LS3 Engine Cylinder Head Replacement Guide

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine History and Replacement Objectives

The LS3 engine, introduced by General Motors in 2007, represents a significant evolution in the LS engine family that began with the LS1 in 1997. This 6.2L V8 aluminum block engine was designed as part of the Gen IV small-block architecture, featuring improved cylinder heads with rectangular intake ports and larger valves compared to its predecessors. Initially developed for the Corvette C6, the LS3 quickly became renowned for its robust performance capabilities, delivering 430 horsepower and 424 lb-ft of torque in its standard configuration.

The development of the LS3 cylinder head specifically addressed previous limitations in airflow and combustion efficiency. Engineers implemented a 15-degree valve angle (compared to the 18-degree design in earlier models) and increased the intake valve diameter to 2.165 inches, resulting in significantly improved breathing characteristics. These design changes contributed to a 20-30 horsepower increase over the LS2 engine while maintaining similar displacement.

Throughout its production history from 2007 to 2017, the LS3 underwent several refinements, particularly in the cylinder head design. Early versions experienced occasional issues with valve guide wear and potential coolant leaks at the head gasket interface, which were addressed in later production runs. The L92-derived cylinder head design became a benchmark for aftermarket performance upgrades due to its excellent flow characteristics and compatibility with various LS-platform engines.

The primary objectives for cylinder head replacement on an LS3 engine typically fall into three categories: restoration, performance enhancement, or addressing mechanical failures. Restoration involves returning the engine to factory specifications after wear or damage. Performance enhancement aims to increase power output through improved airflow characteristics, often utilizing aftermarket heads with larger runners and valves. Addressing mechanical failures may be necessary due to issues such as cracked heads, damaged valve seats, or warped mating surfaces resulting from overheating events.

When approaching cylinder head replacement, technicians must consider several critical factors including proper torque specifications (typically following a specific sequence to prevent warping), valve clearance requirements, and compatibility with existing components such as intake manifolds and valvetrain hardware. The replacement process also presents an opportunity to upgrade to performance-oriented components such as higher-tension valve springs, titanium retainers, or improved rocker arms to complement the cylinder head's capabilities.

The evolution of LS3 cylinder head technology has continued beyond the original equipment specifications, with aftermarket manufacturers developing CNC-ported versions that further optimize the intake and exhaust port designs for maximum airflow efficiency. These technological advancements have established the LS3 as a preferred platform for performance applications ranging from street cars to dedicated racing vehicles.

The development of the LS3 cylinder head specifically addressed previous limitations in airflow and combustion efficiency. Engineers implemented a 15-degree valve angle (compared to the 18-degree design in earlier models) and increased the intake valve diameter to 2.165 inches, resulting in significantly improved breathing characteristics. These design changes contributed to a 20-30 horsepower increase over the LS2 engine while maintaining similar displacement.

Throughout its production history from 2007 to 2017, the LS3 underwent several refinements, particularly in the cylinder head design. Early versions experienced occasional issues with valve guide wear and potential coolant leaks at the head gasket interface, which were addressed in later production runs. The L92-derived cylinder head design became a benchmark for aftermarket performance upgrades due to its excellent flow characteristics and compatibility with various LS-platform engines.

The primary objectives for cylinder head replacement on an LS3 engine typically fall into three categories: restoration, performance enhancement, or addressing mechanical failures. Restoration involves returning the engine to factory specifications after wear or damage. Performance enhancement aims to increase power output through improved airflow characteristics, often utilizing aftermarket heads with larger runners and valves. Addressing mechanical failures may be necessary due to issues such as cracked heads, damaged valve seats, or warped mating surfaces resulting from overheating events.

When approaching cylinder head replacement, technicians must consider several critical factors including proper torque specifications (typically following a specific sequence to prevent warping), valve clearance requirements, and compatibility with existing components such as intake manifolds and valvetrain hardware. The replacement process also presents an opportunity to upgrade to performance-oriented components such as higher-tension valve springs, titanium retainers, or improved rocker arms to complement the cylinder head's capabilities.

The evolution of LS3 cylinder head technology has continued beyond the original equipment specifications, with aftermarket manufacturers developing CNC-ported versions that further optimize the intake and exhaust port designs for maximum airflow efficiency. These technological advancements have established the LS3 as a preferred platform for performance applications ranging from street cars to dedicated racing vehicles.

Market Analysis of LS3 Cylinder Head Aftermarket

The LS3 cylinder head aftermarket represents a significant segment within the performance automotive parts industry, with steady growth observed over the past decade. Market research indicates the global automotive cylinder head market was valued at approximately $8.2 billion in 2022, with the performance aftermarket segment for GM LS engines accounting for roughly $380 million of this total. The LS3 cylinder head replacement market specifically has shown a compound annual growth rate of 4.7% since 2018, outpacing the broader automotive parts aftermarket.

Consumer demand analysis reveals three primary market segments driving growth: professional racing teams seeking maximum performance gains, enthusiast hobbyists upgrading street vehicles for improved power, and restoration specialists requiring factory-equivalent or enhanced replacement parts. The professional racing segment, while smaller in volume, generates higher per-unit revenue with premium products often exceeding $2,500 per pair. The enthusiast segment represents the largest market share by volume, typically purchasing in the $1,200-2,000 range for complete assemblies.

Regional market distribution shows North America dominating with 68% of global LS3 cylinder head aftermarket sales, followed by Australia at 12%, Europe at 9%, and emerging markets in the Middle East and Asia accounting for the remainder. Within North America, the southeastern and western United States represent particularly strong markets, correlating with higher concentrations of motorsport activities and favorable year-round driving conditions.

Industry forecasts project continued market expansion through 2028, driven by several factors. The aging population of LS3-equipped vehicles (production years 2008-2017) is entering prime modification and repair phases. Additionally, the growing popularity of LS engine swaps into classic vehicles creates substantial demand for performance-oriented cylinder head replacements that accommodate modern fuel and emissions requirements while delivering improved power characteristics.

Market research indicates price sensitivity varies significantly by segment, with professional racing customers prioritizing performance over cost, while enthusiast consumers show greater price elasticity. This has created distinct market tiers, from budget-friendly reconditioned OEM heads starting around $800 per pair to premium CNC-ported aluminum offerings exceeding $3,000. Material innovation, particularly in lightweight alloys and thermal management, represents a premium segment with annual growth rates exceeding 7%.

Consumer demand analysis reveals three primary market segments driving growth: professional racing teams seeking maximum performance gains, enthusiast hobbyists upgrading street vehicles for improved power, and restoration specialists requiring factory-equivalent or enhanced replacement parts. The professional racing segment, while smaller in volume, generates higher per-unit revenue with premium products often exceeding $2,500 per pair. The enthusiast segment represents the largest market share by volume, typically purchasing in the $1,200-2,000 range for complete assemblies.

Regional market distribution shows North America dominating with 68% of global LS3 cylinder head aftermarket sales, followed by Australia at 12%, Europe at 9%, and emerging markets in the Middle East and Asia accounting for the remainder. Within North America, the southeastern and western United States represent particularly strong markets, correlating with higher concentrations of motorsport activities and favorable year-round driving conditions.

Industry forecasts project continued market expansion through 2028, driven by several factors. The aging population of LS3-equipped vehicles (production years 2008-2017) is entering prime modification and repair phases. Additionally, the growing popularity of LS engine swaps into classic vehicles creates substantial demand for performance-oriented cylinder head replacements that accommodate modern fuel and emissions requirements while delivering improved power characteristics.

Market research indicates price sensitivity varies significantly by segment, with professional racing customers prioritizing performance over cost, while enthusiast consumers show greater price elasticity. This has created distinct market tiers, from budget-friendly reconditioned OEM heads starting around $800 per pair to premium CNC-ported aluminum offerings exceeding $3,000. Material innovation, particularly in lightweight alloys and thermal management, represents a premium segment with annual growth rates exceeding 7%.

Current Challenges in LS3 Cylinder Head Replacement

The LS3 cylinder head replacement process presents several significant technical challenges that require careful consideration and specialized approaches. The complexity of this procedure stems from both the intricate design of the LS3 engine architecture and the precision required during the replacement operation.

One of the primary challenges involves the proper removal of the existing cylinder heads without causing damage to the engine block mating surface. The aluminum construction of LS3 heads, while beneficial for weight reduction and heat dissipation, creates vulnerability to warping and surface damage during removal. Technicians frequently encounter seized fasteners and corroded components that complicate the disassembly process, particularly in engines with high mileage or those operated in harsh environmental conditions.

Proper torque sequence and specifications represent another critical challenge. The LS3 cylinder head bolts require a specific multi-step torque procedure that must be followed precisely to ensure even clamping force across the head gasket. Deviation from this sequence can result in uneven compression, leading to combustion leaks, performance issues, and potential engine failure. The torque specifications vary depending on whether new or reused head bolts are employed, adding another layer of complexity.

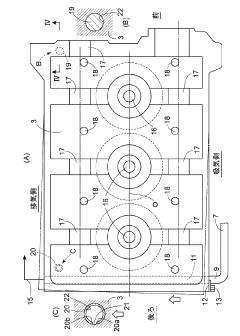

Valve train component compatibility presents significant technical hurdles during replacement operations. The LS3's variable valve timing system requires precise calibration when integrating new cylinder heads. Ensuring proper clearances between valves, pistons, and other moving components demands meticulous measurement and adjustment. Aftermarket performance heads may require additional modifications to maintain compatibility with factory components or to accommodate enhanced performance characteristics.

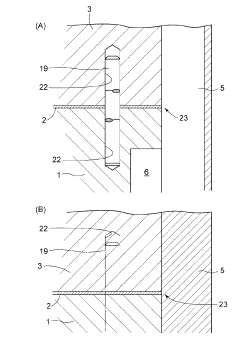

Sealing system integrity poses persistent challenges, particularly regarding the multi-layer steel (MLS) head gaskets used in LS3 engines. These gaskets require exceptionally flat mating surfaces to function properly. Surface preparation of both the cylinder head and block deck surfaces must meet stringent specifications for roughness and flatness. Even minor imperfections can compromise the gasket's ability to maintain combustion sealing under high-pressure conditions.

The integration of modern engine management systems with replacement cylinder heads introduces electronic and calibration challenges. The LS3's oxygen sensors, temperature sensors, and variable valve timing solenoids must be properly transferred and connected to maintain proper engine function. Aftermarket heads may require recalibration of the engine control unit to optimize performance and prevent diagnostic trouble codes from appearing.

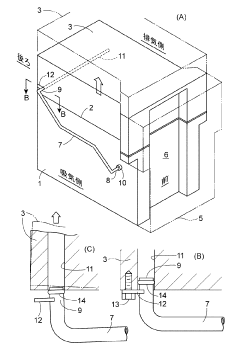

Cooling system management during the replacement process presents additional complications. The proper bleeding of air from the cooling system after head replacement is critical to prevent overheating. The LS3's integrated cooling passages require thorough flushing to remove debris that might have entered during the replacement process, preventing potential blockages that could lead to localized overheating.

One of the primary challenges involves the proper removal of the existing cylinder heads without causing damage to the engine block mating surface. The aluminum construction of LS3 heads, while beneficial for weight reduction and heat dissipation, creates vulnerability to warping and surface damage during removal. Technicians frequently encounter seized fasteners and corroded components that complicate the disassembly process, particularly in engines with high mileage or those operated in harsh environmental conditions.

Proper torque sequence and specifications represent another critical challenge. The LS3 cylinder head bolts require a specific multi-step torque procedure that must be followed precisely to ensure even clamping force across the head gasket. Deviation from this sequence can result in uneven compression, leading to combustion leaks, performance issues, and potential engine failure. The torque specifications vary depending on whether new or reused head bolts are employed, adding another layer of complexity.

Valve train component compatibility presents significant technical hurdles during replacement operations. The LS3's variable valve timing system requires precise calibration when integrating new cylinder heads. Ensuring proper clearances between valves, pistons, and other moving components demands meticulous measurement and adjustment. Aftermarket performance heads may require additional modifications to maintain compatibility with factory components or to accommodate enhanced performance characteristics.

Sealing system integrity poses persistent challenges, particularly regarding the multi-layer steel (MLS) head gaskets used in LS3 engines. These gaskets require exceptionally flat mating surfaces to function properly. Surface preparation of both the cylinder head and block deck surfaces must meet stringent specifications for roughness and flatness. Even minor imperfections can compromise the gasket's ability to maintain combustion sealing under high-pressure conditions.

The integration of modern engine management systems with replacement cylinder heads introduces electronic and calibration challenges. The LS3's oxygen sensors, temperature sensors, and variable valve timing solenoids must be properly transferred and connected to maintain proper engine function. Aftermarket heads may require recalibration of the engine control unit to optimize performance and prevent diagnostic trouble codes from appearing.

Cooling system management during the replacement process presents additional complications. The proper bleeding of air from the cooling system after head replacement is critical to prevent overheating. The LS3's integrated cooling passages require thorough flushing to remove debris that might have entered during the replacement process, preventing potential blockages that could lead to localized overheating.

Standard Replacement Procedures and Best Practices

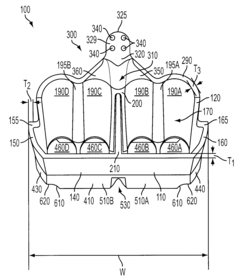

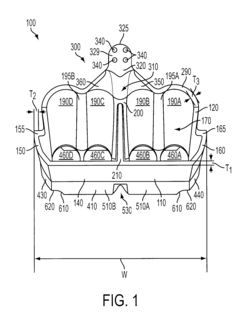

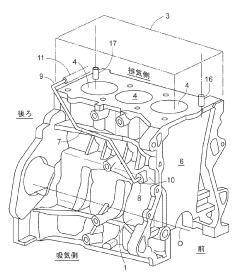

01 Cylinder head design and structure for LS3 engines

The cylinder head design for LS3 engines incorporates specific structural elements to enhance performance and durability. These designs feature optimized combustion chambers, port configurations, and valve arrangements that contribute to improved airflow and combustion efficiency. The structural integrity of the cylinder head is reinforced through strategic material distribution and casting techniques, allowing it to withstand high compression ratios and thermal stresses associated with high-performance applications.- Cylinder head design and structure for LS3 engines: The cylinder head design for LS3 engines incorporates specific structural elements to enhance performance and durability. These designs feature optimized combustion chambers, port configurations, and valve arrangements that contribute to improved airflow and combustion efficiency. The structural integrity of the cylinder head is reinforced to withstand high compression ratios and thermal stresses associated with high-performance applications.

- Cooling and thermal management systems: Advanced cooling systems are integrated into LS3 engine cylinder heads to manage thermal loads effectively. These systems include strategically placed coolant passages, improved water jackets, and enhanced heat dissipation features. Proper thermal management prevents warping, cracking, and premature wear of cylinder head components while maintaining optimal operating temperatures for performance and efficiency.

- Valve train components and configurations: LS3 engine cylinder heads utilize specific valve train configurations to optimize engine breathing and performance. These include specialized rocker arm systems, valve springs, retainers, and lifters designed for high-RPM operation. The valve sizes, angles, and arrangements are engineered to maximize airflow while maintaining reliability. Advanced materials and manufacturing techniques are employed to reduce weight and increase durability of these components.

- Port design and airflow optimization: The intake and exhaust port designs in LS3 cylinder heads are engineered for optimal airflow characteristics. Port shapes, sizes, and surface finishes are carefully developed to reduce flow restrictions and improve volumetric efficiency. Computer-aided design and flow testing are utilized to create port geometries that enhance air movement at various engine speeds, contributing to increased power output and throttle response.

- Manufacturing methods and materials: Specialized manufacturing processes and materials are employed in the production of LS3 engine cylinder heads. These include precision casting techniques, CNC machining, and advanced quality control measures to ensure dimensional accuracy and surface finish. High-grade aluminum alloys with specific heat treatment processes are typically used to achieve the optimal balance of strength, weight, and thermal conductivity required for high-performance applications.

02 Cooling and thermal management systems

LS3 engine cylinder heads incorporate advanced cooling and thermal management systems to maintain optimal operating temperatures. These systems include strategically placed coolant passages, improved water jackets, and enhanced heat dissipation features. The cooling designs help prevent overheating, reduce thermal stress, and maintain consistent performance during various operating conditions, ultimately extending the lifespan of the cylinder head components.Expand Specific Solutions03 Valve train components and configurations

The valve train components in LS3 engine cylinder heads are designed for optimal performance and reliability. These configurations include specific valve sizes, valve angles, rocker arm ratios, and pushrod geometries. Advanced materials and manufacturing techniques are employed to create lightweight yet durable valve components that can withstand high RPM operation. The valve train design contributes significantly to the engine's breathing capability, power output, and overall efficiency.Expand Specific Solutions04 Material composition and manufacturing techniques

LS3 engine cylinder heads utilize specific material compositions and manufacturing techniques to achieve desired performance characteristics. These cylinder heads are typically cast from aluminum alloys with precise silicon content to balance weight reduction with strength and heat dissipation properties. Advanced manufacturing processes, including precision CNC machining, specialized heat treatments, and quality control measures, ensure consistent dimensional accuracy and surface finish critical for optimal engine performance.Expand Specific Solutions05 Performance modifications and aftermarket enhancements

Various performance modifications and aftermarket enhancements are available for LS3 engine cylinder heads to increase power output and efficiency. These modifications include porting and polishing to improve airflow, combustion chamber reshaping for higher compression ratios, valve seat upgrades for better sealing, and installation of larger valves. Aftermarket cylinder heads may also feature revised intake and exhaust port designs, reinforced valve guides, and compatibility with forced induction systems for significant power gains.Expand Specific Solutions

Major Manufacturers and OEM vs Aftermarket Options

The LS3 Engine Cylinder Head Replacement market is in a mature phase, characterized by established repair procedures and widespread availability of replacement parts. The market size is substantial, driven by the large installed base of LS3 engines in various GM vehicles. From a technical maturity perspective, major players like General Motors lead the OEM segment, while aftermarket solutions are dominated by automotive component specialists. Honda, Toyota, Nissan, and Subaru have developed competing engine technologies with similar cylinder head designs, while companies like Cummins and AVL List have contributed advanced engineering solutions for cylinder head replacement procedures. Ford Global Technologies offers alternative engine solutions that compete with the LS3 platform, creating a competitive landscape where technical documentation and repair methodologies continue to evolve.

Honda Motor Co., Ltd.

Technical Solution: Honda's LS3 engine cylinder head replacement approach focuses on precision engineering and accessibility. Their technical solution incorporates a modular design with pre-assembled valve train components that significantly reduces installation complexity. The cylinder head utilizes Honda's proprietary VTEC (Variable Valve Timing and Lift Electronic Control) technology, which allows for optimal performance across different RPM ranges. Honda's replacement guide emphasizes their specialized torque sequence methodology that prevents warping during installation, utilizing a three-stage torquing process with specific values calibrated for the aluminum head material. Their cylinder heads feature integrated cooling channels designed to provide uniform temperature distribution, addressing a common failure point in the LS3 platform. Honda also implements a specialized surface finishing process that ensures optimal sealing with minimal gasket compression, reducing the likelihood of future leaks.

Strengths: Superior quality control with precise manufacturing tolerances; excellent documentation and support materials for technicians; parts widely available through dealer network. Weaknesses: Higher cost compared to aftermarket alternatives; replacement procedures often require specialized Honda tools that may not be commonly available in independent shops.

Nissan Motor Co., Ltd.

Technical Solution: Nissan's approach to LS3 engine cylinder head replacement incorporates their VQ-derived technology with adaptations specific to V8 architecture. Their technical solution features a multi-layer steel (MLS) head gasket system designed to maintain proper sealing under varying thermal conditions. Nissan's cylinder heads utilize a proprietary aluminum alloy with silicon content optimized for thermal expansion characteristics similar to the LS3 block. Their replacement methodology includes a computer-modeled bolt-tightening sequence that distributes clamping force evenly across the head surface. Nissan's cylinder heads incorporate their CVTC (Continuously Variable Timing Control) technology, adapted for the pushrod architecture of the LS3. The company's replacement guide details their specialized port design that enhances airflow while maintaining compatibility with stock manifolds. Nissan also implements a unique valve seat material composition that offers improved durability under high-temperature conditions typical in performance applications.

Strengths: Excellent thermal management characteristics; innovative sealing technology reduces failure rates; comprehensive technical documentation for installation. Weaknesses: Limited availability outside Nissan's dealer network; higher cost compared to direct OEM replacements; may require additional modifications for perfect fitment on LS3 applications.

Key Technical Specifications and Material Analysis

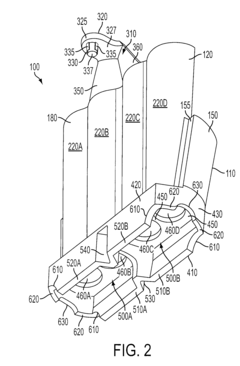

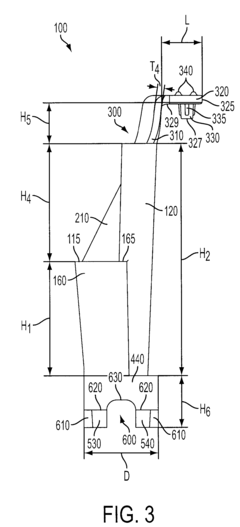

Lifter Guide

PatentInactiveUS20100095916A1

Innovation

- A guide with a valve lifter retention portion, push rod retention portion, and alignment and attachment portion that uses a locator portion clamped between the engine block and cylinder head gasket, eliminating the need for fasteners and allowing for easy installation and alignment of valve lifters and push rods.

Internal combustion engine

PatentActiveJP2018138769A

Innovation

- The use of two positioning pins, a solid first pin and a deformable C-ring second pin, allows the cylinder head to be rotated horizontally, facilitating the separation of external members by aligning their fitting direction with the rotation direction, while maintaining stable positioning.

Tools and Equipment Requirements

Successful cylinder head replacement on the LS3 engine requires a comprehensive set of specialized tools and equipment. Standard hand tools form the foundation of this operation, including socket sets (both metric and standard), combination wrenches, screwdrivers, pliers, and torque wrenches. The torque wrench is particularly critical for achieving the precise bolt tightening specifications required for proper head installation and gasket sealing.

Specialized engine tools are essential for this procedure, including a cylinder head bolt removal kit designed specifically for LS3 engines. A valve spring compressor tool is necessary when transferring valvetrain components from the old head to the new one or when performing valve service. Additionally, a proper head bolt thread chaser and cleaning kit will ensure the head bolt holes in the block are free from debris and thread damage.

Sealing and cleaning supplies represent another crucial category of requirements. These include engine degreaser, brake cleaner, gasket scraper tools, and lint-free shop towels. High-quality thread sealant and RTV silicone gasket maker are needed for specific sealing applications, while a precision straightedge and feeler gauges are required to check the cylinder head for warpage before installation.

Lifting and support equipment must not be overlooked, as cylinder heads are heavy components that require careful handling. An engine hoist or cherry picker provides necessary leverage when working with the heads, while an engine stand offers stability during the procedure. Head holding fixtures can significantly improve safety and precision during the removal and installation process.

Diagnostic tools complete the equipment requirements, with a compression tester and leak-down tester being valuable for verifying engine condition before and after the head replacement. A borescope allows for visual inspection of cylinder walls and valves without complete disassembly, while a digital caliper enables precise measurement of components during reassembly.

Safety equipment represents the final essential category, including safety glasses, chemical-resistant gloves, and proper ventilation systems to manage fumes from cleaning solvents and gasket materials. A fire extinguisher should always be readily accessible when working with engine components and potentially flammable materials.

Specialized engine tools are essential for this procedure, including a cylinder head bolt removal kit designed specifically for LS3 engines. A valve spring compressor tool is necessary when transferring valvetrain components from the old head to the new one or when performing valve service. Additionally, a proper head bolt thread chaser and cleaning kit will ensure the head bolt holes in the block are free from debris and thread damage.

Sealing and cleaning supplies represent another crucial category of requirements. These include engine degreaser, brake cleaner, gasket scraper tools, and lint-free shop towels. High-quality thread sealant and RTV silicone gasket maker are needed for specific sealing applications, while a precision straightedge and feeler gauges are required to check the cylinder head for warpage before installation.

Lifting and support equipment must not be overlooked, as cylinder heads are heavy components that require careful handling. An engine hoist or cherry picker provides necessary leverage when working with the heads, while an engine stand offers stability during the procedure. Head holding fixtures can significantly improve safety and precision during the removal and installation process.

Diagnostic tools complete the equipment requirements, with a compression tester and leak-down tester being valuable for verifying engine condition before and after the head replacement. A borescope allows for visual inspection of cylinder walls and valves without complete disassembly, while a digital caliper enables precise measurement of components during reassembly.

Safety equipment represents the final essential category, including safety glasses, chemical-resistant gloves, and proper ventilation systems to manage fumes from cleaning solvents and gasket materials. A fire extinguisher should always be readily accessible when working with engine components and potentially flammable materials.

Emissions Compliance and Regulatory Considerations

When replacing the LS3 engine cylinder head, compliance with emissions regulations represents a critical consideration that cannot be overlooked. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) maintain strict standards governing vehicle emissions, with particular focus on modifications that might affect the engine's exhaust output. Any cylinder head replacement must maintain or improve upon the original emissions profile to remain street-legal in all jurisdictions.

The LS3 engine was originally designed to meet Tier 2 federal emissions standards, which regulate nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and hydrocarbon emissions. Aftermarket cylinder heads must incorporate compatible exhaust gas recirculation (EGR) passages and maintain proper oxygen sensor positioning to ensure the engine management system can effectively monitor and control emissions. Failure to maintain these systems can trigger check engine lights and result in failed emissions testing.

CARB Executive Orders (E.O.) provide a framework for legal aftermarket parts in emissions-restricted states. When selecting replacement cylinder heads, technicians should verify whether the specific components carry CARB E.O. numbers, particularly for vehicles registered in California or states following California emissions standards. Non-compliant parts may be restricted to off-road or racing applications only, significantly limiting their legal use.

Modifications to cylinder heads often necessitate recalibration of the engine control module (ECM) to maintain proper air-fuel ratios. This recalibration must be performed within regulatory guidelines to avoid creating a "defeat device" as defined by the Clean Air Act. Professional tuning services familiar with emissions compliance can help ensure that performance improvements don't come at the expense of legal operation.

Documentation requirements represent another regulatory consideration. Many jurisdictions require maintenance of records demonstrating that replacement parts meet applicable standards. Technicians should retain manufacturer certifications, CARB E.O. documentation, and emissions test results to demonstrate compliance during inspections or registration renewals.

The penalties for non-compliance with emissions regulations can be severe, ranging from failed vehicle inspections to substantial fines for manufacturers, distributors, and installers of non-compliant parts. The EPA has increasingly targeted aftermarket parts that circumvent emissions controls, making regulatory awareness essential for both professional shops and DIY mechanics undertaking cylinder head replacements.

The LS3 engine was originally designed to meet Tier 2 federal emissions standards, which regulate nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and hydrocarbon emissions. Aftermarket cylinder heads must incorporate compatible exhaust gas recirculation (EGR) passages and maintain proper oxygen sensor positioning to ensure the engine management system can effectively monitor and control emissions. Failure to maintain these systems can trigger check engine lights and result in failed emissions testing.

CARB Executive Orders (E.O.) provide a framework for legal aftermarket parts in emissions-restricted states. When selecting replacement cylinder heads, technicians should verify whether the specific components carry CARB E.O. numbers, particularly for vehicles registered in California or states following California emissions standards. Non-compliant parts may be restricted to off-road or racing applications only, significantly limiting their legal use.

Modifications to cylinder heads often necessitate recalibration of the engine control module (ECM) to maintain proper air-fuel ratios. This recalibration must be performed within regulatory guidelines to avoid creating a "defeat device" as defined by the Clean Air Act. Professional tuning services familiar with emissions compliance can help ensure that performance improvements don't come at the expense of legal operation.

Documentation requirements represent another regulatory consideration. Many jurisdictions require maintenance of records demonstrating that replacement parts meet applicable standards. Technicians should retain manufacturer certifications, CARB E.O. documentation, and emissions test results to demonstrate compliance during inspections or registration renewals.

The penalties for non-compliance with emissions regulations can be severe, ranging from failed vehicle inspections to substantial fines for manufacturers, distributors, and installers of non-compliant parts. The EPA has increasingly targeted aftermarket parts that circumvent emissions controls, making regulatory awareness essential for both professional shops and DIY mechanics undertaking cylinder head replacements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!