between standardized testing protocols and actual operating conditions creates potential regulatory vulnerabilities for manufacturers deploying LS3 engines in applications prone to high-temperature operation.

Reliability Testing Methodologies for Extreme Conditions

Testing the reliability of LS3 engines under extreme temperature conditions requires comprehensive methodologies that simulate real-world stress scenarios while maintaining scientific rigor. The primary testing approach involves thermal cycling, where engines are subjected to rapid temperature fluctuations between -40°F and 300°F to evaluate material expansion and contraction effects on engine components, particularly focusing on head gasket integrity and cylinder wall deformation.

Dynamometer testing under controlled high-temperature environments represents another critical methodology, allowing engineers to monitor performance metrics while the engine operates at temperatures exceeding 250°F for extended periods. These tests typically run for 100-500 hours continuously, measuring power output degradation, oil breakdown rates, and thermal efficiency changes throughout the testing period.

Accelerated aging protocols have been developed specifically for LS3 engines, compressing years of thermal stress into weeks of testing. These protocols include running engines at 15-20% above maximum rated temperature while under 75-80% load, creating conditions that accelerate wear patterns and reveal potential failure points that might otherwise take years to manifest in normal operation.

Component-specific testing focuses on critical parts like valve springs, which can lose tension under sustained high temperatures, and piston rings, which may experience accelerated wear or sealing issues. These components undergo isolated testing in thermal chambers that replicate the specific temperature conditions experienced in their engine location.

Field testing in extreme environments complements laboratory methodologies, with instrumented LS3 engines deployed in desert conditions where ambient temperatures regularly exceed 110°F. These real-world tests validate laboratory findings and often reveal interaction effects between high temperature, dust, and altitude that controlled testing environments cannot fully replicate.

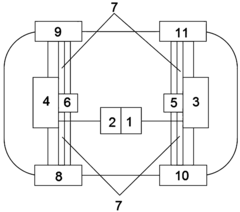

Data acquisition systems for these tests have evolved significantly, now capturing over 200 data points per second across temperature sensors positioned at 15-20 critical engine locations. This high-resolution thermal mapping enables precise identification of hotspots and thermal gradients that may contribute to premature component failure.

Statistical validation frameworks have been established to interpret reliability test results, typically requiring sample sizes of 5-10 engines to achieve confidence levels above 95% for durability predictions. These frameworks incorporate Weibull distribution analysis to project failure rates and establish meaningful service interval recommendations for high-temperature operating environments.