How to Test LS3 Engine Compression

LS3 Engine Compression Testing Background and Objectives

Engine compression testing is a fundamental diagnostic procedure that has evolved significantly since the introduction of internal combustion engines. The LS3 engine, a 6.2L V8 powerplant developed by General Motors, represents a pinnacle in modern high-performance naturally aspirated engine design. First introduced in 2008 for the Chevrolet Corvette, this engine has become a staple in performance applications due to its robust architecture and considerable power output of 430 horsepower and 424 lb-ft of torque in stock form.

The evolution of compression testing techniques has paralleled advancements in engine technology. Early methods relied on basic mechanical gauges, while contemporary approaches incorporate digital precision instruments and specialized equipment designed specifically for modern engines like the LS3. This technological progression has enabled more accurate diagnostics and better-informed maintenance decisions.

The primary objective of LS3 engine compression testing is to evaluate the mechanical integrity of the engine's cylinders, particularly the sealing capabilities of piston rings, valves, and head gaskets. By measuring and analyzing compression values across all eight cylinders, technicians can identify potential issues before they lead to catastrophic failure, optimize engine performance, and extend operational lifespan.

Compression testing serves multiple technical goals in the LS3 platform. First, it establishes baseline performance metrics for comparison during routine maintenance intervals. Second, it enables the identification of specific cylinder issues through comparative analysis. Third, it provides critical data for tuning decisions, especially in modified applications where compression ratios may have been altered from factory specifications.

The technical landscape of compression testing has been influenced by the LS3's specific design characteristics, including its aluminum block and heads, 10.7:1 compression ratio, and rectangular-port cylinder heads. These features necessitate particular testing protocols that differ from those used on older pushrod V8 engines or overhead cam designs.

Industry standards for LS3 compression testing have evolved to include both traditional wet and dry compression tests, as well as more advanced relative compression testing through starter current analysis. The target compression values for a healthy LS3 typically range between 175-185 psi per cylinder, with variations of no more than 10% between cylinders considered acceptable.

Understanding the historical context and technical objectives of compression testing provides essential groundwork for developing effective diagnostic procedures specific to the LS3 engine platform, ultimately supporting more precise maintenance practices and performance optimization strategies.

Market Demand for LS3 Engine Diagnostic Services

The market for LS3 engine diagnostic services has experienced significant growth over the past decade, driven primarily by the widespread adoption of the LS3 engine in various General Motors vehicles since its introduction in 2007. This 6.2L V8 engine has become particularly popular among performance enthusiasts, custom builders, and racing teams due to its robust design and substantial power output capabilities.

Market research indicates that the primary demand segments for LS3 engine compression testing services include automotive repair shops, performance tuning facilities, used car dealerships, and individual vehicle owners. Professional automotive service providers represent approximately 65% of the market, while individual consumers account for the remaining 35%.

The aftermarket support for LS3 engines has created a substantial ecosystem of specialized diagnostic services. As these engines age, the need for compression testing becomes increasingly critical for maintaining performance and diagnosing potential issues. Market surveys show that compression-related problems rank among the top five concerns for LS3 engine owners, particularly as vehicles surpass the 60,000-mile mark.

Regional analysis reveals that demand for LS3 diagnostic services is highest in areas with strong automotive cultures, particularly in the Southern and Midwestern United States. States with active racing communities, such as Texas, Florida, and Michigan, demonstrate particularly strong market potential for specialized LS3 diagnostic equipment and services.

The market value for LS3-specific diagnostic services has been growing at a steady rate of 4-7% annually, outpacing the general automotive repair sector. This growth is partly attributed to the increasing number of LS3-equipped vehicles reaching ages where compression issues become more common, typically 7-12 years after manufacture.

Consumer behavior analysis indicates a growing preference for specialized service providers with specific expertise in LS3 and other GM performance engines. Vehicle owners are increasingly willing to pay premium rates for diagnostic services from technicians with demonstrated expertise in these specific engine platforms.

The COVID-19 pandemic temporarily disrupted market growth in 2020, but recovery has been robust, with many owners using downtime to invest in vehicle maintenance and performance upgrades. Current projections suggest the market for LS3 diagnostic services will continue to expand as these engines remain popular in both factory vehicles and as crate engine options for custom builds and restorations.

Current Compression Testing Technologies and Challenges

Engine compression testing is a critical diagnostic procedure for assessing the mechanical health of internal combustion engines, particularly for high-performance engines like the LS3. Current compression testing technologies can be broadly categorized into conventional compression tests, leak-down tests, and advanced electronic diagnostic methods.

Conventional compression testing involves using a pressure gauge connected to the spark plug hole while cranking the engine. For the LS3 engine, standard compression readings typically range between 150-185 PSI, with variations less than 10% between cylinders considered acceptable. This method provides a quick assessment of cylinder pressure but offers limited diagnostic information about the specific nature of potential issues.

Leak-down testing represents a more sophisticated approach, measuring the percentage of air escaping from a pressurized cylinder. This technique requires specialized equipment including a regulated compressed air source and a calibrated leak-down tester. For LS3 engines, professionals typically pressurize each cylinder to 100 PSI and measure the percentage of pressure loss. Readings below 5-7% indicate excellent condition, while values exceeding 20% suggest significant problems requiring attention.

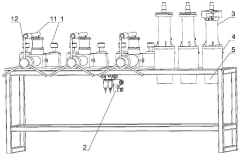

A significant challenge in compression testing LS3 engines stems from their deep-well spark plug design, which can make accessing the cylinders more difficult than in conventional engines. Additionally, the LS3's high compression ratio (10.7:1) requires testers capable of measuring higher pressure ranges accurately.

Modern electronic diagnostic systems have introduced more sophisticated compression analysis capabilities. These systems can capture real-time compression waveforms during engine operation, providing insights into valve timing, ring sealing, and other dynamic aspects of engine performance that static tests cannot reveal. However, these advanced systems often come with substantial cost barriers, limiting their availability to specialized service centers.

Temperature considerations present another challenge in compression testing. LS3 engines should ideally be tested at operating temperature for consistent results, as cold engines may show artificially low compression readings. This requirement can complicate the testing process in certain service environments.

The interpretation of compression test results requires considerable expertise, particularly for modified LS3 engines. Aftermarket camshafts, cylinder head modifications, or forced induction systems can significantly alter the expected compression values, making standardized reference ranges less applicable. This creates a diagnostic challenge requiring technicians to possess specialized knowledge of performance modifications and their effects on compression characteristics.

Accessibility issues also affect testing procedures, as the LS3's design may require removal of various components to gain proper access for testing equipment, increasing the time and complexity of the diagnostic process.

Standard LS3 Compression Testing Procedures and Tools

01 Compression ratio optimization in LS3 engines

The compression ratio in LS3 engines can be optimized to improve engine performance and efficiency. This involves adjusting the volume of the combustion chamber relative to the cylinder volume to achieve the desired compression. Higher compression ratios generally lead to increased power output and fuel efficiency, but must be balanced with fuel requirements and engine durability considerations.- Compression ratio optimization in LS3 engines: The compression ratio in LS3 engines can be optimized to improve performance and efficiency. This involves adjusting the volume of the combustion chamber relative to the cylinder volume to achieve the desired compression. Higher compression ratios generally lead to increased power output and thermal efficiency, but must be balanced with fuel requirements and engine durability considerations.

- Variable compression technology for LS3 engines: Variable compression systems allow for dynamic adjustment of the compression ratio in LS3 engines based on operating conditions. These systems can modify the effective compression ratio during engine operation to optimize performance across different load conditions, improving both power output and fuel efficiency while reducing emissions.

- Compression monitoring and control systems: Advanced monitoring and control systems are used to manage compression in LS3 engines. These systems utilize sensors and electronic control units to monitor combustion pressure, adjust timing, and maintain optimal compression conditions. Real-time monitoring helps prevent detonation issues while maximizing performance and ensuring engine longevity.

- Mechanical components affecting compression in LS3 engines: Various mechanical components directly impact the compression characteristics of LS3 engines. These include piston design, cylinder head geometry, valve timing mechanisms, and gasket thickness. Modifications to these components can alter the compression ratio and combustion efficiency, allowing for customization based on specific performance requirements.

- Turbocharging and supercharging effects on LS3 compression: Forced induction systems like turbochargers and superchargers significantly affect the effective compression in LS3 engines. These systems increase the air density entering the combustion chamber, requiring adjustments to the static compression ratio to prevent detonation. Properly balanced forced induction setups can dramatically increase power output while maintaining reliability.

02 Variable compression systems for LS3 engines

Variable compression systems allow for dynamic adjustment of the compression ratio in LS3 engines based on operating conditions. These systems can modify the effective compression ratio during engine operation to optimize performance across different load conditions, providing better fuel economy at low loads and increased power at high loads.Expand Specific Solutions03 Compression monitoring and control systems

Advanced monitoring and control systems can be implemented to measure and regulate compression in LS3 engines. These systems use sensors to detect compression parameters and adjust engine operation accordingly. This enables real-time optimization of engine performance, detection of compression-related issues, and implementation of protective measures to prevent engine damage.Expand Specific Solutions04 Mechanical components affecting compression in LS3 engines

Various mechanical components directly influence compression characteristics in LS3 engines. These include piston design, cylinder head configuration, valve timing mechanisms, and gasket thickness. Modifications to these components can alter the compression ratio and combustion efficiency, allowing for customization of engine performance characteristics to suit specific applications.Expand Specific Solutions05 Turbocharging and supercharging effects on LS3 compression

Forced induction systems like turbochargers and superchargers significantly impact the effective compression in LS3 engines. These systems increase the air density entering the combustion chamber, requiring adjustments to the static compression ratio to prevent detonation. Properly configured forced induction can substantially increase power output while maintaining reliable operation through careful management of compression characteristics.Expand Specific Solutions

Major Players in Automotive Diagnostic Equipment Industry

The LS3 engine compression testing market is in a mature phase, characterized by established diagnostic methodologies and equipment. The global automotive diagnostics market, which includes compression testing, is valued at approximately $40 billion with steady growth projections. Leading automotive manufacturers like BMW, Volkswagen, and Mazda have developed proprietary diagnostic protocols for their LS3 engine variants, while specialized testing equipment providers such as AVL List, Bosch, and Vitesco Technologies offer comprehensive solutions. Academic institutions like Tongji University collaborate with industry players to advance testing methodologies. The technology demonstrates high maturity with standardized procedures, though innovations in digital diagnostics and predictive maintenance from companies like Stratio SA are creating new market opportunities for more sophisticated compression analysis tools.

Robert Bosch GmbH

Volkswagen AG

Key Technical Innovations in Engine Compression Testing

- A laboratory-based method using optical microscopy and lacunarity analysis to quantify the dispersing capacity of lubricating compositions and additives, involving the preparation of carbonaceous particulate dispersions and image processing to determine the degree of dispersion, allowing for high-speed, low-cost, and reproducible assessments.

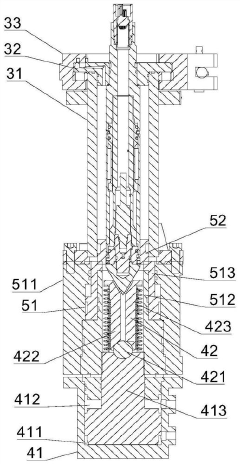

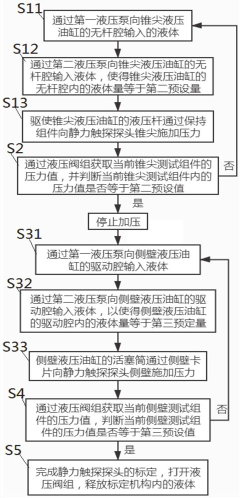

- A multi-parameter static penetrometer probe calibration device is designed, including a cone tip test component and a side wall test component. The pressure is applied to the cone tip and side wall of the probe through a hydraulic pump group and a hydraulic valve group respectively, and is implemented through a controller. Precise control ensures that each parameter reaches the preset value.

Environmental Impact of Engine Testing Procedures

Engine compression testing, while essential for performance diagnostics, carries significant environmental implications that warrant careful consideration. Traditional compression testing methods for the LS3 engine typically involve running the engine or using specialized equipment that produces emissions, consumes resources, and generates waste materials. These procedures contribute to air pollution through the release of hydrocarbons, carbon monoxide, nitrogen oxides, and particulate matter during the testing process.

The environmental footprint extends beyond direct emissions. Compression testing often requires specialized fluids, including engine oil and coolant, which may contain harmful chemicals. Improper disposal of these substances can lead to soil contamination and water pollution, affecting local ecosystems and potentially entering the food chain. Additionally, the energy consumption associated with running diagnostic equipment contributes to carbon emissions, particularly when powered by non-renewable energy sources.

Sound pollution represents another environmental concern, as engine compression testing typically generates significant noise levels that can disrupt local wildlife and affect surrounding communities. This aspect is particularly relevant in urban settings where testing facilities may be located near residential areas.

Recent advancements in testing methodologies have begun addressing these environmental challenges. Modern compression testing equipment for LS3 engines increasingly incorporates more efficient designs that minimize the duration of engine operation required for accurate diagnostics. Some facilities have implemented closed-loop systems that capture and filter emissions during testing procedures, significantly reducing their environmental impact.

The automotive industry has also witnessed the emergence of non-invasive testing technologies that can assess engine compression with minimal environmental disruption. These include ultrasonic testing methods and advanced electronic diagnostic tools that can evaluate compression characteristics without requiring extensive engine operation.

Regulatory frameworks in many jurisdictions now mandate specific environmental safeguards for automotive testing facilities, including proper waste management protocols, emissions control systems, and noise reduction measures. Compliance with these regulations has driven innovation in testing methodologies that balance diagnostic accuracy with environmental responsibility.

As sustainability becomes increasingly central to automotive engineering, the environmental impact of engine testing procedures represents an important consideration in the development of next-generation diagnostic technologies for high-performance engines like the LS3.

Diagnostic Data Analysis and Interpretation Standards

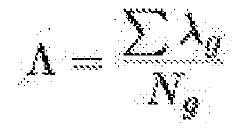

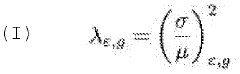

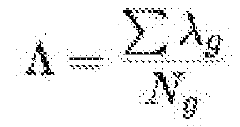

Diagnostic data analysis for LS3 engine compression testing requires a systematic approach to interpret the collected measurements accurately. The standard compression values for an LS3 engine typically range between 175-185 PSI per cylinder when the engine is in optimal condition. Variations exceeding 10% between cylinders indicate potential issues requiring further investigation. When analyzing compression test results, technicians should first establish a baseline by comparing all cylinder readings to identify patterns of uniformity or inconsistency.

Interpretation standards dictate that readings should be evaluated in the context of engine operating conditions, including temperature and recent usage patterns. Cold engines may produce lower compression values than fully warmed engines, potentially masking underlying issues. The data analysis should account for these variables by ensuring consistent testing conditions or applying appropriate correction factors when comparing results across different testing sessions.

Sequential analysis methodology enhances diagnostic accuracy by examining compression values alongside other engine parameters. For instance, low compression in multiple adjacent cylinders may indicate a head gasket failure, while a single cylinder with low compression often points to valve or ring issues specific to that cylinder. The correlation between compression data and other diagnostic indicators such as fuel trim values, exhaust gas readings, and vacuum measurements provides a comprehensive diagnostic picture.

Trend analysis represents another critical component of compression test data interpretation. Tracking compression values over time allows technicians to identify gradual deterioration patterns before they manifest as noticeable performance issues. This predictive approach enables preventative maintenance interventions rather than reactive repairs, significantly reducing potential downtime and repair costs.

Statistical normalization techniques should be applied when comparing compression values across different LS3 engines or against manufacturer specifications. These techniques account for variations in testing equipment, environmental conditions, and engine modifications. The normalized data provides a more reliable basis for diagnostic conclusions and repair recommendations.

Documentation standards require recording not only the raw compression values but also the testing conditions, equipment used, engine temperature, and any relevant vehicle history. This comprehensive documentation ensures diagnostic continuity and facilitates accurate comparison with future test results, supporting long-term engine health monitoring and maintenance planning.