LS3 Engine Performance Analysis Techniques

LS3 Engine Background and Performance Objectives

The LS3 engine represents a significant milestone in General Motors' small-block V8 engine evolution, introduced in 2008 as part of the Gen IV family. This 6.2-liter naturally aspirated powerplant was prominently featured in high-performance vehicles including the Chevrolet Corvette C6 and Camaro SS, delivering 430 horsepower and 424 lb-ft of torque in its standard configuration. The engine's aluminum block construction, high-flow cylinder heads, and advanced valvetrain technology established it as a benchmark for performance and efficiency in its class.

Performance analysis techniques for the LS3 engine have evolved considerably since its introduction, driven by advancements in computational modeling, sensor technology, and data acquisition systems. Early analysis methods relied primarily on dynamometer testing and basic computer simulations, whereas contemporary approaches incorporate sophisticated real-time monitoring systems and predictive analytics to optimize engine performance across various operating conditions.

The primary technical objectives for LS3 engine performance analysis center on four key areas: power output optimization, fuel efficiency enhancement, emissions reduction, and reliability improvement. These objectives reflect the automotive industry's broader transition toward balancing raw performance with environmental sustainability and consumer expectations for durability. Modern analysis techniques aim to identify the optimal balance between these sometimes competing priorities.

Historical performance analysis of the LS3 has revealed several critical areas for optimization, including intake airflow dynamics, combustion chamber design, exhaust gas scavenging, and thermal management. The progression of analysis techniques has enabled engineers to move beyond simple horsepower and torque measurements to more nuanced understanding of volumetric efficiency, combustion stability, and transient response characteristics.

The technological trajectory of LS3 performance analysis demonstrates a clear shift from isolated component testing toward integrated systems analysis. This evolution mirrors broader industry trends in powertrain development, where the interactions between engine subsystems are increasingly recognized as critical determinants of overall performance. Advanced computational fluid dynamics (CFD) simulations, coupled with high-precision in-cylinder pressure monitoring, now allow for unprecedented insight into combustion events occurring at millisecond intervals.

Looking forward, performance analysis objectives for LS3 and similar engines increasingly incorporate adaptability to alternative fuels, compatibility with hybrid powertrain systems, and optimization for emerging driving cycles that better reflect real-world usage patterns. These forward-looking objectives acknowledge the engine's continued relevance in a rapidly evolving automotive landscape, where traditional performance metrics are being supplemented by new parameters related to environmental impact and integration with electrification technologies.

Market Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles with superior power and efficiency. The global high-performance engine market was valued at approximately $27 billion in 2022 and is projected to reach $38 billion by 2028, representing a compound annual growth rate of 5.8%. This growth is particularly evident in regions with strong automotive manufacturing bases, including North America, Europe, and parts of Asia.

The market for LS3 engine performance analysis techniques is positioned within this broader high-performance engine ecosystem. As General Motors' 6.2L V8 engine found in various Chevrolet, GMC, and other performance vehicles, the LS3 has developed a substantial following among automotive enthusiasts, racing teams, and aftermarket modification specialists. This has created a specialized market segment focused on performance optimization and analysis tools.

Consumer demographics for high-performance engines like the LS3 primarily include automotive enthusiasts aged 25-55 with above-average disposable income. Professional racing teams, automotive tuning shops, and performance research facilities constitute the commercial segment of this market. These professional users typically invest in sophisticated analysis techniques to maximize engine output while maintaining reliability.

Market research indicates that demand for advanced LS3 engine performance analysis techniques has grown by approximately 12% annually since 2018. This growth correlates with the increasing sophistication of engine management systems and the rising popularity of data-driven performance tuning. The aftermarket for LS3 engines and related performance components exceeds $450 million annually in North America alone.

Competition in this market segment comes from established automotive diagnostic equipment manufacturers, specialized performance tuning software developers, and emerging startups focusing on innovative analysis methodologies. Key market drivers include the growing popularity of motorsports, increasing consumer interest in vehicle customization, and technological advancements in sensor technology and data analytics.

The market shows regional variations, with North America representing approximately 58% of global demand for LS3-specific analysis tools, followed by Europe (22%) and Australia (11%). This distribution reflects the popularity of GM performance vehicles in these markets and the strength of their respective motorsport communities.

Future market growth is expected to be driven by integration with artificial intelligence for predictive performance analysis, cloud-based collaborative tuning platforms, and more accessible consumer-grade analysis tools. These innovations are likely to expand the market by making sophisticated analysis techniques available to a broader range of users beyond professional tuning shops and racing teams.

Current LS3 Diagnostics and Limitations

The current diagnostic capabilities for the LS3 engine rely primarily on the Engine Control Module (ECM) and its integrated On-Board Diagnostics II (OBD-II) system. This system monitors various engine parameters through a network of sensors including Mass Air Flow (MAF), Manifold Absolute Pressure (MAP), oxygen sensors, knock sensors, and temperature sensors. When parameters fall outside predetermined thresholds, the ECM generates Diagnostic Trouble Codes (DTCs) that can be retrieved using scan tools through the standardized OBD-II port.

Standard diagnostic equipment for the LS3 includes manufacturer-specific scan tools like GM's Tech2 and GDS2 systems, as well as aftermarket OBD-II scanners with varying capabilities. These tools provide real-time data monitoring, freeze frame data capture, and basic actuation testing. Additionally, chassis dynamometers are commonly used for load testing and performance verification, while specialized equipment such as compression testers, leak-down testers, and fuel pressure gauges supplement electronic diagnostics.

Despite these capabilities, current LS3 diagnostics face significant limitations. The factory ECM has restricted access to certain parameters and limited sampling rates, which constrains detailed analysis of transient conditions. Most OBD-II scan tools only capture data at 1-5 Hz, insufficient for analyzing rapid combustion events or detecting momentary anomalies that occur between sampling intervals.

Another major limitation is the lack of cylinder-specific diagnostics. While the ECM can identify general misfires, it cannot precisely characterize combustion quality or efficiency on a per-cylinder basis. This makes it difficult to diagnose subtle imbalances that may affect performance without triggering fault codes. The factory oxygen sensors also provide limited resolution for air-fuel ratio analysis, typically operating in a narrow band around stoichiometric conditions rather than providing linear wideband measurements across the entire operating range.

Integration challenges further complicate diagnostics, as aftermarket modifications often introduce variables that factory diagnostic systems cannot properly interpret. Modified camshafts, forced induction systems, or fuel system upgrades can create conditions where standard diagnostic thresholds no longer apply, leading to false positives or missed detection of actual issues.

Temperature compensation represents another diagnostic gap, as the factory system has limited ability to account for how thermal conditions affect sensor readings and mechanical tolerances. This becomes particularly problematic when diagnosing intermittent issues that only manifest under specific temperature conditions or during thermal transition periods.

Current LS3 Performance Analysis Methods

01 Engine control systems for LS3 performance optimization

Advanced control systems are implemented to optimize the performance of LS3 engines. These systems include electronic control units that monitor and adjust various engine parameters in real-time, such as fuel injection timing, ignition timing, and air-fuel ratio. By precisely controlling these parameters, the engine's power output, efficiency, and reliability can be significantly improved. These control systems may also include adaptive learning capabilities to optimize performance under varying operating conditions.- Engine control systems for LS3 performance optimization: Advanced control systems are implemented to optimize the performance of LS3 engines. These systems monitor and adjust various engine parameters in real-time, including fuel injection timing, ignition timing, and air-fuel ratio. By precisely controlling these parameters, the engine can achieve improved power output, better fuel efficiency, and reduced emissions. These control systems often incorporate sensors to gather data about engine conditions and use sophisticated algorithms to make adjustments accordingly.

- Mechanical modifications for LS3 engine enhancement: Various mechanical modifications can be applied to LS3 engines to enhance their performance. These modifications include improved intake and exhaust systems, upgraded camshafts, and modified cylinder heads. By optimizing the flow of air and fuel into the combustion chamber and facilitating the efficient removal of exhaust gases, these modifications can significantly increase horsepower and torque. Additionally, internal engine components can be upgraded to withstand higher operating temperatures and pressures associated with increased performance.

- Diagnostic and testing methods for LS3 engines: Specialized diagnostic and testing methods are employed to evaluate and improve LS3 engine performance. These methods include dynamometer testing, compression testing, and advanced electronic diagnostics. By accurately measuring engine output and identifying areas for improvement, these diagnostic approaches enable precise tuning and optimization. Testing procedures can also help identify potential issues before they lead to performance degradation or engine failure, ensuring consistent and reliable performance.

- Thermal management systems for LS3 performance: Effective thermal management is crucial for maximizing LS3 engine performance. Advanced cooling systems, including improved radiators, oil coolers, and water pumps, help maintain optimal operating temperatures under high-performance conditions. By preventing overheating and ensuring consistent operating temperatures, these systems allow the engine to deliver maximum power output while maintaining reliability. Some thermal management solutions also incorporate electronic controls to adjust cooling based on engine load and ambient conditions.

- Performance monitoring and data analysis for LS3 engines: Sophisticated monitoring systems and data analysis techniques are used to evaluate and enhance LS3 engine performance. These systems collect real-time data on various engine parameters, including RPM, temperature, pressure, and air-fuel ratios. By analyzing this data, engineers can identify performance bottlenecks and optimize engine tuning. Some monitoring systems also provide feedback to drivers, allowing for adjustments to driving style to maximize performance and efficiency. Advanced data analysis can also predict potential issues before they affect engine performance.

02 Mechanical modifications for LS3 engine enhancement

Various mechanical modifications can be applied to LS3 engines to enhance their performance. These modifications include improved intake and exhaust systems, upgraded camshafts, and modified valve timing mechanisms. By optimizing the flow of air and fuel into the combustion chamber and facilitating the efficient removal of exhaust gases, these modifications can significantly increase horsepower and torque. Additionally, strengthened internal components can allow the engine to operate at higher RPMs and withstand increased cylinder pressures.Expand Specific Solutions03 Diagnostic and testing methods for LS3 engines

Specialized diagnostic and testing methods are developed to evaluate and improve LS3 engine performance. These methods include advanced sensors and monitoring systems that can detect performance issues and inefficiencies. Dynamometer testing allows for precise measurement of power output under controlled conditions, while computational models can simulate engine behavior under various operating scenarios. These diagnostic approaches enable engineers to identify performance bottlenecks and validate the effectiveness of performance enhancements.Expand Specific Solutions04 Fuel system optimizations for LS3 performance

Optimizations to the fuel system can significantly enhance LS3 engine performance. These include high-flow fuel injectors, upgraded fuel pumps, and precision fuel pressure regulators. Advanced fuel management systems can dynamically adjust fuel delivery based on engine load and operating conditions. Additionally, modifications to support alternative fuels or fuel additives can improve combustion efficiency and power output. These fuel system enhancements ensure optimal air-fuel mixture across the entire operating range of the engine.Expand Specific Solutions05 Thermal management solutions for LS3 engines

Effective thermal management is crucial for maximizing LS3 engine performance. Advanced cooling systems, including improved water pumps, radiators, and oil coolers, help maintain optimal operating temperatures under high-load conditions. Heat shields and thermal barriers can protect sensitive components from excessive heat. Additionally, precision cooling strategies that target specific engine areas can prevent hotspots and ensure more uniform temperature distribution. These thermal management solutions allow the engine to operate at peak performance while maintaining reliability and longevity.Expand Specific Solutions

Major Manufacturers and Competition Analysis

The LS3 Engine Performance Analysis market is currently in a growth phase, with increasing demand for advanced diagnostic and optimization techniques. The market size is expanding due to automotive industry's focus on efficiency and emissions reduction. Technologically, the field is moderately mature but evolving rapidly with digital analytics integration. Key players demonstrate varying levels of expertise: academic institutions like Tongji University and Jilin University provide theoretical foundations; automotive manufacturers including Changan Automobile and SAIC Motor contribute practical applications; research organizations such as China Automotive Engineering Research Institute and Weichai Power lead in specialized testing methodologies; while energy companies like Sinopec bring fuel optimization perspectives. The competitive landscape shows a collaborative ecosystem between academia, industry, and research institutions driving innovation in engine performance analysis.

China Automotive Engineering Research Institute Co., Ltd.

Chongqing Changan Automobile Co. Ltd.

Key Patents in Engine Diagnostics Technology

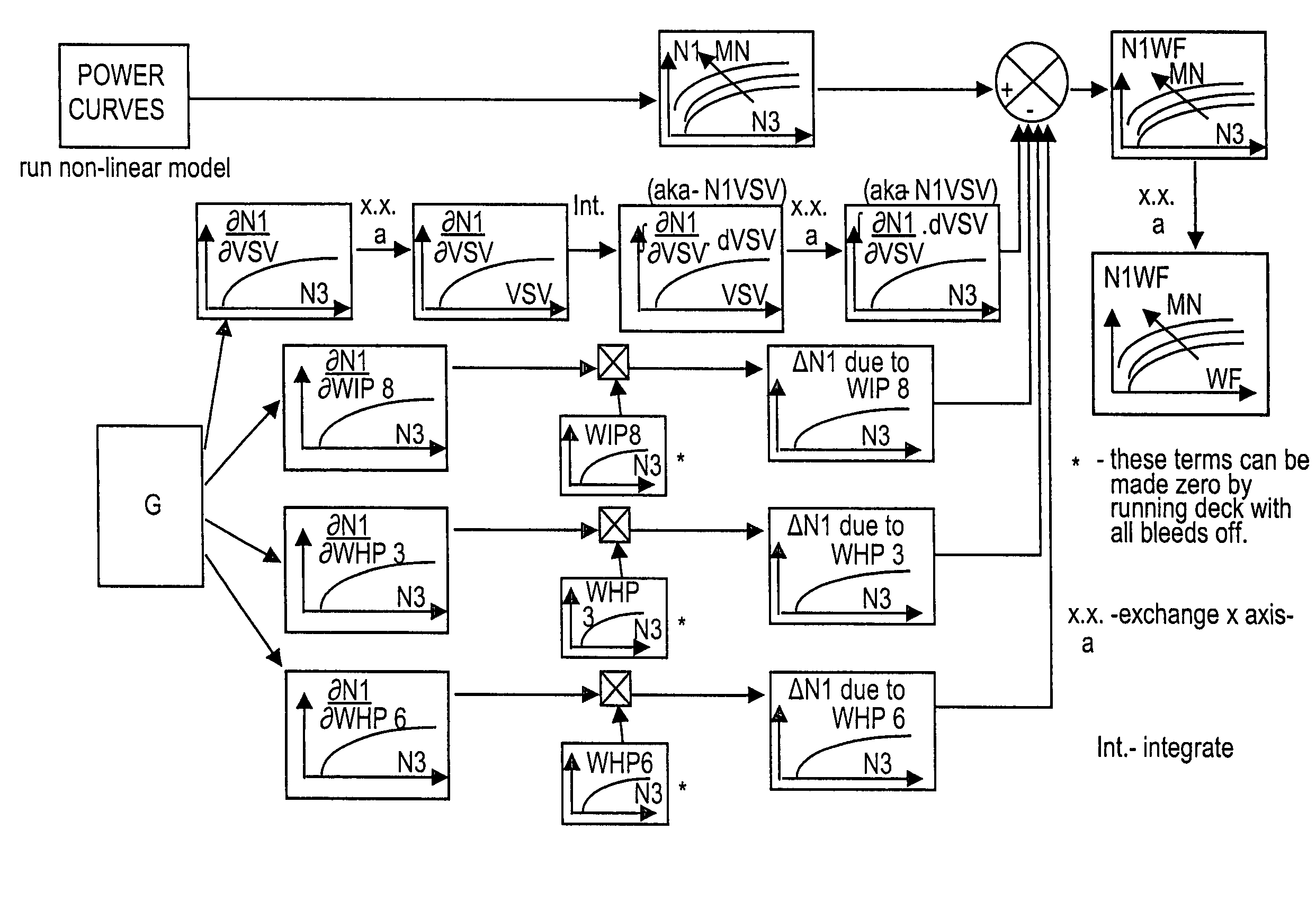

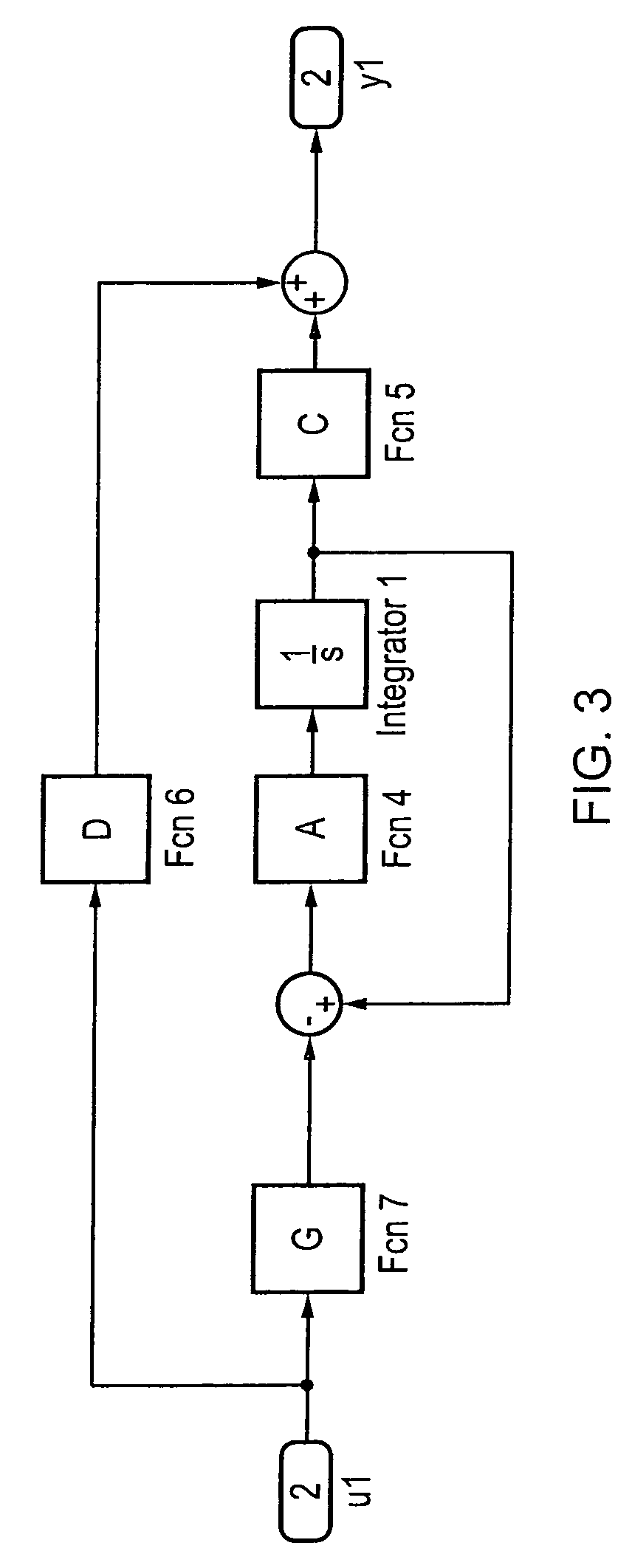

- A method to construct a piecewise linear engine performance model by determining partial derivatives of engine performance variables with respect to control and state variables, integrating these derivatives to reduce errors, and combining them to create a model that accurately calculates steady-state values, improving fidelity and reducing solution times.

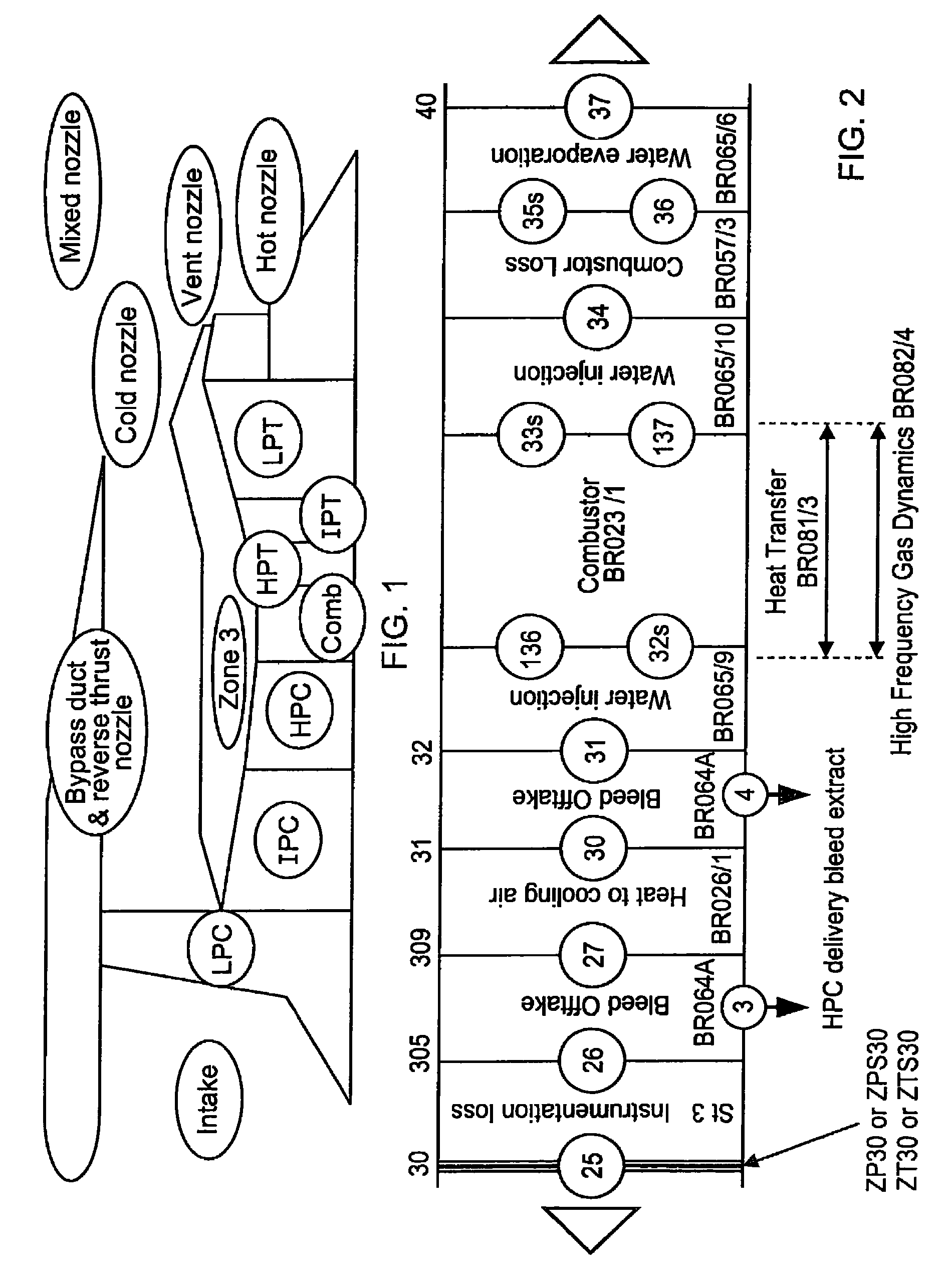

- A method and system that utilize a processor to input flight and engine output parameters, perform correlation and orientation reductions, and employ neural networks to produce estimated corrections, enhancing the accuracy of gas turbine engine modeling by filtering outliers and adjusting data to improve model fidelity.

Emissions Regulations Impact on LS3 Development

The evolution of the LS3 engine's performance analysis techniques has been significantly influenced by increasingly stringent emissions regulations worldwide. When General Motors developed the LS3 6.2L V8 engine for the fifth-generation Corvette and other high-performance vehicles, engineers had to balance power output with compliance to emissions standards such as EPA Tier 2 in the United States and Euro 5 in European markets.

These regulations necessitated sophisticated analysis techniques to monitor and control combustion processes. Engineers implemented advanced computational fluid dynamics (CFD) modeling to predict emissions formation during the combustion cycle, allowing for optimization of chamber design and fuel delivery systems. This approach enabled the LS3 to achieve its 430 horsepower while maintaining acceptable emissions levels.

Variable valve timing technology became a critical focus area for emissions compliance. Performance analysis techniques evolved to include real-time monitoring of valve events and their correlation with emissions output. This data-driven approach allowed engineers to fine-tune the camshaft profile and valve timing to reduce NOx formation during high-load conditions while maintaining optimal volumetric efficiency.

Exhaust gas recirculation (EGR) strategies required new testing methodologies to analyze their impact on performance. Engineers developed specialized test protocols to measure the precise effects of different EGR rates on both power output and emissions levels. These techniques involved sophisticated gas analyzers and engine dynamometer testing under various load conditions to establish optimal EGR mapping.

Catalytic converter efficiency became another critical parameter requiring advanced analysis. Thermal imaging and chemical composition testing of exhaust gases before and after catalyst treatment provided valuable data on conversion efficiency. This information guided material selection and placement of catalysts to maximize their effectiveness without creating excessive backpressure that would hamper performance.

Fuel system analysis techniques also evolved significantly. High-precision fuel injector testing equipment was developed to analyze spray patterns and droplet size at microsecond intervals. This level of analysis enabled engineers to optimize fuel atomization, reducing unburned hydrocarbon emissions while improving combustion efficiency and power output.

The integration of emissions compliance with performance objectives ultimately led to more sophisticated engine management systems. Analysis techniques expanded to include comprehensive mapping of thousands of operating conditions, with emissions data correlated to each point. This holistic approach to engine development ensured the LS3 could deliver impressive performance while meeting regulatory requirements across global markets.

Dyno Testing Advancements for LS3 Engines

Dynamometer testing for LS3 engines has undergone significant technological evolution in recent years, transforming from basic power measurement tools to sophisticated analytical systems. Modern dyno testing equipment now incorporates advanced data acquisition systems capable of capturing thousands of data points per second, providing unprecedented insight into engine performance characteristics under various load conditions.

The integration of digital technology has revolutionized LS3 engine testing methodologies. Contemporary dynamometers feature high-precision torque sensors and load cells that can detect minute variations in engine output, enabling engineers to identify performance anomalies that would have gone unnoticed with previous generation equipment. This precision has become particularly valuable when evaluating the effects of minor tuning adjustments on LS3 engines.

Environmental simulation capabilities represent another major advancement in dyno testing technology. Current systems can replicate various atmospheric conditions, including temperature, humidity, and barometric pressure variations. This capability allows for standardized testing protocols that produce comparable results regardless of ambient testing conditions, addressing a longstanding challenge in engine performance analysis for LS3 platforms.

Real-time fuel analysis systems have been integrated into modern dynamometer setups, enabling simultaneous monitoring of air-fuel ratios, fuel consumption rates, and combustion efficiency. These systems provide critical data for optimizing LS3 engine calibration parameters, resulting in improved performance and efficiency. The ability to correlate fuel delivery characteristics with power output has proven especially valuable for high-performance applications.

Wireless telemetry has eliminated the need for extensive wiring harnesses during testing, reducing setup time and potential points of failure. Engineers can now monitor test data remotely and in real-time, facilitating collaborative analysis and decision-making. This advancement has significantly improved testing workflow efficiency for LS3 engine development programs.

Perhaps most significantly, modern dyno systems now incorporate sophisticated simulation capabilities that can predict how modifications might affect real-world performance. These predictive models utilize machine learning algorithms trained on vast datasets of LS3 performance metrics, enabling engineers to virtually test modifications before physical implementation. This approach has substantially reduced development cycles and associated costs while improving outcomes.