LS3 Engine Sequential Fuel Injection: How to Retrofit

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Sequential Injection Background and Objectives

The LS3 engine, introduced by General Motors in 2007, represents a significant evolution in the LS engine family, featuring advanced fuel delivery systems. Originally designed with a sequential fuel injection system, the LS3 delivers precise amounts of fuel to each cylinder according to specific timing sequences, resulting in improved combustion efficiency, enhanced power output, and reduced emissions compared to its predecessors. This technology marked a departure from batch-fire injection methods used in earlier engine designs.

The evolution of fuel injection systems in automotive engines has progressed from mechanical systems to electronic fuel injection (EFI), and further to sequential fuel injection. This progression reflects the industry's continuous pursuit of improved engine performance, fuel economy, and emissions control. Sequential fuel injection technology specifically addresses the limitations of earlier systems by precisely timing the fuel delivery to coincide with each cylinder's intake stroke, optimizing the air-fuel mixture for combustion.

For owners of older LS-series engines or those with modified systems using batch-fire injection, retrofitting to sequential fuel injection presents an opportunity to achieve modern engine performance characteristics. The primary objective of such retrofitting is to enhance engine efficiency, increase power output, improve throttle response, and reduce fuel consumption while meeting stricter emissions standards.

The technical goals for retrofitting sequential fuel injection to LS3 engines include implementing cylinder-specific fuel timing, integrating compatible engine control units (ECUs) capable of managing sequential injection, installing appropriate fuel injectors and fuel rails, and ensuring proper wiring and sensor integration. Additionally, the retrofit aims to maintain or improve reliability while providing tuning flexibility for various applications ranging from daily drivers to high-performance racing vehicles.

Current market trends indicate growing interest in modernizing older LS engines with advanced fuel delivery systems, driven by enthusiasts seeking improved performance without the expense of complete engine replacements. This trend aligns with broader automotive industry movements toward more efficient combustion technologies and electronic engine management systems.

The retrofitting process must address several technical challenges, including compatibility with existing engine components, proper calibration of fuel delivery timing, integration with oxygen sensors for closed-loop operation, and ensuring adequate fuel pressure and volume throughout the operating range. Understanding these background elements and technical objectives provides the foundation for developing effective sequential fuel injection retrofit solutions for LS3 engines.

The evolution of fuel injection systems in automotive engines has progressed from mechanical systems to electronic fuel injection (EFI), and further to sequential fuel injection. This progression reflects the industry's continuous pursuit of improved engine performance, fuel economy, and emissions control. Sequential fuel injection technology specifically addresses the limitations of earlier systems by precisely timing the fuel delivery to coincide with each cylinder's intake stroke, optimizing the air-fuel mixture for combustion.

For owners of older LS-series engines or those with modified systems using batch-fire injection, retrofitting to sequential fuel injection presents an opportunity to achieve modern engine performance characteristics. The primary objective of such retrofitting is to enhance engine efficiency, increase power output, improve throttle response, and reduce fuel consumption while meeting stricter emissions standards.

The technical goals for retrofitting sequential fuel injection to LS3 engines include implementing cylinder-specific fuel timing, integrating compatible engine control units (ECUs) capable of managing sequential injection, installing appropriate fuel injectors and fuel rails, and ensuring proper wiring and sensor integration. Additionally, the retrofit aims to maintain or improve reliability while providing tuning flexibility for various applications ranging from daily drivers to high-performance racing vehicles.

Current market trends indicate growing interest in modernizing older LS engines with advanced fuel delivery systems, driven by enthusiasts seeking improved performance without the expense of complete engine replacements. This trend aligns with broader automotive industry movements toward more efficient combustion technologies and electronic engine management systems.

The retrofitting process must address several technical challenges, including compatibility with existing engine components, proper calibration of fuel delivery timing, integration with oxygen sensors for closed-loop operation, and ensuring adequate fuel pressure and volume throughout the operating range. Understanding these background elements and technical objectives provides the foundation for developing effective sequential fuel injection retrofit solutions for LS3 engines.

Market Analysis for LS3 Sequential Fuel Injection Retrofits

The sequential fuel injection retrofit market for LS3 engines represents a significant segment within the automotive aftermarket industry, with growing demand driven by performance enthusiasts and restoration specialists. Current market analysis indicates that this sector has expanded at approximately 7% annually over the past five years, outpacing the broader automotive aftermarket growth rate of 3-4%.

The primary market segments for LS3 sequential fuel injection retrofits include classic car restoration projects, performance upgrades for older GM vehicles, racing applications, and custom builds. The restoration segment alone accounts for nearly 40% of retrofit installations, as owners of vintage vehicles seek modern fuel delivery systems that improve reliability while maintaining period-correct appearances.

Consumer demographics reveal that retrofit customers typically fall into three categories: professional mechanics and shops (35%), dedicated DIY enthusiasts with advanced technical knowledge (45%), and collectors who hire specialists for installation (20%). The average customer spends between $1,200 and $3,500 on complete sequential fuel injection retrofit kits, with additional expenditure for professional installation when required.

Regional market distribution shows strongest adoption in North America (65% of global market), followed by Europe (20%), Australia (8%), and emerging markets (7%). Within North America, the highest concentration of customers exists in traditional automotive hubs such as Michigan, California, Texas, and the Southeastern United States.

Market research indicates that consumers prioritize several key factors when selecting retrofit systems: compatibility with existing engine components (cited by 87% of buyers), ease of installation (76%), performance gains (92%), and fuel efficiency improvements (68%). Price sensitivity varies significantly by segment, with racing applications demonstrating the least price sensitivity and restoration projects showing moderate price concerns.

Competition in this market includes established automotive electronics manufacturers like Holley, FAST, and FiTech, alongside specialized LS-focused companies such as Texas Speed & Performance and Lingenfelter Performance Engineering. Market concentration remains moderate, with the top five providers controlling approximately 65% of sales volume.

Growth projections suggest the LS3 sequential fuel injection retrofit market will continue expanding at 8-10% annually through 2027, driven by increasing classic car values, growing interest in restomodding, and the continued popularity of LS-series engines as swap candidates for a wide variety of vehicles. The market is expected to reach a global value of $450 million by 2025, representing a significant opportunity for both established players and innovative newcomers.

The primary market segments for LS3 sequential fuel injection retrofits include classic car restoration projects, performance upgrades for older GM vehicles, racing applications, and custom builds. The restoration segment alone accounts for nearly 40% of retrofit installations, as owners of vintage vehicles seek modern fuel delivery systems that improve reliability while maintaining period-correct appearances.

Consumer demographics reveal that retrofit customers typically fall into three categories: professional mechanics and shops (35%), dedicated DIY enthusiasts with advanced technical knowledge (45%), and collectors who hire specialists for installation (20%). The average customer spends between $1,200 and $3,500 on complete sequential fuel injection retrofit kits, with additional expenditure for professional installation when required.

Regional market distribution shows strongest adoption in North America (65% of global market), followed by Europe (20%), Australia (8%), and emerging markets (7%). Within North America, the highest concentration of customers exists in traditional automotive hubs such as Michigan, California, Texas, and the Southeastern United States.

Market research indicates that consumers prioritize several key factors when selecting retrofit systems: compatibility with existing engine components (cited by 87% of buyers), ease of installation (76%), performance gains (92%), and fuel efficiency improvements (68%). Price sensitivity varies significantly by segment, with racing applications demonstrating the least price sensitivity and restoration projects showing moderate price concerns.

Competition in this market includes established automotive electronics manufacturers like Holley, FAST, and FiTech, alongside specialized LS-focused companies such as Texas Speed & Performance and Lingenfelter Performance Engineering. Market concentration remains moderate, with the top five providers controlling approximately 65% of sales volume.

Growth projections suggest the LS3 sequential fuel injection retrofit market will continue expanding at 8-10% annually through 2027, driven by increasing classic car values, growing interest in restomodding, and the continued popularity of LS-series engines as swap candidates for a wide variety of vehicles. The market is expected to reach a global value of $450 million by 2025, representing a significant opportunity for both established players and innovative newcomers.

Technical Challenges in LS3 Sequential Injection Conversion

Converting an LS3 engine to sequential fuel injection presents several significant technical challenges that must be addressed for successful implementation. The primary obstacle lies in the electronic control system integration. The LS3 engine's factory ECU is specifically programmed for batch-fire injection, and reprogramming or replacing it with a sequential-capable ECU requires extensive knowledge of engine management systems and calibration expertise.

Wiring harness modification represents another major challenge. The existing harness must be substantially altered or completely replaced to accommodate the sequential injection timing signals. This involves precise routing of additional wires, proper shielding to prevent electromagnetic interference, and ensuring correct pin-out connections between the ECU and injectors.

Injector selection and compatibility issues also present technical hurdles. Sequential injection typically requires high-impedance injectors with specific flow rates calibrated for the LS3's displacement and performance targets. The physical fitment of these injectors into the LS3 intake manifold may require custom adapters or modifications to ensure proper sealing and spray pattern orientation.

Fuel pressure regulation becomes more critical in sequential systems. The fuel rail must maintain consistent pressure across all cylinders despite the more complex firing sequence. This often necessitates upgrading to a return-style fuel system with a high-quality regulator capable of maintaining stable pressure under varying demand conditions.

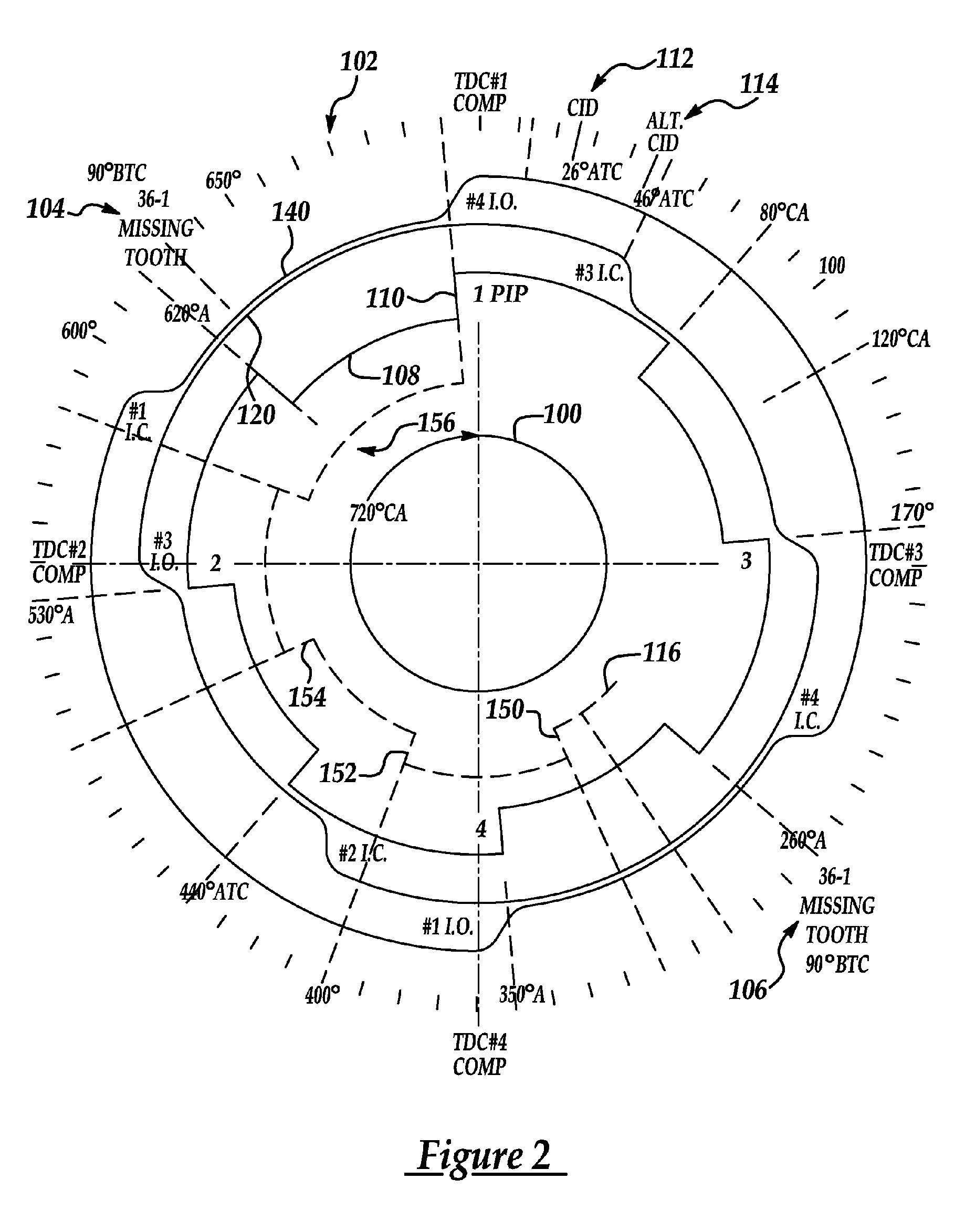

Timing synchronization presents perhaps the most complex challenge. Sequential injection requires precise crankshaft and camshaft position sensing to accurately time each injection event. The stock LS3 sensors may need upgrading or supplementation with additional position sensors to achieve the resolution necessary for optimal sequential timing.

Calibration and tuning complexity increases exponentially with sequential injection. Each cylinder must be individually mapped and tuned across the entire operating range of the engine. This requires sophisticated diagnostic equipment, data logging capabilities, and extensive dyno time to optimize fuel delivery for each cylinder under various load conditions.

Cold-start and transient operation management becomes more sophisticated in sequential systems. The ECU must be programmed with specific strategies for these conditions, often requiring additional sensors and complex algorithms to maintain proper air-fuel ratios during these critical operating phases.

Finally, diagnostic capabilities must be enhanced to troubleshoot the more complex sequential system. This includes implementing comprehensive error detection and reporting systems to identify individual cylinder injection issues that might otherwise go undetected in batch-fire systems.

Wiring harness modification represents another major challenge. The existing harness must be substantially altered or completely replaced to accommodate the sequential injection timing signals. This involves precise routing of additional wires, proper shielding to prevent electromagnetic interference, and ensuring correct pin-out connections between the ECU and injectors.

Injector selection and compatibility issues also present technical hurdles. Sequential injection typically requires high-impedance injectors with specific flow rates calibrated for the LS3's displacement and performance targets. The physical fitment of these injectors into the LS3 intake manifold may require custom adapters or modifications to ensure proper sealing and spray pattern orientation.

Fuel pressure regulation becomes more critical in sequential systems. The fuel rail must maintain consistent pressure across all cylinders despite the more complex firing sequence. This often necessitates upgrading to a return-style fuel system with a high-quality regulator capable of maintaining stable pressure under varying demand conditions.

Timing synchronization presents perhaps the most complex challenge. Sequential injection requires precise crankshaft and camshaft position sensing to accurately time each injection event. The stock LS3 sensors may need upgrading or supplementation with additional position sensors to achieve the resolution necessary for optimal sequential timing.

Calibration and tuning complexity increases exponentially with sequential injection. Each cylinder must be individually mapped and tuned across the entire operating range of the engine. This requires sophisticated diagnostic equipment, data logging capabilities, and extensive dyno time to optimize fuel delivery for each cylinder under various load conditions.

Cold-start and transient operation management becomes more sophisticated in sequential systems. The ECU must be programmed with specific strategies for these conditions, often requiring additional sensors and complex algorithms to maintain proper air-fuel ratios during these critical operating phases.

Finally, diagnostic capabilities must be enhanced to troubleshoot the more complex sequential system. This includes implementing comprehensive error detection and reporting systems to identify individual cylinder injection issues that might otherwise go undetected in batch-fire systems.

Current Retrofit Solutions for LS3 Sequential Fuel Injection

01 Sequential Fuel Injection System Design for LS3 Engines

Sequential fuel injection systems for LS3 engines involve precise timing control where each injector is activated individually in sequence with the engine's firing order. These systems improve fuel efficiency, power output, and emissions control compared to batch-fire systems. The design typically includes electronic control units that monitor various engine parameters to optimize fuel delivery timing based on engine load, speed, and operating conditions.- Sequential Fuel Injection System Design for LS3 Engines: Sequential fuel injection systems for LS3 engines involve precise timing control where each injector is activated individually in sequence with the engine's firing order. This design improves fuel efficiency, power output, and emissions control compared to batch firing systems. The system typically includes electronic control units that monitor various engine parameters to optimize fuel delivery timing and quantity for each cylinder independently.

- Electronic Control Unit (ECU) Programming for Retrofit Applications: Retrofitting an LS3 engine with sequential fuel injection requires specialized ECU programming to manage the timing and duration of injection events. These control systems can be reprogrammed to accommodate the specific requirements of the LS3 engine architecture, including cylinder firing order, fuel pressure parameters, and throttle response characteristics. Advanced ECUs may include self-learning capabilities to optimize performance based on driving conditions and engine feedback.

- Fuel Delivery Components and Hardware Integration: Retrofitting sequential fuel injection to an LS3 engine requires specific hardware components including high-pressure fuel rails, compatible injectors, fuel pressure regulators, and appropriate sensors. The integration of these components must maintain proper fuel pressure across all operating conditions while ensuring compatibility with the existing engine architecture. Special attention must be paid to injector placement and orientation to optimize fuel atomization and combustion efficiency.

- Performance Optimization and Calibration Techniques: After retrofitting sequential fuel injection to an LS3 engine, calibration is essential to optimize performance. This involves adjusting fuel maps, ignition timing, and air-fuel ratios across various engine loads and speeds. Advanced calibration techniques may include dynamometer testing, wide-band oxygen sensor feedback, and iterative tuning processes to achieve the desired balance between power, efficiency, and emissions compliance. Proper calibration ensures the retrofit system performs optimally under all operating conditions.

- Emissions Compliance and Diagnostic Systems: Sequential fuel injection retrofits for LS3 engines must address emissions compliance requirements through proper system design and calibration. This includes implementing on-board diagnostic capabilities to monitor system performance and detect malfunctions. Modern retrofit systems incorporate oxygen sensors, exhaust gas recirculation compatibility, and other emissions control strategies to meet regulatory standards while maintaining performance benefits. Diagnostic systems help identify issues with injector performance, fuel pressure, or control system malfunctions.

02 Electronic Control Units for Retrofit Applications

Specialized electronic control units (ECUs) are essential for retrofitting sequential fuel injection to LS3 engines. These ECUs are programmed to manage the precise timing of fuel delivery and can be calibrated to accommodate modifications to the stock engine. Advanced ECUs include adaptive learning capabilities that adjust fuel delivery based on feedback from oxygen sensors and other inputs, allowing for optimal performance across various driving conditions.Expand Specific Solutions03 Fuel Injector Modifications and Requirements

Retrofitting an LS3 engine with sequential fuel injection requires specific injector configurations. High-impedance injectors compatible with the LS3 fuel rail system are typically used, with flow rates matched to the engine's horsepower goals. Proper injector placement and orientation are critical for optimal fuel atomization and combustion efficiency. Modifications may include custom fuel rails, injector adapters, and pressure regulators to ensure consistent fuel delivery across all cylinders.Expand Specific Solutions04 Wiring Harness and Sensor Integration

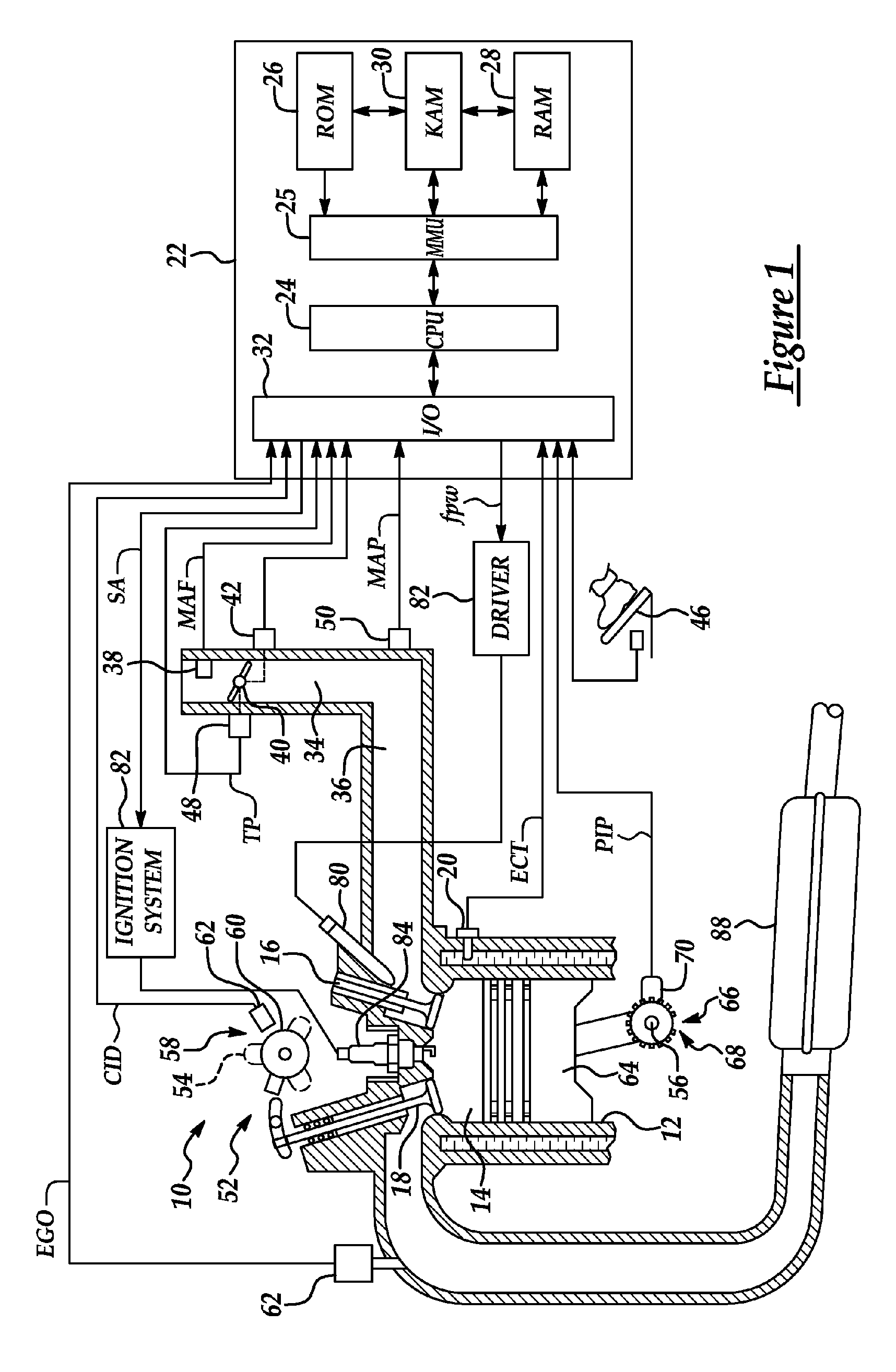

A comprehensive wiring harness is required to connect the ECU to various engine sensors and actuators in a sequential fuel injection retrofit. This includes integration with crankshaft position sensors, camshaft position sensors, throttle position sensors, and oxygen sensors. The harness must be designed to withstand engine bay temperatures and vibration while providing reliable connections. Proper sensor calibration and placement are essential for accurate engine monitoring and fuel delivery timing.Expand Specific Solutions05 Performance Tuning and Calibration Methods

After retrofitting an LS3 engine with sequential fuel injection, proper tuning and calibration are essential to optimize performance. This involves adjusting fuel maps, ignition timing, and air-fuel ratios across the engine's operating range. Dyno testing and data logging are commonly used to fine-tune the system for maximum power, efficiency, and drivability. Advanced tuning techniques may include individual cylinder fuel trim adjustments to compensate for variations in airflow between cylinders.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers Analysis

The LS3 Engine Sequential Fuel Injection retrofit market is currently in a growth phase, with increasing demand for performance upgrades in the automotive aftermarket sector. The market size is expanding as enthusiasts seek to modernize older vehicles with advanced fuel delivery systems. From a technical maturity perspective, established automotive component manufacturers like DENSO Corp., Robert Bosch GmbH, and Mitsubishi Electric lead with sophisticated electronic fuel injection technologies. OEMs such as Mercedes-Benz, Honda, Hyundai, and Nissan provide factory-level integration expertise, while specialized companies like Progress Rail Locomotive and Marelli offer retrofit-specific solutions. Academic institutions including Tianjin University and Beihang University contribute research advancements, creating a competitive landscape balanced between established industrial players and emerging specialized retrofit solution providers.

DENSO Corp.

Technical Solution: DENSO has engineered a comprehensive sequential fuel injection retrofit system for LS3 engines that leverages their expertise in OEM fuel delivery systems. Their solution features high-impedance fuel injectors specifically calibrated for the LS3's displacement and flow requirements, with flow rates precisely matched to ensure balanced cylinder-to-cylinder fuel distribution. DENSO's system incorporates their proprietary air-mass sensor technology for accurate air intake measurement, coupled with a specialized ECU capable of managing both sequential injection timing and adaptive fuel mapping. The retrofit kit includes custom-designed fuel rails manufactured to OEM tolerances, ensuring proper fitment and pressure stability across the entire RPM range. DENSO's implementation utilizes advanced noise filtering algorithms in their ECU to maintain precise injection timing even in electromagnetically noisy environments, addressing a common challenge in retrofit applications.

Strengths: Exceptional manufacturing precision and consistency across components, ensuring reliable performance and longevity. Comprehensive integration with existing GM sensor architecture. Weaknesses: More limited tuning flexibility compared to some aftermarket-focused solutions and higher initial investment cost.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive retrofit solutions for LS3 engine sequential fuel injection systems through their Motronic engine management technology. Their system integrates electronic control units (ECUs) specifically calibrated for GM LS3 engines with high-precision fuel injectors capable of multiple injection events per cycle. Bosch's retrofit kit includes plug-and-play wiring harnesses, specialized fuel rails, and pressure regulators designed to maintain optimal fuel delivery across varying engine loads. Their solution incorporates advanced closed-loop feedback systems using wide-band oxygen sensors to continuously adjust fuel mapping for optimal air-fuel ratios. Bosch's sequential injection timing is synchronized with the engine's firing order through a crankshaft position sensor, enabling precise fuel delivery at the exact moment intake valves open for each cylinder.

Strengths: Industry-leading fuel injector technology with microsecond response times and exceptional atomization characteristics. Comprehensive technical support and widely available replacement parts. Weaknesses: Higher initial cost compared to competitors and more complex installation requiring specialized knowledge of Bosch ECU programming.

Key Patents and Innovations in Sequential Injection Technology

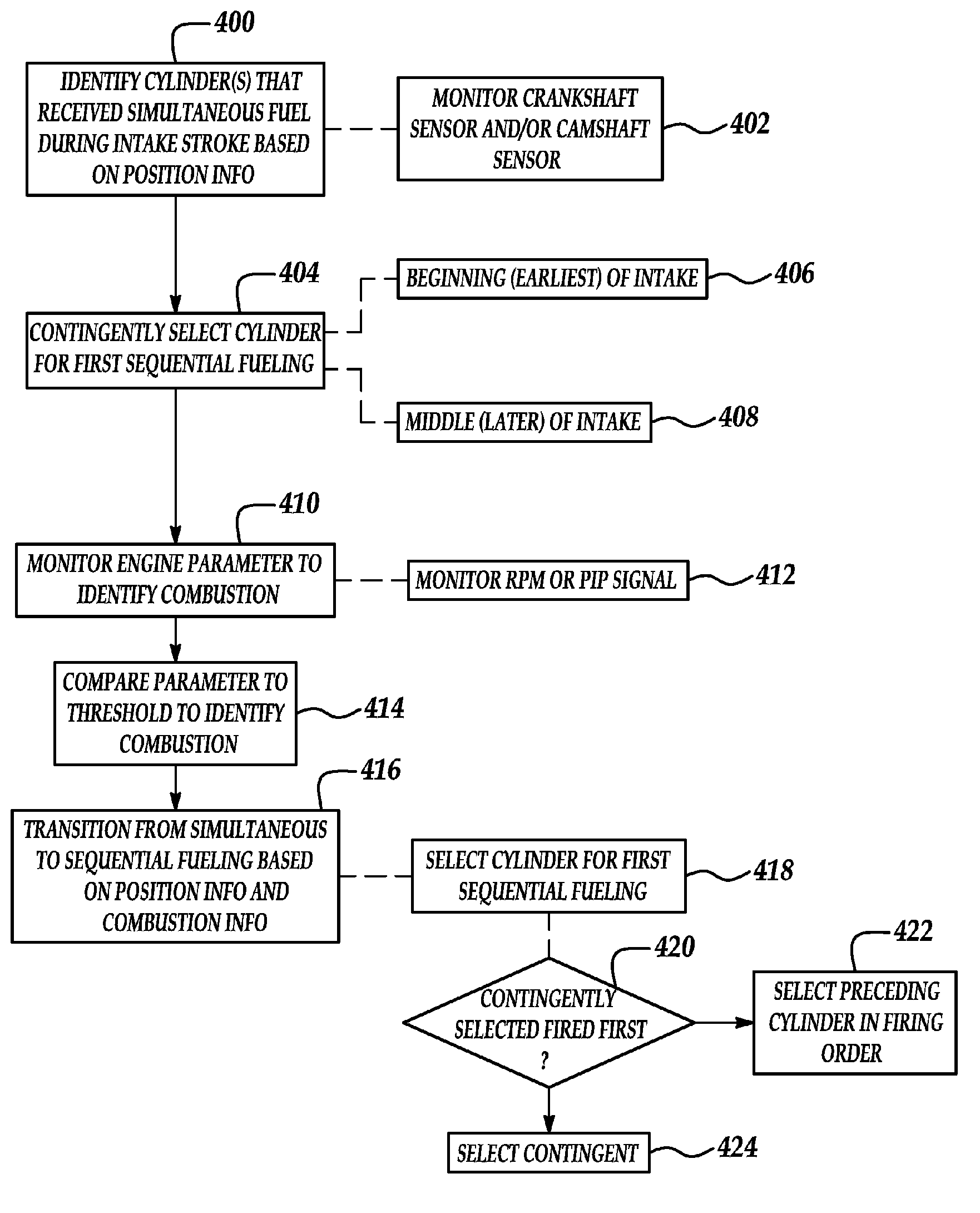

System and method for starting sequential fuel injection internal combustion engine

PatentInactiveUS7124743B2

Innovation

- A system and method that uses combustion information to supplement position sensor data to conditionally select a cylinder for sequential fuel injection, monitoring engine rotational speed to determine which cylinder fired first and adjusting the fueling pulse accordingly, without requiring additional sensors.

Fuel injection control system for multi-cylinder internal combustion engine with feature of improved response characteristics to acceleration enrichment demand

PatentInactiveUS4911132A

Innovation

- A fuel injection control system that uses asynchronous acceleration enrichment, where fuel injection timing is adjusted based on real-time engine acceleration demand and load conditions, with sensors monitoring engine speed, load, and throttle angle to dynamically modify fuel injection amounts and timings, ensuring proper atomization and response to load changes.

Emissions Compliance Considerations for Retrofit Applications

Retrofitting an LS3 engine with sequential fuel injection necessitates careful consideration of emissions regulations to ensure legal compliance. Federal EPA standards and state-specific requirements, particularly California's stringent CARB regulations, establish the regulatory framework for aftermarket modifications. Any retrofit must maintain or improve upon the original emissions performance of the vehicle to avoid potential legal penalties and environmental harm.

The retrofit process requires selection of CARB or EPA-certified components whenever possible. These components have undergone rigorous testing to verify they do not increase emissions beyond factory specifications. For LS3 sequential fuel injection retrofits, this includes ensuring the ECU programming, injectors, and sensors work together to maintain proper air-fuel ratios across all operating conditions. Manufacturers offering retrofit kits should provide documentation of compliance testing or appropriate Executive Orders for legal installation.

Oxygen sensor placement and functionality represent critical factors in emissions compliance. The retrofit must maintain proper closed-loop operation with functional pre-catalytic and post-catalytic O2 sensors. This ensures the system can self-adjust fuel delivery to maintain stoichiometric combustion when appropriate, significantly reducing harmful emissions. Modifications to exhaust systems must preserve or enhance catalytic converter efficiency, as these components play a vital role in reducing NOx, CO, and hydrocarbon emissions.

Evaporative emissions control systems present another compliance challenge. The retrofit must maintain all factory evaporative controls, including charcoal canisters, purge valves, and fuel tank pressure sensors. Failure to properly integrate these systems can result in increased hydrocarbon emissions and potential check engine lights. Modern sequential fuel injection systems must also incorporate proper diagnostics to detect emission-related malfunctions, maintaining OBD-II compatibility.

Testing and verification constitute essential steps in ensuring emissions compliance. Post-retrofit emissions testing at certified facilities can verify the modification meets applicable standards. This may include idle emissions tests, loaded mode testing, or full dynamometer testing depending on local requirements. Documentation of these test results should be maintained with the vehicle to demonstrate compliance in case of regulatory inspection.

Long-term compliance requires ongoing maintenance considerations. The retrofit system should include clear service intervals and replacement parts specifications to ensure emissions performance does not degrade over time. Owners should understand that modifications may affect warranty coverage and inspection requirements in their jurisdiction. Professional installation by technicians familiar with both emissions regulations and fuel system dynamics significantly reduces compliance risks.

The retrofit process requires selection of CARB or EPA-certified components whenever possible. These components have undergone rigorous testing to verify they do not increase emissions beyond factory specifications. For LS3 sequential fuel injection retrofits, this includes ensuring the ECU programming, injectors, and sensors work together to maintain proper air-fuel ratios across all operating conditions. Manufacturers offering retrofit kits should provide documentation of compliance testing or appropriate Executive Orders for legal installation.

Oxygen sensor placement and functionality represent critical factors in emissions compliance. The retrofit must maintain proper closed-loop operation with functional pre-catalytic and post-catalytic O2 sensors. This ensures the system can self-adjust fuel delivery to maintain stoichiometric combustion when appropriate, significantly reducing harmful emissions. Modifications to exhaust systems must preserve or enhance catalytic converter efficiency, as these components play a vital role in reducing NOx, CO, and hydrocarbon emissions.

Evaporative emissions control systems present another compliance challenge. The retrofit must maintain all factory evaporative controls, including charcoal canisters, purge valves, and fuel tank pressure sensors. Failure to properly integrate these systems can result in increased hydrocarbon emissions and potential check engine lights. Modern sequential fuel injection systems must also incorporate proper diagnostics to detect emission-related malfunctions, maintaining OBD-II compatibility.

Testing and verification constitute essential steps in ensuring emissions compliance. Post-retrofit emissions testing at certified facilities can verify the modification meets applicable standards. This may include idle emissions tests, loaded mode testing, or full dynamometer testing depending on local requirements. Documentation of these test results should be maintained with the vehicle to demonstrate compliance in case of regulatory inspection.

Long-term compliance requires ongoing maintenance considerations. The retrofit system should include clear service intervals and replacement parts specifications to ensure emissions performance does not degrade over time. Owners should understand that modifications may affect warranty coverage and inspection requirements in their jurisdiction. Professional installation by technicians familiar with both emissions regulations and fuel system dynamics significantly reduces compliance risks.

Cost-Benefit Analysis of Sequential Injection Conversion

Converting an LS3 engine from batch fire to sequential fuel injection represents a significant investment that must be carefully evaluated through comprehensive cost-benefit analysis. The initial financial outlay for a sequential injection conversion typically ranges from $1,200 to $3,500, depending on component quality, brand selection, and whether professional installation is required. This investment includes the sequential injection controller ($600-$1,200), upgraded fuel injectors ($300-$600), wiring harness modifications ($150-$400), and potentially new fuel rails ($200-$500).

Beyond the immediate costs, labor expenses must be considered. Professional installation can add $500-$1,000 to the total investment, while DIY conversion requires 15-25 hours of technical work, representing a significant time commitment for enthusiasts.

The benefits of sequential injection conversion provide compelling counterbalance to these costs. Fuel efficiency improvements of 5-15% can be realized, translating to meaningful savings over the vehicle's lifetime. For a vehicle consuming 500 gallons annually, even a 10% efficiency improvement could save $150-$200 per year at current fuel prices.

Performance gains represent another significant benefit. Sequential injection typically delivers 5-8% horsepower increases and 3-7% torque improvements through more precise fuel delivery. Throttle response becomes noticeably more immediate, enhancing the driving experience. Emissions reductions of 10-20% for hydrocarbons and carbon monoxide also contribute to environmental benefits and potential regulatory compliance.

The return on investment timeline varies based on usage patterns. High-mileage applications may recoup costs within 2-4 years through fuel savings alone, while performance-focused enthusiasts might justify the expense through improved driving dynamics and competitive advantages. For show vehicles or weekend drivers, the aesthetic and technical prestige may outweigh pure financial calculations.

Maintenance considerations also factor into the equation. While sequential systems generally require less frequent maintenance than batch-fire setups, they introduce greater complexity that may necessitate specialized diagnostic equipment and expertise when problems arise. This represents a hidden cost that should be factored into long-term ownership calculations.

For optimal decision-making, vehicle owners should consider their specific usage patterns, performance goals, and financial constraints when evaluating the viability of sequential injection conversion for their LS3 engine application.

Beyond the immediate costs, labor expenses must be considered. Professional installation can add $500-$1,000 to the total investment, while DIY conversion requires 15-25 hours of technical work, representing a significant time commitment for enthusiasts.

The benefits of sequential injection conversion provide compelling counterbalance to these costs. Fuel efficiency improvements of 5-15% can be realized, translating to meaningful savings over the vehicle's lifetime. For a vehicle consuming 500 gallons annually, even a 10% efficiency improvement could save $150-$200 per year at current fuel prices.

Performance gains represent another significant benefit. Sequential injection typically delivers 5-8% horsepower increases and 3-7% torque improvements through more precise fuel delivery. Throttle response becomes noticeably more immediate, enhancing the driving experience. Emissions reductions of 10-20% for hydrocarbons and carbon monoxide also contribute to environmental benefits and potential regulatory compliance.

The return on investment timeline varies based on usage patterns. High-mileage applications may recoup costs within 2-4 years through fuel savings alone, while performance-focused enthusiasts might justify the expense through improved driving dynamics and competitive advantages. For show vehicles or weekend drivers, the aesthetic and technical prestige may outweigh pure financial calculations.

Maintenance considerations also factor into the equation. While sequential systems generally require less frequent maintenance than batch-fire setups, they introduce greater complexity that may necessitate specialized diagnostic equipment and expertise when problems arise. This represents a hidden cost that should be factored into long-term ownership calculations.

For optimal decision-making, vehicle owners should consider their specific usage patterns, performance goals, and financial constraints when evaluating the viability of sequential injection conversion for their LS3 engine application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!