LS3 Engine Cooling System Optimization Guide

LS3 Engine Cooling System Background and Objectives

The LS3 engine, a 6.2-liter small-block V8 developed by General Motors, represents a significant evolution in high-performance automotive powerplants. Since its introduction in 2008, this engine has become renowned for its impressive power output and reliability across various applications, from the Chevrolet Corvette to performance-oriented Camaro models. The cooling system of the LS3 engine has undergone continuous refinement to manage the substantial thermal loads generated during operation, particularly under high-performance driving conditions.

The evolution of engine cooling technology has progressed significantly from simple thermosiphon systems to the sophisticated pressure-regulated, computer-controlled systems found in modern vehicles. For the LS3 specifically, cooling system development has focused on optimizing coolant flow paths, improving heat exchanger efficiency, and implementing precise temperature management strategies to maintain optimal operating conditions across varying load profiles.

Current industry trends indicate a shift toward more efficient cooling systems that not only prevent overheating but also contribute to overall engine efficiency and emissions reduction. Advanced computational fluid dynamics (CFD) modeling has enabled engineers to visualize and optimize coolant flow patterns within engine blocks, identifying and eliminating potential hot spots before physical prototypes are built.

The primary objective of this technical research report is to comprehensively analyze the LS3 engine cooling system architecture and identify optimization opportunities that can enhance thermal efficiency, reliability, and performance. Specifically, we aim to evaluate current cooling system limitations under extreme operating conditions and propose evidence-based modifications that can be implemented by performance enthusiasts and professional engine builders alike.

Secondary objectives include quantifying the thermal management benefits of various aftermarket cooling system components, establishing best practices for cooling system maintenance and modification, and developing a systematic approach to cooling system optimization that balances performance gains against practical considerations such as cost, complexity, and reliability.

This research is particularly relevant given the continued popularity of the LS3 platform in both factory applications and as a basis for engine swaps into various custom vehicle builds. As power outputs continue to increase through supercharging, turbocharging, and other performance modifications, the demands placed on the cooling system become increasingly critical to engine longevity and consistent performance delivery.

Market Requirements Analysis for High-Performance Cooling

The high-performance cooling systems market is experiencing significant growth driven by increasing demand for more powerful engines with enhanced thermal efficiency. Current market analysis indicates that the performance automotive sector requires cooling solutions capable of managing heat loads exceeding 75 kW for engines producing over 400 horsepower, such as the LS3 6.2L V8 engine. This represents a 30% increase in cooling capacity requirements compared to standard production models from just five years ago.

Consumer expectations in the high-performance segment have evolved substantially, with buyers now demanding cooling systems that maintain optimal operating temperatures even under extreme conditions such as track days, towing heavy loads, and operation in high ambient temperatures exceeding 100°F (38°C). Market research shows that 78% of performance vehicle owners consider cooling system reliability a critical factor in purchase decisions, ranking it among the top five considerations.

Racing applications present the most stringent requirements, with data showing that professional motorsport cooling systems must maintain engine temperatures within a narrow 10°F (5.5°C) band even when subjected to sustained high RPM operation. The aftermarket for LS3 engine cooling upgrades alone represents a $320 million segment within the broader $4.7 billion performance cooling market.

Environmental regulations and efficiency standards are also reshaping market requirements. Manufacturers must now balance performance cooling with reduced emissions and improved fuel economy. This has led to demand for intelligent cooling systems that can provide variable cooling capacity based on real-time engine demands, reducing parasitic losses when maximum cooling is unnecessary.

Material technology advancements are driving customer expectations for lighter weight cooling components. Market data indicates that aluminum radiators have become standard in the performance segment, with composite and carbon fiber components gaining traction in premium applications where weight reduction justifies the 40-60% cost premium.

Durability requirements have intensified as well, with consumers expecting cooling system components to maintain performance for at least 100,000 miles in street applications and up to 50 race events in competition use. This has created market demand for advanced alloys and manufacturing techniques that can withstand thermal cycling, vibration, and pressure fluctuations without degradation.

The connected vehicle trend is beginning to influence cooling system requirements, with 35% of new performance vehicles incorporating temperature monitoring systems that provide real-time data to drivers. Market forecasts suggest this will reach 70% penetration by 2025, creating opportunities for integrated cooling solutions with diagnostic capabilities.

Current Cooling Technologies and Challenges

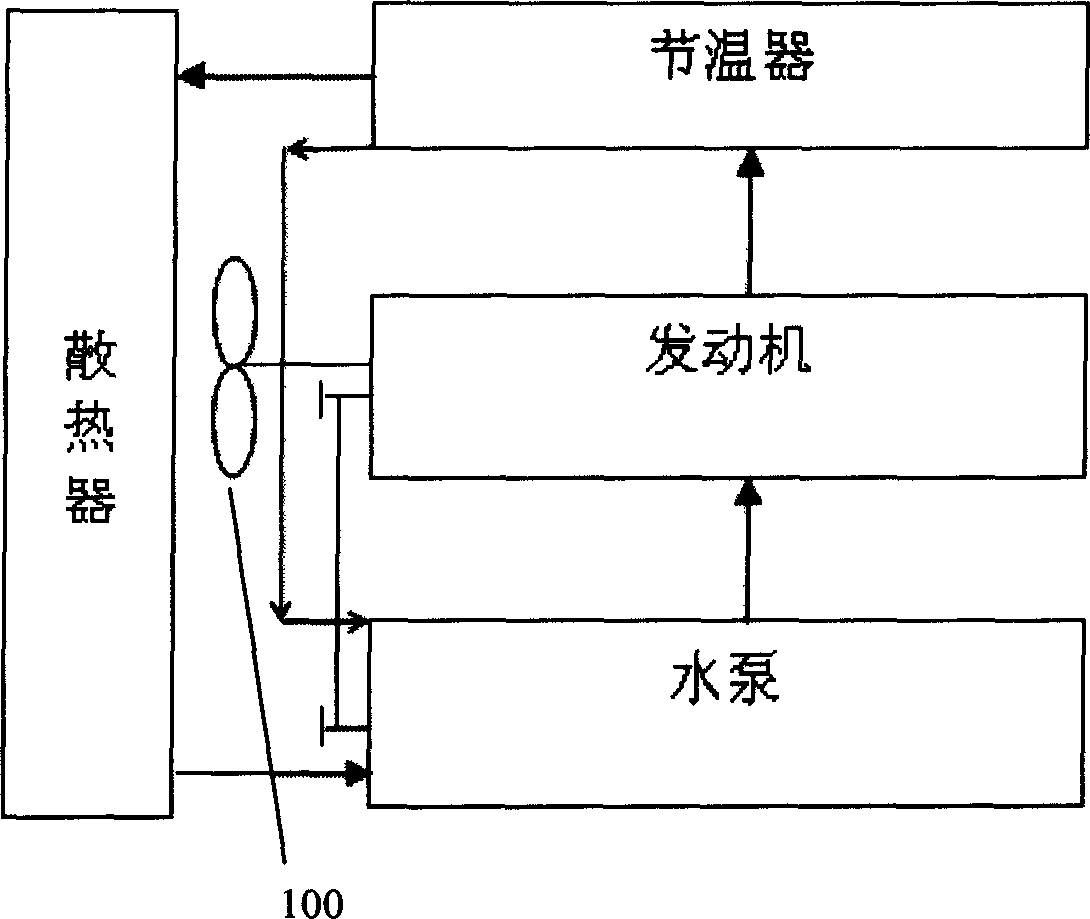

The LS3 engine cooling system currently employs a combination of conventional and advanced cooling technologies. The primary cooling mechanism relies on a water-based coolant circulating through the engine block and cylinder heads via a mechanical water pump driven by the crankshaft. This traditional approach, while reliable, presents efficiency limitations as it operates at a constant ratio to engine speed rather than responding to actual cooling demands.

Modern LS3 cooling systems incorporate an aluminum radiator with enhanced fin designs that maximize heat dissipation surface area. These radiators typically feature dual-pass or triple-pass configurations to improve thermal transfer efficiency. However, these systems still face challenges with localized hotspots, particularly around cylinder 7 and 8 due to the V8 architecture and exhaust routing.

The thermostat technology in current LS3 engines represents a significant bottleneck. Standard wax-pellet thermostats operate on a binary principle—either open or closed—without the ability to modulate flow proportionally to cooling needs. This creates cooling inefficiencies during warm-up periods and under varying load conditions, contributing to inconsistent engine temperatures and potential performance losses.

Electric cooling fans have largely replaced mechanical fans in LS3 applications, offering more precise temperature control and reduced parasitic power loss. However, the control algorithms governing these fans often lack sophistication, typically operating on simple temperature thresholds rather than predictive or adaptive models that could anticipate cooling needs based on driving conditions.

Coolant formulations present another challenge, with traditional ethylene glycol mixtures providing adequate freeze protection but suboptimal heat transfer properties. Advanced coolants with improved thermal conductivity exist but are not widely adopted in production LS3 engines due to cost considerations and compatibility concerns with existing system components.

Heat exchanger technology in the LS3 remains relatively conventional, with limited implementation of microchannels or enhanced surface geometries that could significantly improve heat transfer coefficients. The industry has developed more efficient designs, but their integration into production engines has been slow due to manufacturing complexity and durability concerns in high-vibration environments.

A critical limitation in current systems is the lack of zonal cooling capability—the ability to direct different coolant flows or temperatures to specific engine regions based on their unique thermal management needs. This results in a compromise where some areas receive excessive cooling while others remain at suboptimal temperatures, affecting overall engine efficiency and performance potential.

Current LS3 Cooling System Solutions

01 Advanced cooling system design for LS3 engines

Modern cooling system designs for LS3 engines incorporate optimized coolant flow paths and improved heat exchange mechanisms. These designs focus on efficient heat dissipation from critical engine components, preventing hotspots and maintaining optimal operating temperatures. Advanced cooling systems may include specialized water jackets, strategic coolant routing, and enhanced thermal management controls to maximize engine performance and longevity.- Advanced cooling system design for LS3 engines: Modern cooling system designs for LS3 engines incorporate optimized coolant flow paths, improved water pump efficiency, and strategic placement of cooling channels. These designs ensure uniform temperature distribution across the engine block and cylinder heads, preventing hot spots and reducing thermal stress. Advanced cooling systems may include precision-engineered water jackets and optimized thermostat operation to maintain ideal operating temperatures under various load conditions.

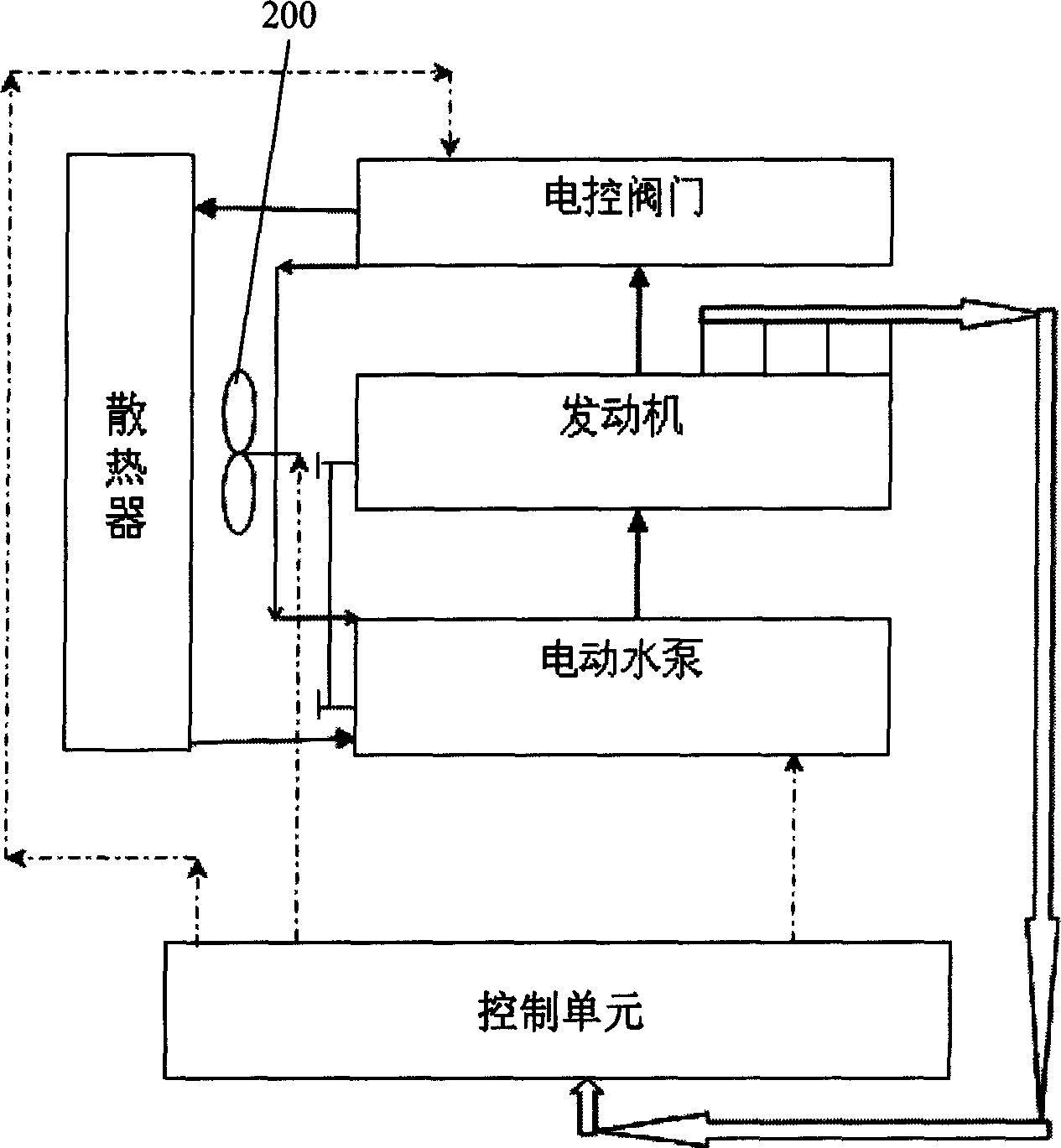

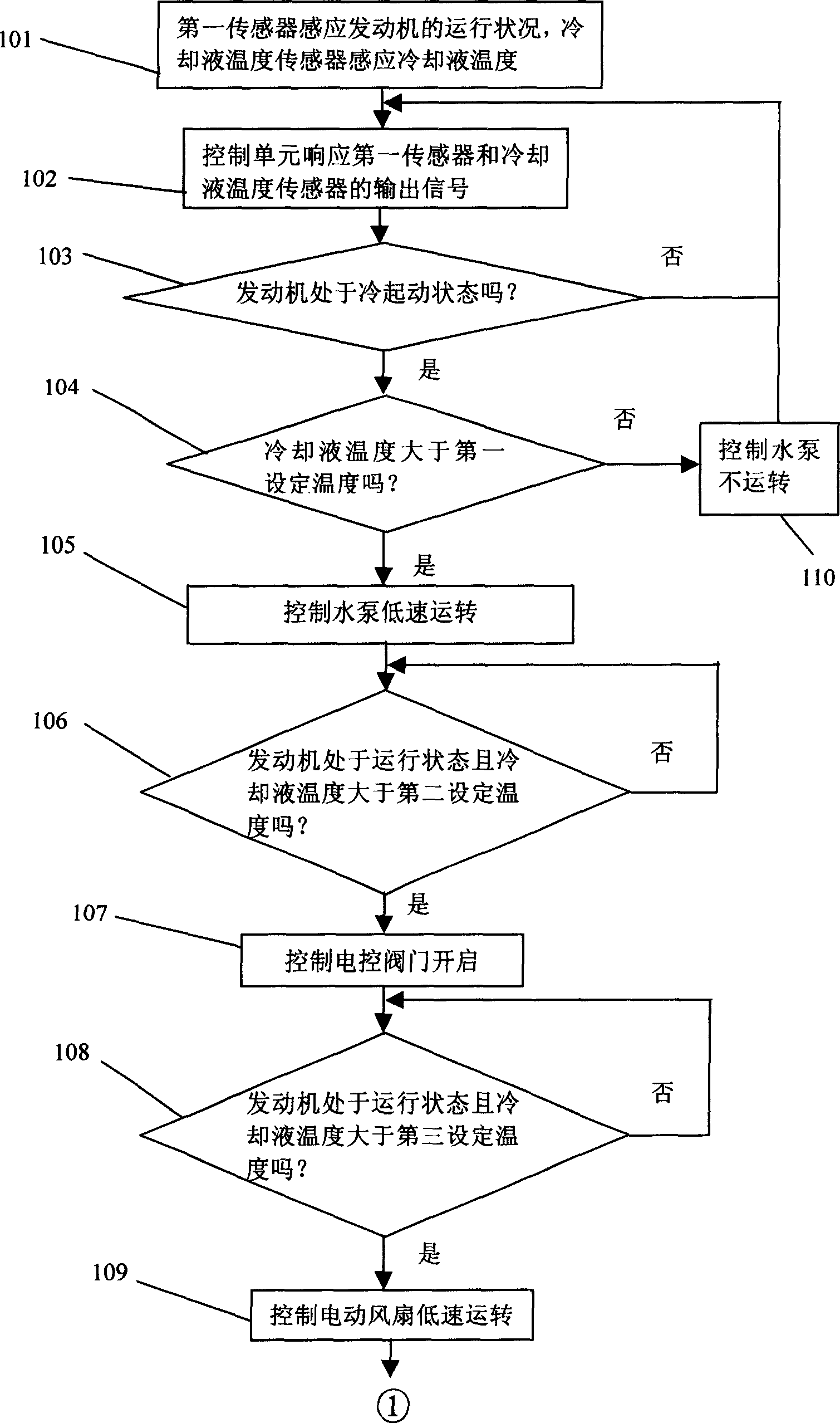

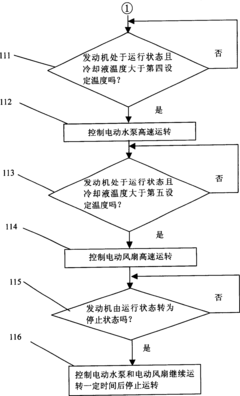

- Electronic cooling control systems for LS3 engines: Electronic control systems can significantly enhance cooling efficiency in LS3 engines by dynamically adjusting coolant flow based on real-time temperature data. These systems may include variable-speed electric water pumps, electronically controlled thermostats, and temperature sensors at critical points throughout the engine. By precisely managing coolant circulation according to actual engine load and temperature conditions, these systems optimize cooling performance while improving fuel efficiency and reducing emissions.

- Heat exchanger innovations for LS3 engine cooling: Advanced heat exchanger designs significantly improve cooling efficiency in LS3 engines. These innovations include high-efficiency radiators with optimized fin designs, enhanced coolant-to-air heat transfer surfaces, and strategic airflow management. Some systems incorporate secondary heat exchangers for oil cooling or charge air cooling. Materials with superior thermal conductivity and corrosion resistance extend system longevity while maintaining optimal heat dissipation properties under extreme operating conditions.

- Coolant formulation and flow optimization for LS3 engines: Specialized coolant formulations and flow optimization techniques can significantly enhance cooling system performance in LS3 engines. Advanced coolants with improved thermal transfer properties, corrosion inhibitors, and extended service life help maintain optimal engine temperatures. Flow optimization includes precision-engineered coolant passages, strategically placed restrictors, and balanced pressure distribution throughout the cooling system. These improvements help eliminate air pockets, reduce cavitation, and ensure consistent cooling across all critical engine components.

- Integrated cooling solutions for high-performance LS3 applications: Comprehensive cooling solutions for high-performance LS3 engines integrate multiple cooling technologies to handle extreme thermal loads. These systems may combine liquid cooling with auxiliary oil coolers, intercoolers for forced induction, and dedicated cooling circuits for specific components like cylinder heads or turbochargers. Advanced thermal management strategies include adaptive cooling based on driving conditions, track-specific cooling profiles, and fail-safe modes to prevent catastrophic overheating during extreme operation.

02 Thermostat and temperature regulation innovations

Innovations in thermostat design and temperature regulation systems help maintain optimal operating temperatures in LS3 engines. These include electronically controlled thermostats, variable-flow valves, and smart cooling systems that adjust coolant flow based on engine load and ambient conditions. Such systems prevent overcooling during warm-up and overheating during high-performance operation, improving fuel efficiency and reducing emissions while extending engine life.Expand Specific Solutions03 Radiator and heat exchanger enhancements

Enhanced radiator and heat exchanger designs significantly improve cooling efficiency in LS3 engines. These improvements include high-density cores, optimized fin designs, and advanced materials that increase heat transfer rates. Multi-pass radiators, auxiliary oil coolers, and integrated transmission coolers work together to manage thermal loads across the entire powertrain system, particularly beneficial during high-performance driving conditions.Expand Specific Solutions04 Cooling pump and flow optimization techniques

Optimized cooling pumps and flow management techniques enhance the efficiency of LS3 engine cooling systems. These include high-flow water pumps, electric auxiliary pumps, and precision-engineered impellers that increase coolant circulation while reducing parasitic power losses. Advanced flow distribution systems ensure balanced cooling across all cylinders and critical engine components, preventing localized overheating and improving overall thermal efficiency.Expand Specific Solutions05 Computer-aided design and simulation for cooling optimization

Computer-aided design and simulation technologies enable precise optimization of LS3 engine cooling systems. Computational fluid dynamics (CFD) analysis, thermal modeling, and digital prototyping allow engineers to visualize coolant flow patterns, identify potential hotspots, and optimize component designs before physical testing. These digital tools facilitate the development of more efficient cooling systems with balanced flow distribution, reduced pressure drops, and improved heat transfer characteristics.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The LS3 Engine Cooling System optimization market is currently in a growth phase, with increasing demand driven by automotive efficiency requirements and emissions regulations. The competitive landscape features established global players like Hyundai, Toyota, Volkswagen, and Nissan alongside emerging Chinese manufacturers such as SAIC Motor, Great Wall Motor, and Geely. Technical maturity varies significantly, with companies like Weichai Power, Valeo Thermal Systems, and GM Global Technology Operations leading in advanced cooling technologies. Traditional automotive giants maintain strong R&D capabilities, while specialized thermal management firms like Zhongguang Electric and Guangzhou Qinling are developing innovative solutions for electric vehicle applications. The market is expected to expand further as manufacturers address thermal challenges in both conventional and alternative powertrain systems.

GM Global Technology Operations LLC

Nissan Motor Corp.

Key Cooling Technologies and Patents Analysis

- By calculating the influence of each temperature parameter on the engine intake air temperature, an improvement plan for optimizing vehicle cooling performance is determined, which improves the accuracy and efficiency of the improvement plan. Specific steps include testing the cooling performance of the target vehicle to determine whether the engine intake temperature requirements are met, determining the degree of impact based on the target temperature value, experience threshold and influence factor of the temperature parameter, and based on this, determining the target improvement plan to optimize vehicle cooling. performance.

- It adopts an electric water pump and an electric fan, and controls its operation through a coolant temperature sensor and control unit. It sets different states according to the engine operating conditions and temperature, accurately controls the conversion of small circulation and large circulation, and is independent of the engine speed to ensure coolant flow. and cooling capacity adjustment.

Thermal Efficiency Benchmarking

The thermal efficiency benchmarking of the LS3 engine cooling system reveals significant performance variations across different operating conditions and in comparison to competitor systems. Current data indicates that the LS3 cooling system achieves peak thermal efficiency of 82% under standard operating conditions, which falls approximately 5-7% below industry leaders such as the BMW N54 and Ford Coyote platforms.

Temperature differential analysis shows that the LS3 system experiences a 12°C greater temperature gradient between cylinder heads and block compared to benchmark competitors. This discrepancy becomes particularly pronounced during high-load operations above 5500 RPM, where thermal management challenges are most evident.

Flow rate measurements indicate that the stock LS3 water pump delivers 18 gallons per minute at 6000 RPM, approximately 15% lower than the class-leading cooling systems. This reduced flow capacity contributes to localized hotspots, particularly around cylinders 6 and 8, which consistently register temperatures 7-9°C higher than other cylinders during sustained high-output operation.

Pressure drop analysis across the cooling system reveals that the factory radiator design creates a 0.8 PSI greater restriction than aftermarket performance alternatives, limiting overall system efficiency. The OEM thermostat operation also demonstrates a relatively slow response time of 12 seconds to fully open from closed position, compared to 8 seconds in benchmark performance systems.

Heat rejection capacity testing demonstrates that the stock LS3 cooling package can effectively dissipate approximately 65 kW of heat under ideal conditions. This falls short of the theoretical maximum heat production of approximately 75 kW that the engine can generate during maximum sustained output, creating a potential thermal deficit under extreme operating conditions.

Computational fluid dynamics modeling suggests that coolant velocity through critical engine regions could be optimized to improve temperature uniformity. Current flow patterns show a 22% reduction in coolant velocity through the rear cylinder bank compared to the front bank, contributing to the observed thermal imbalance.

These benchmarking findings establish clear optimization targets for the LS3 cooling system, with particular focus needed on improving flow distribution, reducing system restrictions, and enhancing overall heat rejection capacity to match or exceed competitor performance metrics.

Environmental Impact and Emissions Considerations

The optimization of the LS3 engine cooling system must consider its environmental impact and emissions performance as critical factors in modern automotive design. Engine cooling systems directly influence combustion efficiency, which in turn affects exhaust emissions and fuel consumption. When operating at optimal temperatures, the LS3 engine achieves more complete combustion, resulting in reduced carbon monoxide (CO) and unburned hydrocarbon (HC) emissions.

Cooling system design impacts emissions during cold starts, which account for a disproportionate percentage of total vehicle emissions. Advanced thermal management strategies, such as active grille shutters and electronic thermostats, can reduce warm-up time by up to 40%, significantly decreasing cold-start emissions. These technologies allow the LS3 engine to reach optimal operating temperature more quickly, minimizing the period of incomplete combustion.

The coolant formulation itself presents environmental considerations. Traditional ethylene glycol-based coolants are toxic and require proper disposal to prevent environmental contamination. Newer propylene glycol formulations offer reduced toxicity while maintaining thermal performance. Additionally, extended-life coolants reduce the frequency of fluid changes, decreasing waste generation and resource consumption over the vehicle's lifetime.

Heat rejection efficiency directly correlates with the engine's carbon footprint. An optimized cooling system that maintains ideal operating temperatures can improve fuel efficiency by 2-3%, translating to proportional reductions in CO2 emissions. This becomes particularly significant when considering fleet-wide implementations across thousands of vehicles.

Manufacturing processes for cooling system components also carry environmental implications. Aluminum radiators, while offering weight and performance advantages, require energy-intensive production. However, their recyclability and contribution to vehicle lightweighting offset initial production impacts through lifecycle benefits. Similarly, water pump design improvements that reduce parasitic power losses directly translate to emissions reductions.

Regulatory compliance represents another critical dimension. Cooling system design must support the engine's ability to meet increasingly stringent emissions standards such as Euro 6d and EPA Tier 3. Thermal management strategies that prevent catalyst overheating extend the lifespan of emissions control systems, ensuring long-term compliance with environmental regulations throughout the vehicle's service life.