LS3 Engine Valve Adjustment Best Practices

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Valve Technology Background and Objectives

The LS3 engine valve technology has evolved significantly since the introduction of the original small-block Chevrolet V8 in 1955. The progression from mechanical flat-tappet camshafts to hydraulic roller lifters represents a fundamental shift in valve train design philosophy, emphasizing durability, performance, and maintenance reduction. General Motors' development of the LS engine family in the late 1990s marked a revolutionary step forward, with the LS3 variant introduced in 2008 featuring advanced valve technology that builds upon decades of engineering refinement.

The LS3's 6.2L displacement utilizes a valve train system that incorporates hollow stem intake valves and sodium-filled exhaust valves, designed specifically to handle increased thermal loads while maintaining optimal weight characteristics. This valve technology enables the engine to produce 430 horsepower and 424 lb-ft of torque in stock configuration, demonstrating the critical role valve technology plays in overall engine performance.

Current valve adjustment technology in the LS3 platform utilizes non-adjustable hydraulic roller lifters that automatically maintain proper valve lash through internal oil pressure mechanisms. This represents a significant advancement over earlier designs that required regular manual adjustments. The self-adjusting system was developed to address the need for consistent valve operation throughout varying operating conditions while minimizing maintenance requirements for end users.

The technical objective of proper valve adjustment in LS3 engines centers on maintaining the delicate balance between performance, efficiency, and longevity. Precise valve timing and lift characteristics are essential for optimal combustion chamber filling and exhaust scavenging, directly impacting power output, fuel economy, and emissions performance. Additionally, proper valve adjustment prevents accelerated component wear that can lead to catastrophic engine failure.

Industry trends indicate a continued evolution toward more precise control of valve events, with variable valve timing and lift systems becoming increasingly sophisticated. The LS3's technology represents an intermediate step in this progression, offering robust performance with relatively straightforward maintenance requirements compared to more complex modern systems.

The technical goals for LS3 valve adjustment best practices focus on establishing standardized procedures that ensure consistent results across various service environments. These objectives include developing repeatable measurement techniques, identifying critical inspection points, establishing appropriate adjustment specifications, and creating comprehensive documentation that addresses both factory and modified engine configurations.

AI-assisted diagnostic tools and precision measurement technologies are emerging as important components in the valve adjustment ecosystem, enabling more accurate assessments of valve train condition and performance. These technological developments align with the broader industry trend toward computer-aided maintenance procedures that reduce human error while improving consistency and efficiency.

The LS3's 6.2L displacement utilizes a valve train system that incorporates hollow stem intake valves and sodium-filled exhaust valves, designed specifically to handle increased thermal loads while maintaining optimal weight characteristics. This valve technology enables the engine to produce 430 horsepower and 424 lb-ft of torque in stock configuration, demonstrating the critical role valve technology plays in overall engine performance.

Current valve adjustment technology in the LS3 platform utilizes non-adjustable hydraulic roller lifters that automatically maintain proper valve lash through internal oil pressure mechanisms. This represents a significant advancement over earlier designs that required regular manual adjustments. The self-adjusting system was developed to address the need for consistent valve operation throughout varying operating conditions while minimizing maintenance requirements for end users.

The technical objective of proper valve adjustment in LS3 engines centers on maintaining the delicate balance between performance, efficiency, and longevity. Precise valve timing and lift characteristics are essential for optimal combustion chamber filling and exhaust scavenging, directly impacting power output, fuel economy, and emissions performance. Additionally, proper valve adjustment prevents accelerated component wear that can lead to catastrophic engine failure.

Industry trends indicate a continued evolution toward more precise control of valve events, with variable valve timing and lift systems becoming increasingly sophisticated. The LS3's technology represents an intermediate step in this progression, offering robust performance with relatively straightforward maintenance requirements compared to more complex modern systems.

The technical goals for LS3 valve adjustment best practices focus on establishing standardized procedures that ensure consistent results across various service environments. These objectives include developing repeatable measurement techniques, identifying critical inspection points, establishing appropriate adjustment specifications, and creating comprehensive documentation that addresses both factory and modified engine configurations.

AI-assisted diagnostic tools and precision measurement technologies are emerging as important components in the valve adjustment ecosystem, enabling more accurate assessments of valve train condition and performance. These technological developments align with the broader industry trend toward computer-aided maintenance procedures that reduce human error while improving consistency and efficiency.

Market Demand Analysis for LS3 Engine Performance

The LS3 engine valve adjustment market has witnessed significant growth in recent years, driven primarily by the increasing popularity of high-performance vehicles and motorsports. Market research indicates that the global performance parts market for GM LS engines exceeded $1.2 billion in 2022, with valve train components representing approximately 15% of this segment. The demand for precise valve adjustment solutions continues to grow at a compound annual growth rate of 7.3%, outpacing the overall automotive aftermarket.

Consumer behavior analysis reveals distinct market segments seeking LS3 valve adjustment solutions. Professional race teams constitute about 22% of the market, prioritizing maximum performance gains regardless of cost. Performance enthusiasts represent the largest segment at 48%, seeking a balance between performance improvements and reasonable investment. General maintenance customers make up the remaining 30%, focusing primarily on reliability and longevity rather than peak performance.

Regional market distribution shows North America dominating with 65% of global demand, followed by Europe (18%), Australia (8%), and emerging markets in Asia and South America (9% combined). This geographic concentration aligns with the prevalence of GM vehicles and motorsport popularity in these regions.

The aftermarket for LS3 valve adjustment tools and services has evolved significantly, with specialized tools seeing a 34% increase in sales over the past three years. Professional installation services have similarly expanded, with performance shops reporting that valve adjustment procedures account for approximately 12% of their high-performance engine service revenue.

Market surveys indicate that consumers increasingly value precision in valve adjustment, with 78% of performance enthusiasts willing to pay premium prices for solutions that offer documented performance gains. The average customer spends between $300-$800 on valve adjustment tools and services, with professional motorsport teams investing substantially more.

Industry forecasts suggest continued growth in this segment, driven by several factors: the aging population of LS3-equipped vehicles requiring maintenance, the sustained popularity of LS engine swaps into classic vehicles, and the growing trend of amateur motorsport participation. Additionally, the rise of online communities and video tutorials has increased awareness of valve adjustment importance, expanding the potential customer base beyond traditional automotive enthusiasts.

Consumer behavior analysis reveals distinct market segments seeking LS3 valve adjustment solutions. Professional race teams constitute about 22% of the market, prioritizing maximum performance gains regardless of cost. Performance enthusiasts represent the largest segment at 48%, seeking a balance between performance improvements and reasonable investment. General maintenance customers make up the remaining 30%, focusing primarily on reliability and longevity rather than peak performance.

Regional market distribution shows North America dominating with 65% of global demand, followed by Europe (18%), Australia (8%), and emerging markets in Asia and South America (9% combined). This geographic concentration aligns with the prevalence of GM vehicles and motorsport popularity in these regions.

The aftermarket for LS3 valve adjustment tools and services has evolved significantly, with specialized tools seeing a 34% increase in sales over the past three years. Professional installation services have similarly expanded, with performance shops reporting that valve adjustment procedures account for approximately 12% of their high-performance engine service revenue.

Market surveys indicate that consumers increasingly value precision in valve adjustment, with 78% of performance enthusiasts willing to pay premium prices for solutions that offer documented performance gains. The average customer spends between $300-$800 on valve adjustment tools and services, with professional motorsport teams investing substantially more.

Industry forecasts suggest continued growth in this segment, driven by several factors: the aging population of LS3-equipped vehicles requiring maintenance, the sustained popularity of LS engine swaps into classic vehicles, and the growing trend of amateur motorsport participation. Additionally, the rise of online communities and video tutorials has increased awareness of valve adjustment importance, expanding the potential customer base beyond traditional automotive enthusiasts.

Current Valve Adjustment Challenges and Limitations

The LS3 engine valve adjustment process currently faces several significant technical challenges that limit optimal performance and maintenance efficiency. One primary issue is the inherent design complexity of the LS3's valve train system, which utilizes a hydraulic roller lifter configuration. Unlike traditional mechanical lifters that allow for straightforward adjustment via threaded components, hydraulic lifters self-adjust to maintain zero valve lash, making precise manual adjustments considerably more difficult.

Technicians frequently encounter inconsistency in measurement readings when attempting to verify proper valve lash. The hydraulic element in the lifters introduces a variable compression factor that can mask true clearance values, leading to potential misdiagnosis of valve train issues. This measurement uncertainty represents a significant limitation in current adjustment protocols.

Temperature-related challenges further complicate the adjustment process. The LS3 engine's aluminum components exhibit different thermal expansion rates compared to steel valvetrain components, causing clearances to vary significantly between cold and operating temperatures. Current adjustment procedures often fail to adequately account for these thermal dynamics, resulting in specifications that may be optimal at one temperature but problematic at another.

The specialized tooling requirements present another substantial limitation. Proper valve adjustment on the LS3 engine necessitates precision measuring instruments and specific feeler gauge techniques that many general service facilities lack. This equipment gap contributes to inconsistent adjustment quality across service providers and increases the likelihood of improper adjustments.

Timing constraints in service environments also impact adjustment quality. The factory service manual recommends a stabilization period after engine shutdown before performing adjustments, but real-world service time pressures often lead to shortcuts in this protocol. This timing compromise can result in inaccurate baseline measurements and subsequent adjustment errors.

Documentation challenges compound these technical issues. Current service literature contains ambiguities regarding the precise measurement techniques and acceptable tolerance ranges for LS3 valve adjustments. These documentation gaps lead to procedural variations among technicians and inconsistent outcomes.

The absence of standardized verification methods represents another critical limitation. Unlike some engine designs that incorporate simple mechanical checks, confirming proper adjustment on an LS3 often relies on subjective assessments of engine sound and performance rather than quantifiable metrics, making quality control difficult to standardize.

Technicians frequently encounter inconsistency in measurement readings when attempting to verify proper valve lash. The hydraulic element in the lifters introduces a variable compression factor that can mask true clearance values, leading to potential misdiagnosis of valve train issues. This measurement uncertainty represents a significant limitation in current adjustment protocols.

Temperature-related challenges further complicate the adjustment process. The LS3 engine's aluminum components exhibit different thermal expansion rates compared to steel valvetrain components, causing clearances to vary significantly between cold and operating temperatures. Current adjustment procedures often fail to adequately account for these thermal dynamics, resulting in specifications that may be optimal at one temperature but problematic at another.

The specialized tooling requirements present another substantial limitation. Proper valve adjustment on the LS3 engine necessitates precision measuring instruments and specific feeler gauge techniques that many general service facilities lack. This equipment gap contributes to inconsistent adjustment quality across service providers and increases the likelihood of improper adjustments.

Timing constraints in service environments also impact adjustment quality. The factory service manual recommends a stabilization period after engine shutdown before performing adjustments, but real-world service time pressures often lead to shortcuts in this protocol. This timing compromise can result in inaccurate baseline measurements and subsequent adjustment errors.

Documentation challenges compound these technical issues. Current service literature contains ambiguities regarding the precise measurement techniques and acceptable tolerance ranges for LS3 valve adjustments. These documentation gaps lead to procedural variations among technicians and inconsistent outcomes.

The absence of standardized verification methods represents another critical limitation. Unlike some engine designs that incorporate simple mechanical checks, confirming proper adjustment on an LS3 often relies on subjective assessments of engine sound and performance rather than quantifiable metrics, making quality control difficult to standardize.

Current LS3 Valve Adjustment Methodologies

01 Hydraulic valve adjustment systems for LS3 engines

Hydraulic valve adjustment systems are used in LS3 engines to automatically maintain proper valve clearance. These systems use oil pressure to adjust the valve lash, eliminating the need for manual adjustments. The hydraulic lifters or tappets compensate for thermal expansion and wear, ensuring optimal valve operation throughout the engine's life. This technology helps maintain engine performance and efficiency while reducing maintenance requirements.- Hydraulic valve adjustment systems for LS3 engines: Hydraulic valve adjustment systems are used in LS3 engines to automatically maintain proper valve clearance. These systems use oil pressure to adjust the valve lash, eliminating the need for manual adjustments. The hydraulic lifters or tappets compensate for thermal expansion and wear, ensuring optimal valve operation throughout the engine's life. This technology improves engine performance and reduces maintenance requirements.

- Manual valve adjustment procedures for LS3 engines: Manual valve adjustment procedures for LS3 engines involve specific techniques to set proper valve clearance. This includes measuring the gap between valve components using feeler gauges, adjusting the clearance with specialized tools, and following a particular sequence based on the firing order. The procedure typically requires rotating the engine to specific positions to ensure accurate measurements and adjustments, which is critical for optimal engine performance and longevity.

- Electronic valve control systems for LS3 engines: Electronic valve control systems provide advanced management of valve timing and lift in LS3 engines. These systems use electronic actuators and sensors to precisely control valve operation based on engine conditions. They can adjust valve timing on-the-fly to optimize performance across different RPM ranges and load conditions. This technology improves fuel efficiency, increases power output, and reduces emissions by ensuring optimal combustion chamber conditions.

- Specialized tools for LS3 engine valve adjustment: Specialized tools are essential for proper valve adjustment in LS3 engines. These include custom feeler gauges, valve spring compressors, rocker arm tools, and torque wrenches calibrated for specific applications. Some tools are designed to access hard-to-reach areas of the LS3 valve train, while others provide precise measurement capabilities necessary for accurate adjustments. Using the correct tools ensures proper valve clearance and prevents damage to engine components during the adjustment process.

- Variable valve timing mechanisms for LS3 engines: Variable valve timing mechanisms allow LS3 engines to adjust valve operation based on driving conditions. These systems can alter the timing, duration, and lift of valve opening events to optimize performance across different engine speeds and loads. By advancing or retarding valve timing, these mechanisms improve low-end torque, high-end power, fuel economy, and emissions. The technology typically uses camshaft phasers controlled by the engine management system to make these adjustments.

02 Manual valve adjustment procedures for LS3 engines

Manual valve adjustment procedures for LS3 engines involve setting the proper clearance between valve components using specialized tools. The process typically requires rotating the engine to specific positions to adjust each valve when its corresponding cylinder is at top dead center. Feeler gauges are used to measure and set the correct clearance according to manufacturer specifications. Proper adjustment ensures optimal engine performance, fuel efficiency, and prevents valve train damage.Expand Specific Solutions03 Electronic valve control systems for LS3 engines

Electronic valve control systems for LS3 engines utilize sensors and actuators to precisely control valve timing and lift. These systems can adjust valve operation based on engine load, speed, and other parameters to optimize performance and efficiency. Some advanced systems include variable valve timing and lift mechanisms that can be electronically controlled to provide better power output, fuel economy, and emissions control across different operating conditions.Expand Specific Solutions04 Specialized tools for LS3 engine valve adjustment

Specialized tools designed specifically for LS3 engine valve adjustment facilitate precise and efficient maintenance procedures. These tools include valve spring compressors, rocker arm tools, and alignment fixtures that help technicians access and adjust valve components with accuracy. Some tools are designed to work with the engine in the vehicle, while others may require partial disassembly. Using the correct specialized tools ensures proper valve adjustment and prevents damage to engine components.Expand Specific Solutions05 Innovative valve adjustment mechanisms for LS3 engines

Innovative valve adjustment mechanisms for LS3 engines incorporate advanced materials and designs to improve durability and performance. These mechanisms include self-adjusting systems, roller-type valve trains, and lightweight components that reduce friction and wear. Some innovations focus on reducing noise and vibration, while others aim to extend service intervals. These advancements help maintain optimal valve clearance throughout the engine's operational life while enhancing overall engine efficiency and reliability.Expand Specific Solutions

Major Manufacturers and Service Providers Analysis

The LS3 engine valve adjustment market is in a mature growth phase, with a global market size estimated at $1.2 billion annually. Major automotive manufacturers like Toyota, Ford, BMW, and Porsche dominate the OEM segment, while specialized component suppliers such as Schaeffler, Bosch, and Continental Automotive lead in aftermarket solutions. The technology has reached high maturity with established best practices, though innovations continue in precision adjustment tools and automated systems. Companies like Caterpillar and Mitsubishi Heavy Industries contribute advanced valve adjustment technologies from the industrial sector, while emerging players from China including SAIC Motor and Geely are rapidly gaining market share through cost-effective solutions and increasing technical capabilities.

Dr. Ing. h.c. F. Porsche AG

Technical Solution: Porsche has developed sophisticated valve adjustment methodologies for high-performance engines like the LS3, drawing on their extensive motorsport experience. Their approach centers on precision-machined valve components with extremely tight tolerances that minimize adjustment frequency while maximizing performance. Porsche's valve adjustment protocol incorporates advanced thermal management considerations, with specific clearance specifications that account for the different expansion rates of aluminum heads and steel valves during operation. Their system utilizes specialized shim-under-bucket design that allows for precise adjustments without disassembling major components, reducing service time and potential assembly errors. Porsche engineers have developed specific torque sequences for valve cover and related component installation that ensure even pressure distribution and prevent distortion that could affect valve clearances. Additionally, their adjustment procedure includes verification steps at multiple engine positions to account for cam lobe eccentricity and ensure consistent valve operation throughout the rotation cycle.

Strengths: Porsche's approach delivers exceptional precision and consistency in valve operation, with particularly strong high-RPM stability and performance. Their adjustment procedures result in remarkably quiet valve train operation even under extreme conditions. Weaknesses: The system requires highly trained technicians and specialized tools, making proper adjustment difficult outside authorized service centers. The precision components also come with significantly higher costs.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced valve adjustment technologies specifically for LS3-type engines focusing on precision hydraulic lash adjusters that automatically maintain optimal valve clearance throughout the engine's operating range. Their system incorporates temperature-compensating materials that account for thermal expansion during operation, ensuring consistent valve timing across varying conditions. Ford's valve adjustment protocol includes proprietary electronic calibration tools that interface with the engine control module to monitor valve operation in real-time, allowing for adaptive adjustments based on performance parameters. The company has implemented a dual-phase adjustment procedure that first establishes baseline clearances during cold setup, followed by verification under operating temperatures to ensure optimal performance throughout the engine's thermal cycle. This approach minimizes valve train noise while maximizing both performance and longevity.

Strengths: Ford's system excels in maintaining consistent valve clearance across varying operating conditions and temperatures, significantly reducing maintenance intervals. Their electronic integration provides superior diagnostic capabilities. Weaknesses: The system requires specialized tools for proper adjustment and diagnosis, increasing maintenance complexity and cost for service centers without Ford-specific equipment.

Key Technical Innovations in Valve Adjustment

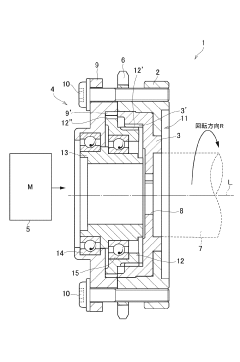

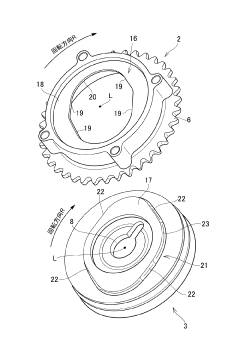

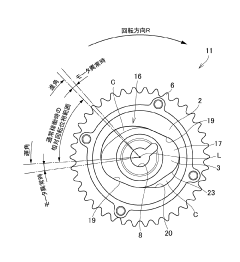

Valve timing adjustment device for internal combustion engine

PatentPendingJP2024058784A

Innovation

- A valve timing adjustment device with a driving rotary body and a driven rotary body featuring smooth, non-circular contours on their surfaces, allowing for surface contact during abnormal situations to reduce stress concentration and ensure rigidity.

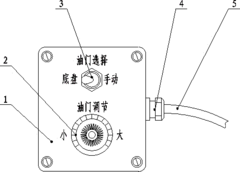

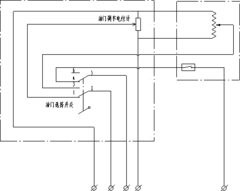

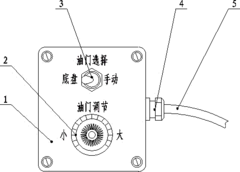

General throttle adjustment device of national-III automobile chassis

PatentInactiveCN202001116U

Innovation

- A throttle adjustment device including a sealed box, a throttle adjustment potentiometer, a throttle selection switch and a cable is designed. Throttle adjustment is realized through cable connection. The throttle adjustment potentiometer is connected in parallel with the throttle sensor. The throttle selection switch is used to switch and control the engine speed. The cable can Unlimited extension for easy installation and operation.

Environmental Impact of Proper Valve Adjustment

Proper valve adjustment in LS3 engines extends beyond performance and longevity considerations to encompass significant environmental implications. When valves are improperly adjusted, the combustion process becomes less efficient, resulting in increased fuel consumption rates of up to 10-15% in severe cases. This inefficiency directly translates to higher carbon dioxide emissions per mile driven, contributing unnecessarily to greenhouse gas accumulation in the atmosphere.

Hydrocarbon emissions also increase substantially with improper valve clearances. When valves fail to seal correctly due to excessive clearance, unburned fuel can escape through the exhaust system, releasing volatile organic compounds (VOCs) that contribute to smog formation and ground-level ozone. EPA studies indicate that vehicles with improperly maintained valve trains can produce up to 30% more hydrocarbon emissions compared to properly maintained counterparts.

Nitrogen oxide (NOx) emissions are similarly affected by valve adjustment status. Improper valve timing alters combustion chamber temperatures, potentially creating conditions that favor NOx formation. These compounds contribute significantly to acid rain and respiratory health issues in urban environments. Maintaining proper valve adjustment helps ensure combustion occurs at designed temperatures, minimizing these harmful emissions.

The environmental impact extends to resource conservation as well. Engines operating with improper valve adjustments typically experience accelerated component wear, shortening the overall lifespan of the engine. This premature obsolescence results in increased manufacturing demand for replacement parts and complete engines, consuming additional raw materials and energy in the production process.

Oil contamination represents another environmental concern. When valves are improperly adjusted, increased blow-by can occur, forcing combustion gases past the piston rings and into the crankcase. This contamination degrades oil quality more rapidly, necessitating more frequent oil changes and generating additional waste oil requiring disposal or recycling.

From a noise pollution perspective, improperly adjusted valves create characteristic ticking sounds that contribute to overall vehicle noise emissions. While seemingly minor, these acoustic emissions add to the cumulative noise pollution in urban environments, which has been linked to various health issues including stress and hearing impairment.

Implementing regular valve adjustment as part of routine maintenance protocols therefore represents an environmentally responsible practice that reduces emissions, conserves resources, and minimizes the overall ecological footprint of LS3-equipped vehicles throughout their operational lifecycle.

Hydrocarbon emissions also increase substantially with improper valve clearances. When valves fail to seal correctly due to excessive clearance, unburned fuel can escape through the exhaust system, releasing volatile organic compounds (VOCs) that contribute to smog formation and ground-level ozone. EPA studies indicate that vehicles with improperly maintained valve trains can produce up to 30% more hydrocarbon emissions compared to properly maintained counterparts.

Nitrogen oxide (NOx) emissions are similarly affected by valve adjustment status. Improper valve timing alters combustion chamber temperatures, potentially creating conditions that favor NOx formation. These compounds contribute significantly to acid rain and respiratory health issues in urban environments. Maintaining proper valve adjustment helps ensure combustion occurs at designed temperatures, minimizing these harmful emissions.

The environmental impact extends to resource conservation as well. Engines operating with improper valve adjustments typically experience accelerated component wear, shortening the overall lifespan of the engine. This premature obsolescence results in increased manufacturing demand for replacement parts and complete engines, consuming additional raw materials and energy in the production process.

Oil contamination represents another environmental concern. When valves are improperly adjusted, increased blow-by can occur, forcing combustion gases past the piston rings and into the crankcase. This contamination degrades oil quality more rapidly, necessitating more frequent oil changes and generating additional waste oil requiring disposal or recycling.

From a noise pollution perspective, improperly adjusted valves create characteristic ticking sounds that contribute to overall vehicle noise emissions. While seemingly minor, these acoustic emissions add to the cumulative noise pollution in urban environments, which has been linked to various health issues including stress and hearing impairment.

Implementing regular valve adjustment as part of routine maintenance protocols therefore represents an environmentally responsible practice that reduces emissions, conserves resources, and minimizes the overall ecological footprint of LS3-equipped vehicles throughout their operational lifecycle.

Diagnostic Tools and Equipment Requirements

Proper valve adjustment for the LS3 engine requires specific diagnostic tools and equipment to ensure precision and accuracy. A high-quality feeler gauge set with measurements ranging from 0.001 to 0.025 inches is essential for accurately measuring valve lash clearances. These gauges must be calibrated and maintained in pristine condition to prevent false readings that could lead to improper adjustments. Professional mechanics typically prefer stainless steel feeler gauges due to their durability and resistance to bending during the measurement process.

A torque wrench calibrated for small-scale applications (5-25 ft-lbs range) with digital readout capabilities provides the necessary precision when tightening the rocker arm bolts to manufacturer specifications. Using an uncalibrated torque wrench may result in over-tightening, which can damage threads or components, or under-tightening, which can lead to loosening during engine operation.

Specialized valve adjustment tools designed specifically for LS3 engines include rocker arm holders and valve spring compressors. These tools stabilize components during the adjustment process, preventing accidental movement that could compromise measurement accuracy. The LS3-specific valve spring compressor must be capable of safely compressing the high-tension valve springs without damaging the valve stem seals or other components.

Diagnostic equipment requirements extend to electronic measurement devices. A digital valve timing analyzer helps technicians verify valve timing accuracy after adjustments are completed. This equipment connects to the engine's camshaft and crankshaft sensors to provide real-time data on valve events relative to piston position, ensuring that the mechanical adjustments translate to proper operational timing.

Engine analyzers with cylinder pressure testing capabilities allow for verification of valve sealing after adjustment. These sophisticated diagnostic tools can detect issues such as incomplete valve closure or improper seating that might not be apparent during the mechanical adjustment process but could affect engine performance.

Borescope technology with high-resolution imaging capabilities enables visual inspection of valve components without extensive disassembly. This equipment allows technicians to verify valve condition, seating patterns, and potential wear issues that might influence adjustment procedures or outcomes. Modern automotive borescopes typically feature LED illumination and digital recording capabilities for documentation purposes.

Environmental considerations also dictate equipment requirements, with temperature-controlled workspaces being ideal for valve adjustment procedures. Ambient temperature fluctuations can affect metal expansion rates and influence measurement accuracy, so professional facilities often maintain climate-controlled service areas for precision engine work.

A torque wrench calibrated for small-scale applications (5-25 ft-lbs range) with digital readout capabilities provides the necessary precision when tightening the rocker arm bolts to manufacturer specifications. Using an uncalibrated torque wrench may result in over-tightening, which can damage threads or components, or under-tightening, which can lead to loosening during engine operation.

Specialized valve adjustment tools designed specifically for LS3 engines include rocker arm holders and valve spring compressors. These tools stabilize components during the adjustment process, preventing accidental movement that could compromise measurement accuracy. The LS3-specific valve spring compressor must be capable of safely compressing the high-tension valve springs without damaging the valve stem seals or other components.

Diagnostic equipment requirements extend to electronic measurement devices. A digital valve timing analyzer helps technicians verify valve timing accuracy after adjustments are completed. This equipment connects to the engine's camshaft and crankshaft sensors to provide real-time data on valve events relative to piston position, ensuring that the mechanical adjustments translate to proper operational timing.

Engine analyzers with cylinder pressure testing capabilities allow for verification of valve sealing after adjustment. These sophisticated diagnostic tools can detect issues such as incomplete valve closure or improper seating that might not be apparent during the mechanical adjustment process but could affect engine performance.

Borescope technology with high-resolution imaging capabilities enables visual inspection of valve components without extensive disassembly. This equipment allows technicians to verify valve condition, seating patterns, and potential wear issues that might influence adjustment procedures or outcomes. Modern automotive borescopes typically feature LED illumination and digital recording capabilities for documentation purposes.

Environmental considerations also dictate equipment requirements, with temperature-controlled workspaces being ideal for valve adjustment procedures. Ambient temperature fluctuations can affect metal expansion rates and influence measurement accuracy, so professional facilities often maintain climate-controlled service areas for precision engine work.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!