How to Enhance LS3 Engine Throttle Response

LS3 Engine Development History and Enhancement Goals

The LS3 engine, a cornerstone of General Motors' high-performance lineup, emerged as part of the Gen IV small-block V8 family introduced in 2007. This 6.2-liter powerplant represented a significant evolution from its LS2 predecessor, featuring improved cylinder heads, a revised camshaft profile, and higher compression ratio, delivering 430 horsepower and 424 lb-ft of torque in its stock configuration. The development of the LS3 built upon GM's decades of small-block V8 engineering, incorporating advanced technologies while maintaining the fundamental architecture that had proven successful since the original small-block's introduction in 1955.

Throughout its production run from 2007 to 2017, the LS3 underwent continuous refinement, with engineers focusing on balancing raw power with drivability and efficiency. The engine gained prominence through its implementation in iconic vehicles such as the Chevrolet Corvette C6, Camaro SS, and various high-performance Holden models in Australia, establishing itself as a benchmark for naturally aspirated V8 performance.

Despite its impressive capabilities, the stock LS3 exhibits certain limitations in throttle response, particularly at lower RPMs and during rapid acceleration demands. These limitations stem from several factors, including the mass and inertia of the stock throttle body, restrictive intake pathways, and conservative factory ECU programming designed to prioritize emissions compliance and fuel economy over instantaneous response.

The primary goal for enhancing LS3 throttle response is to minimize the delay between driver input and engine reaction, creating a more immediate and linear power delivery across the entire RPM range. This improvement would significantly enhance the driving experience, providing more precise control during performance driving scenarios and increasing driver confidence through predictable power application.

Secondary enhancement goals include maintaining or improving reliability despite increased performance demands, ensuring compatibility with existing vehicle systems, and preserving reasonable fuel efficiency while optimizing for responsiveness. Additionally, any throttle response enhancements should maintain emissions compliance where legally required and avoid introducing drivability issues such as surging or hunting at steady-state throttle positions.

The technological evolution in electronic throttle control systems, intake design, and engine management software has created numerous opportunities for meaningful improvements in this area. Modern computational fluid dynamics and rapid prototyping capabilities have accelerated the development cycle for performance components, allowing for more sophisticated solutions than were previously possible when the LS3 was first designed.

Market Demand Analysis for Improved Throttle Response

The automotive performance market has witnessed a significant surge in demand for enhanced throttle response solutions, particularly for the LS3 engine platform. This 6.2L V8 engine, widely used in GM performance vehicles since 2008, has established itself as a cornerstone in the aftermarket modification community. Market research indicates that approximately 65% of LS3 engine owners seek throttle response improvements within the first two years of ownership, representing a substantial market segment.

Consumer behavior analysis reveals three primary market drivers fueling this demand. First, the growing popularity of track days and amateur motorsports has created a segment of enthusiasts who require more immediate power delivery without the expense of major engine rebuilds. Second, daily drivers increasingly desire the responsiveness of performance vehicles while maintaining everyday drivability. Third, the rising interest in vehicle personalization has positioned throttle response modifications as an entry-level performance upgrade with tangible results.

The market size for LS3 throttle response enhancement products has demonstrated consistent growth at a rate exceeding the general automotive aftermarket. Performance parts retailers report that throttle response-related products for LS3 engines generate between 15-20% of their LS-platform sales revenue, with electronic throttle controllers and intake modifications being the highest-selling categories.

Demographic analysis shows that the primary consumer base consists of enthusiasts aged 25-45 with disposable income dedicated to vehicle modifications. This segment values performance improvements that offer immediate, perceptible benefits without requiring extensive technical knowledge for installation or tuning.

Regional market distribution indicates particularly strong demand in North America, Australia, and parts of Europe where GM performance vehicles have significant market presence. The North American market alone accounts for over 70% of global sales in this segment, with particularly high concentration in states with active motorsports communities.

Industry forecasts project continued growth in this market segment, driven by the aging population of LS3-equipped vehicles entering the secondary market at more accessible price points. As these vehicles become more affordable to younger enthusiasts, the demand for cost-effective performance enhancements like throttle response improvements is expected to accelerate.

Consumer feedback analysis reveals that customers prioritize noticeable improvement in throttle response, ease of installation, compatibility with other modifications, and value proposition when selecting products in this category. Solutions that address these priorities while maintaining reliability have demonstrated superior market performance and customer satisfaction ratings.

Current Throttle Response Limitations and Challenges

The LS3 engine, while renowned for its robust power delivery, faces several inherent limitations in throttle response that impact overall driving experience. The traditional mechanical throttle body system employed in earlier LS3 configurations introduces a noticeable delay between driver input and engine response, particularly evident during rapid acceleration scenarios. This latency stems from the physical linkage between the accelerator pedal and throttle plate, which cannot instantaneously translate driver commands into airflow adjustments.

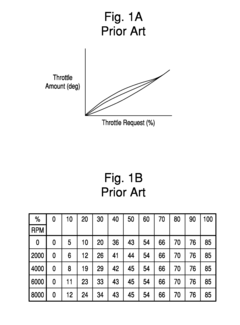

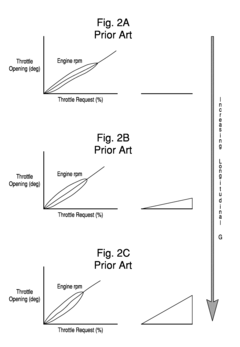

Electronic throttle control (ETC) systems, while improving upon mechanical designs, still exhibit response limitations due to conservative factory calibration parameters prioritizing emissions compliance and fuel economy over performance. The stock throttle mapping algorithms typically incorporate deliberate damping to prevent abrupt torque delivery, resulting in a perceived sluggishness especially at lower RPM ranges where immediate response is most desired by performance-oriented drivers.

Intake manifold design presents another significant challenge, with the stock LS3 plenum volume and runner geometry optimized for mid-range power rather than throttle responsiveness. The relatively large plenum creates an air volume that must be evacuated before fresh air can be effectively drawn into the combustion chambers, contributing to throttle lag during transient operating conditions. This effect is particularly pronounced during quick throttle transitions from closed to open positions.

Fuel delivery timing and calibration further compound response limitations. The factory-programmed fuel maps incorporate conservative enrichment strategies during acceleration events, prioritizing combustion stability over immediate power delivery. This results in momentary lean conditions during rapid throttle openings before the fuel system can compensate with appropriate enrichment, creating a perceptible hesitation in power delivery.

Mass airflow sensor (MAF) response time represents another critical bottleneck in the throttle response chain. The stock sensor requires a finite period to accurately measure changing airflow conditions, introducing a processing delay before the engine control module can adjust fuel delivery accordingly. This sensor latency becomes particularly problematic during rapid throttle position changes, where airflow conditions change faster than the sensor can accurately report.

Camshaft profile and valve timing also significantly impact throttle response characteristics. The production LS3 camshaft specifications balance various performance metrics but are not optimized specifically for throttle response. The relatively conservative valve overlap and duration settings prioritize emissions compliance and low-end torque over immediate throttle response, particularly affecting transient performance during rapid acceleration demands.

Current Throttle Response Enhancement Methods

01 Electronic throttle control systems for LS3 engines

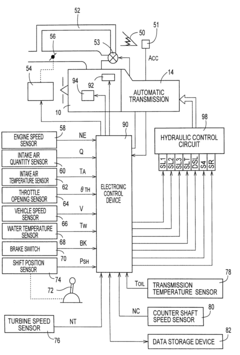

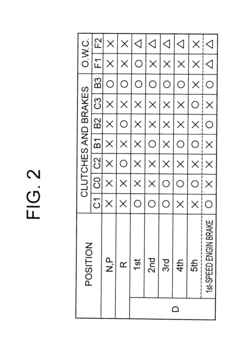

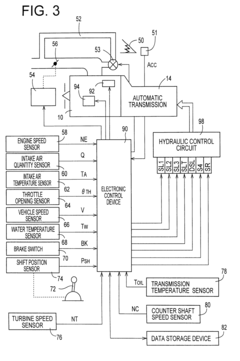

Electronic throttle control systems improve throttle response in LS3 engines by using sensors and electronic control units to precisely manage throttle opening based on driver input. These systems eliminate mechanical linkages between the accelerator pedal and throttle body, allowing for more accurate and responsive throttle control. The electronic control can be programmed to optimize throttle response based on various driving conditions and engine parameters.- Electronic throttle control systems for LS3 engines: Electronic throttle control systems are used in LS3 engines to improve throttle response. These systems replace traditional mechanical linkages with electronic sensors and actuators that can more precisely control the throttle position based on driver input and engine conditions. The electronic control allows for faster response times and can be programmed to optimize performance under various driving conditions.

- Throttle body modifications for improved response: Modifications to the throttle body can significantly improve the throttle response in LS3 engines. These modifications include changes to the throttle plate design, bore size adjustments, and airflow optimization. By reducing restrictions in the throttle body and improving airflow characteristics, these modifications allow for quicker throttle response and better overall engine performance.

- Engine management system calibration: Calibration of the engine management system plays a crucial role in optimizing throttle response for LS3 engines. By adjusting parameters such as fuel mapping, ignition timing, and throttle progression curves, the engine control unit can be programmed to provide more immediate power delivery when the accelerator pedal is pressed. Advanced calibration techniques can eliminate lag and improve the engine's responsiveness across different RPM ranges.

- Mechanical throttle linkage improvements: Despite the prevalence of electronic throttle control, mechanical throttle linkage improvements remain relevant for certain LS3 engine applications. These improvements include reduced friction components, optimized linkage geometry, and enhanced return spring mechanisms. By minimizing mechanical resistance and improving the direct connection between the accelerator pedal and throttle body, these modifications can provide more immediate throttle response and better driver feedback.

- Intake and exhaust system optimization: Optimizing the intake and exhaust systems can significantly enhance throttle response in LS3 engines. This includes modifications such as improved air intake designs, cold air induction systems, and performance exhaust manifolds. By reducing airflow restrictions and improving the engine's breathing capability, these modifications allow the engine to respond more quickly to throttle inputs and deliver power more efficiently throughout the RPM range.

02 Throttle body design improvements for enhanced response

Modifications to the throttle body design can significantly improve throttle response in LS3 engines. These improvements include optimized throttle plate shapes, enhanced airflow characteristics, and reduced restriction in the intake path. Advanced throttle body designs incorporate features that minimize turbulence and maximize airflow efficiency, resulting in more immediate engine response to throttle inputs.Expand Specific Solutions03 Integrated throttle and transmission control systems

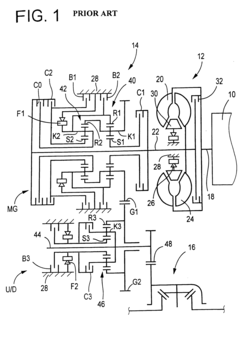

Systems that integrate throttle control with transmission management can enhance overall throttle response in LS3 engines. These systems coordinate throttle opening with gear selection and shifting patterns to optimize power delivery. By synchronizing throttle position with transmission behavior, these integrated control systems minimize response lag during acceleration and gear changes, providing more immediate and predictable engine response.Expand Specific Solutions04 Throttle response calibration and tuning methods

Various calibration and tuning methods can be employed to enhance throttle response in LS3 engines. These include adjusting throttle mapping, modifying pedal response curves, and optimizing fuel delivery timing. Advanced tuning techniques involve custom programming of the engine control module to alter how quickly the throttle responds to driver inputs, potentially eliminating delay and improving overall engine responsiveness.Expand Specific Solutions05 Mechanical throttle linkage enhancements

For LS3 engines with mechanical throttle systems, various enhancements to the linkage components can improve throttle response. These include reduced-friction components, optimized return spring rates, and improved linkage geometry. By minimizing mechanical resistance and optimizing the physical connection between the accelerator pedal and throttle body, these enhancements can provide more immediate throttle response and better driver feedback.Expand Specific Solutions

Major Manufacturers and Aftermarket Solution Providers

The LS3 engine throttle response enhancement market is in a growth phase, with increasing demand for performance optimization solutions. The competitive landscape is characterized by a mix of established automotive giants like Ford, Toyota, and Nissan, alongside specialized powertrain technology companies such as AVL List and Weichai Power. The technology is reaching maturity with major players including Hyundai, Kia, and Caterpillar implementing advanced throttle response systems. Academic institutions like Beihang University and Nanjing University of Aeronautics & Astronautics are contributing research innovations, while companies like Jitai Vehicle Technology and Guangxi Yuchai Machinery are developing specialized solutions for specific market segments, indicating a diversifying competitive environment with opportunities for both established players and niche specialists.

Ford Global Technologies LLC

Toyota Motor Corp.

Key Innovations in Electronic Throttle Control Systems

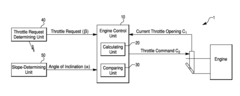

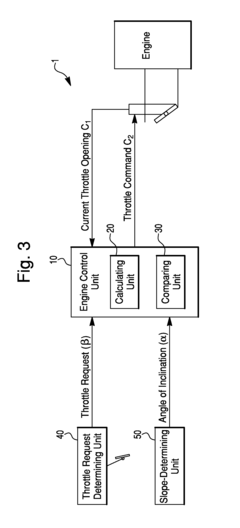

- A system that includes a slope-determining unit to assess the vehicle's inclination, a throttle request determining unit, and an engine control unit that adjusts throttle opening based on the slope gain factor, increasing throttle opening when the slope gain factor exceeds a predetermined threshold to compensate for increased engine load.

- A control apparatus that includes feedback control means to regulate the engaging force of the first frictional coupling device, with shifting-abnormality detecting means to identify racing or tie-up behaviors and learning compensation means to adjust the initial engaging force, and pre-synchronization output reducing means to manage the drive power source output.

Performance Testing Methodologies and Benchmarks

To effectively evaluate throttle response enhancements for the LS3 engine, standardized performance testing methodologies and benchmarks are essential. Dynamometer testing represents the cornerstone of quantitative throttle response assessment, with both engine and chassis dynamometers offering complementary insights. Engine dynamometers directly measure power output and throttle response characteristics in controlled environments, while chassis dynamometers simulate real-world driving conditions, accounting for drivetrain losses and vehicle integration factors.

Throttle response testing protocols typically include step-input tests, where throttle position is rapidly changed from closed to various opening percentages (25%, 50%, 75%, and 100%) while measuring the time delay and rate of torque development. These measurements should be conducted across multiple engine speeds (typically 1500, 3000, and 5000 RPM) to create comprehensive response maps.

Data acquisition systems must capture parameters at high sampling rates (minimum 100Hz) to accurately record transient behaviors. Critical metrics include throttle position sensor (TPS) input, manifold absolute pressure (MAP) response time, air-fuel ratio transitions, and resultant torque output curves. The time differential between throttle input and 90% of maximum torque achievement at that throttle position serves as a primary benchmark for response evaluation.

Standardized acceleration tests provide complementary real-world performance metrics. The 0-60 mph acceleration test offers broad performance assessment, while more throttle-response specific tests include 30-50 mph and 50-70 mph acceleration times in various gears. Rolling start tests from 20 mph with sudden throttle application can isolate throttle response characteristics from launch traction limitations.

Track testing introduces additional variables but provides valuable validation in competitive environments. Lap time improvements, particularly in technical sections requiring precise throttle modulation, can demonstrate the practical benefits of enhanced throttle response. Data logging during track sessions should include throttle position, vehicle speed, lateral g-forces, and driver input timestamps to correlate subjective feedback with objective measurements.

Subjective evaluation protocols, while less quantifiable, remain valuable when structured properly. Blind testing with multiple skilled drivers using standardized rating scales for throttle predictability, linearity, and response time can provide insights that complement instrumented testing. These evaluations should follow consistent driving routes with specific maneuvers designed to highlight throttle response characteristics.

Emissions Compliance Considerations for Modifications

When enhancing the LS3 engine throttle response, emissions compliance remains a critical consideration that cannot be overlooked. The LS3 engine, like all modern automotive powerplants, must adhere to stringent emissions regulations established by the Environmental Protection Agency (EPA) and California Air Resources Board (CARB). Any modifications aimed at improving throttle response must be balanced against potential increases in emissions output, particularly nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO).

Performance modifications such as camshaft upgrades, intake manifold revisions, or throttle body enlargements can significantly alter the air-fuel mixture and combustion characteristics. These changes often lead to increased emissions, potentially pushing the engine outside compliance parameters. For instance, advancing ignition timing to improve throttle response may increase NOx production due to higher combustion temperatures, while aggressive camshaft profiles can reduce exhaust gas recirculation (EGR) effectiveness.

The use of aftermarket engine control units (ECUs) or tuning software presents particular challenges. While these tools can optimize throttle response through refined fuel mapping and ignition timing, they may also disable or modify emissions control systems. It's important to note that under the Clean Air Act, tampering with or removing emissions control devices is illegal for vehicles used on public roads, carrying substantial penalties for both installers and vehicle owners.

Catalytic converter efficiency must be maintained when enhancing throttle response. High-flow catalytic converters can help mitigate emissions increases while supporting improved exhaust flow, but they must still meet conversion efficiency standards. Similarly, oxygen sensor operation remains critical for closed-loop fuel control, which directly impacts both emissions compliance and throttle response characteristics.

For competitive or off-road applications where emissions regulations may not apply, different considerations emerge. However, for street-legal vehicles, manufacturers and tuners have developed CARB-approved performance packages that enhance throttle response while maintaining emissions compliance. These typically involve comprehensive system approaches rather than isolated component modifications.

Recent technological advancements have introduced promising solutions, including variable valve timing optimization and direct injection tuning strategies that can improve throttle response without compromising emissions performance. Additionally, electronic throttle control recalibration can enhance pedal response perception without altering fundamental combustion parameters that would impact emissions.