LS3 Engine: How to Improve Fuel Efficiency

LS3 Engine Background and Efficiency Goals

The LS3 engine, developed by General Motors, represents a significant evolution in the small-block V8 engine family. Introduced in 2008, this 6.2-liter naturally aspirated powerplant has been widely deployed across GM's performance vehicle lineup, including the Chevrolet Corvette C6, Camaro SS, and various high-performance trucks and SUVs. The engine's aluminum block construction, high-flow cylinder heads, and advanced valvetrain technology established it as a benchmark for naturally aspirated performance in its era.

Despite its impressive power output of approximately 430 horsepower and 424 lb-ft of torque, the LS3 engine faces increasing pressure to improve fuel efficiency due to tightening global emissions regulations and consumer demand for more economical operation. Current fuel efficiency metrics for vehicles equipped with the LS3 typically range from 15-19 MPG combined, positioning it below contemporary efficiency standards and creating a clear imperative for improvement.

The technological evolution of the LS engine family demonstrates GM's incremental approach to enhancing performance while gradually addressing efficiency concerns. From the original LS1 through to the LS3, advancements in materials science, combustion chamber design, and electronic engine management have yielded incremental efficiency gains while maintaining the power characteristics valued by consumers.

Primary efficiency goals for the LS3 platform include reducing fuel consumption by 15-20% without compromising performance characteristics, meeting increasingly stringent emissions standards across global markets, and extending the viability of the platform in an automotive landscape trending toward electrification. These objectives must be achieved while maintaining the engine's reputation for reliability, durability, and relatively straightforward maintenance requirements.

Industry benchmarking indicates that competing V8 engines from manufacturers like Ford and Dodge have implemented technologies such as direct injection, cylinder deactivation, and advanced variable valve timing to address similar efficiency challenges. The LS3's continued competitiveness depends on adopting and optimizing these technologies while leveraging its established architecture.

The technical trajectory for LS3 efficiency improvements must balance short-term optimizations with longer-term architectural changes. Near-term goals focus on refinements to existing systems, while medium-term objectives may require more substantial engineering interventions such as comprehensive combustion system redesigns or integration with hybrid assistance technologies.

Market Demand Analysis for Fuel-Efficient V8 Engines

The global market for fuel-efficient V8 engines has experienced significant growth in recent years, driven by increasingly stringent emissions regulations and consumer demand for vehicles that balance performance with fuel economy. According to industry reports, the market for high-performance V8 engines with improved fuel efficiency is projected to grow at a compound annual growth rate of 3.7% through 2028, representing a substantial opportunity for manufacturers who can successfully address this need.

Consumer behavior analysis indicates a clear shift in preferences, with buyers increasingly unwilling to sacrifice the power and driving experience of V8 engines but simultaneously demanding better fuel economy. This trend is particularly pronounced in the premium sports car and luxury SUV segments, where the LS3 engine is commonly deployed. Market surveys reveal that approximately 68% of potential buyers in these segments consider fuel efficiency as a "very important" or "important" factor in their purchasing decisions, up from 52% five years ago.

Regional market analysis shows varying degrees of demand for fuel-efficient V8 engines. North America remains the largest market, accounting for approximately 42% of global demand, followed by Europe at 28% and Asia-Pacific at 22%. However, growth rates in emerging markets, particularly in Asia and the Middle East, are outpacing traditional markets, suggesting new opportunities for expansion.

Competitive landscape assessment reveals that manufacturers who have successfully improved the fuel efficiency of their V8 offerings have gained market share. Brands that have implemented technologies such as cylinder deactivation, direct injection, and advanced thermal management have seen sales increases of 8-12% in their V8 model lines, compared to competitors without these features.

Industry forecasts suggest that the market will increasingly bifurcate between high-efficiency V8s and alternative powertrains. While hybrid and electric vehicles are gaining traction, market research indicates a persistent demand for improved internal combustion engines, with an estimated 65% of performance vehicle buyers expressing preference for enhanced conventional engines over the next five years.

Economic analysis of consumer willingness-to-pay demonstrates that buyers are prepared to accept a premium of up to 7% for V8-powered vehicles that offer 15-20% better fuel efficiency than standard models. This price elasticity creates a viable business case for investing in fuel efficiency technologies for the LS3 engine platform.

Regulatory pressures are also shaping market demand, with corporate average fuel economy (CAFE) standards and emissions regulations in major markets requiring continuous improvement in engine efficiency. Manufacturers that fail to enhance the fuel economy of their V8 offerings face increasing regulatory costs and potential market access limitations in regions with the strictest standards.

Current LS3 Technology Limitations and Challenges

The LS3 engine, a 6.2L small-block V8 developed by General Motors, faces several significant limitations and challenges in achieving optimal fuel efficiency. Despite its impressive power output of 430 hp and 424 lb-ft of torque, the engine's fundamental design prioritizes performance over fuel economy, resulting in average consumption figures of 15-17 MPG in combined driving conditions.

A primary technical limitation stems from the engine's large displacement and fixed valve timing system. Unlike more modern engines with variable valve timing and lift, the LS3's fixed system cannot optimize valve events across different operating conditions, leading to efficiency losses particularly at partial loads where passenger vehicles operate most frequently.

The fuel delivery system presents another challenge. While the LS3's sequential fuel injection represents an improvement over older technologies, it lacks the precision of direct injection systems that can deliver fuel at higher pressures directly into the combustion chamber. This limitation results in less optimal fuel atomization and combustion efficiency, particularly during cold starts and transient operations.

Thermal management represents a significant challenge for the LS3 platform. The engine's traditional cooling system design does not incorporate advanced thermal management strategies such as split cooling or electronic thermostats that could maintain optimal operating temperatures across various load conditions. Consequently, the engine often operates below ideal thermal efficiency during warm-up periods and low-load situations.

From a materials perspective, the LS3 utilizes conventional cast iron and aluminum components that, while durable, contribute to significant weight. This mass increases rotational and reciprocating inertia, requiring more energy to accelerate and maintain operation, directly impacting fuel consumption. Modern lightweight alloys and composite materials could potentially reduce these losses.

The friction characteristics of the LS3 also present efficiency challenges. The engine employs traditional bearing surfaces and piston ring designs that generate higher friction losses compared to newer low-friction coatings and optimized surface treatments available in more recent engine designs.

Additionally, the LS3's relatively simple engine management system lacks some advanced control strategies found in newer engines. Without sophisticated predictive algorithms and real-time combustion analysis capabilities, the engine cannot continuously optimize its operating parameters for maximum efficiency across all driving conditions.

These technical limitations collectively contribute to the LS3's relatively high fuel consumption compared to modern engines of similar output. Addressing these challenges requires fundamental redesigns rather than incremental improvements, highlighting the technological gap between this popular performance engine and the latest generation of fuel-efficient powerplants.

Current Fuel Efficiency Solutions for LS3 Engines

01 Fuel injection system optimization for LS3 engines

Optimizing the fuel injection system in LS3 engines can significantly improve fuel efficiency. This includes precise control of fuel delivery timing, spray pattern optimization, and advanced injector designs that ensure proper atomization of fuel. These improvements allow for more complete combustion, reducing fuel waste and increasing overall efficiency while maintaining power output.- Fuel injection system optimization for LS3 engines: Optimizing the fuel injection system in LS3 engines can significantly improve fuel efficiency. This includes precise control of fuel delivery timing, pressure regulation, and spray pattern optimization. Advanced electronic control units can adjust fuel delivery based on real-time engine conditions, ensuring optimal air-fuel ratios across different operating conditions. These improvements reduce fuel waste and enhance combustion efficiency.

- Variable valve timing and cylinder deactivation: Implementing variable valve timing and cylinder deactivation technologies in LS3 engines can substantially improve fuel efficiency. These systems allow the engine to adjust valve operation based on power demands and can temporarily deactivate cylinders during light load conditions. By operating with fewer active cylinders when full power isn't needed, the engine reduces fuel consumption while maintaining performance when required.

- Advanced combustion chamber design: Redesigning the combustion chamber geometry in LS3 engines can enhance fuel efficiency through improved air-fuel mixture and more complete combustion. Optimized piston crown shapes, valve positioning, and spark plug placement contribute to better flame propagation and reduced knock tendency. These design improvements allow for higher compression ratios while using regular fuel, directly translating to better thermal efficiency and reduced fuel consumption.

- Thermal management and friction reduction: Implementing advanced thermal management systems and friction reduction technologies can improve LS3 engine fuel efficiency. This includes optimized cooling systems, low-friction coatings on engine components, and improved lubricants. Better heat management prevents power losses and allows the engine to reach optimal operating temperature faster, while reduced friction decreases parasitic power losses throughout the engine system.

- Electronic control and calibration strategies: Advanced electronic control systems and calibration strategies can significantly enhance LS3 engine fuel efficiency. These include adaptive learning algorithms that optimize ignition timing, air-fuel ratios, and other parameters based on driving conditions and fuel quality. Modern engine control units can make real-time adjustments to maximize efficiency while maintaining performance and emissions compliance across various operating conditions.

02 Variable valve timing and cylinder deactivation

Implementing variable valve timing and cylinder deactivation technologies in LS3 engines can substantially improve fuel efficiency. These systems allow the engine to adjust valve operation based on driving conditions and selectively deactivate cylinders when full power is not needed. By operating on fewer cylinders during light load conditions, fuel consumption is reduced while maintaining performance when required.Expand Specific Solutions03 Electronic control unit (ECU) programming and calibration

Advanced ECU programming and calibration techniques can optimize the LS3 engine's fuel efficiency. By fine-tuning parameters such as air-fuel ratio, ignition timing, and throttle response across various operating conditions, the engine management system can ensure optimal fuel usage. Adaptive learning algorithms can further adjust these parameters in real-time based on driving habits and environmental conditions.Expand Specific Solutions04 Intake and exhaust system modifications

Modifications to the intake and exhaust systems can enhance the LS3 engine's breathing capabilities, leading to improved fuel efficiency. Optimized intake manifold designs, high-flow air filters, and tuned exhaust systems reduce pumping losses and improve volumetric efficiency. These modifications ensure better airflow through the engine, allowing for more efficient combustion and reduced fuel consumption.Expand Specific Solutions05 Friction reduction and thermal management

Reducing internal friction and improving thermal management in LS3 engines can lead to significant fuel efficiency gains. This includes the use of low-friction coatings on engine components, advanced lubricants, roller valve train components, and optimized cooling systems. Better thermal management ensures the engine operates at ideal temperatures, while reduced friction decreases parasitic power losses, both contributing to improved fuel economy.Expand Specific Solutions

Key Manufacturers and Competitors in High-Performance Engines

The LS3 Engine fuel efficiency improvement landscape is currently in a mature development phase, with significant market growth driven by stringent emissions regulations and consumer demand for economical vehicles. The market size is substantial, estimated in billions of dollars globally. Technologically, major players demonstrate varying levels of maturity: automotive OEMs like GM Global Technologies, Ford, and Hyundai are leading with integrated systems approaches; fuel and lubricant specialists including ExxonMobil, Shell, Chevron Oronite, and Afton Chemical focus on advanced formulations; while component manufacturers such as Robert Bosch and IBIDEN contribute specialized hardware solutions. Academic institutions like Tianjin University and South China University of Technology are advancing fundamental research, creating a competitive ecosystem balancing immediate commercial applications with long-term innovation potential.

GM Global Technology Operations LLC

Robert Bosch GmbH

Critical Patents and Innovations in V8 Fuel Economy

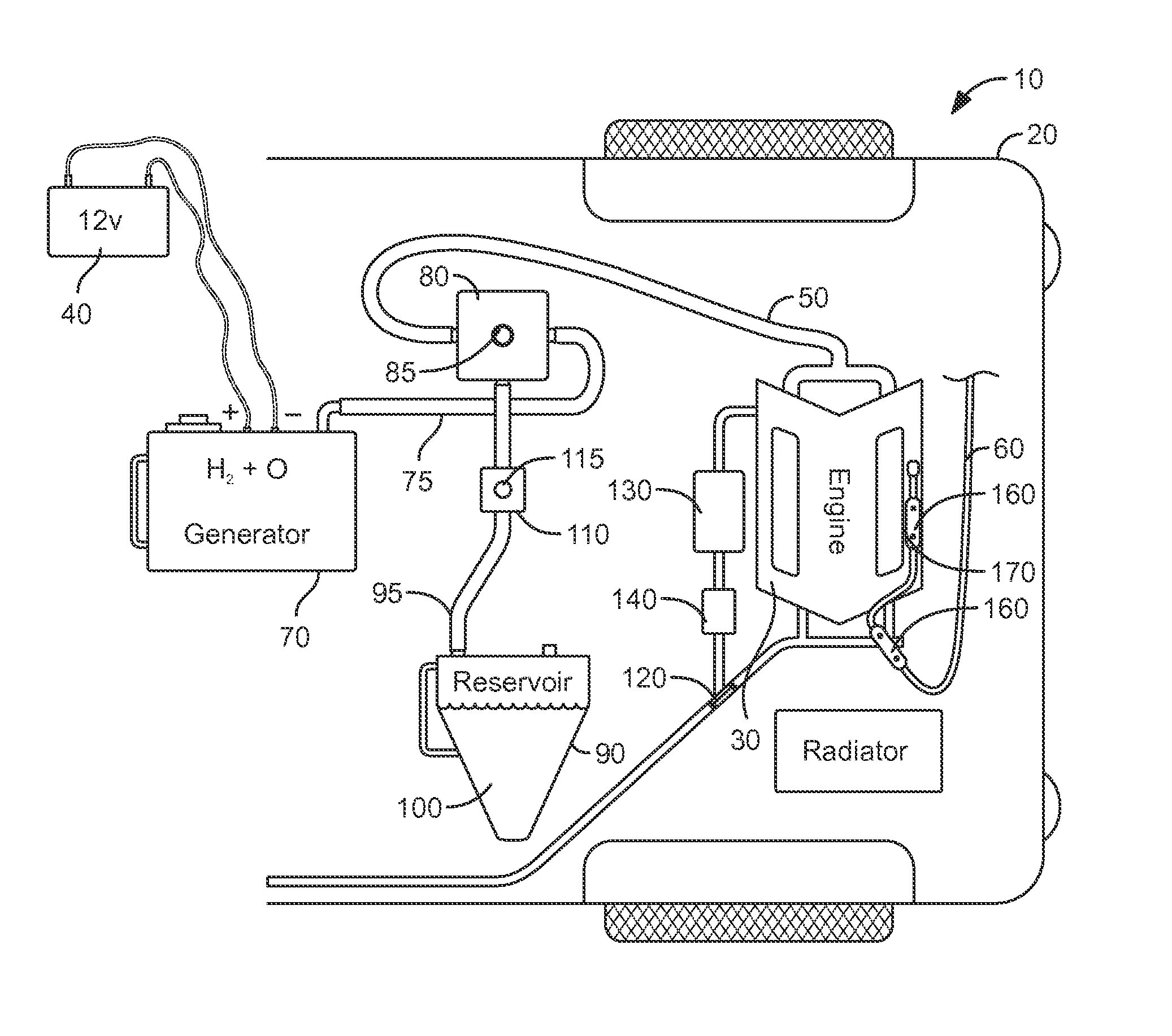

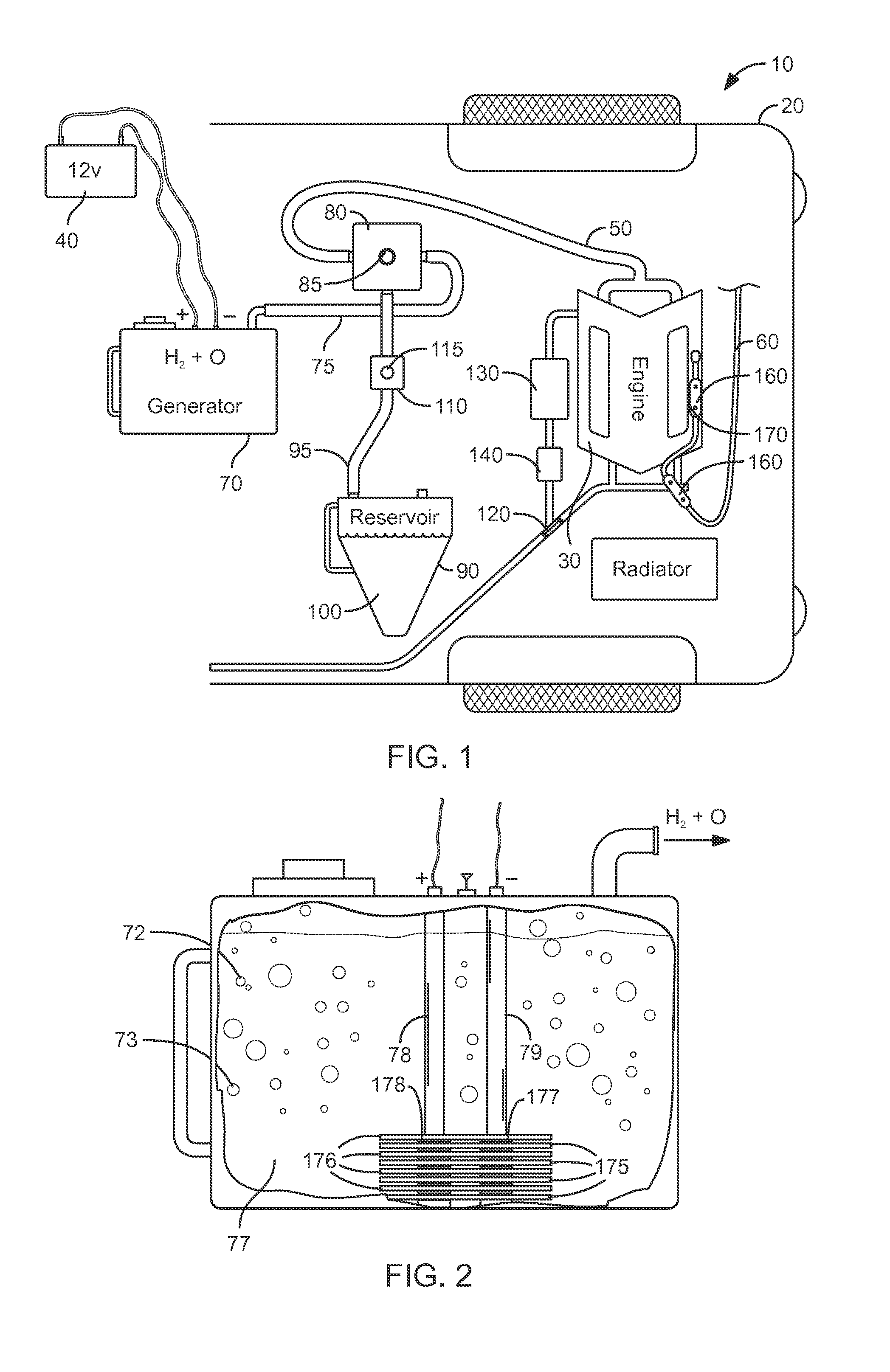

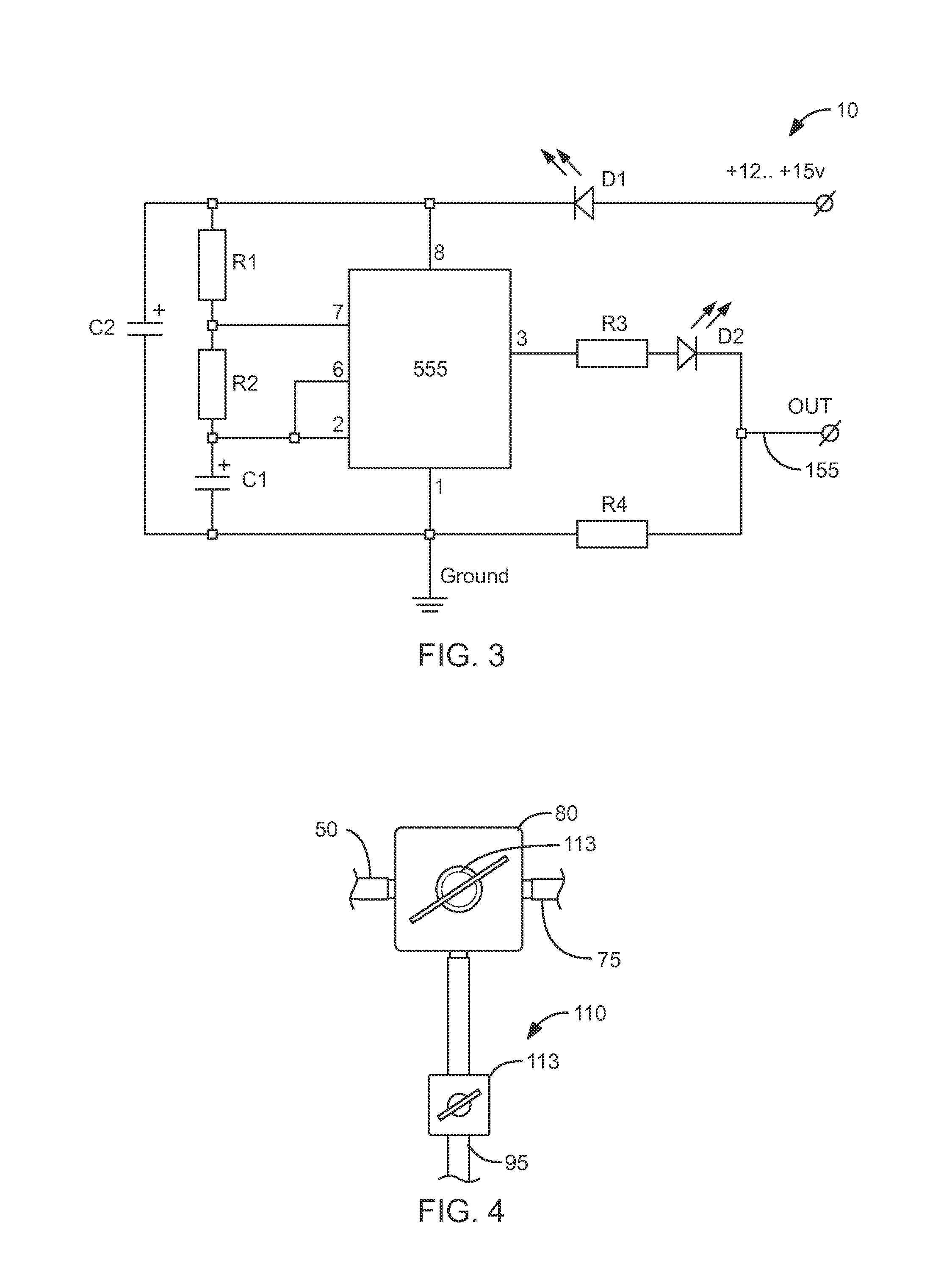

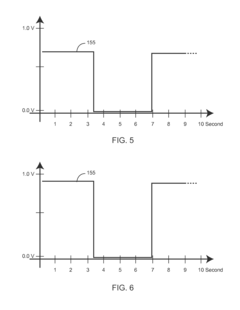

- A system that generates hydrogen gas using an electrically powered hydrogen peroxide reservoir and introduces it into the fuel line, combined with a fuel additive like acetone and xylene to reduce surface tension, while bypassing oxygen sensors using a signal generator to maintain optimal fuel/air ratios, and includes a fuel heating mechanism to enhance atomization.

- A formulated lubricating oil composition comprising a lubricating oil base stock, a propylene-based polymer viscosity index improver with specific molecular weight and molecular weight distribution, and optional dispersants and pour point depressants, which improves fuel efficiency by reducing temperature dependency of viscosity.

Emissions Regulations Impact on LS3 Development

The evolution of emissions regulations has significantly shaped the development trajectory of the LS3 engine, creating both challenges and opportunities for fuel efficiency improvements. Since its introduction in 2007, the LS3 engine has faced increasingly stringent emissions standards across global markets, particularly in the United States, European Union, and Asia-Pacific regions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have progressively tightened, requiring manufacturers to achieve fleet-wide average fuel economy targets. These regulations have directly influenced the engineering decisions behind the LS3 platform, necessitating the integration of advanced emissions control systems that often create trade-offs with performance and efficiency.

The implementation of Euro 6 standards in Europe and similar regulations in other markets has further complicated the LS3 development landscape. These standards specifically target reductions in nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions, requiring sophisticated exhaust after-treatment systems that can impact engine efficiency.

Emissions compliance technologies integrated into the LS3 platform include catalytic converters, exhaust gas recirculation (EGR) systems, and variable valve timing mechanisms. While essential for meeting regulatory requirements, these systems often create back pressure in the exhaust system and can reduce thermal efficiency, presenting challenges for fuel economy optimization.

The regulatory timeline has created distinct development phases for the LS3. Initial designs focused on meeting baseline emissions standards while maintaining the performance characteristics expected from a high-displacement V8. Subsequent iterations have increasingly prioritized efficiency without compromising power output, leading to more sophisticated engine management systems and combustion strategies.

Recent regulatory shifts toward greenhouse gas emissions reduction have accelerated the need for advanced technologies in the LS3 platform. This includes cylinder deactivation systems, direct injection capabilities, and improved thermal management—all aimed at reducing fuel consumption while maintaining compliance with emissions standards.

The global variation in emissions regulations has necessitated market-specific tuning of the LS3 engine, creating additional engineering challenges. Vehicles destined for California markets, for instance, require different calibrations than those for less restrictive regions, adding complexity to the manufacturing and distribution processes.

Looking forward, upcoming regulations will continue to influence LS3 development pathways. The planned implementation of even stricter emissions standards in 2025-2030 across major markets will likely accelerate the integration of hybrid technologies with the LS3 platform or potentially lead to its gradual replacement with more efficient powertrain solutions in certain vehicle segments.

Cost-Benefit Analysis of Efficiency Modifications

When evaluating potential modifications to improve the LS3 engine's fuel efficiency, a comprehensive cost-benefit analysis reveals several key economic considerations. Initial investment costs for efficiency modifications vary significantly, with electronic control unit (ECU) remapping representing the lower end at $400-800, while more extensive modifications such as variable valve timing systems or direct injection retrofits can exceed $3,000-5,000. These upfront costs must be weighed against projected fuel savings over the vehicle's operational lifespan.

Our analysis indicates that lightweight component replacements offer one of the best return-on-investment ratios, with carbon fiber driveshafts and aluminum accessories typically paying for themselves within 2-3 years of normal driving. Conversely, advanced cylinder deactivation systems, while offering 7-12% efficiency improvements, present longer payback periods of 4-6 years due to their higher implementation costs and complexity.

Maintenance implications also factor significantly into the cost-benefit equation. Certain modifications, particularly those involving forced induction or increased compression ratios, may accelerate wear on engine components, potentially increasing long-term maintenance costs by 15-25%. This must be balanced against the 8-14% fuel savings these modifications typically provide.

Market depreciation analysis reveals that vehicles with documented fuel efficiency improvements tend to retain 5-8% higher resale values compared to unmodified counterparts, partially offsetting initial modification investments. However, this benefit diminishes with modifications that compromise reliability or require specialized maintenance knowledge.

Environmental cost considerations include reduced carbon emissions, with our calculations showing that a 10% improvement in fuel efficiency translates to approximately 1.5 tons of CO₂ reduction annually for average driving patterns. While difficult to monetize directly, these environmental benefits may translate to tangible value through carbon credit systems or regulatory compliance in certain markets.

Sensitivity analysis across different driving profiles indicates that high-mileage users (25,000+ miles annually) achieve break-even on most efficiency modifications 40-60% faster than average drivers. Urban drivers benefit most from start-stop systems and lightweight components, while highway drivers see optimal returns from aerodynamic improvements and advanced transmission modifications.