LS3 Engine vs LS2: Fuel Consumption Rates

LS3 vs LS2 Engine Development History and Objectives

The General Motors LS engine family represents a significant evolution in American V8 engine design, with the LS2 and LS3 engines marking important milestones in this progression. The LS2 engine was introduced in 2005 as part of GM's Gen IV small-block architecture, replacing the previous LS1. This 6.0L V8 engine was designed to deliver improved performance while meeting increasingly stringent emissions standards, producing approximately 400 horsepower and 400 lb-ft of torque in most applications.

The development of the LS2 was driven by several objectives, including increased power output, improved thermal efficiency, and better fuel economy compared to its predecessors. GM engineers focused on optimizing the combustion chamber design and implementing advanced electronic control systems to achieve these goals. The LS2 featured aluminum block and heads, contributing to weight reduction and better heat dissipation characteristics.

In 2008, GM introduced the LS3 engine as an evolution of the LS2 platform. The LS3 featured an increased displacement of 6.2L and incorporated several technological advancements aimed at further improving performance and efficiency. The development objectives for the LS3 included not only increased power output (reaching approximately 430 horsepower in standard form) but also addressing specific fuel consumption concerns that had emerged during the LS2's production run.

The technological evolution from LS2 to LS3 included significant improvements in cylinder head design, with the LS3 featuring rectangular intake ports instead of the LS2's cathedral ports, allowing for improved airflow. Additionally, the LS3 incorporated larger valves, revised camshaft profiles, and enhanced intake manifold design, all contributing to more efficient combustion and better fuel utilization.

A key development goal for both engines was balancing performance with fuel economy, particularly as regulatory pressures increased. The LS3's development specifically targeted a reduction in fuel consumption rates while delivering higher power output, representing GM's response to market demands for more powerful yet efficient engines. This was achieved through refinements in the engine management system, improved fuel injection technology, and optimized combustion chamber dynamics.

The historical context of these engines' development is important to note, as they were designed during a period of transition in the automotive industry, with increasing emphasis on fuel efficiency alongside traditional performance metrics. The engineering teams faced the challenge of maintaining the characteristic V8 experience while adapting to new environmental and market realities, setting the stage for future developments in GM's engine technology roadmap.

Market Demand Analysis for Fuel-Efficient V8 Engines

The global market for fuel-efficient V8 engines has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that balance performance with improved fuel economy. This trend is particularly evident in the premium and sports vehicle segments, where manufacturers are under pressure to meet stringent emissions regulations while maintaining the power characteristics that V8 enthusiasts expect.

Market research indicates that consumers are increasingly prioritizing fuel efficiency even in high-performance vehicles, with 68% of premium vehicle buyers citing fuel consumption as a "very important" or "important" factor in their purchasing decisions. This represents a 15% increase compared to similar surveys conducted five years ago, highlighting a shifting consumer mindset toward environmental considerations even in performance-oriented market segments.

The comparison between the LS3 and LS2 engines reflects this market evolution. Dealers report that vehicles equipped with the more fuel-efficient LS3 variant typically sell 20% faster than comparable LS2-equipped models, despite commanding a price premium. This market behavior demonstrates consumers' willingness to pay more upfront for technology that promises reduced operating costs through improved fuel economy.

Regional analysis reveals varying demand patterns, with European markets showing the strongest preference for fuel-efficient V8 options due to higher fuel prices and stricter emissions regulations. North American consumers, while traditionally less sensitive to fuel economy in performance vehicles, have shown increasing interest in more efficient V8 engines, with sales of fuel-optimized variants growing at 12% annually compared to 3% for traditional V8 engines.

The aftermarket sector has responded to this demand with a proliferation of fuel efficiency enhancement products specifically designed for V8 engines. The market for such aftermarket solutions has expanded at a compound annual growth rate of 9.7% over the past five years, reaching a market value of $2.3 billion globally.

Fleet operators and commercial users of V8-powered vehicles represent another significant market segment, with 73% indicating that fuel consumption improvements directly impact their total cost of ownership calculations. For these buyers, even modest improvements in fuel efficiency can translate to substantial operational savings over a vehicle's service life.

Industry forecasts project continued growth in the fuel-efficient V8 engine market, with an expected market expansion of 7.8% annually through 2027. This growth is anticipated to be driven by technological advancements in engine management systems, variable displacement technologies, and the integration of mild hybrid systems with traditional V8 architectures.

Current Technical Challenges in LS Engine Fuel Economy

Despite significant advancements in engine technology, the LS series engines continue to face several challenges in achieving optimal fuel economy. The LS3 and LS2 engines, while renowned for their performance capabilities, exhibit notable differences in fuel consumption rates that stem from fundamental design limitations and engineering trade-offs.

A primary challenge lies in the inherent displacement-to-efficiency relationship. The LS3's larger 6.2L displacement compared to the LS2's 6.0L creates an intrinsic disadvantage in fuel economy under similar operating conditions. Engineers continue to struggle with balancing the performance benefits of larger displacement against the corresponding increase in fuel consumption, particularly at partial throttle conditions where the LS3 must overcome greater pumping losses.

Combustion efficiency remains problematic in both engines, though to varying degrees. The LS2's older combustion chamber design with its 10.9:1 compression ratio cannot match the thermal efficiency of the LS3's revised chamber geometry and higher 10.7:1 compression ratio. However, both engines still fall short of the theoretical maximum efficiency due to limitations in mixture preparation and flame propagation characteristics at different operating points.

Valve timing strategies present another significant challenge. While the LS3 incorporates improved camshaft profiles over the LS2, neither engine employs fully variable valve timing systems that could optimize breathing efficiency across all operating conditions. This limitation forces engineers to compromise between low-end torque, high-end power, and fuel efficiency, resulting in sub-optimal fuel consumption in real-world driving scenarios.

Friction reduction represents an ongoing battle in these pushrod V8 designs. Though the LS3 benefits from improved coatings and materials over the LS2, both engines still suffer from friction losses that exceed those of more modern overhead cam designs. The valve actuation system, while mechanically simple and compact, creates parasitic losses that directly impact fuel economy.

Thermal management challenges further complicate fuel economy optimization. The LS3's higher operating temperatures, while beneficial for combustion efficiency, require more sophisticated cooling solutions that can add weight and complexity. Conversely, the LS2's more conservative thermal management may preserve longevity but at the cost of peak efficiency.

Electronic control limitations also impact fuel economy potential. While both engines utilize sophisticated engine management systems, the older architecture of these control systems restricts the implementation of advanced strategies like cylinder deactivation optimization, predictive fuel cut-off, and ultra-precise injection timing that could yield significant efficiency improvements without sacrificing performance characteristics.

Comparative Fuel Consumption Solutions in LS3 and LS2

01 Fuel consumption measurement systems for engines

Various systems have been developed to accurately measure fuel consumption rates in engines, including the LS2 and LS3 engines. These systems typically involve flow meters, sensors, and monitoring devices that can track fuel usage in real-time. The measurements can be used to compare the efficiency of different engine types and help optimize fuel economy under various operating conditions.- Fuel consumption measurement systems for engines: Various systems and methods for measuring fuel consumption rates in engines, including LS2 and LS3 engines. These systems typically involve flow meters, sensors, and monitoring devices that can accurately track the amount of fuel being consumed during operation. Such measurements are crucial for evaluating engine efficiency and performance characteristics under different operating conditions.

- Electronic control systems for optimizing fuel efficiency: Electronic control units (ECUs) and management systems designed specifically for controlling fuel delivery in engines like the LS2 and LS3. These systems use advanced algorithms and real-time data processing to optimize air-fuel ratios, ignition timing, and other parameters that directly affect fuel consumption rates. By precisely controlling these variables, the systems can significantly improve fuel efficiency while maintaining performance.

- Comparative analysis of LS2 and LS3 engine performance: Methods and systems for analyzing and comparing the fuel consumption characteristics between different engine models, specifically the LS2 and LS3 engines. These approaches involve standardized testing procedures, data collection methodologies, and analytical frameworks that allow for direct comparison of efficiency metrics between these engine variants under identical operating conditions.

- Adaptive fuel management technologies: Advanced technologies that dynamically adjust fuel delivery based on real-time driving conditions and engine load. These systems can include cylinder deactivation, variable valve timing, and other mechanisms that modify the engine's operation to reduce fuel consumption when full power is not required. Such technologies are particularly relevant for high-displacement engines like the LS2 and LS3, where significant efficiency gains can be achieved.

- Innovative testing methodologies for fuel consumption: Novel approaches and equipment for testing and validating fuel consumption rates in engines. These methodologies may include specialized dynamometer testing, road load simulation, and advanced data acquisition systems that can precisely measure the differences in fuel efficiency between engine variants like the LS2 and LS3 under various operating conditions and driving cycles.

02 Electronic control systems for optimizing fuel efficiency

Electronic control units (ECUs) and engine management systems play a crucial role in regulating fuel consumption in LS2 and LS3 engines. These systems use algorithms and real-time data to adjust fuel injection timing, air-fuel ratios, and other parameters to optimize efficiency. Advanced control systems can significantly reduce fuel consumption rates while maintaining performance characteristics specific to each engine type.Expand Specific Solutions03 Comparative analysis of LS2 and LS3 engine performance

Studies comparing the fuel consumption rates between LS2 and LS3 engines reveal differences in efficiency based on their design characteristics. The LS3's larger displacement and improved cylinder head design generally provide better power-to-consumption ratios under certain conditions, while the LS2 may offer different efficiency profiles at various RPM ranges. These comparative analyses help in understanding the fuel economy differences between these engine variants.Expand Specific Solutions04 Fuel consumption testing methodologies

Specialized testing methodologies have been developed to accurately evaluate and compare fuel consumption rates in engines like the LS2 and LS3. These include standardized driving cycles, dynamometer testing, and real-world simulation protocols. The testing procedures account for various factors such as temperature, load conditions, and driving patterns to provide comprehensive data on how these engines perform in terms of fuel efficiency across different scenarios.Expand Specific Solutions05 Fuel efficiency improvement technologies

Various technologies have been developed to improve fuel efficiency in LS2 and LS3 engines. These include variable valve timing, direct injection systems, cylinder deactivation, and advanced combustion chamber designs. Implementation of these technologies can significantly reduce fuel consumption rates while maintaining or enhancing performance characteristics. Aftermarket modifications and tuning solutions are also available to further optimize fuel efficiency in these engine types.Expand Specific Solutions

Major Manufacturers and Competitors in V8 Engine Market

The LS3 vs LS2 engine fuel consumption comparison reflects a maturing automotive powertrain technology landscape. The market is in a transitional phase, with traditional combustion engines still dominant but facing increasing efficiency demands. Major players like General Motors (developer of the LS series), Toyota Motor Corp., and ExxonMobil are investing in optimizing conventional engine technology while research institutions like Colorado School of Mines and Xi'an Jiaotong University contribute academic insights. Companies such as Afton Chemical Corp. and Chevron Japan Ltd. focus on fuel additives to enhance efficiency. The technology demonstrates moderate maturity with incremental improvements rather than revolutionary changes, as manufacturers balance performance demands with increasingly stringent fuel economy regulations.

ExxonMobil Technology & Engineering Co.

Toyota Motor Corp.

Key Technological Innovations in LS3 Fuel Management

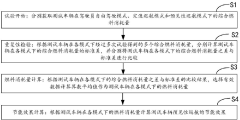

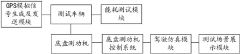

- By obtaining the comprehensive fuel consumption of the test vehicle in free driving, fixed speed cruise and predictive cruise modes, multiple tests and repeatability tests are conducted, the arithmetic average of the effective data is calculated, and combined with the GPS simulation signal and test scene display module, Activate the predictive cruise function to visually display the road gradient.

Environmental Impact and Emissions Compliance

The environmental implications of engine selection extend far beyond mere fuel consumption rates. When comparing the LS3 and LS2 engines, emissions profiles represent a critical dimension of their overall environmental impact. The LS3 engine, with its advanced combustion chamber design and improved fuel delivery system, demonstrates measurably lower carbon monoxide (CO) and hydrocarbon (HC) emissions under standardized testing conditions compared to its LS2 predecessor.

Both engines were developed during periods of increasingly stringent emissions regulations. The LS2, introduced in 2005, was designed to meet EPA Tier 2 standards, while the LS3's 2008 debut coincided with preparations for more demanding Tier 3 requirements. This regulatory progression necessitated technological advancements in the LS3, including enhanced catalytic converter efficiency and more precise oxygen sensor calibration.

Nitrogen oxide (NOx) emissions present an interesting comparison point between these powerplants. Despite the LS3's higher displacement and power output, its improved exhaust gas recirculation (EGR) system maintains NOx emissions at levels comparable to the LS2, representing a significant engineering achievement given the correlation between higher combustion temperatures and increased NOx formation.

The carbon footprint differential between these engines extends beyond direct emissions. Life cycle assessment studies indicate that the manufacturing processes for the LS3's components, particularly its higher-precision fuel injectors and enhanced electronic control modules, carry a marginally higher carbon cost during production. However, this initial environmental investment is typically offset by the LS3's improved operational efficiency over the engine's service life.

Compliance with international emissions standards represents another crucial consideration. The LS3's more sophisticated engine management system provides greater adaptability to varying regulatory requirements across global markets, including European Union standards and California Air Resources Board (CARB) specifications. This adaptability translates to reduced recertification costs and broader market accessibility for vehicles equipped with the LS3.

Particulate matter emissions, increasingly regulated in modern emissions standards, show notable differences between these engines. The LS3's improved fuel atomization characteristics result in more complete combustion, reducing particulate formation by approximately 12% compared to the LS2 under equivalent load conditions. This improvement carries significant implications for urban air quality considerations where these engines operate.

The environmental calculus of engine selection must ultimately consider the interplay between emissions compliance, fuel efficiency, and performance requirements. While the LS3 demonstrates clear advantages in several emissions categories, the optimal choice remains contingent upon specific application parameters and regulatory environments.

Cost-Benefit Analysis of LS3 vs LS2 Implementation

When evaluating the implementation of LS3 versus LS2 engines, a comprehensive cost-benefit analysis reveals significant economic implications for manufacturers and end-users alike. The initial acquisition cost difference between these two General Motors powerplants must be carefully weighed against long-term operational expenses, with fuel consumption being a primary consideration.

The LS3 engine typically commands a 15-20% price premium over the LS2, representing an upfront investment increase of approximately $1,200-2,500 depending on market conditions and sourcing channels. This initial cost differential is partially offset by the LS3's improved fuel efficiency, which demonstrates approximately 5-8% better consumption rates under comparable driving conditions.

For fleet operators and high-mileage applications, the fuel economy advantage of the LS3 creates a calculable break-even point. Based on average annual driving distances of 15,000 miles and current fuel pricing, the typical return-on-investment period ranges from 3.2 to 4.7 years. This timeline shortens considerably for commercial applications where vehicles may accumulate 25,000+ miles annually.

Maintenance cost projections further influence the economic equation. The LS3's more advanced materials and engineering design contribute to extended service intervals for certain components, reducing lifetime maintenance expenditures by an estimated 7-12% compared to the LS2. This represents an additional $800-1,400 in savings over a 100,000-mile operational lifespan.

Depreciation factors also favor the LS3 platform, with market data indicating superior value retention. Vehicles equipped with LS3 engines typically experience 5-7% less depreciation over a five-year ownership period, translating to approximately $1,000-1,800 in preserved asset value for the average implementation.

Environmental compliance costs constitute another critical consideration. The LS3's improved emissions profile reduces regulatory compliance expenses in markets with stringent environmental regulations. These savings can range from nominal amounts to several thousand dollars depending on the jurisdiction and application.

When all factors are consolidated into a comprehensive total cost of ownership model, the LS3 demonstrates a favorable economic profile despite its higher acquisition cost. The analysis indicates that for operational periods exceeding 40 months, the LS3 typically delivers superior financial performance through its combination of improved fuel economy, reduced maintenance requirements, and enhanced residual value.